钻削精密深孔扭振发生装置的设计(任务书,开题报告,外文翻译,进度计划表,论文说明书18000字,cad图纸3张)

摘 要

孔加工是金属切削加工中最常用的加工工艺。据统计,孔加工的金属切除量约占切削加工总金属切除量的1/3,钻头的产量约占刀具总产量的60%。目前用于加工微小孔的工艺方法虽然较多,但应用最广泛、生产实用性最强的仍是采用麻花钻钻削加工。随着对孔加工质量和效率的要求不断提高,传统的钻削工艺已显示出极大的局限性,而近年来迅速发展的振动钻削工艺则日益显示出其独特的优势及广阔的应用前景。本文主要介绍了振动钻削,振动钻削是振动切削的一个分支,它与普通钻削的区别在于钻孔过程中通过振动装置使钻头与工件之间产生可控的相对运动。振动方式主要有三种,即轴向振动、扭转振动和复合振动。

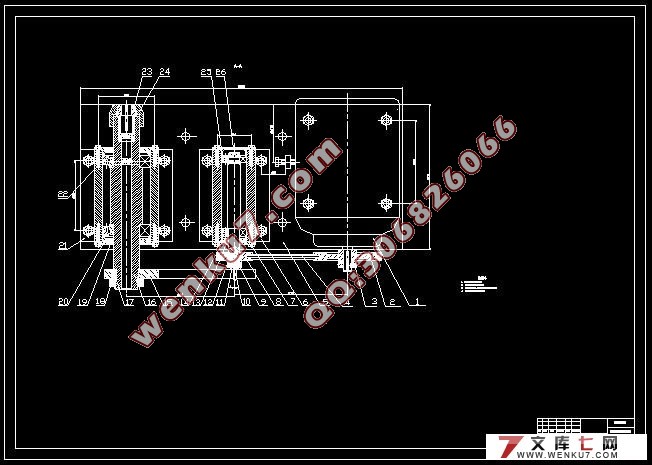

本文讲述了如何匹配加工参数来实现精密深孔的加工,并设计了扭振发生装置,综合分析了振动钻削的工艺效果。低频振动切削技术目前已应用于孔加工(包括钻、扩、铰、锁、攻丝等)和外圆车削加工等领域,解决实际生产中诸如切屑处理、改善切削加工性、提高加工质量、延长刀具寿命等问题,理论上也获得了许多发展。

关键词 : 麻花钻 ;振动钻削 ;振动装置 ;低频振动

Abstract

Hole processing is the most commonly used metal cutting machining processing technology. According to statistics, hole machining of metal removal accounted for about one-third of the total machining metal removal of the, drill production accounted for about 60% of the total tool production. Process methods now used for machining small holes while more, but the strongest is still the most widely used, the production practicality is uses the twist drill drilling processing. As the hole of the requirement of increasing the quality and efficiency, the traditional drilling technology has shown great limitations, in recent years the rapid development of the vibration drilling technology is increasingly shows its unique advantages and broad application prospects.Vibration drilling is mainly introduced in this paper, the vibration drilling is a branch of vibration cutting, the difference between it and common drilling through vibration device in the process of drilling bit and generate controllable relative movement between parts. Vibration mode mainly has three kinds, namely axial vibration, torsional vibration, and vibration compound.

This article tells the story of how the matching processing parameters to achieve precision deep hole machining, and torsional vibration generator is designed, the comprehensive analysis of the vibration drilling technology effect. Low frequency vibration cutting technology has been applied to the machining (including drilling, expanding, hinge, lock, tapping, etc.) and cylindrical turning processing, etc, to solve practical production in cutting machining, such as chip removal, improve processing quality, prolong tool life and other issues, theory also received many development.

Keywords: Twist drill ;Vibration drilling;Vibration device;Low frequency vibration

本设计(论文或其他)应达到的要求:

① 熟悉低频振动深孔钻削的发展历程,特别是近十几年来提出的直径小于0.5mm的微小孔加工;

② 熟悉低频振动深孔钻削的工艺效果;

③ 熟练掌握低频振动深孔钻削的三种振动方式:轴向振动(振动方向与钻头轴线方向相同)、扭转振动(振动方向与钻头旋转方向相同)和复合振动(轴向振动与扭转振动迭加);

④ 掌握了解针对不同的材料所需要的加工参数;

