汽车进气门刀具的设计与制造(含CAD零件图,PROE三维图)(论文说明书10000字,CAD图纸1张,PROE三维图)

摘 要:切削加工是现代制造业应用最广泛的加工技术之一。据统计,国外切削加工在整个制造加工中所占比例约为80%~85%,而在国内这一比例则高达90%。 刀具是切削加工中不可缺少的重要工具,无论是普通机床,还是先进的数控机床(NC)、加工中心(MC)和柔性制造系统(FMC),都必须依靠刀具才能完成切削加工。刀具的发展对提高生产率和加工质量具有直接影响。材料、结构和几何形状是决定刀具切削性能的三要素,其中刀具材料的性能起着关键性作用。国际生产工程学会(CIRP)在一项研究报告中指出:“由于刀具材料的改进,允许的切削速度每隔l0年几乎提高一倍”。刀具材料已从20世纪初的高速钢、硬质合金发展到现在的高性能陶瓷、超硬材料等,耐热温度已由500~600℃提高到1200℃以上,允许切削速度已超过1000m/min,使切削加工生产率在不到100年时间内提高了100多倍。因此可以说,刀具材料的发展历程实际上反映了切削加工技术的发展史。

关键词: 车刀、制造、加工、刀具

Abstract :Cutting is one of the most widely used processing technologies in modern manufacturing industry. According to statistics, the proportion of foreign cutting processing in the whole manufacturing process is about 80%-85%, while in China the proportion is as high as 90%. Tool is an indispensable and important tool in cutting. Whether it is an ordinary machine tool, or an advanced numerical control machine tool (NC), a machining center (MC) and a flexible manufacturing system (FMC), it must rely on the tool to complete the cutting process. The development of cutting tools has a direct impact on improving productivity and processing quality. Material, structure and geometric shape are the three factors that determine the cutting performance of the tool, and the performance of the tool material plays a key role. The International Society of Production Engineering (CIRP) pointed out in a research report that "due to the improvement of tool materials, the allowable cutting speed almost doubles every 10 years". Tool materials have been developed from high-speed steel and cemented carbide in the early 20th century to high-performance ceramics and superhard materials. The heat-resistant temperature has been raised from 500-600 degrees C to over 1200 degrees C, the allowable cutting speed has exceeded 1000m/min, and the cutting productivity has increased more than 100 times in less than 100 years. Therefore, it can be said that the development history of tool materials actually reflects the development history of cutting technology.

