开式纹杆滚筒式花生脱壳装置的设计

来源:wenku7.com 资料编号:WK74146 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK74146

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

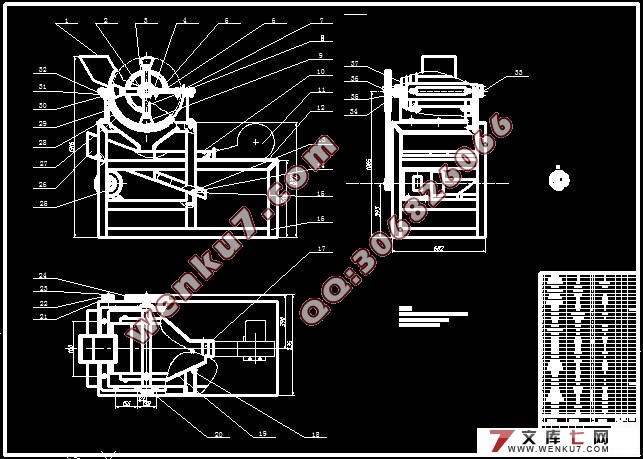

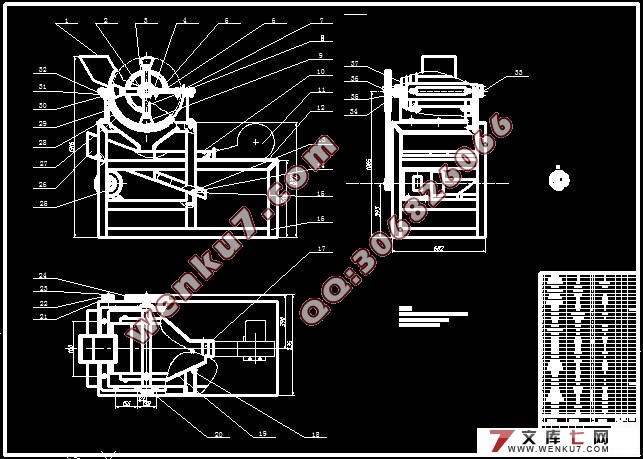

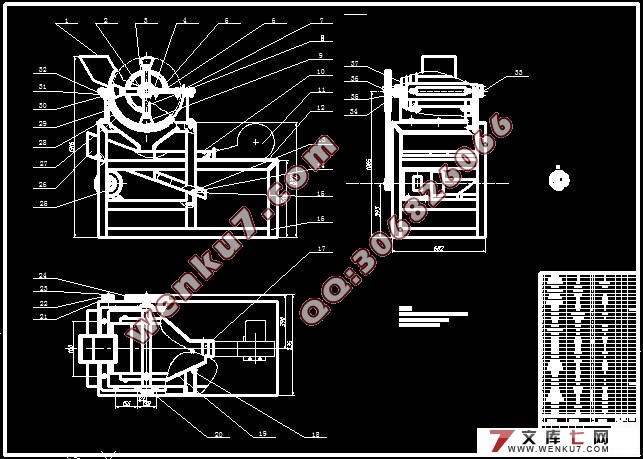

开式纹杆滚筒式花生脱壳装置的设计(论文说明书9200字,cad图纸9张)

