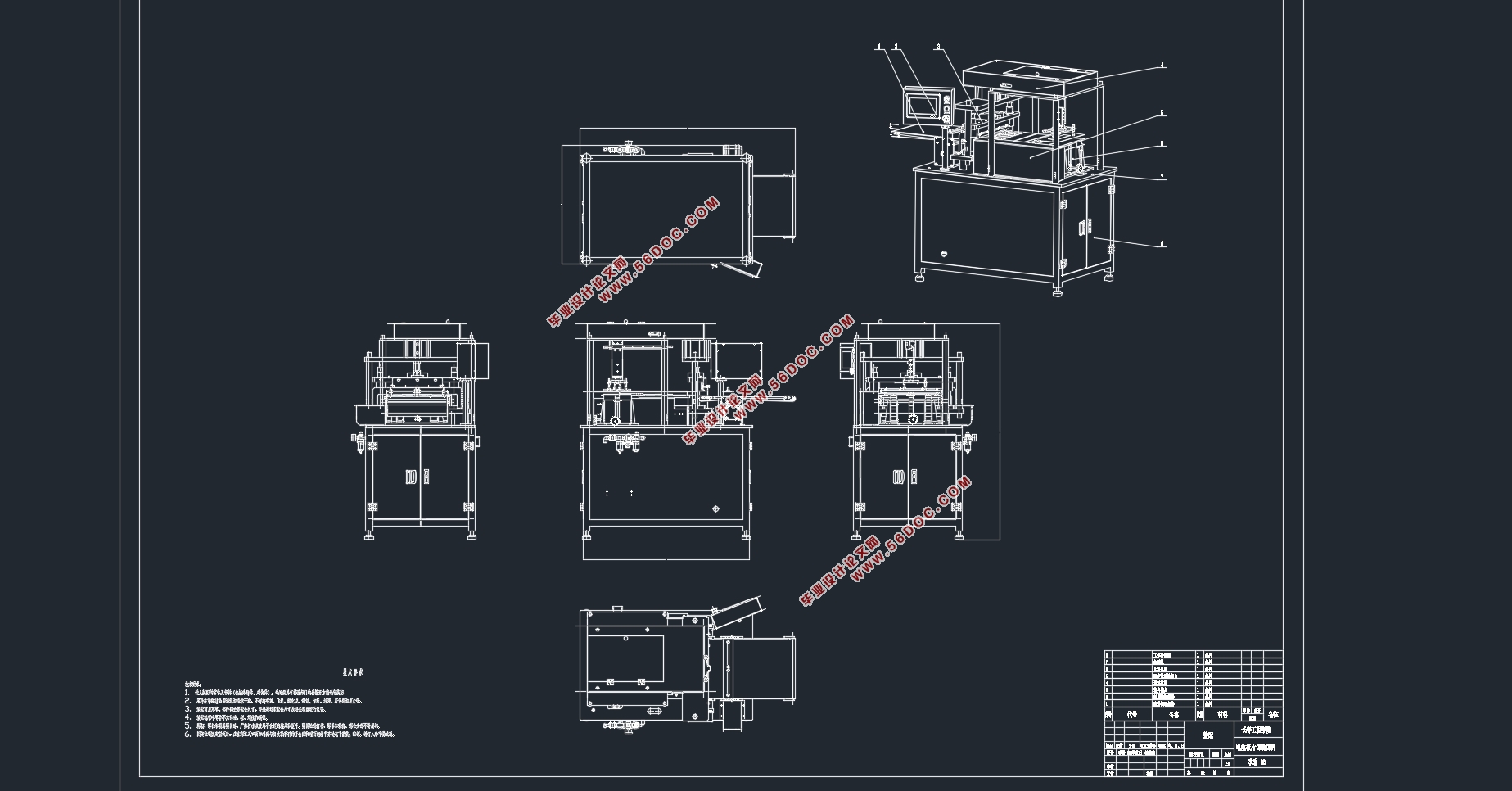

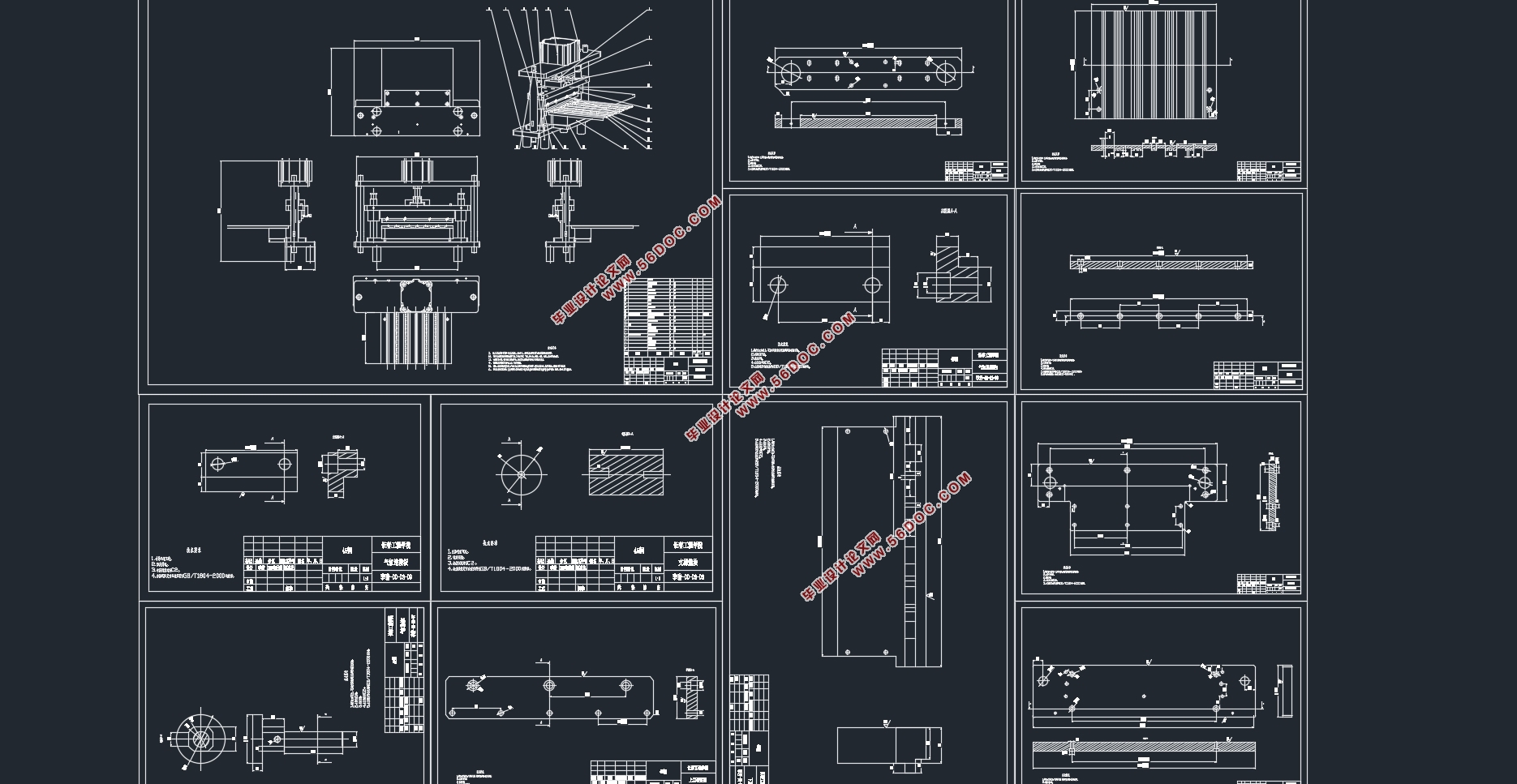

