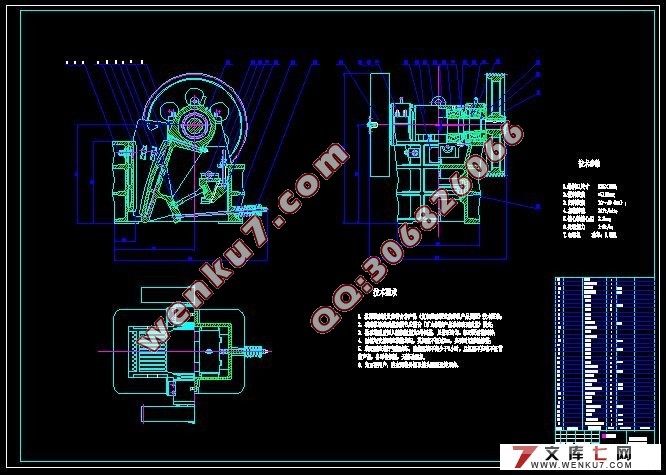

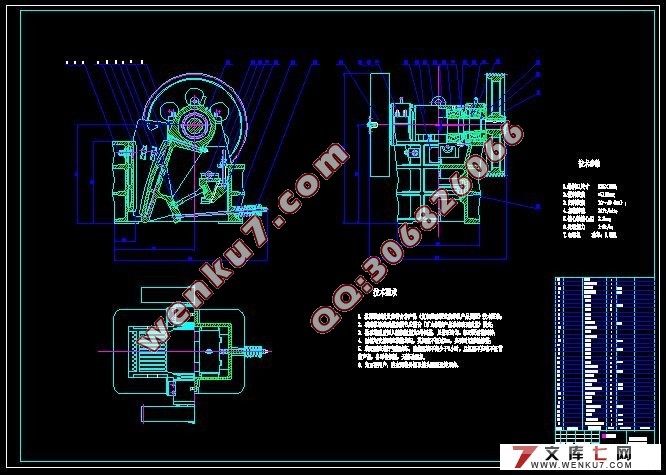

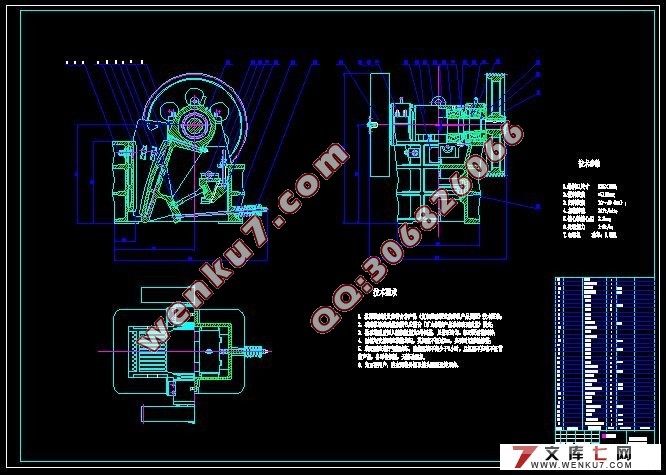

复摆腭式破碎机设计(开题报告,外文翻译,毕业论文说明书15000字,CAD图纸7张)

摘要:腭式破碎机在工矿企业被广泛的应用,这是因为该机构结构简单、机型齐全并已大型化。腭式破碎机经过100多年的实践和不断改进,其机构已日臻完善。虽然腭式破碎机算的上比较老的机型了,但是随着社会的发展需求破碎的要求不断提高,对产品和产品的质量也大大的提高了,破碎机的机型已经发展到很多种了。

本文主要是对复摆腭式破碎机设计研究。复摆腭式破碎机是因为其动腭在其它机件的带动下作复杂的一般平面运动而得名,其动腭上的轨迹一般为封闭曲线。复摆破碎机由于偏心轴负荷大一般制成中型和小型的,其破碎比可达10。随着工业技术的发展和要求,复摆腭式破碎机已经向大型化发展。复摆腭式破碎机在工作时偏心轴作逆时针旋转,对所装入的物料有向下退并夹持作用。该机型垂直摆幅下大上小,有利于出料口处动腭将成品推出。由于整块动腭作复杂运动因此对物料块不但起挤压、劈裂、弯折作用,还能起碾搓作用,故可破碎稍微粘湿的物料。采用正支撑复摆腭式破碎机,动腭下部的特性值m很大,使得动腭和定腭的衬板磨损很快,但却具有较高的生产能力。由实际生产说明,正支撑式腭式破碎机的结构形式具有动腭轨迹分布合理、生产能力高、结构更简单等优点,使其得到广泛应用。

关键词:破碎比 动腭 正支撑 特性值

Compound pendulum palate crusher design

Abstract: Palate crusher in the industrial and mining enterprises were widely used, this is because the body structure is simple, and complete and large-scale models of. Palate crusher after 100 years of practice and continue to improve, their bodies have been improving. Although the palate crusher count on the relatively old models, but with the social development needs of the requirements broken constantly improve the products and the quality of the products have greatly improved, the crusher models have been developed to a variety .