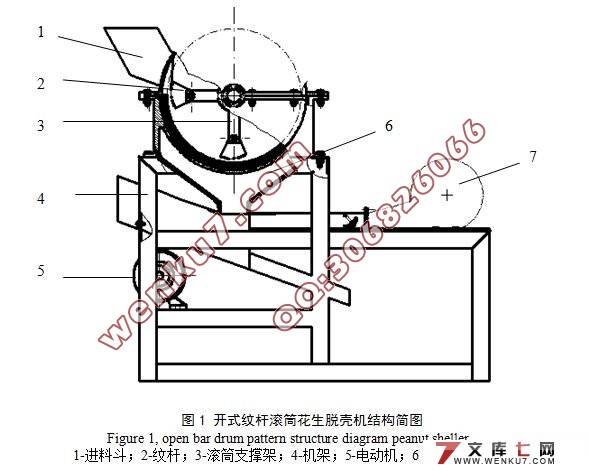

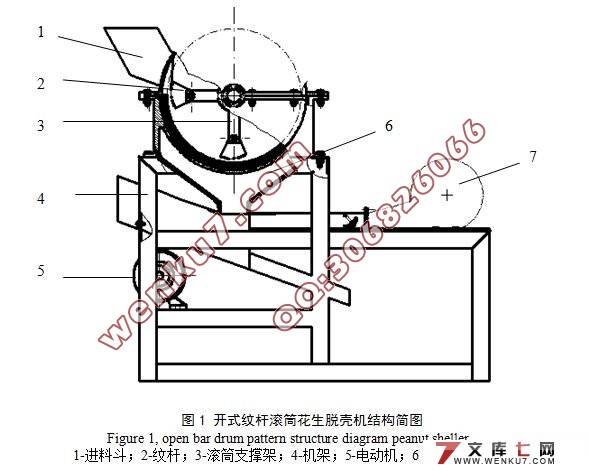

摘 要:花生脱壳机是将花生荚果去掉外壳得到花生仁的场上作业机械。由于花生本身的生理特点决定了花生脱壳不能与花生田间收获一起进行联合作业,而只能在花生果的含水率降低到一定程度后才能进行脱壳。花生脱壳机在减轻人们的劳动强度、提高生产率方面起到了积极作用,促进了花生工业的发展。随着花生种植业的不断发展,花生手工脱壳已经无法满足高效生产要求,实行脱壳机械花迫在眉睫。但是,目前国内外花生脱壳机对花生破碎率和损伤率的指标要求都比较高,超出种用籽和商品化的标准,限制了使用范围。因此,降低花生脱壳机的破碎率和损伤率仍是研制花生脱壳机的关键问题。针对花生果的物理特性本论文设计了一种开式纹杆滚筒式花生脱壳装置,该脱壳装置功能单一,结构简单,价格便宜,满足小型规模的生产需求,为花生联合生产设备的研究设计提供理论依据。

关键词:花生;纹杆滚筒;脱壳装置

Design of The Peanut Shelling Device

Abstract: Peanuts shell out is to remove the pods of peanuts fruit from the mechanical groundnut kernel work for peanuts. their physical characteristics determine the peanuts shell out and peanuts to join in the fields harvesting his homework, but only in groundnut in shell moisture content down to a certain extent before be able to take off your nut peanuts shell ease off in the labour intensity and raise productivity has played an active role in promoting the industrial development along with peanuts. As peanuts crop farmingto develop, peanuts shell manual has been unable to meet your requirements of production and efficient implementation of the machinery cost of his face. but, at present and peanuts shell out for the broken machine peanuts and injury rate of demand is high, kinds of seeds and commercial use of limited scope.Therefore, lowering your peanuts shell of a broken and damaged rate is still working for peanuts shell out the key issues. groundnut in shell to the physical properties of the paper designed a kind of open lines with peanuts shell get dressed, take off the shell devices function a single, simple structure, cheap, for small the scale of production needs and joint production of peanuts for the study is designed to offer a theoretical basis.

Keyword : peanut;bar drum pattern;shelling device

本文是围绕农用机械产品——花生脱壳机的设计,实现了花生剥壳的机械化,应用本机器后,可使广大农民群众大大节省劳动量,提高生产效率和生产质量。该机的关键部分是纹杆结构与编织网凹板结构,因为花生剥壳的整个过程都是由这两部分完成的,剥出来的花生能不能符合要求,完全是看纹杆与编织网凹板的性能能不能达到要求。本文也介绍了目前各种花生剥壳原理及装备,并对花生剥壳机械的发展现状以及发展前景作出了简明的概括和分析。