电池极片载切机的设计(含CAD零件图装配图)(选题审核表,任务书,开题报告,外文翻译,论文说明书15000字,CAD图44张)

Design of Battery Pole Chip Cutting Machine

摘 要

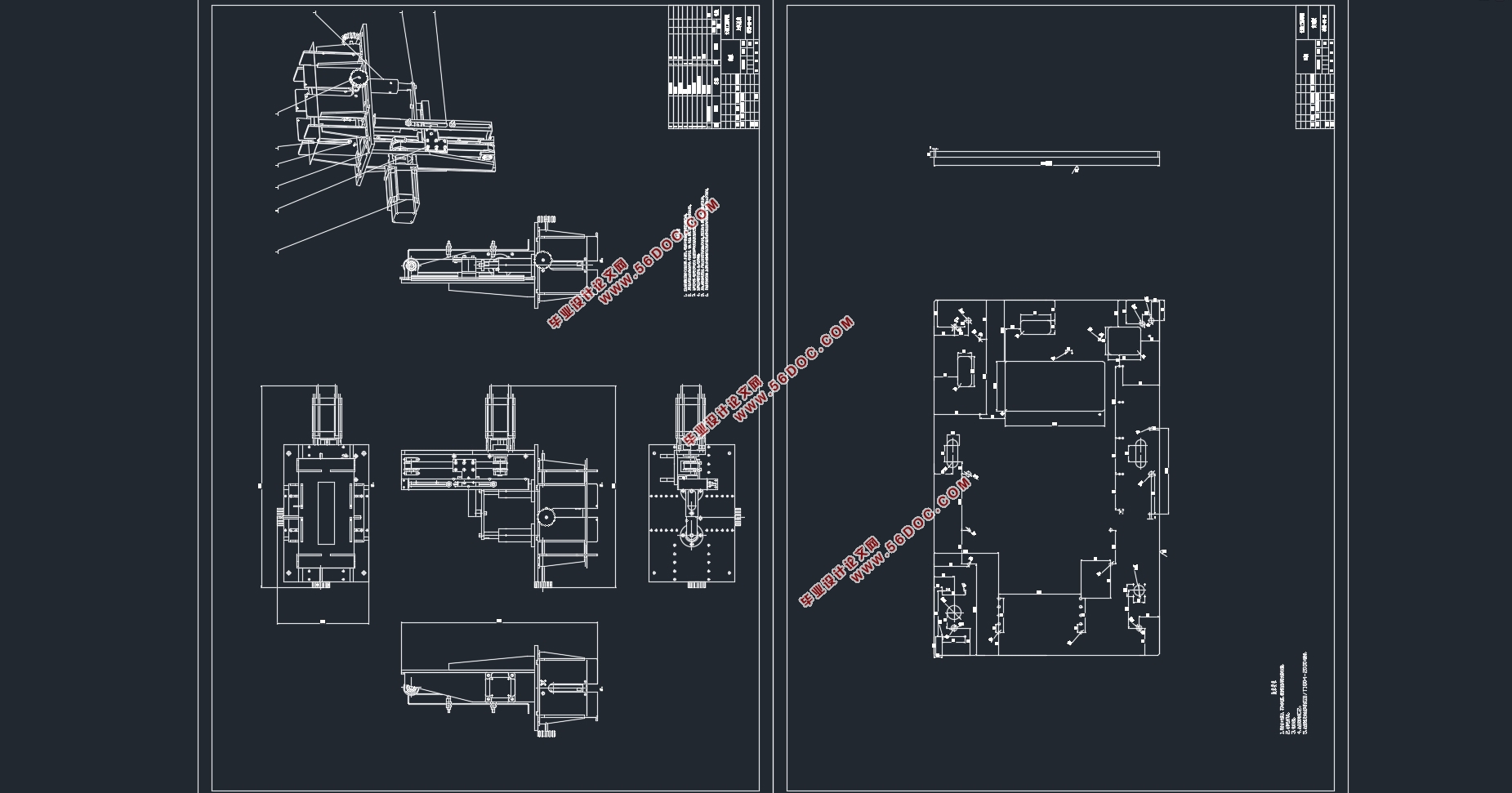

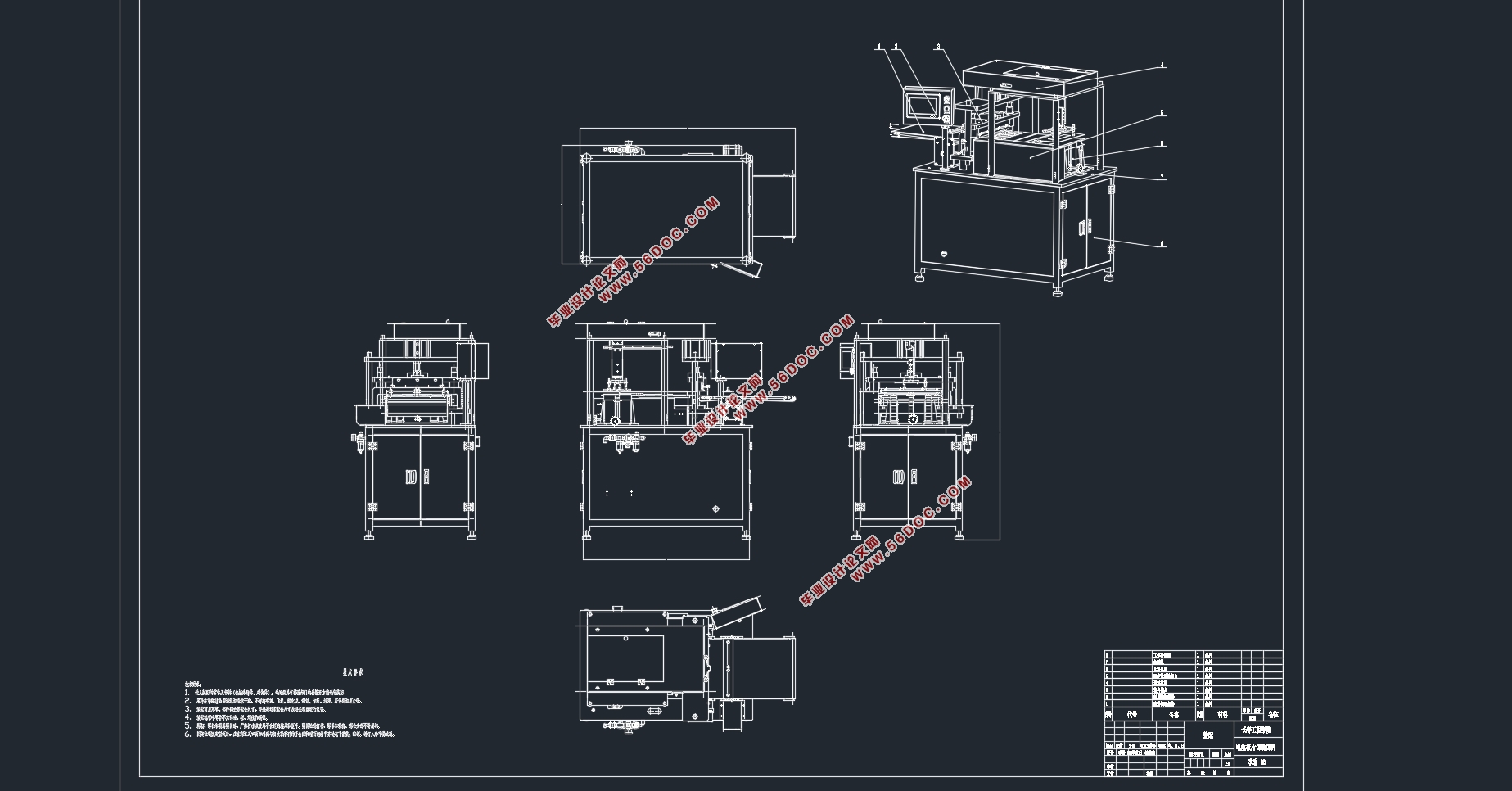