⑤ 能够熟练使用振动钻削的自动控制系统,实现振动钻削的自动化和智能化。

目 录

摘 要 IV

Abstract V

目 录 VI

1 绪论 1

1.1 振动钻削技术的发展历史 1

1.2 振动钻削的工艺效果 2

1.3 振动钻削的应用前景及前沿课题 4

2 振动钻削的原理 7

2.1 振动钻削的机理 7

2.2 振动钻削系统的稳定性与振幅损失 8

2.2.1 振动钻削时的切削力 9

2.2.2 振动钻削系统的稳定性 10

2.2.3 产生横向摆振与钻杆弯曲振动的原因 12

2.2.4 振幅损失 13

3 深孔加工的高效解决方案 14

3.1 深孔加工 14

4 装置设计 16

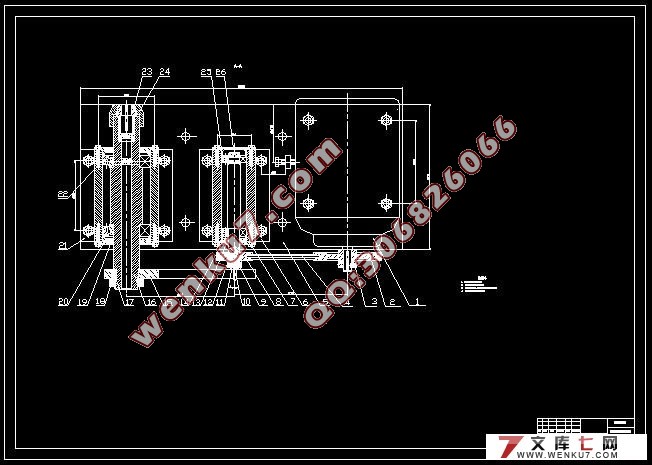

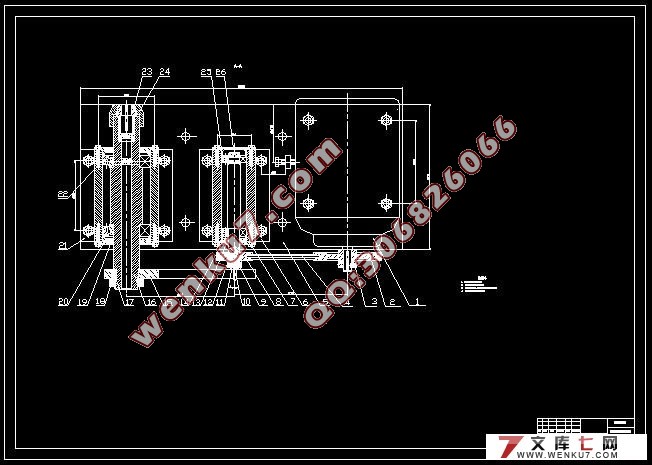

4.1 装置总体方案 16

4.2 电机的选择 18

4.3 带传动设计 20

4.3.1 确定计算功率Pca 20

4.3.2 选择带型 20

4.3.3 确定带轮的基准直径 20

4.3.4 确定中心距a和带的基准长度Ld 21

4.3.5 验算主动轮上的包角α1 21

4.3.6 确定带的根数Z 21