Key words: turning tool, manufacturing, processing, cutting tool

目 录

摘 要 1

一、 绪论 3

1 车刀发展史 3

2 车刀结构组成 3

3 国内外研究现状与发展前景 4

4 车刀的种类 4

4.1.1折叠切断车刀 5

4.1.2成形车刀 5

二、 车刀主要零件设计 6

2.1零件的建模的基本特征 6

2.1.1 概念 6

2.1.2 零件的设计步骤 6

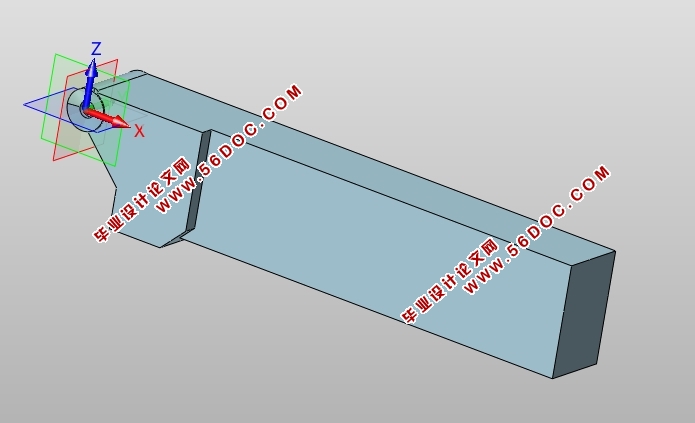

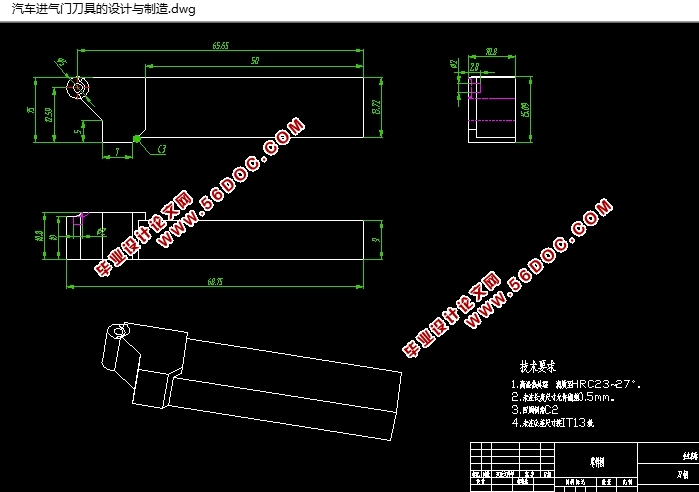

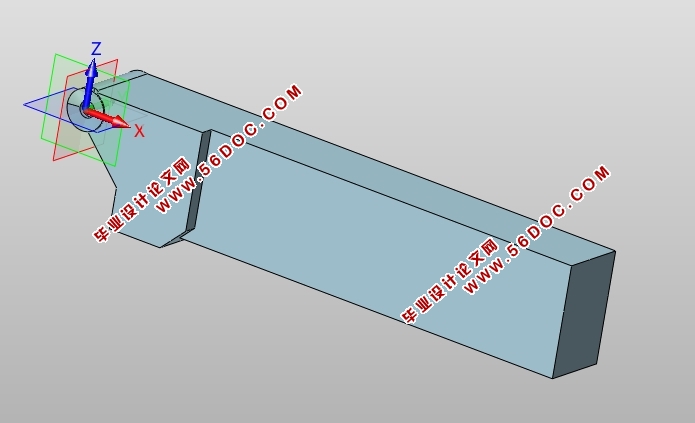

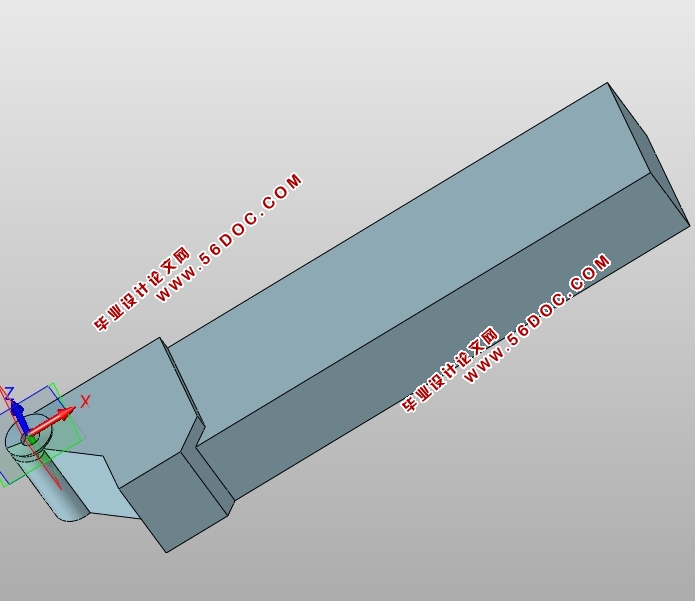