目 录

摘要1

关键词1

1 引言2

1.1课题提出的背景2

1.2目前花生脱壳机采用的脱壳原理3

1.3花生脱壳机械存在的问题4

1.4花生脱壳机研究重点4

1.5花生脱壳机应用前景展望5

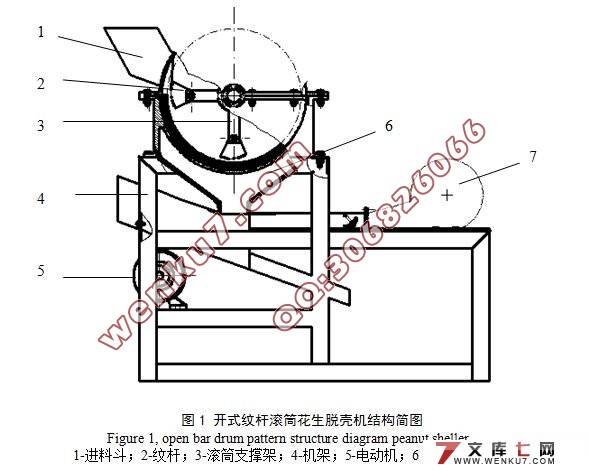

2 纹杆式花生脱壳机的工作原理及结构6

2.1纹杆式花生脱壳机的工作原理6

2.2纹杆式花生脱壳机的结构6

3 纹杆式花生脱壳机主要部件的结构设计7

3.1传动装置的设计7

3.1.1电机的选择7

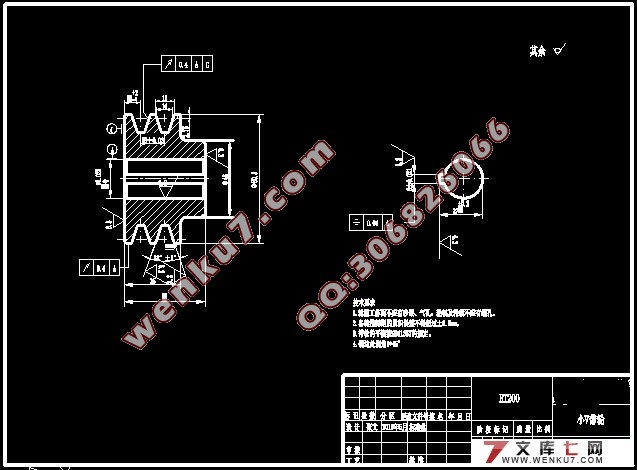

3.1.2V带的设计8

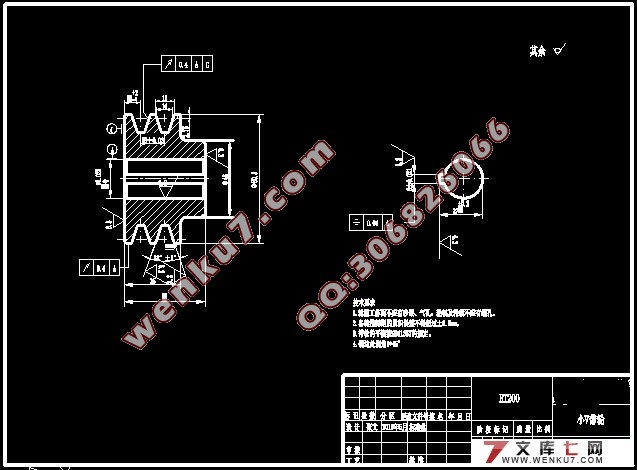

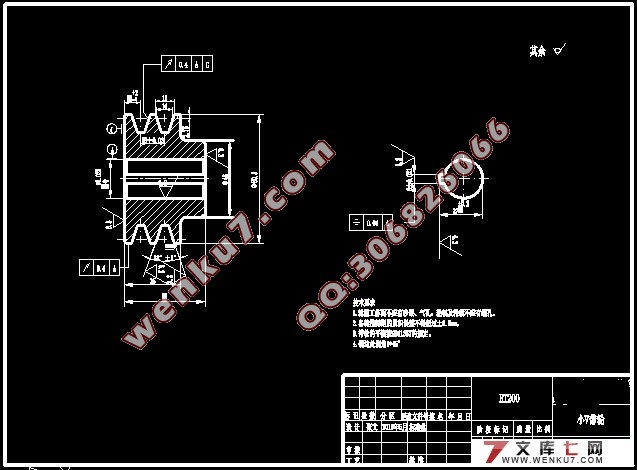

3.1.3V带轮的设计9

3.2脱壳装置的设计10

3.2.1滚筒轴的结构设计及校核11

3.2.2纹杆的设计15

3.2.3支撑架的设计15

3.2.4编织网凹板的设计15

3.3除杂装置的设计16

3.2机架17

3.5 附件17

4 结论18

参考文献19

致谢20

|