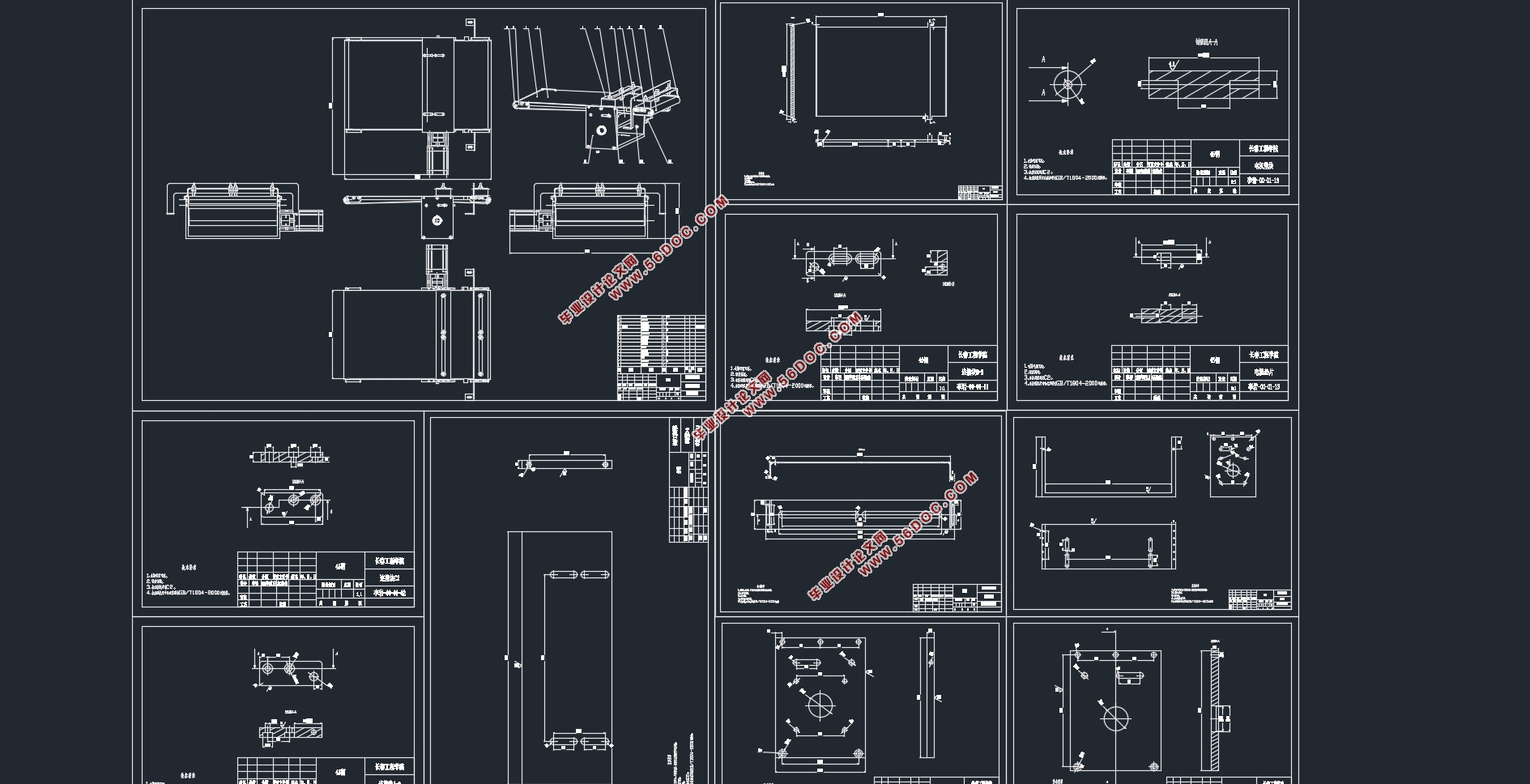

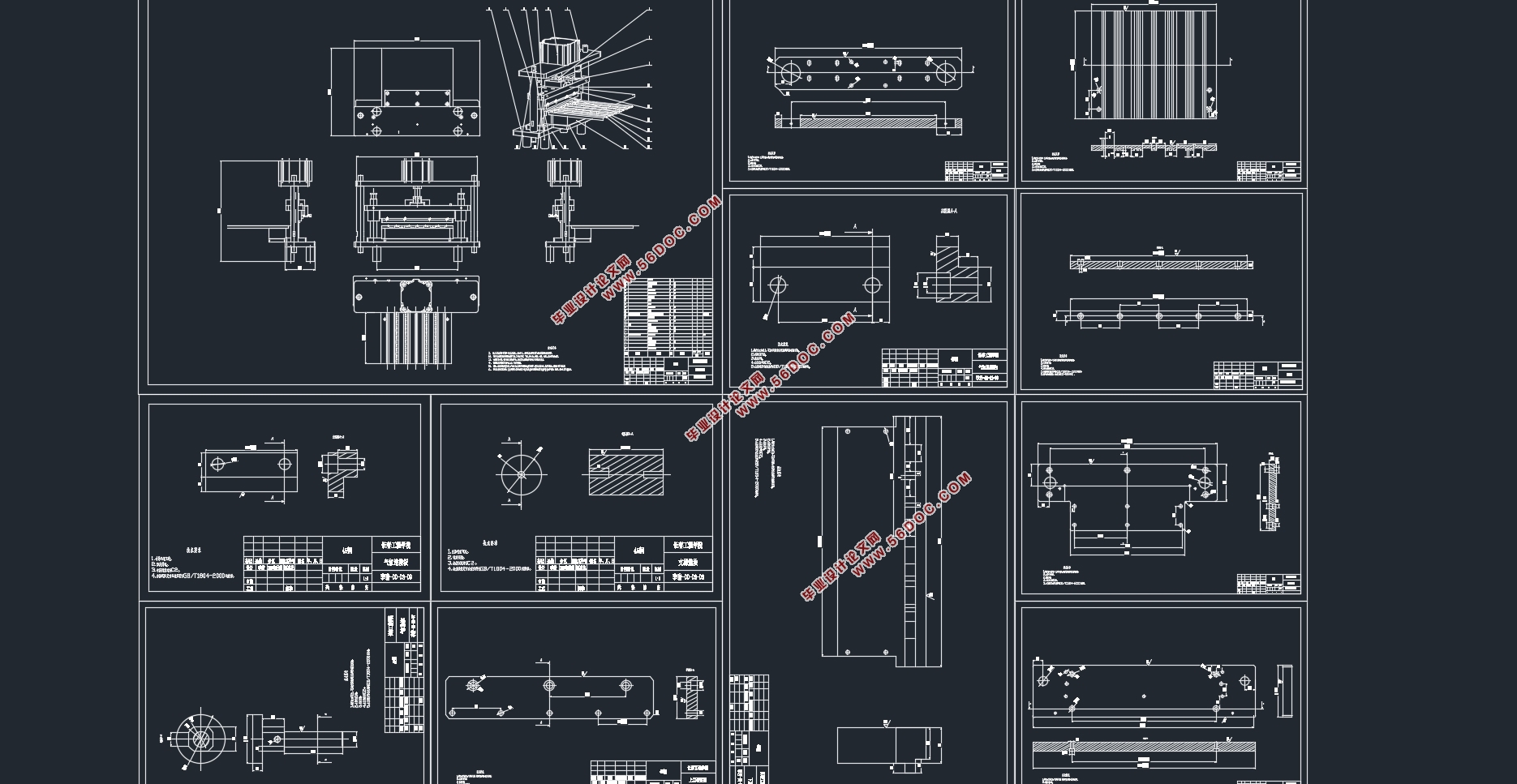