4.3.7 确定带的预紧力F0 22

4.3.8 计算带传动作用在轴上的力(简称压轴力)Fp 22

4.3.9 V带轮设计 22

4.3.10 V带传动的张紧装置 23

4.4 偏心轴及其附件设计. 24

4.4.1 轴承的选用 26

4.4.2 轴承底座 27

4.4.3 端盖和透盖 28

4.4.4 偏心销钉 29

4.5 主轴及其附件设计 29

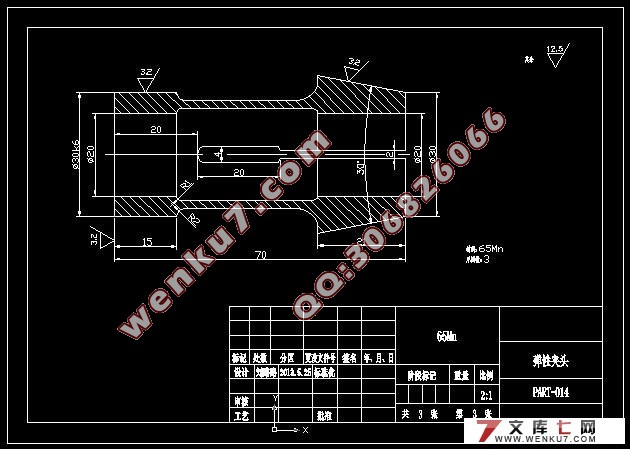

4.5.1 主轴 29

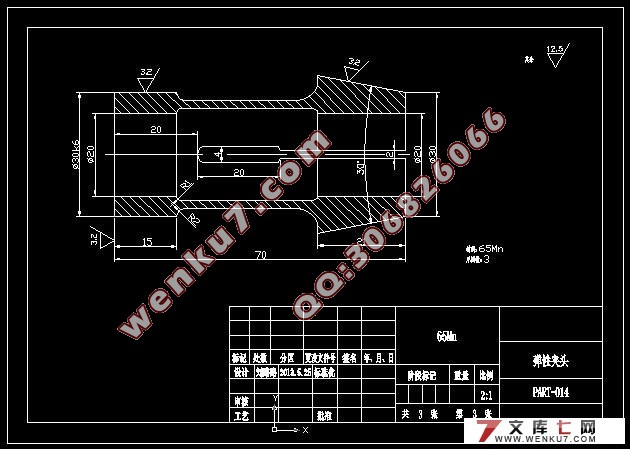

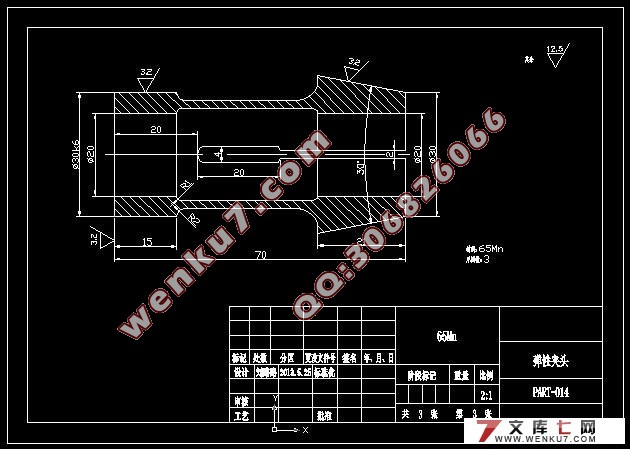

4.5.2 弹性夹头 30

4.5.3 轴承的选用 31

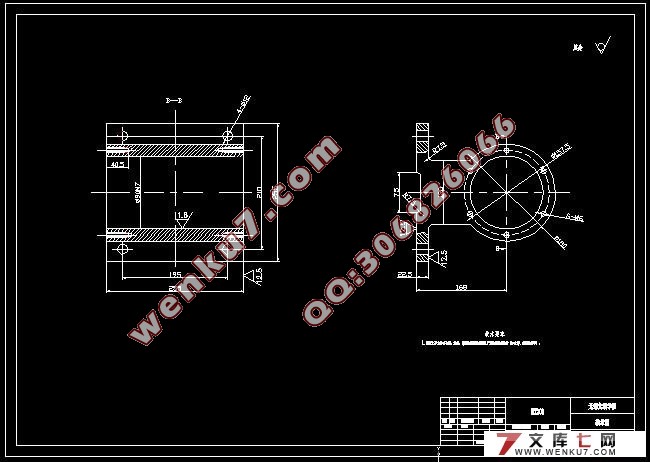

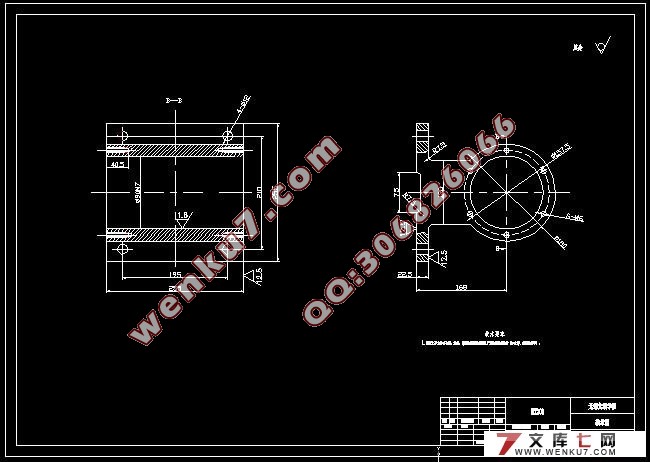

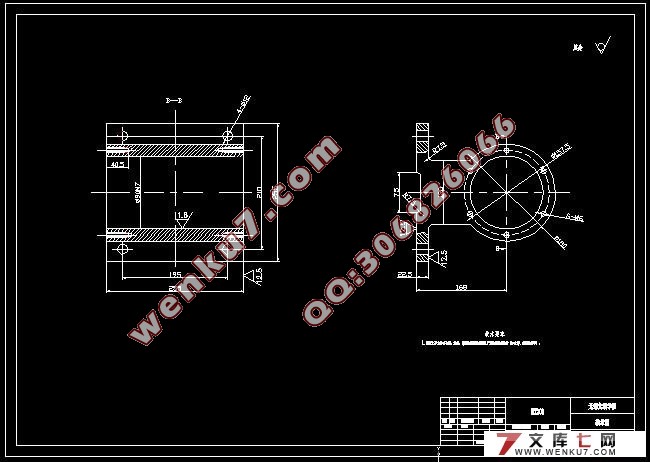

4.5.4 轴承座 32

4.5.5 夹紧螺母 32

4.5.6 轴承盖 33

4.5.7 摆杆 33

4.6 底板设计 33

5 致谢 35

参考文献 36

|