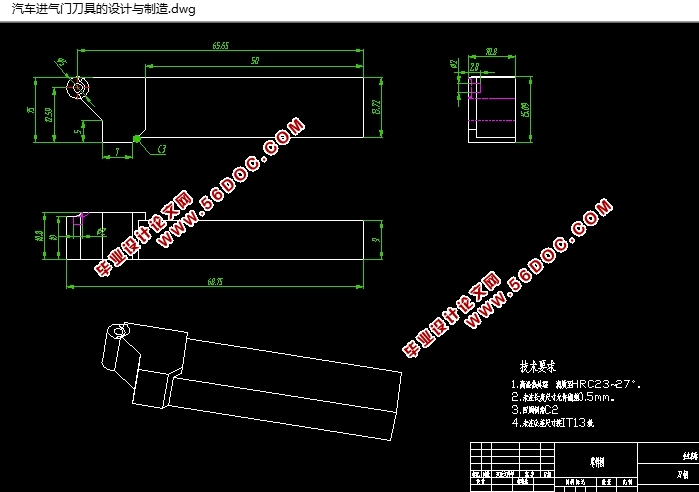

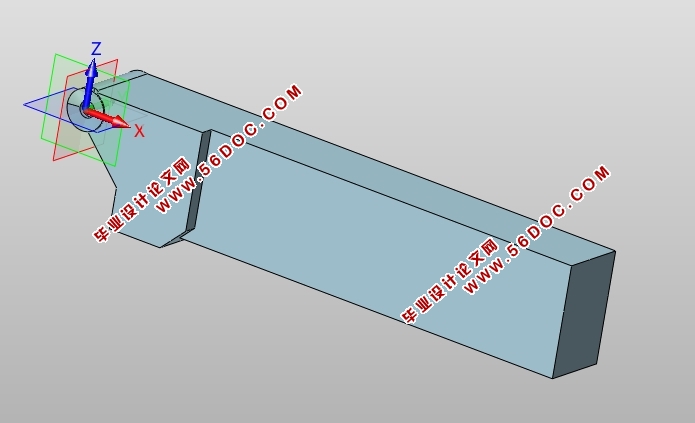

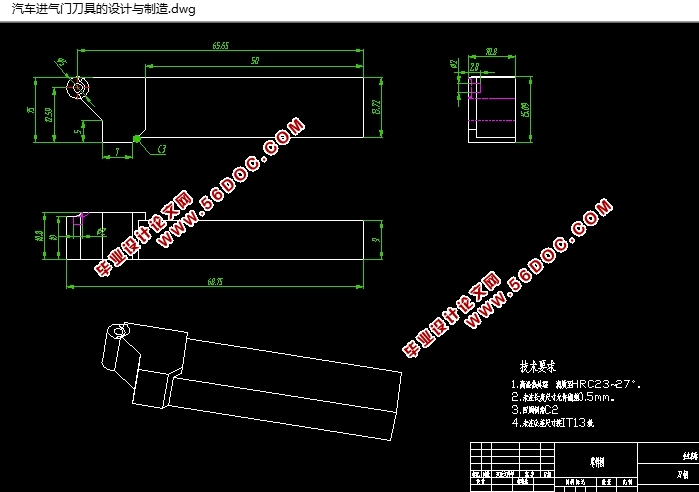

2.2 刀柄零件图的创建 7

2.2.1 刀柄零件图 7

2.2.2 刀柄零件图创建的操作步骤 1

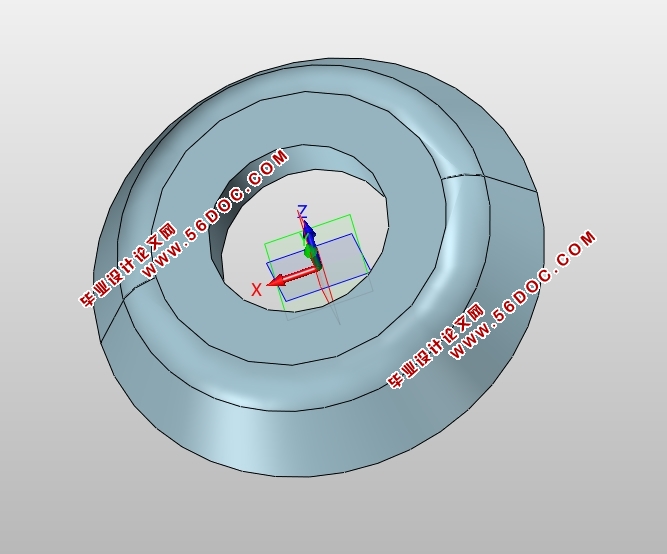

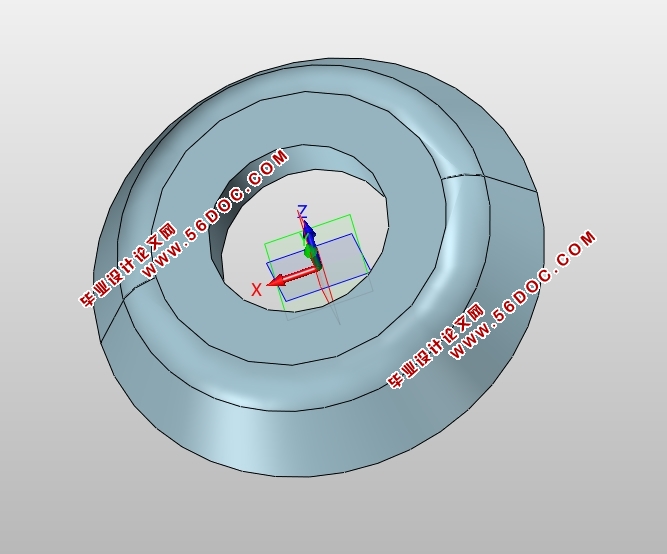

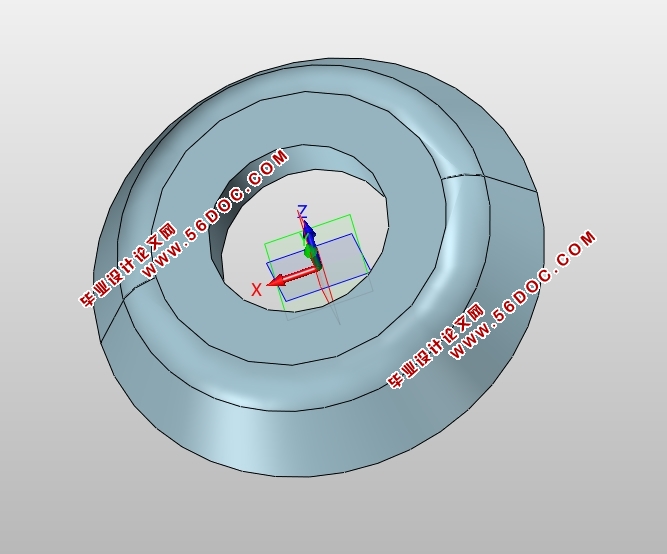

三、 车刀主要零件设计装配 6

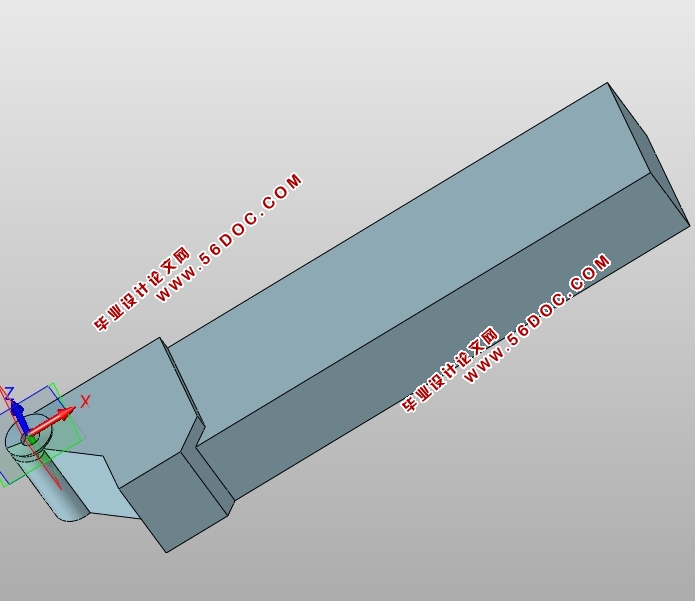