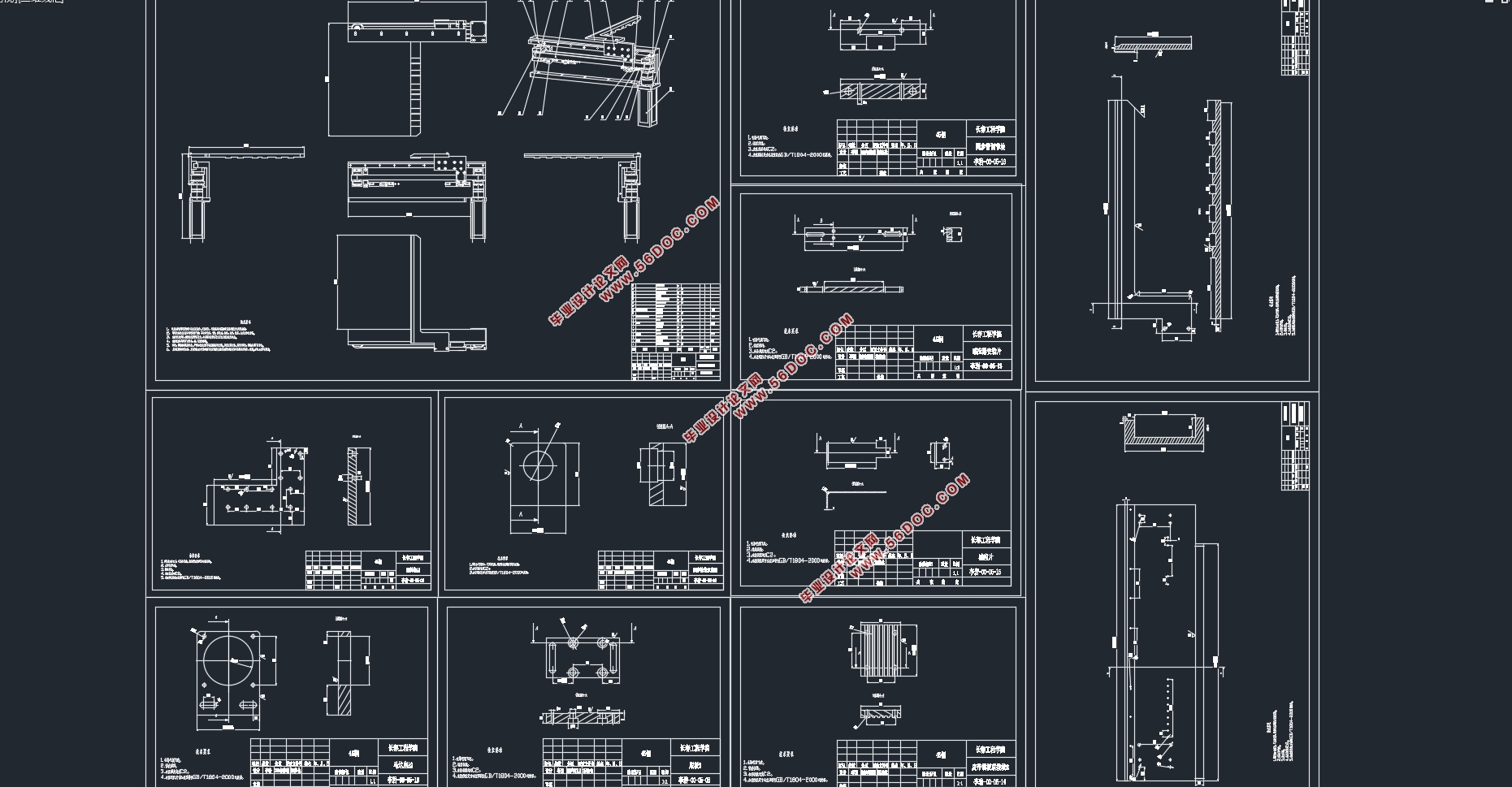

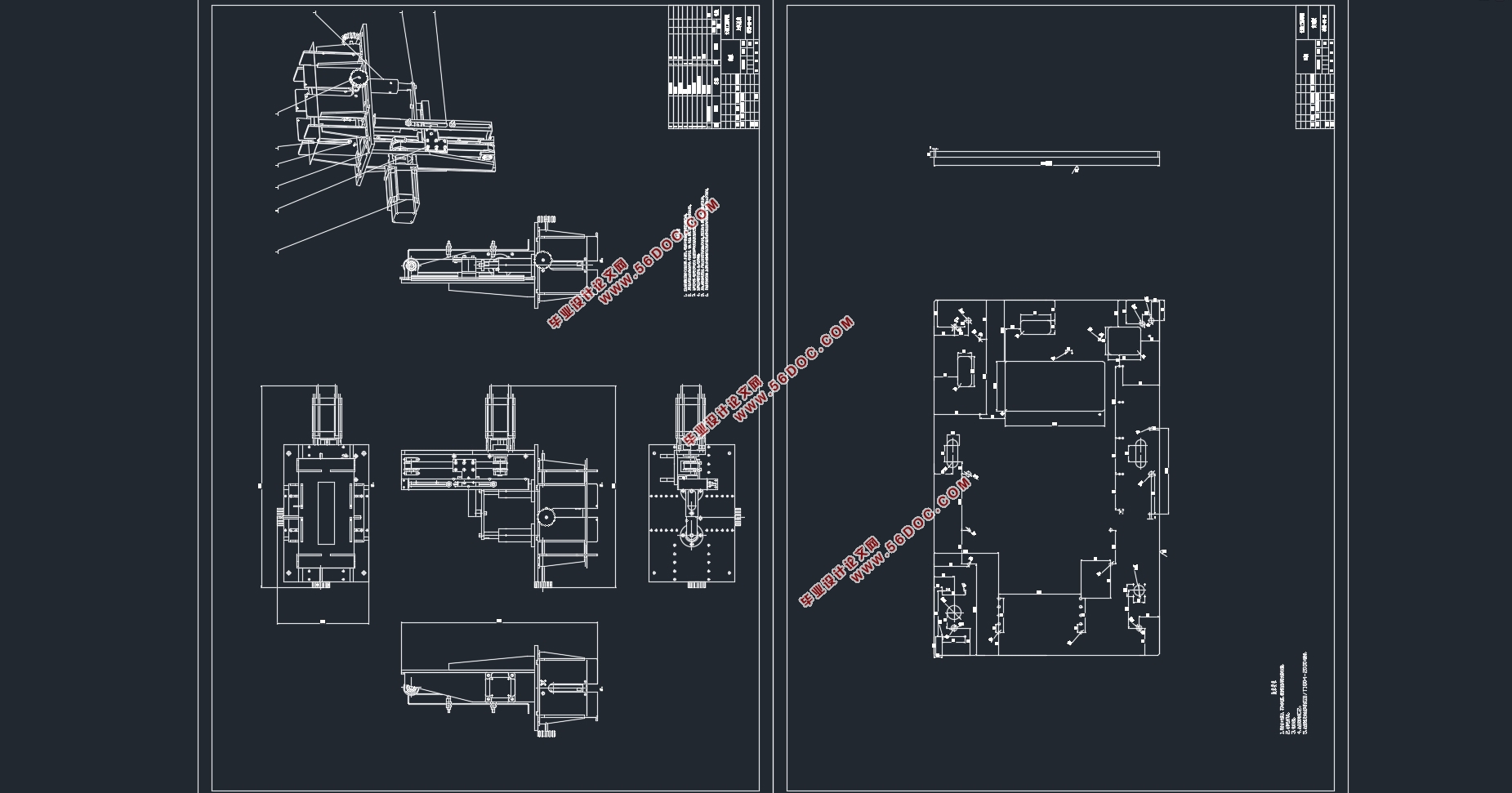

