驻车制动器在线装调设备系统设计(含CAD零件图装配图,CATIA三维图)(任务书,开题报告,外文翻译,文献摘要,论文说明书28000字,CAD图10张,CATIA三维图)

摘 要

驻车制动器是在汽车停驻时,用于稳定车辆,防止汽车滑行的制动装置。车辆制动系统的可靠性是评价汽车性能的主要指标,其使用性能直接影响着汽车驻车制动时的安全性。若其装调过程不合理,会导致车辆驻车制动力不足,或制动卡钳自动调整间隙过小,进而带来车轮阻滞力偏大、制动拖滞等问题,影响汽车可靠性。利用自动装调设备,可以降低车辆行驶阻滞力矩,提高整车燃油经济性与动力性,具有重要经济价值。研发符合汽车总装生产要求的驻车制动在线装调系统,实现汽车驻车制动系统装调生产的自动化是一种必然趋势和客观需要,能提升汽车产品质量,降低故障率,提升汽车安全性,具有实际应用价值。

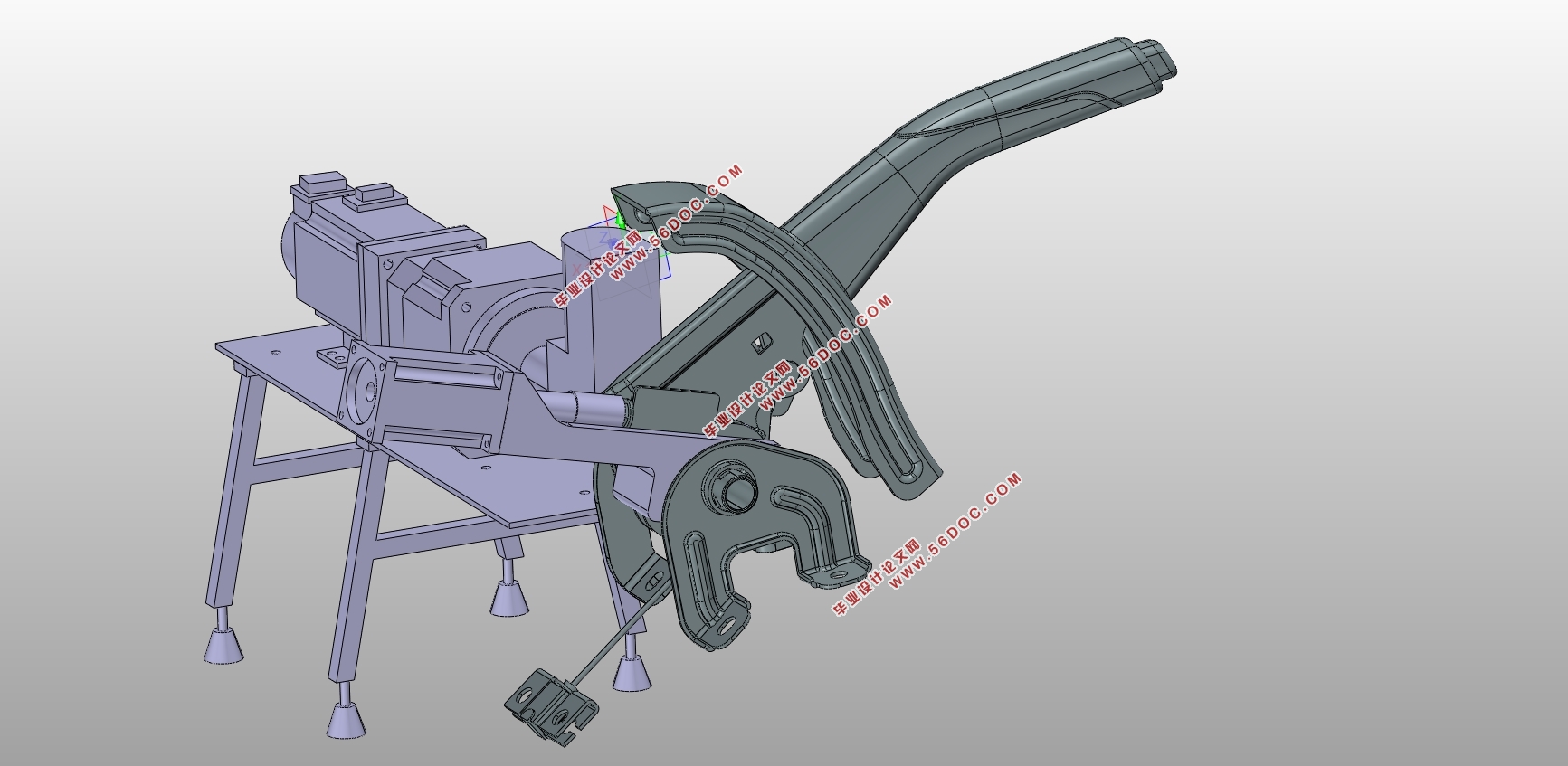

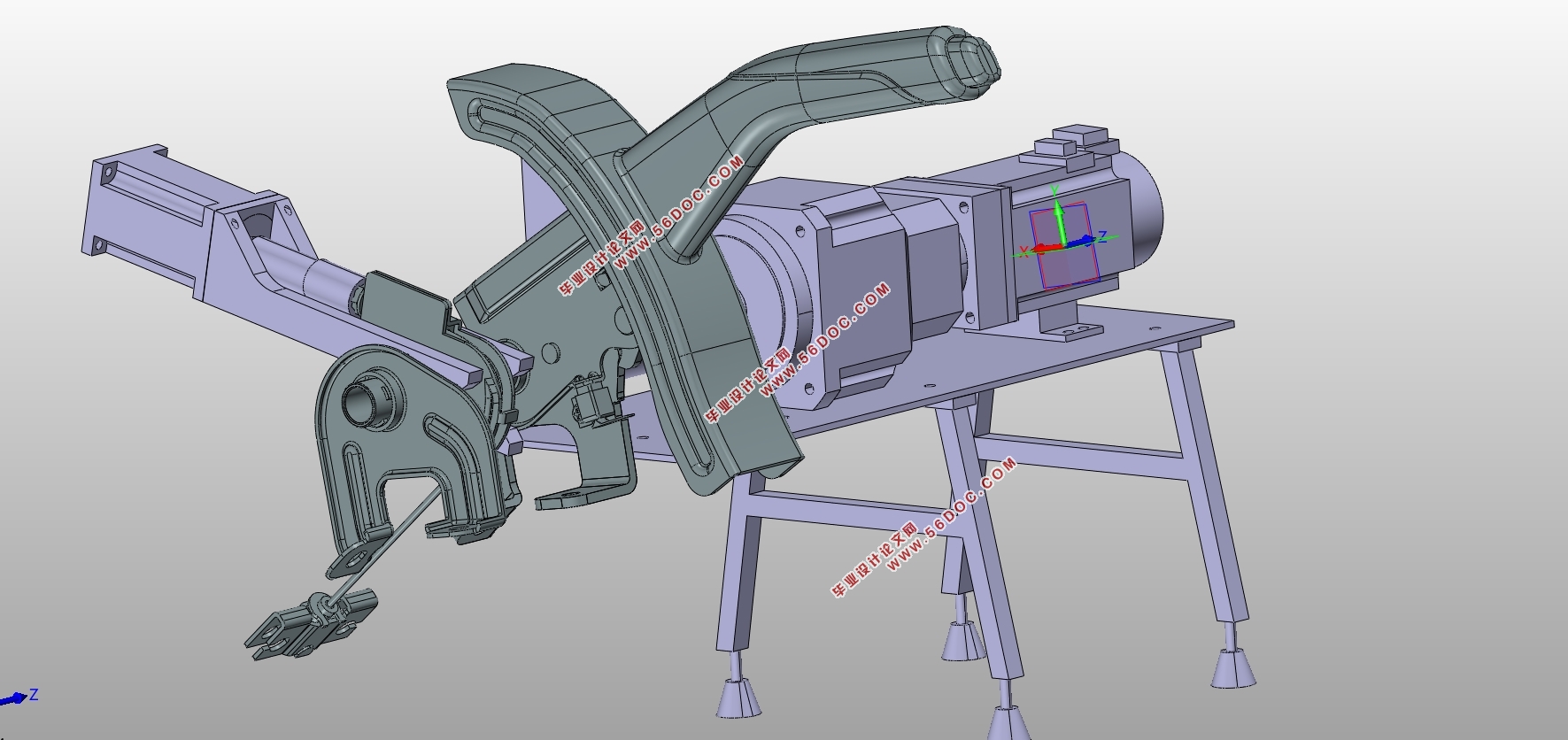

通过分析驻车制动系统及驻车制动手柄的结构和工作原理,对比驻车制动人工调整工艺并分析其存在的缺陷,设计了一种驻车制动在线装调系统。论文主要研究了以下几方面内容:

(1)介绍驻车制动系统的结构和原理。通过了解并分析驻车制动系统人工调整的方法,找出其中存在的缺陷,并由此进行驻车制动器在线装调设备系统设计的基础构思。

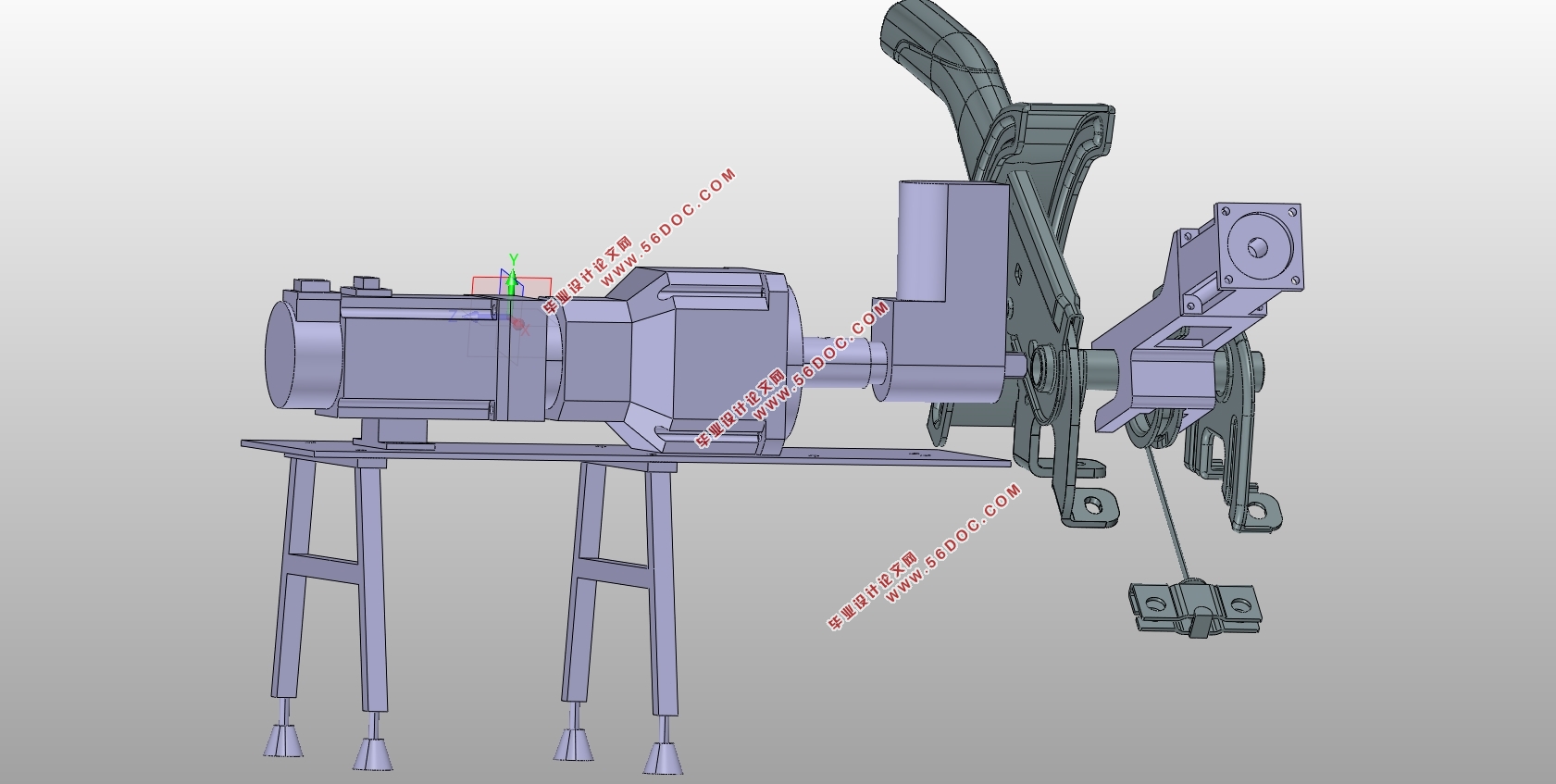

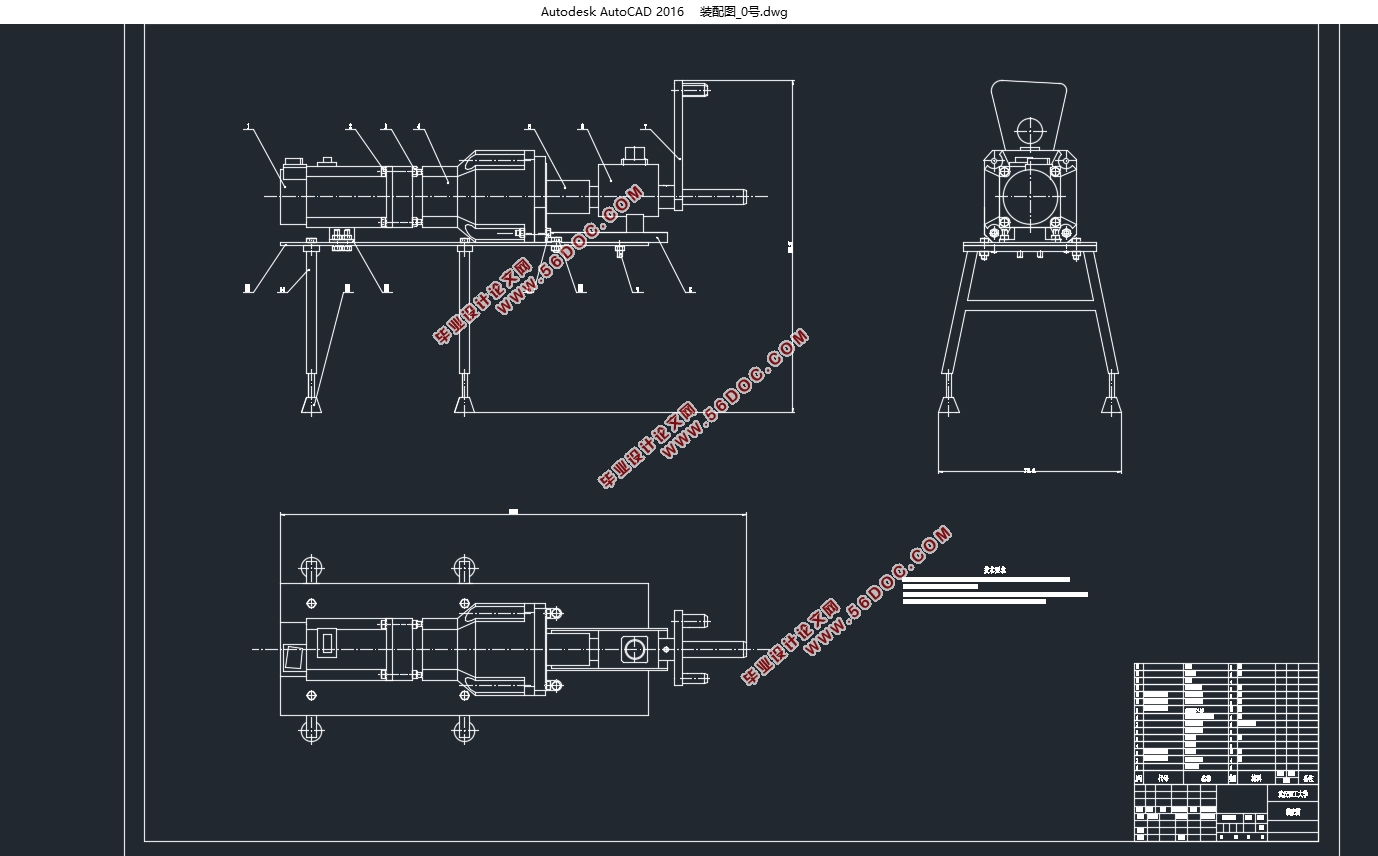

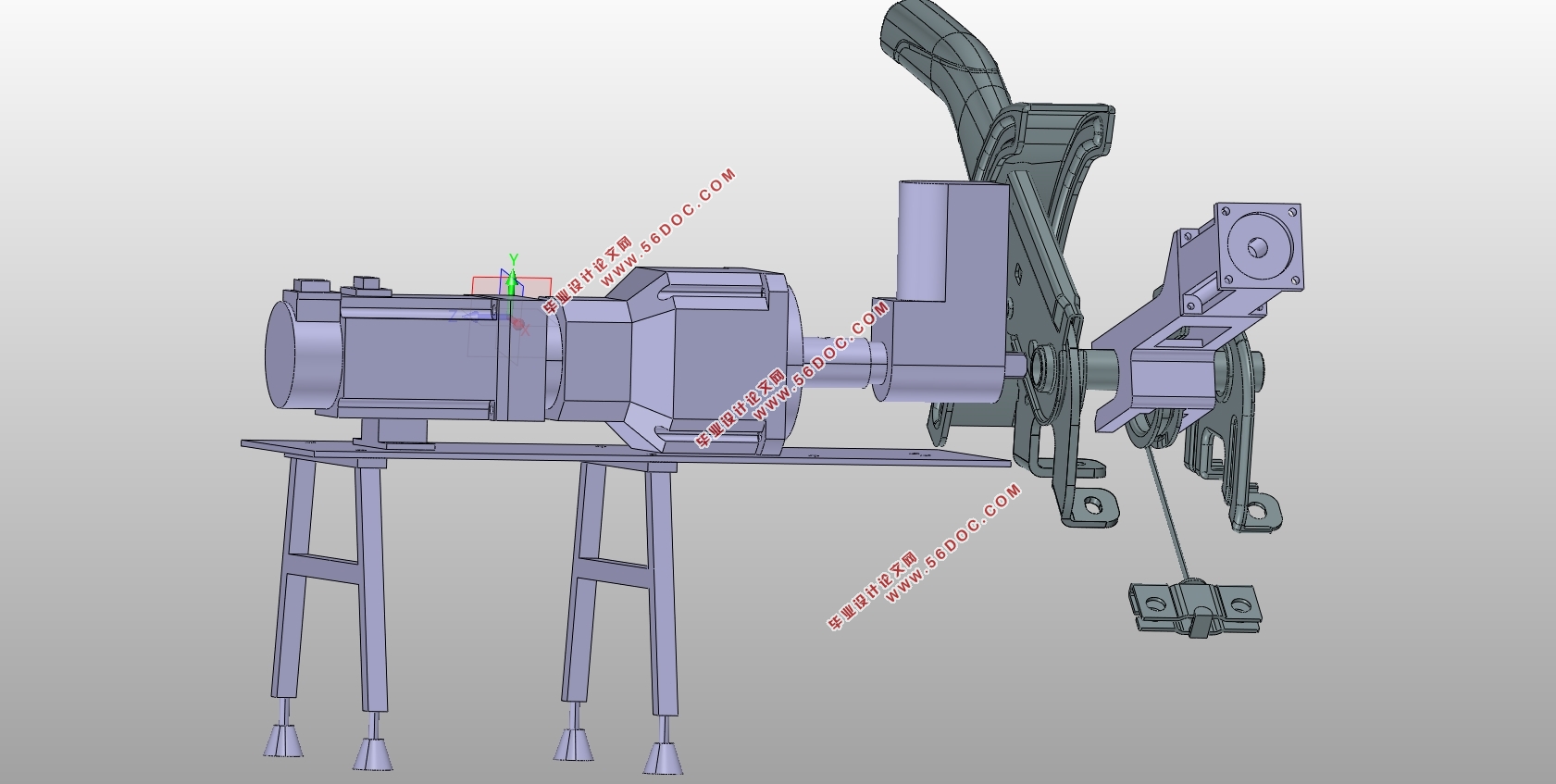

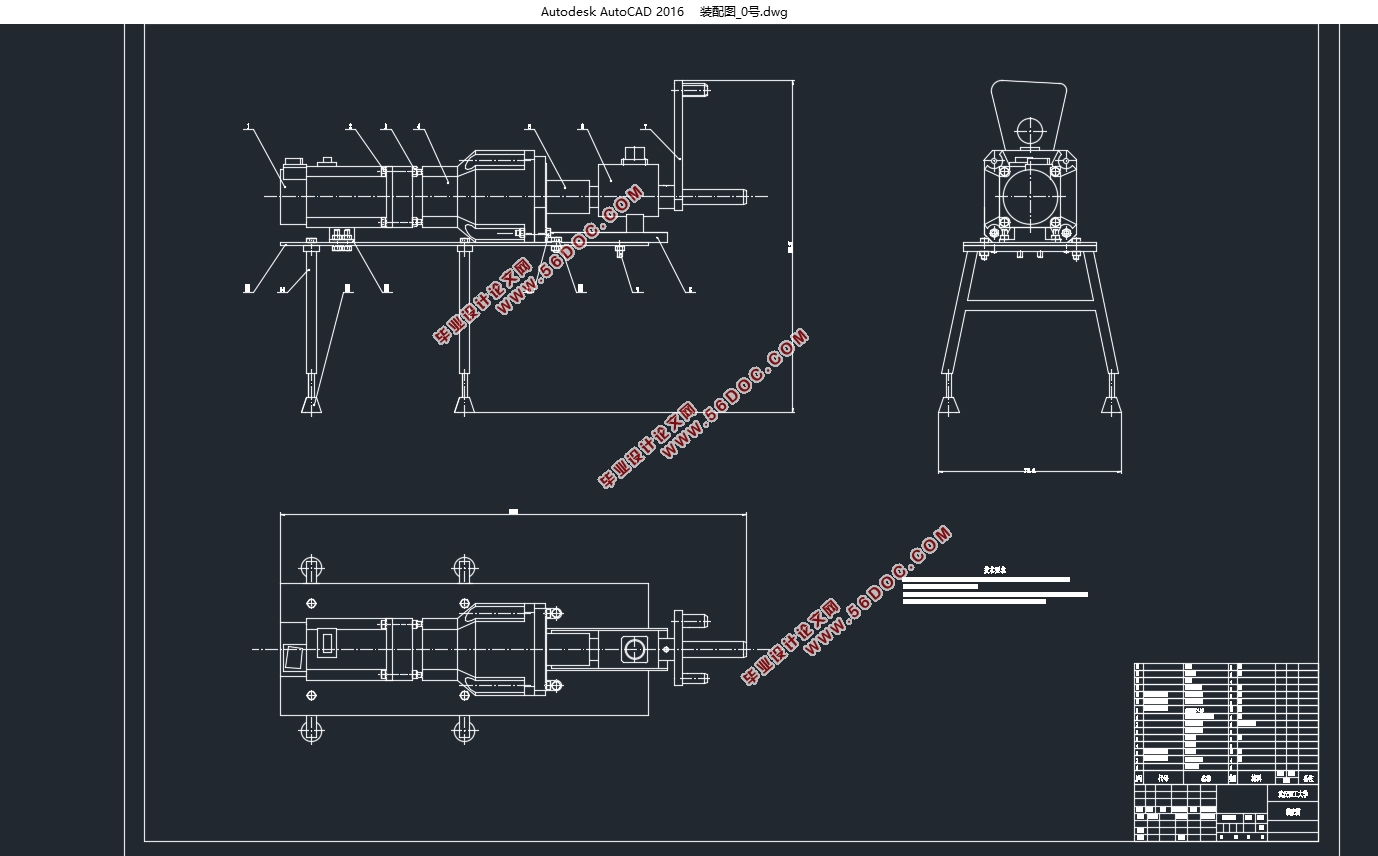

(2)根据在线装调设备系统的要求以及对驻车制动系统调整过程中所需扭矩的计算,对设备中所用伺服电机、减速机和扭矩传感器进行选型。

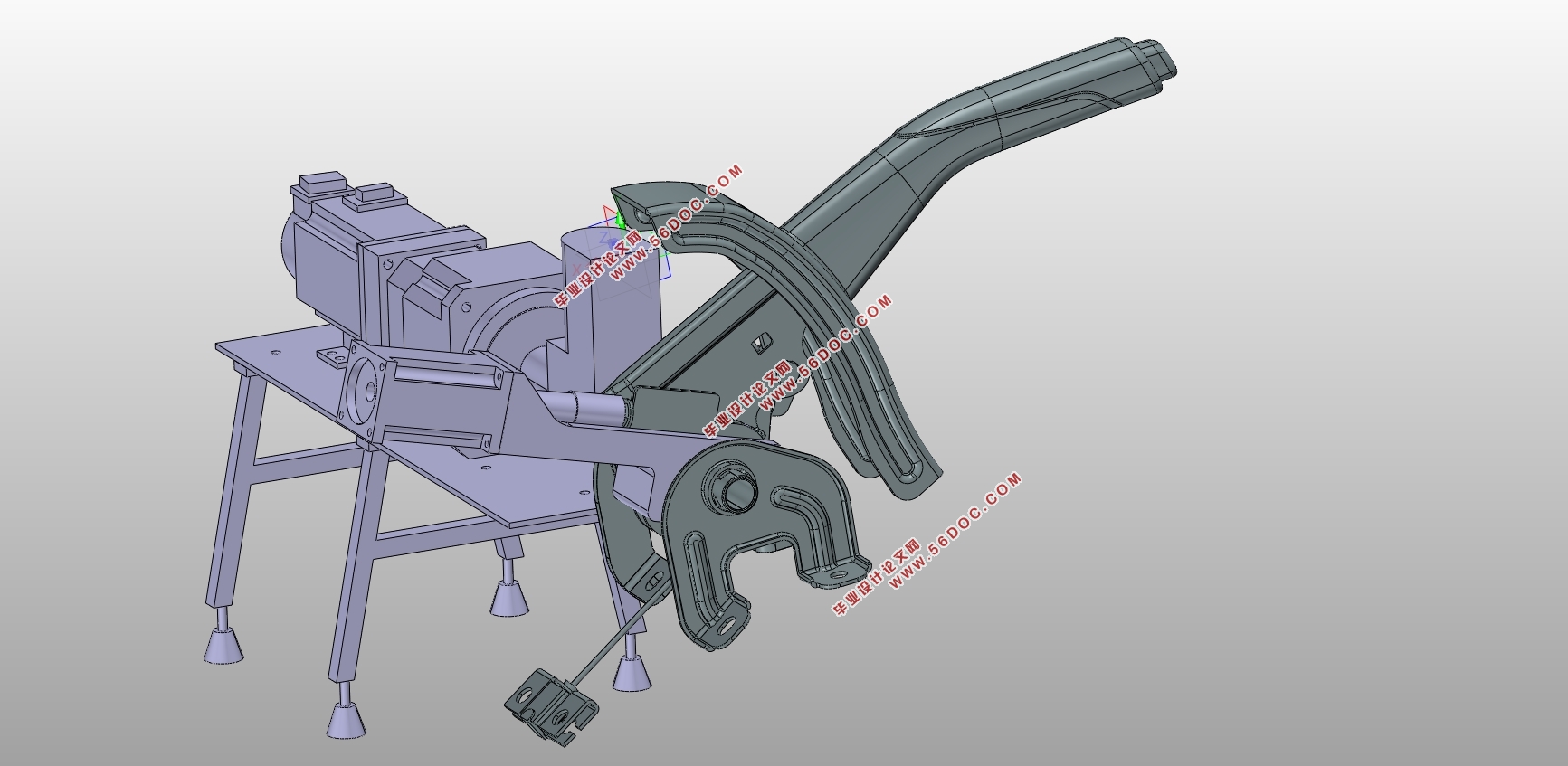

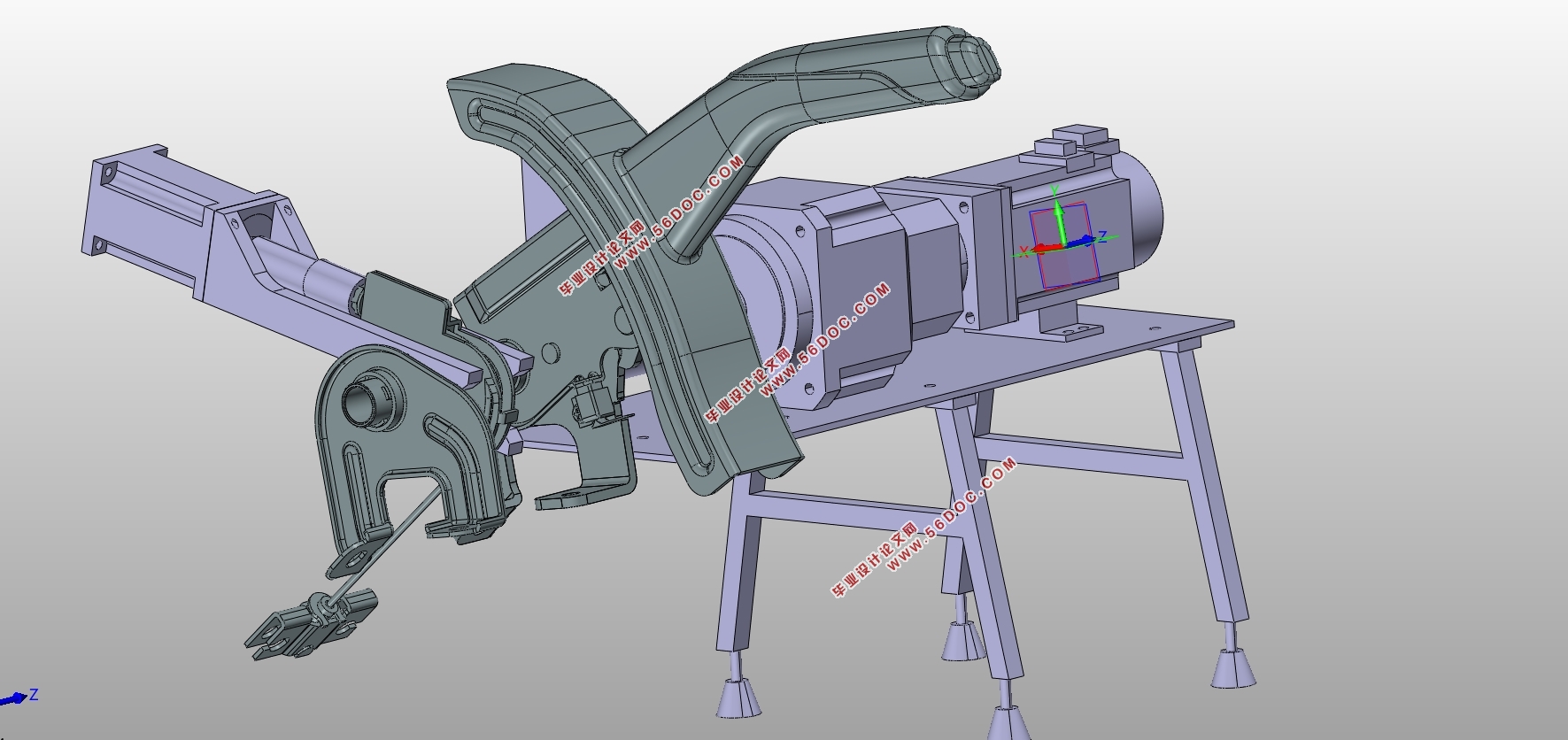

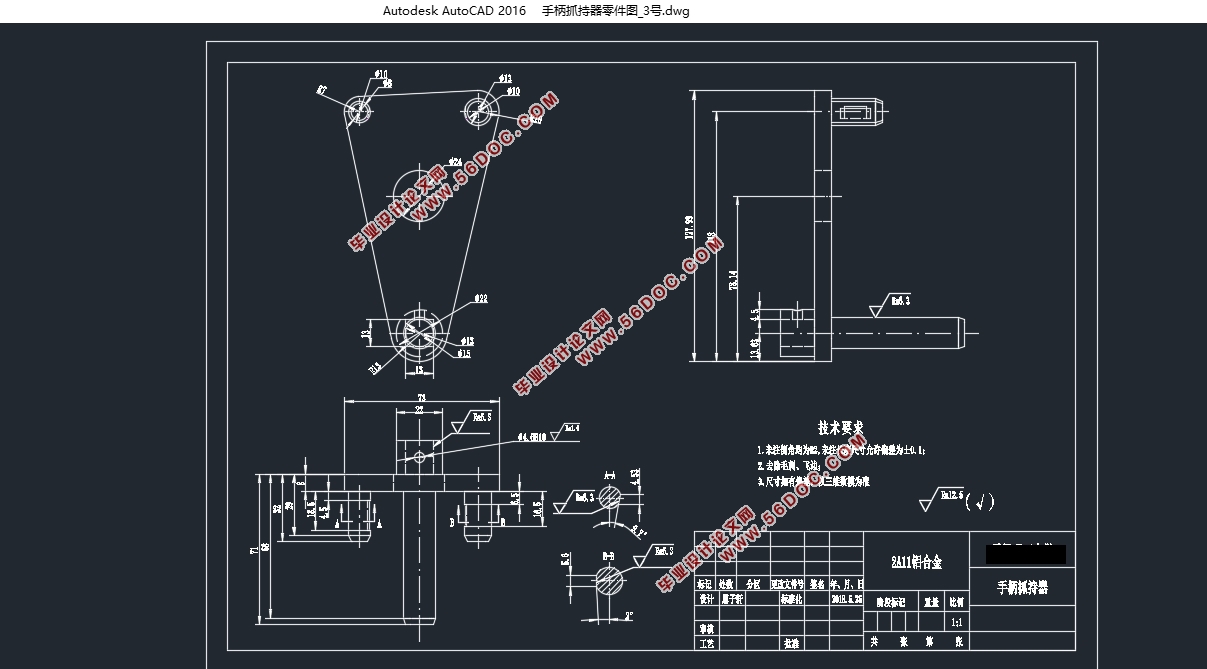

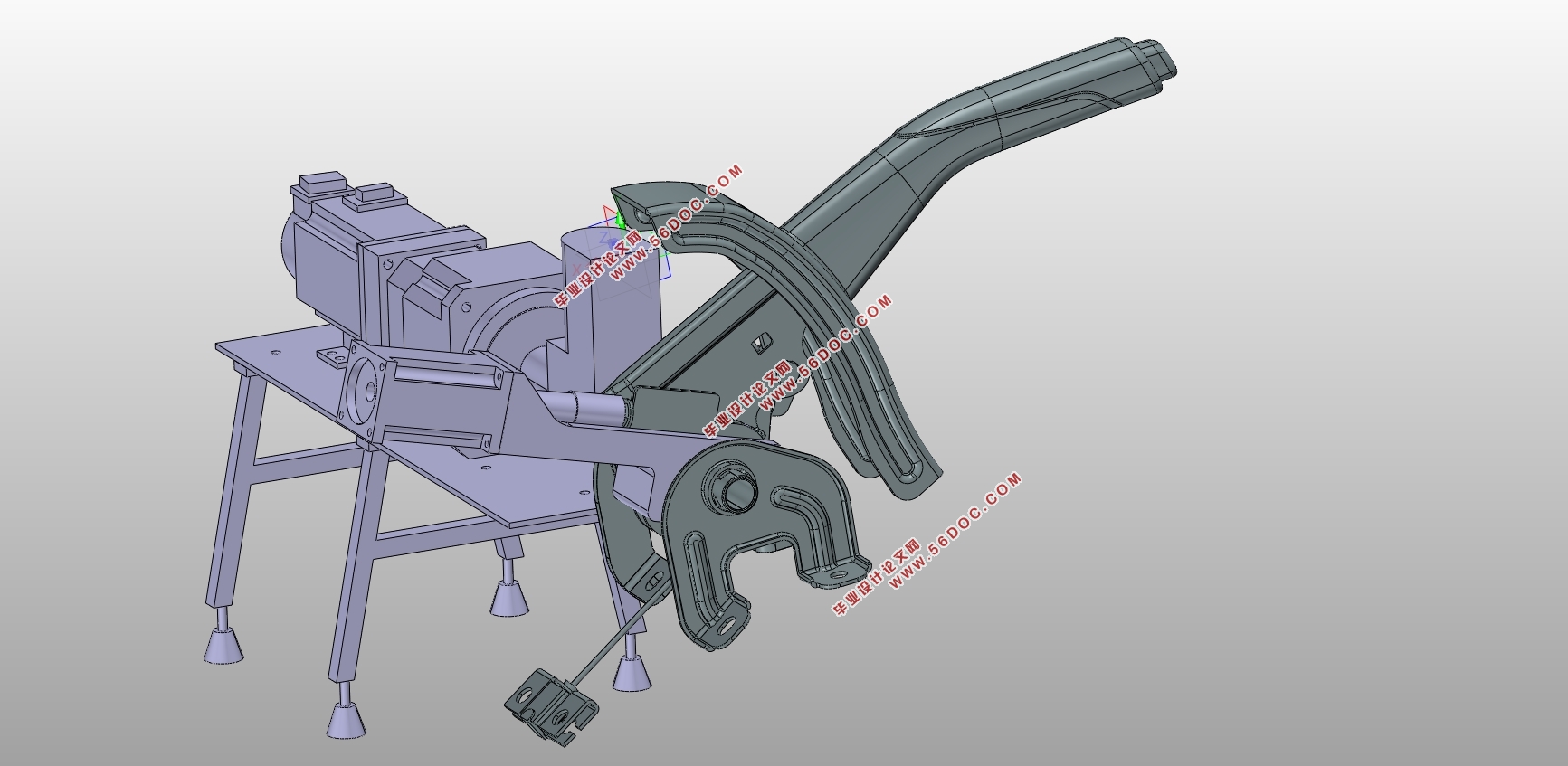

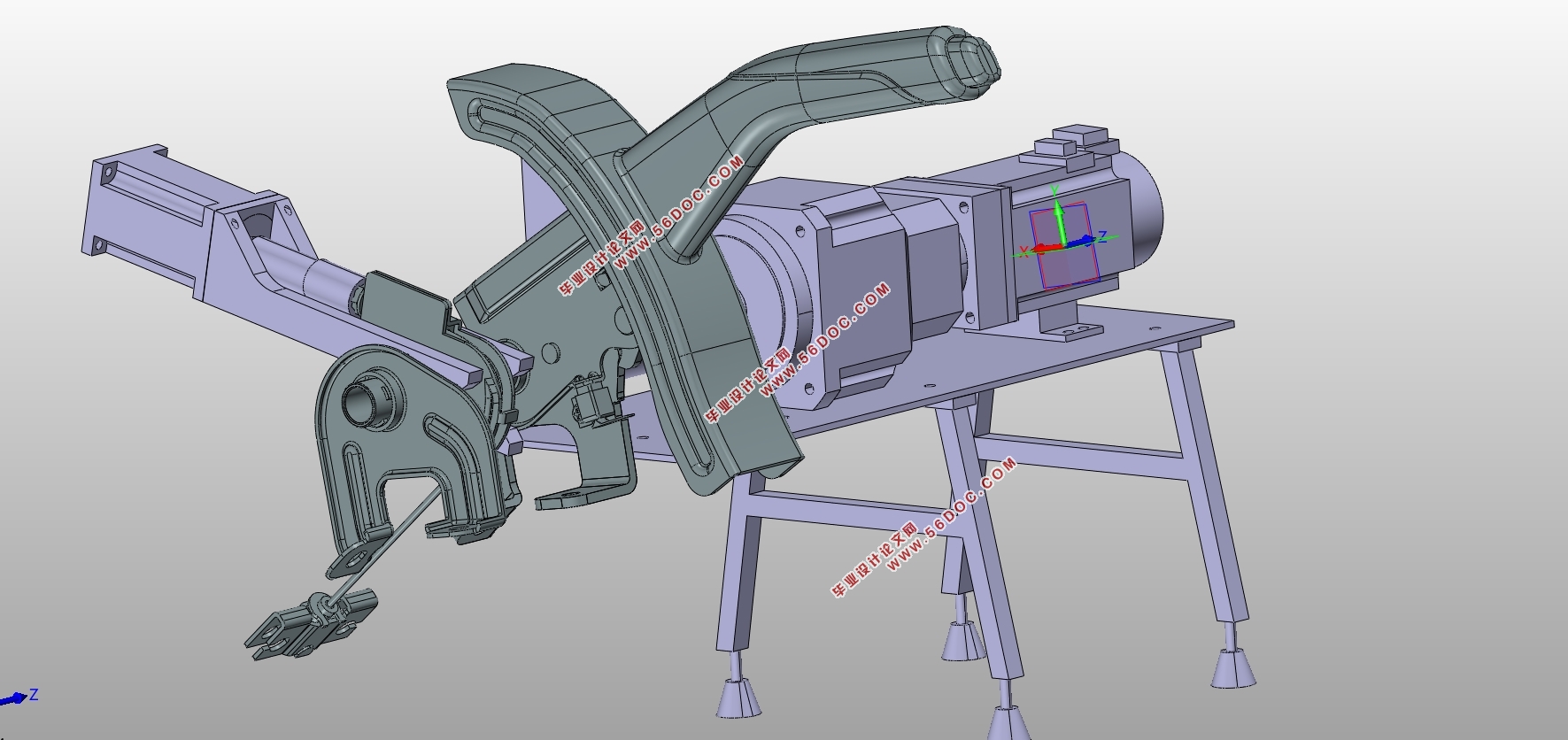

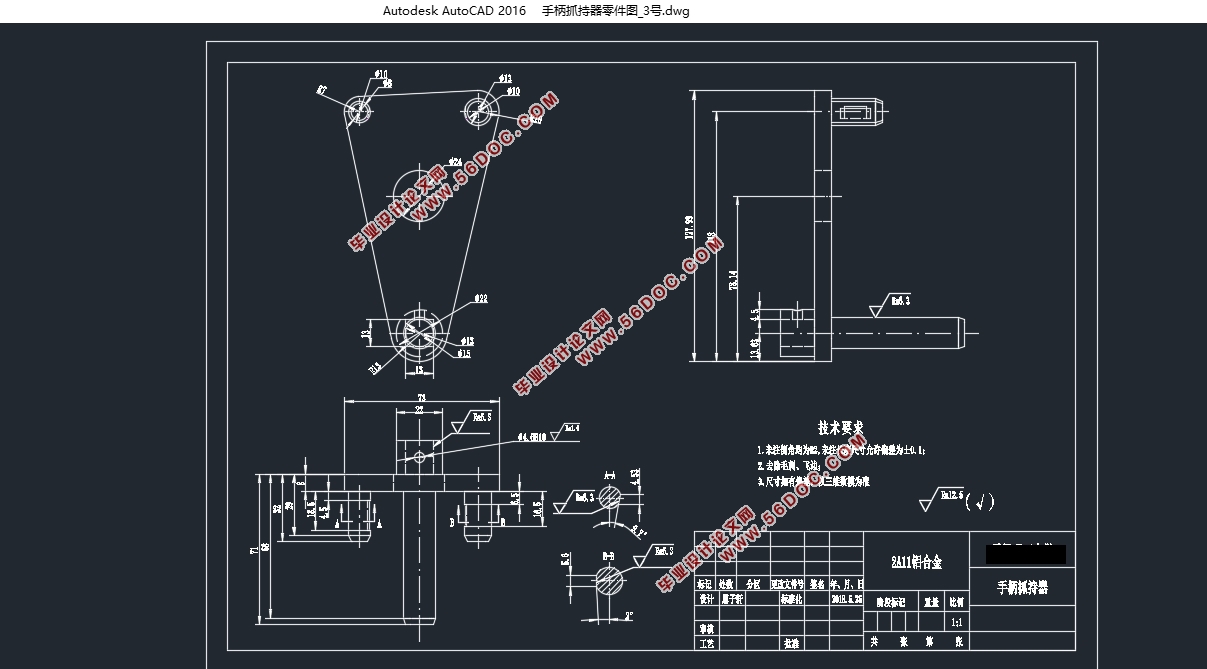

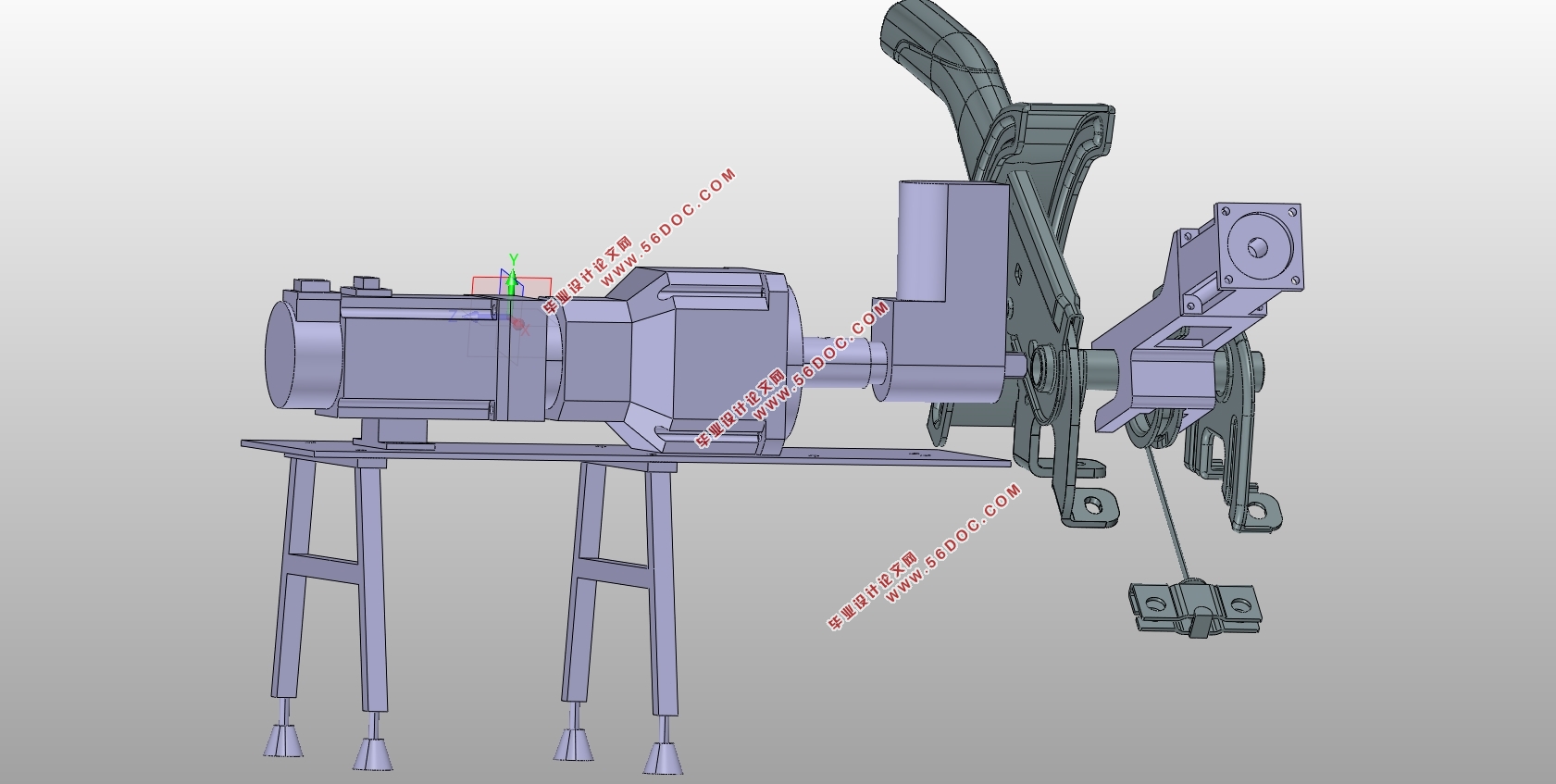

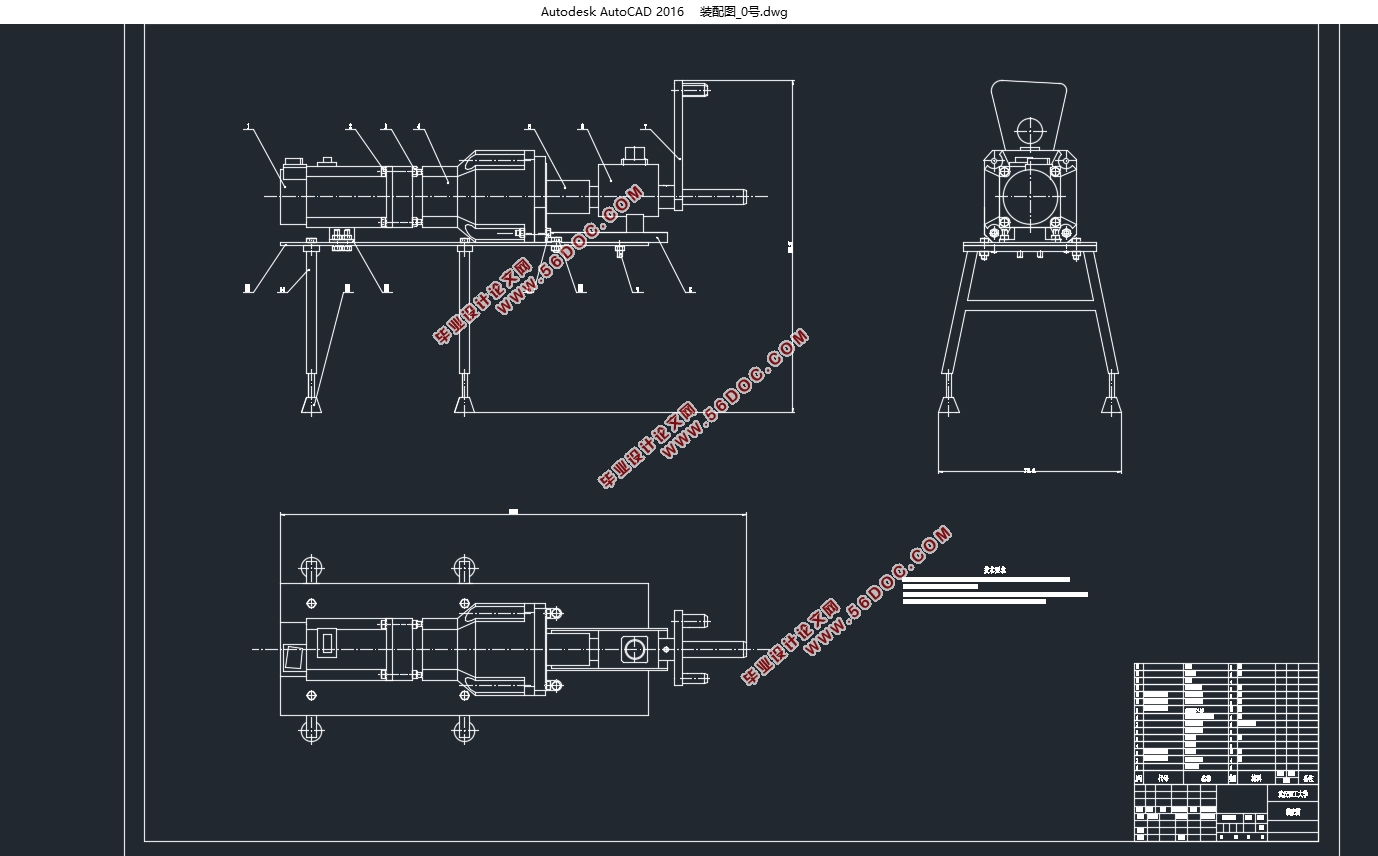

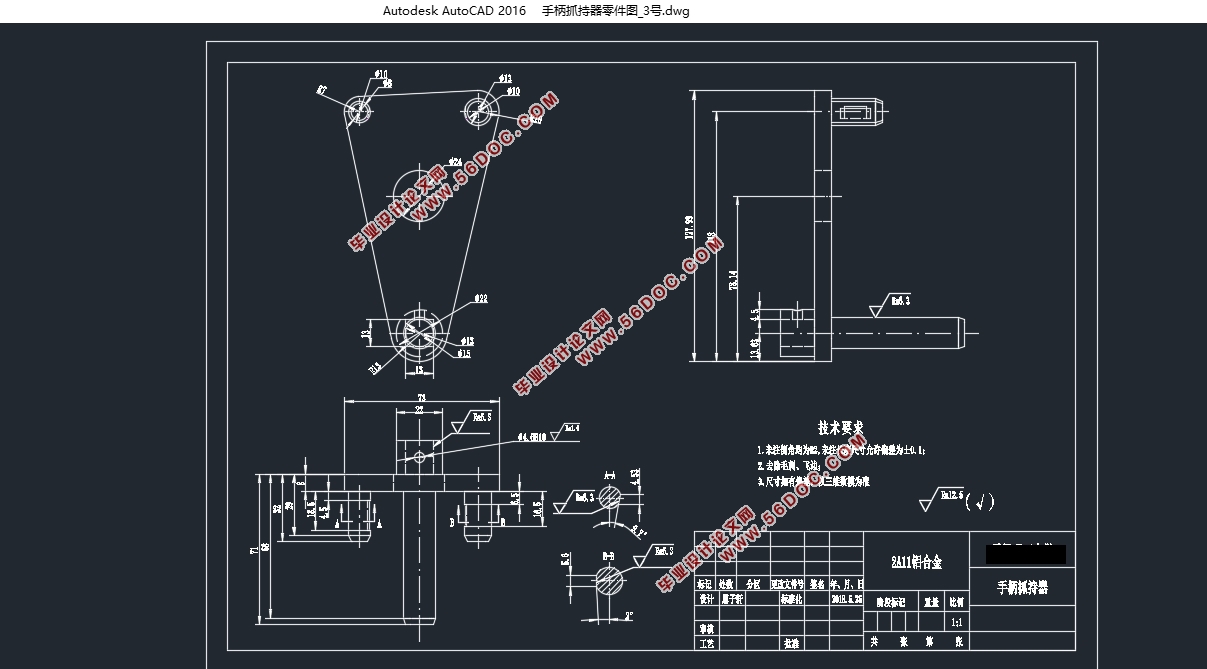

(3)根据制动手柄和汽车内底板的具体结构,对手柄抓持器、棘轮锁释放器、调整螺母操纵机构专用支架和扭矩传感器的固定装置等非标准件进行设计。同时通过对制动手柄操纵机构进行受力分析发现了操纵机构的翻转问题,并针对此问题提出了相应的解决方案。最后利用WORKBENCH对手柄抓持器进行了有限元分析,并根据分析结果对手柄抓持器的结构进行改进。

