100t液压支架搬运车悬架系统CAE分析与优化设计(含CAD零件图装配图)(任务书,开题报告,文献摘要,外文翻译,论文说明书12000字,CAD图6张)

摘 要

本文主要是对100t液压支架搬运车的悬架系统进行有限元分析以及优化设计。首先研究了国内外支架搬运车的研究现状,说明了各类支架搬运车在实际使用中所遇到的问题,结合国内外研究背景,了解了国内外支架搬运车的研究现状,为本次CAE分析和优化设计指明了方向。

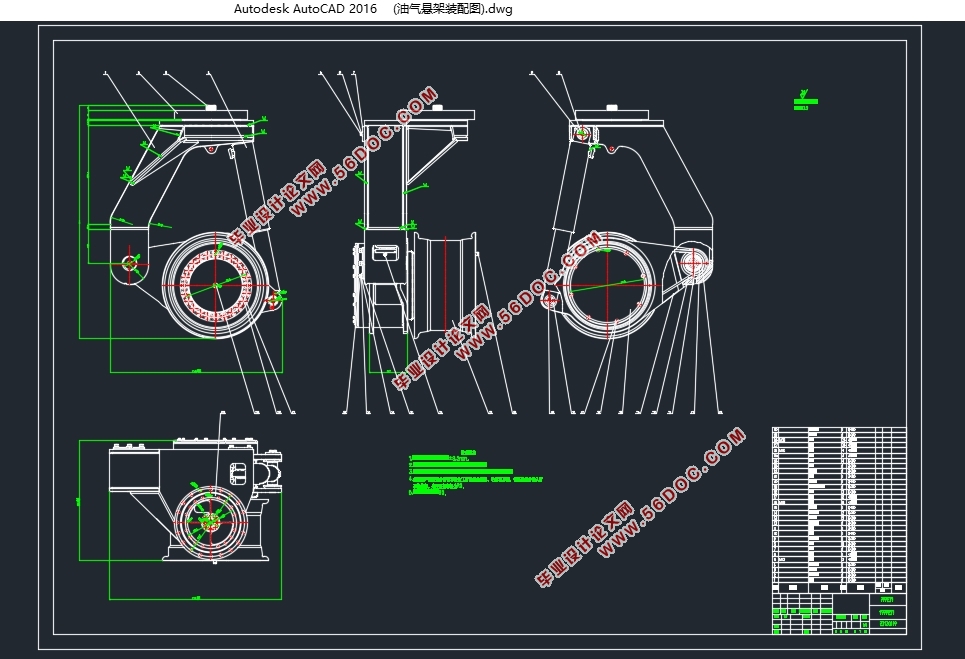

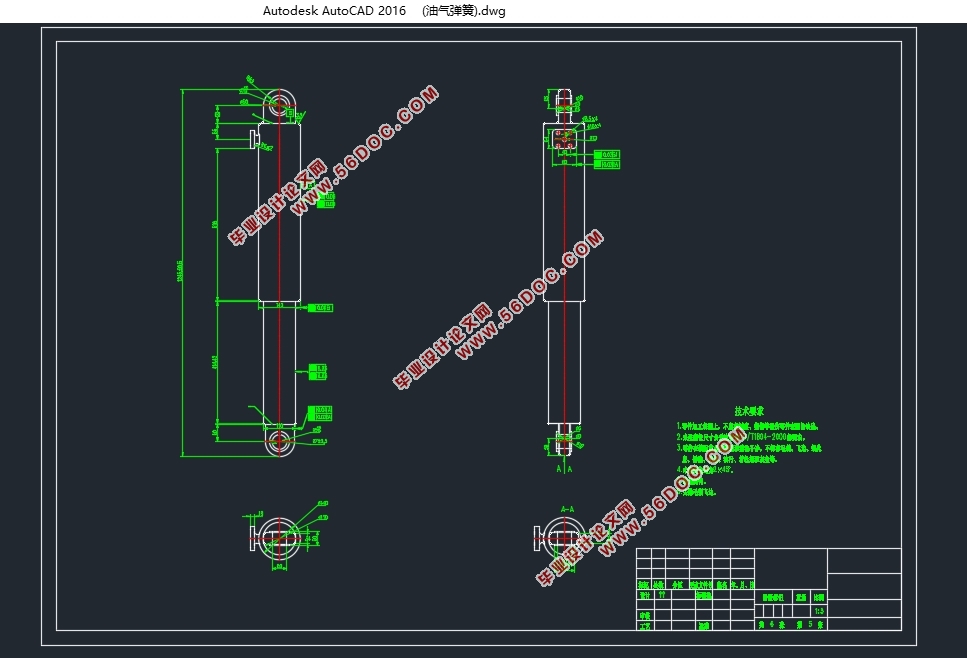

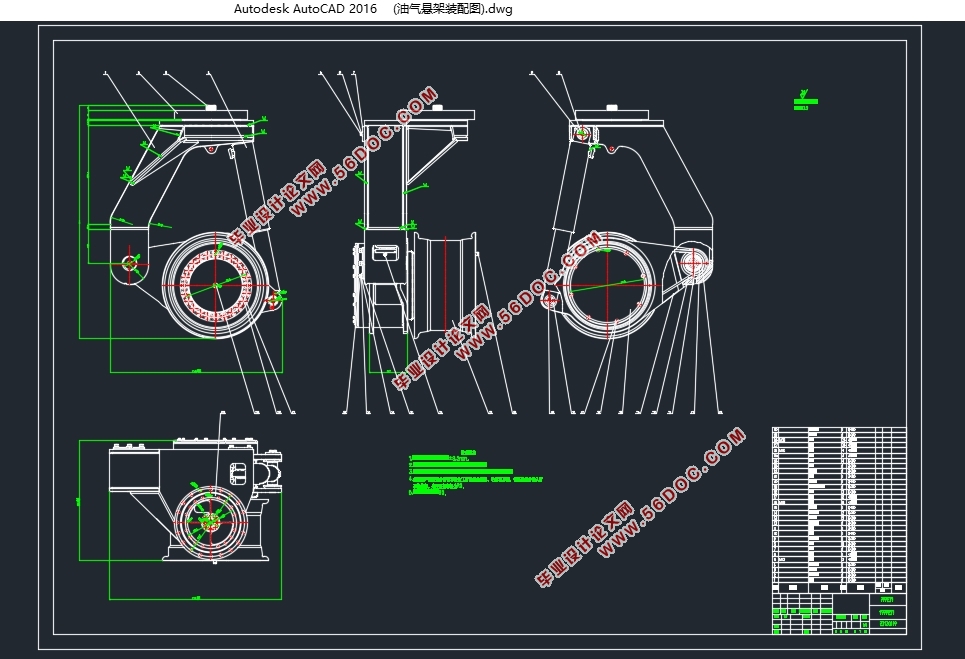

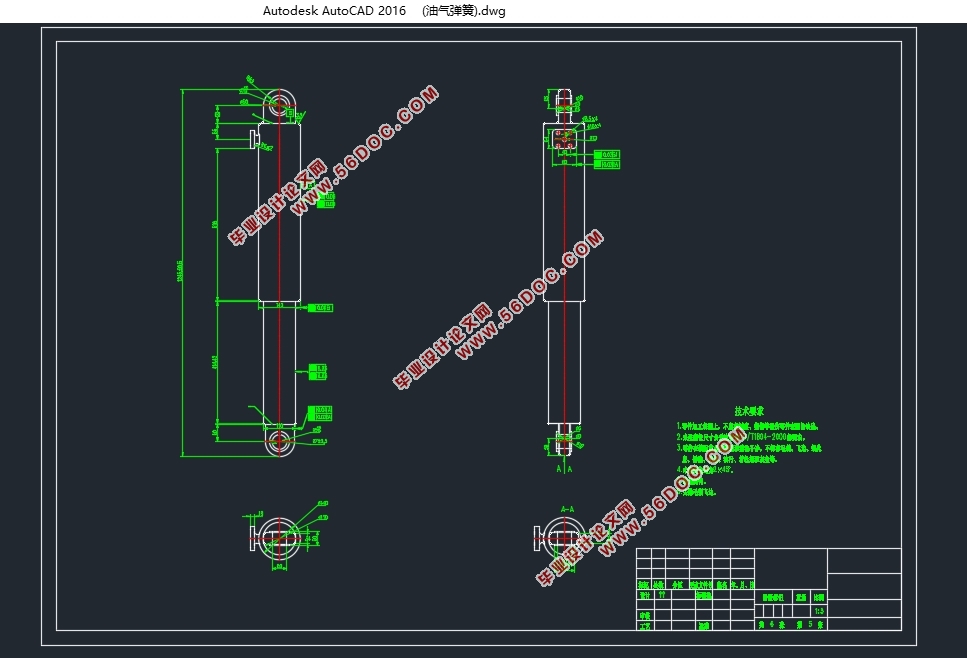

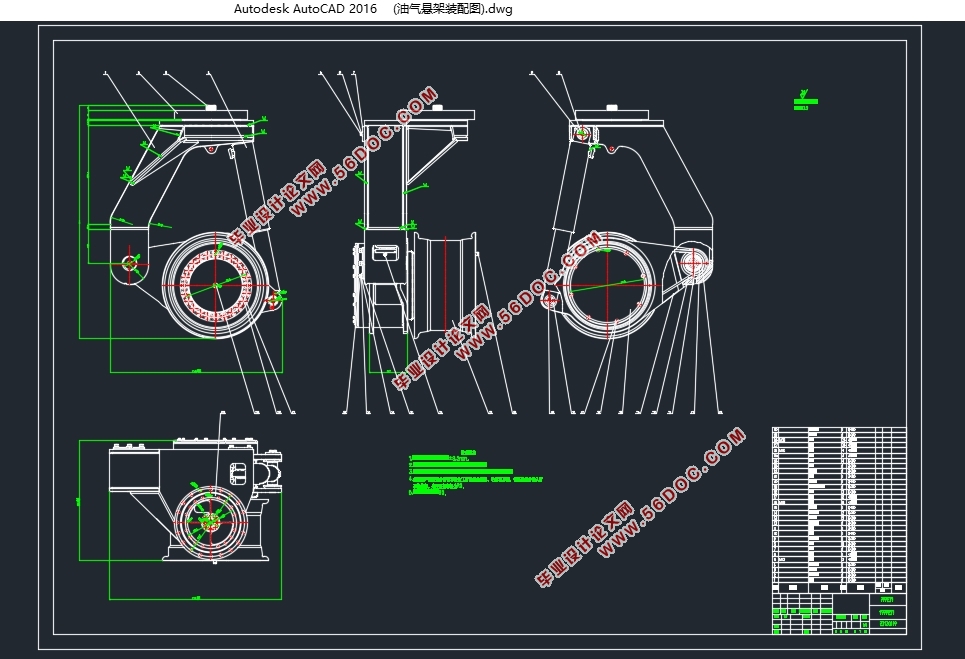