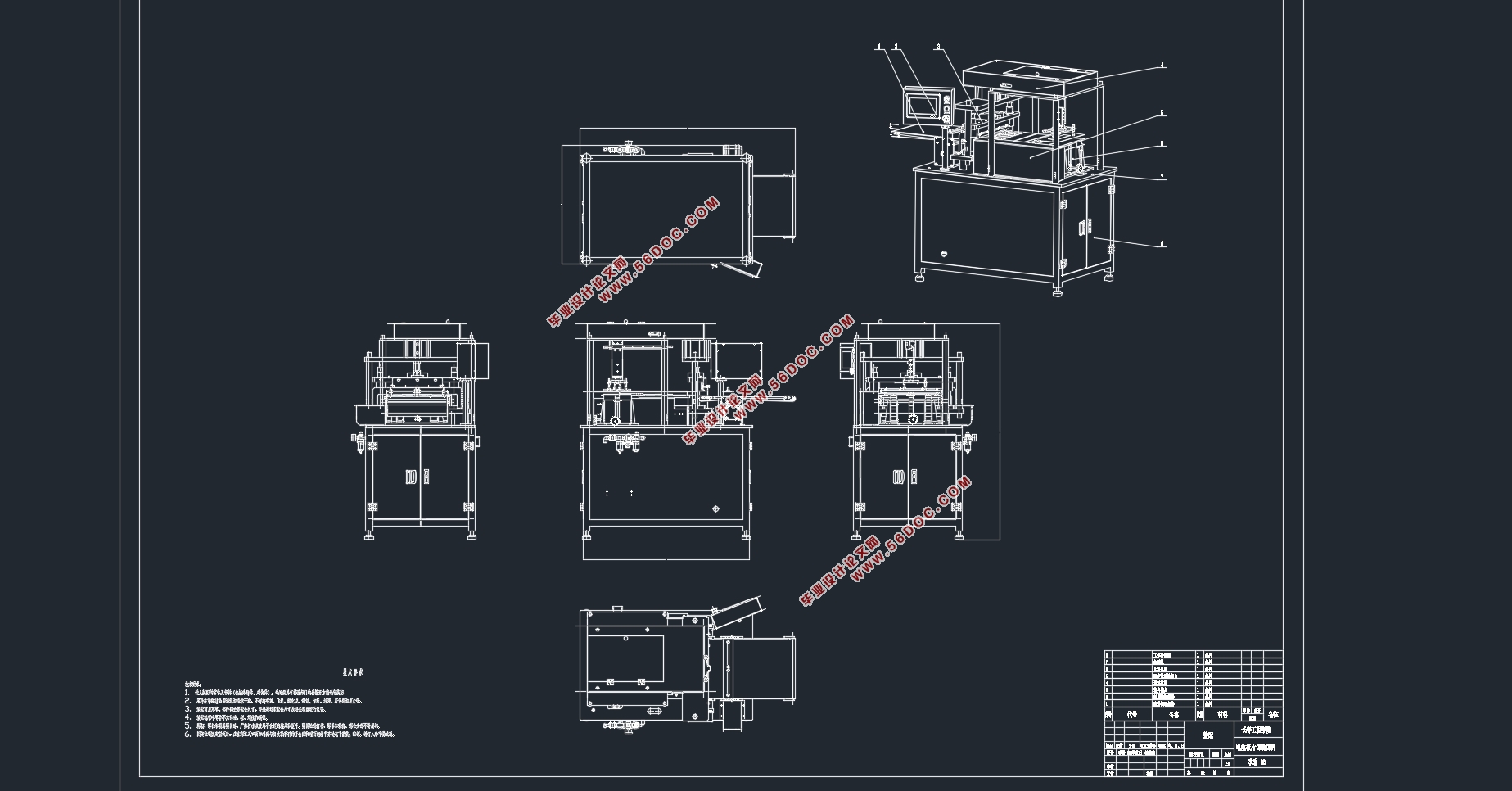