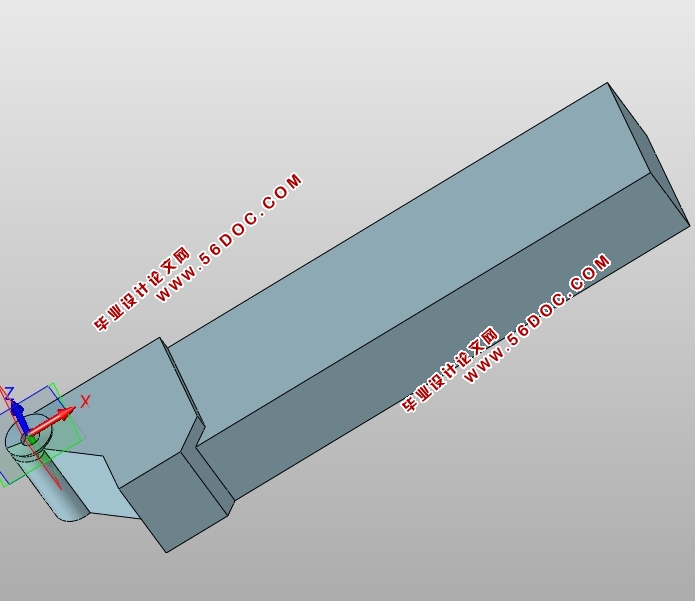

2.2 刀柄零件图的创建 8

2.2.1 刀柄零件图 8

2.2.3 进气门零件创建的操作步骤 I

四、 车刀刀柄的制造加工 III

4.1 刀柄零件的加工工艺分析 III

2.2 确定毛坯 IV

2.3 选择定位基准 IV

2.3.1 粗基准的选择 IV

2.3.2 精基准选择的原则 V

2.4 工艺路线的确定 V

2.4.1 选择各表面及孔的加工方法 V

2.4.2 平面的加工 VI

2.4.3 孔的加工方案 VI

2.5 工艺路线的拟订 VI

2.5.1 加工阶段的划分 VI

2.5.2 加工工艺路线方案 VII

2.5.3 工序的合理组合 VIII

2.6 刀柄零件的加工余量,工序尺寸及毛坯尺寸 VIII

总结 XI

致谢 XI

参考文献 XII

|