This paper is facing compound pendulum palate crusher design study. Compound pendulum palate crusher because of its dynamic palate in other parts of the lead plane for the general sports complex named after. Moved palate its trajectory is generally closed curve. Crushing machine-placed eccentric axle load due to the generally made of medium-sized and small, broken up over 10. With the development of industrial technology and demands placed palate-breakers have been large-scale development. Compound pendulum palate crusher at work for the eccentric shaft counterclockwise rotation, the load of materials and a retreat clamping downward effect. The models under a vertical swing on small and is conducive to moving the material I will be refined palate launched. As block palate for complex dynamic movement of materials therefore not only blocks from the extrusion, Split, bending role, but also from the roller rubbing role, it can be slightly broken stick wet materials. Support is facing a complex palate crusher, moving the lower part of the palate of great value m, making dynamic palate and the palate of liner wear very quickly, but it has a high production capacity. From the actual production that are supporting-palate structure of the Breakers palatine form a dynamic trajectory of a reasonable, high-capacity, the advantages of a simpler structure, it is widely used.

Key Words: broken up ratio moved palate be prop up eigenvalue

毕业设计(论文)所用的主要技术与方法:

1、研究的基本内容,拟解决的主要问题:

(1)鄂式破碎机的主要零部件的设计;

(2)主要参数的确定;

(3)主要零部件强度、刚度计算;

(4)鄂式破碎机的使用和维护;

目 录

1 概 述

2 物料破碎及其意义

2.1 物料破碎及其意义 ………………………………………2

2.1.1 破碎的目的…………………………………………………2

2.1.2 破碎工艺 …………………………………………………3

2.2 破碎物料的性能及破碎比 ………………………………4

2.2.1 粒度及其表示方法 ………………………………………4

2.2.2 破碎产品的粒级特性 …………………………………5

2.2.3 矿石的破碎及力学性能 …………………………………8

3 工作原理和构造

3.1 工作原理 ………………………………………………9

3.2 腭式破碎机的结构 ……………………………………10

4 主要零部件的结构分析

4.1 动腭 ……………………………………………………12

4.2 齿板的结构 ………………………………………………12

4.3 肘板(推力板) ………………………………………13

4.4 调整装置 ………………………………………………14

4.5 保险装置 ………………………………………………15

4.6 机架结构 ………………………………………………15

4.7 传动件 …………………………………………………17

4.9 飞轮 ……………………………………………………17

4.10 润滑装置 …………………………………………………17

5 复摆腭式破碎机的主参数设计计算

5.1.1 主轴转速 …………………………………………………18

5.1.2生产能力 …………………………………………………19

5.1.3 偏心距e的计算 …………………………………………20

5.2 破碎力 ……………………………………………………20

5.2.1 破碎力的计算………………………………………………20

5.2.2 最大破碎力 ………………………………………………23

5.3 功率的计算 ………………………………………………23

5.4 主要零件受力计算 ……………………………………………24

6 各主要零件的设计

6.1带轮的设计 …………………………………………………26

6.2 曲轴(偏心轴)的设计计算 ……………………………………28

6.3 滚动轴承的设计计算 ………………………………………33

6.3.1 轴承的选择 ………………………………………………33

6.3.2 轴承的验算 ………………………………………………33

7 对一个主要零件进行有限元分析

7.1 Solidworks软件介绍…………………………………………34

7.2 Solidworks的功能和特点……………………………………34

7.3 对一个零件的有限元分析 ……………………………………34

7.3.1 建模……………………………………………………………34

7.3.2 分析类型与选项………………………………………………37

7.3.3 材料定义属性…………………………………………………38

7.3.4 载荷与约束……………………………………………………39

7.3.5 网格的划分……………………………………………………41

7.3.6 运行分析………………………………………………………41

8 腭式破碎机的安装与运转

7.1破碎机的安装 ……………………………………………………43

7.2机架的安装 ………………………………………………………44

总 结 ……………………………………………………………45

参考文献 ……………………………………………………………46

致 谢 ……………………………………………………………47

附 录 ……………………………………………………………48

|