(4)在LabVIEW平台的基础上完成了装调系统的软件实现,主要包括制动手柄的运动控制,调整螺母的调节。同时从整个工作流程出发考虑了突发情况下急停的必要性。

研究结果表明:驻车制动器在线装调系统能弥补人工调整时一致性差,精确度低的缺陷并极大的提高装调质量和效率,具有很高的工业应用价值。

本文的特色:层次分明、数据可靠、文字简炼、说明透彻、推理严谨、立论正确。

关键词:驻车制动器,在线装调,LabVIEW,控制策略

Abstract

The parking brake is a braking device that is used to stabilize the vehicle and prevent the car from sliding when the vehicle is parked. The reliability of the vehicle brake system is the main indicator to evaluate the performance of the car, and its using performance directly affects the safety of the car when parking brake. If the adjustment process is unreasonable, it will lead to insufficient vehicle parking brake force, or the automatic adjustment clearance of the brake caliper is too small, and then bring about problems such as the wheel brake force is too large, brake delay and other issues, affecting vehicle reliability. The use of automatic adjustment equipment can reduce the drag torque of the vehicle and improve the fuel economy and power of the vehicle. It has important economic value. It is an inevitable trend and objective need to develop a parking brake on-line installation and adjustment system that meets the requirements of automobile assembly and production. At the same time, the system can improve the quality of automobile products, reduce the failure rate, improve the safety of vehicles, and has practical application value.

By analyzing the structure and working principle of the parking brake system and parking brake handle, comparing the manual adjustment process of the parking brake and analyzing its defects, an on-line parking brake adjustment system was designed. The paper mainly studied several aspects:

(1) Introduce the structure and principle of the parking brake system. Through understanding and analyzing the manual adjustment method of the brake system, the defects existing in the brake system are found out, and the basic conception of the design of on-line installation and adjustment equipment system of parking brake is carried out.

(2) According to the requirements of the on-line installation and adjustment equipment system and the calculation of the torque required in the adjustment process of the parking braking system, the servo motor, reducer and torque sensor used in the equipment are selected.

(3) According to the structure of brake handle and automobile inner bottom plate, non-standard parts such as handle gripper, ratchet lock release device, special support for adjusting nut operation mechanism and fixing device for torque sensor are designed. At the same time, the turning problem of the steering mechanism is found through the force analysis of the brake handle control mechanism, and the corresponding solution is put forward. Finally, the handle gripper is analyzed by using WORKBENCH, and the structure of the handle gripper is improved according to the analysis results.

(4) On the basis of the LabVIEW platform, the software realization of the installation and adjustment system is completed, which mainly includes the motion control of the brake handle, the adjustment of the adjusting nut and the storage and reading of the data. At the same time, starting from the whole workflow, the necessity of sudden stop and the corresponding strategy are considered, and the control strategy of automatically terminating the program in the case of torque overload is also considered.

The research results show that the on-line installation and adjustment system of parking brake can make up for the defects of poor consistency and low precision in manual adjustment, and greatly improve the quality and efficiency of installation and adjustment, so it has a high engineering application value.

The characteristics of this article: hierarchical, reliable data, simple text, thorough explanation, rigorous reasoning, correct argument.

Key words:Parking brake,Online adjustment, LabVIEW ,Control strategy

在线装调系统的要求

(1)操纵驻车制动手柄的转矩在0~80N∙m的范围内自由可调,以保证该系统能满足公司在产所有车型及以后开发各车型的使用要求;

(2)操纵驻车制动手柄的行程在0~90°的范围内自由可调;

(3)用于调节螺母的操纵机构的拧紧力矩在0~3N∙m的范围内自由可调,以保证该系统能满足公司在产所有车型及以后开发各车型的使用要求;