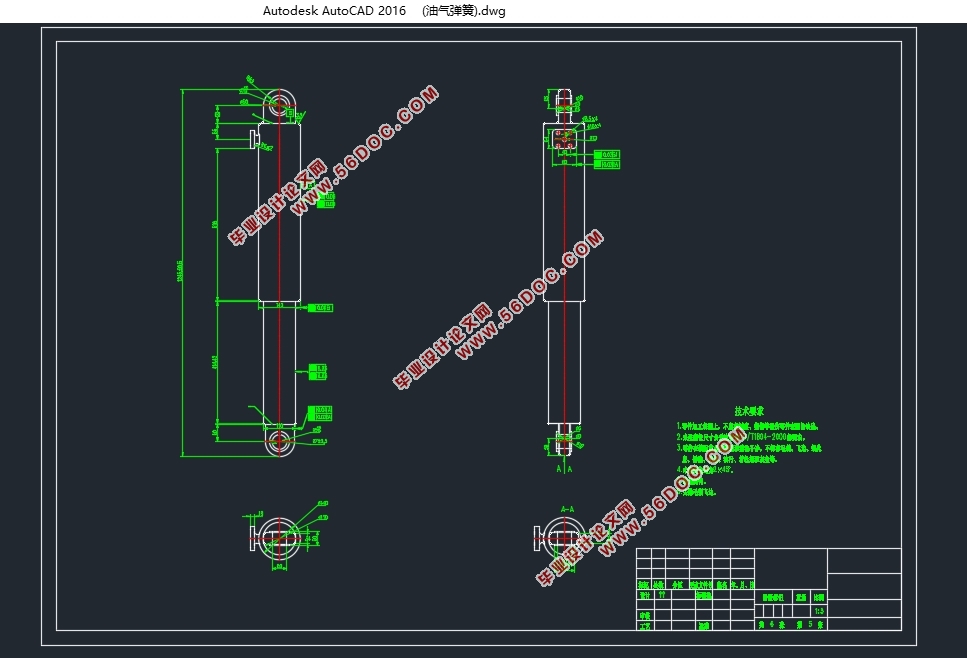

本文所研究的是100t液压支架搬运车悬架系统的CAE分析和优化设计。我们只研究该搬运车车厢部分。该车共有8个车轮,分别配备8个独立悬架。与一般矿用车一样采用了承载能力较强油气悬架系统。本文简单说明了油气悬架系统的结构和简单的工作原理,并且在原理的基础上分析油气悬架动力学特性和强度刚度特性。最后利用仿真所得到的的数据对悬架系统进行优化设计。