(4)精度:驻车制动系统调整结果的控制精度为±1N∙m;

(5)能够实时显示驻车制动手柄操纵机构的操纵转矩;

(6)调整检测速度:满足总装线生产节拍的要求;

(7)检测结果:驻车制动手柄操纵机构的输出扭矩、检测扭矩等。

目录

第一章绪论 1

1.1 研究背景 1

1.2 目的及意义 2

1.3 国内外研究现状 3

1.3.1 国外研究现状 3

1.3.2 国内研究现状 4

1.4 课题研究内容 6

1.5 预期目标 6

1.6 本章小结 6

第2章驻车制动在线调整设备系统的理论研究 7

2.1 驻车制动系统的研究 7

2.2 驻车制动手柄的研究 8

2.3 驻车制动系统人工调整工艺的研究 9

2.4 在线装调系统的设计方案 10

2.4.1 在线装调的工艺流程 10

2.4.2 驻车制动器在线装调设备 10

2.4.3 驻车制动在线装调系统工作流程 11

2.5 本章小结 12

第3章在线装调系统的硬件 13

3.1 在线装调系统的要求 13

3.2标准件的选型 13

3.2.1 伺服电机 13

3.2.2 减速机 16

3.2.3 扭矩传感器 17

3.3 非标准件的设计 18

3.3.1 驻车制动手柄抓持器 18

3.3.2 驻车制动手柄棘轮锁释放器 20

3.3.3 扭矩传感器固定支架 21

3.4 调整螺母的操纵机构固定支架 23

3.5 手柄抓持器的各项分析 25

3.5.1 驻车制动手柄转动角度误差分析 25

3.5.2 驻车制动手柄抓持器的有限元分析 27

3.6 驻车制动手柄操纵机构的翻转分析 28

3.7 本章小结 33

第4章在线装调设备系统的软件开发 34

4.1 后面板介绍 34

4.2 前面板介绍 42

4.3 本章小结 42

第5章结论 44

5.1 研究总结 44

5.2 研究展望 45

致谢 46

参考文献 47

|