首先建立悬架系统的动力学模型,将CATIA中建立的油气悬架模型导入ADAMS中,然后加上各种约束和力后模拟路面行驶在轮毂部分加上位移。对悬架系统模型上销、下销以及减震处销这三个核心点的受力以及上销的加速度进行仿真。分析其结构特性对悬架系统的动力学特性的影响。

动力学仿真完成后,利用Hypermesh画网格,对悬架系统进行刚度和强度分析,提供了优化所需的参数。

本文对100t液压支架搬运车悬架系统进行了动力学分析以及强度刚度分析,研究了其结构特性对悬架系统性能的影响,通过优化使系统满足实际要求,增强其耐磨损度和使用寿命。提高了自己对工程车辆悬架系统在实际使用中的认识。

关键词:支架搬运车,油气悬架,动力学分析,强度和刚度,优化设计

Abstract

This paper is mainly about the finite element analysis and optimization design of the suspension system of 100t hydraulic support van. Firstly, the research status of support van at home and abroad is studied, and the problems encountered in practical use are explained, combined with domestic and foreign research background, the research status of support van at home and abroad is understood, which indicates the direction of CAE analysis and optimization design.

The CAE analysis and optimization design of suspension system of 100t hydraulic powered support vehicle are studied in this paper. We only study the part of the van. The car has a total of eight wheels, equipped with eight independent suspension. As with the general mine vehicle use the bearing capacity strong oil and gas suspension system. This paper briefly describes the structure and simple working principle of hydro-pneumatic suspension system, and analyzes the dynamic characteristics and strength stiffness characteristics of hydro-pneumatic suspension on the basis of principle. Finally, the suspension system is optimized by the data obtained from the simulation.

Firstly, the dynamic model of the suspension system is established. The oil and gas suspension model established in CATIA is introduced into ADAMS, and then various constraints and forces are used to simulate the displacement of the road surface. The stress of the three core points and the acceleration of the upper pin are simulated on the suspension system, the lower pin and the cushioning system. And the influence of its structural characteristics on the dynamic characteristics of the suspension system was analyzed.

After the simulation is complete, the stiffness and strength of the suspension system are analyzed by using the Hypermesh grid, which provides the parameters needed for optimization.

This paper carries on the dynamic analysis and strength stiffness analysis of the suspension system of 100t hydraulic support van, studies the effect of its structural characteristics on the suspension system performance, and through optimization to make the system meet the actual requirements, enhance its wear and service life. Improve the understanding of the engineering vehicle suspension system in actual use.

Key Words:Stent cart,Oil and gas suspension,kinetics analysis,Strength and stiffness,Optimized design

目录

第一章绪论 1

1.1研究背景 1

1.2国内外研究现状 1

1.3研究意义 2

1.4研究的主要内容 2

第二章悬架系统模型的建立和动力学仿真 3

2.1概述 3

2.2ADAMS软件介绍 3

2.3油气悬架的原理 4

2.4油气悬架模型的建立 4

2.5悬架系统动力学仿真 5

2.6架系统动力学仿真的结果 7

2.7本章小结 15

第三章悬架系统刚度以及强度仿真 15

3.1HyperMesh软件介绍 15

3.2HyperMesh导入模型 15

3.3HyperMesh模型处理(几何清理) 16

3.4Hypermesh画网格 18

3.5定义材料属性与赋予材料 19

3.6施加边界条件 20

3.7添加约束和载荷 21

3.8建立工况 23

3.9求解 23

3.10桥壳支臂刚度和强度分析 25

3.11本章小结 27

第四章优化设计 27

4.1优化设计 27

4.2优化后支柱刚度和强度分析 29

4.3本章小结 29

结 论 30

参考文献 31

致谢 32

|