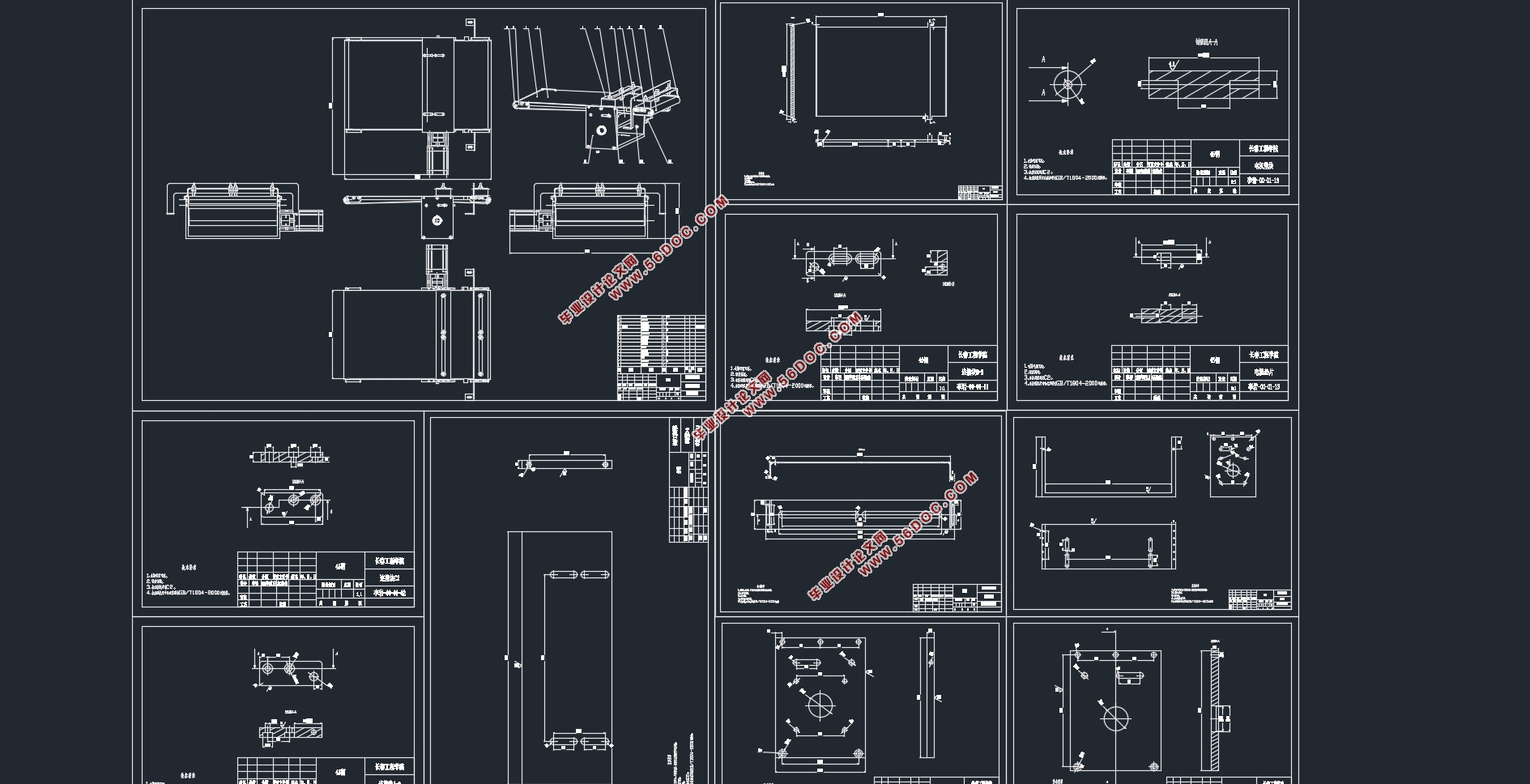

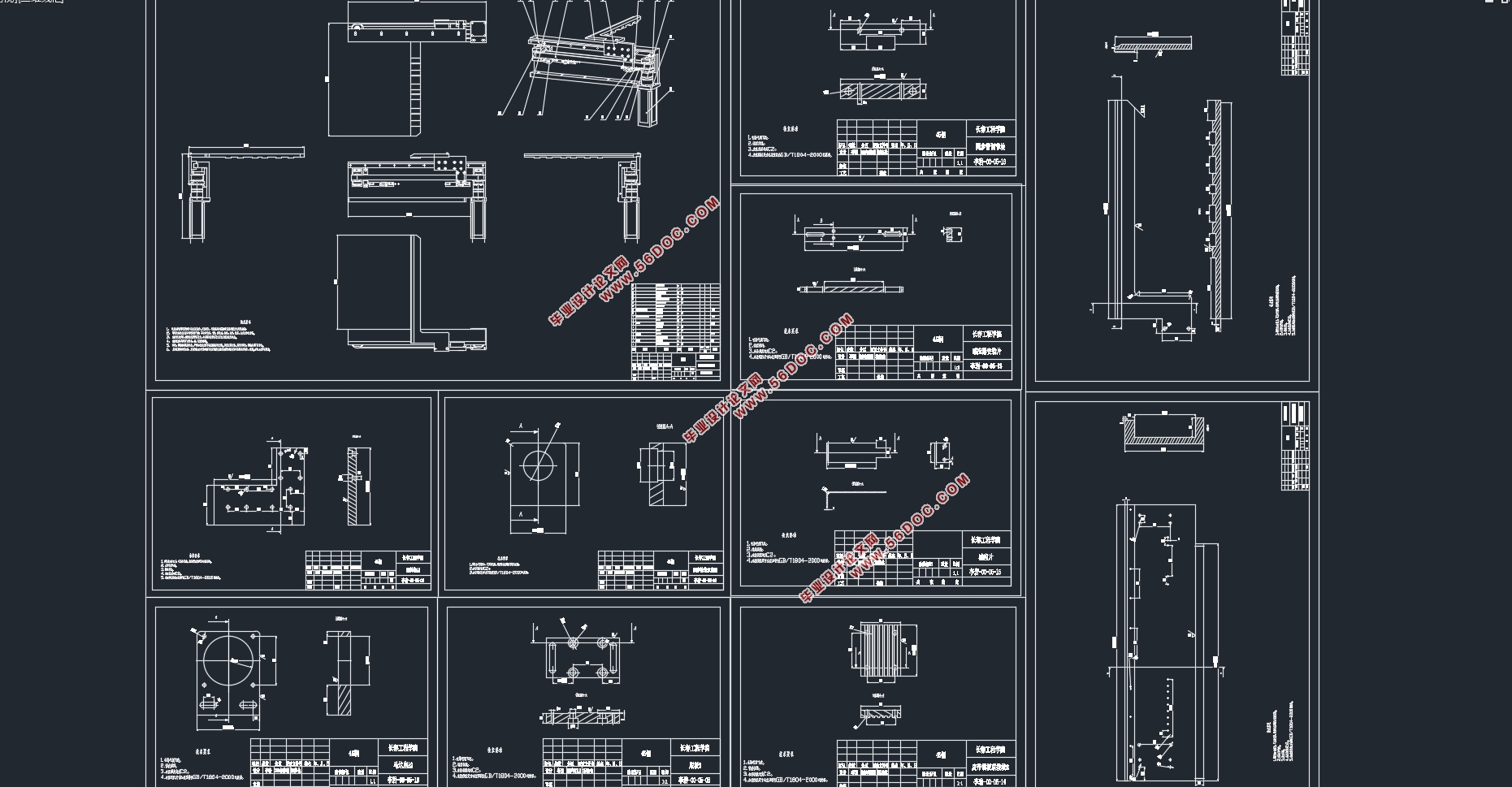

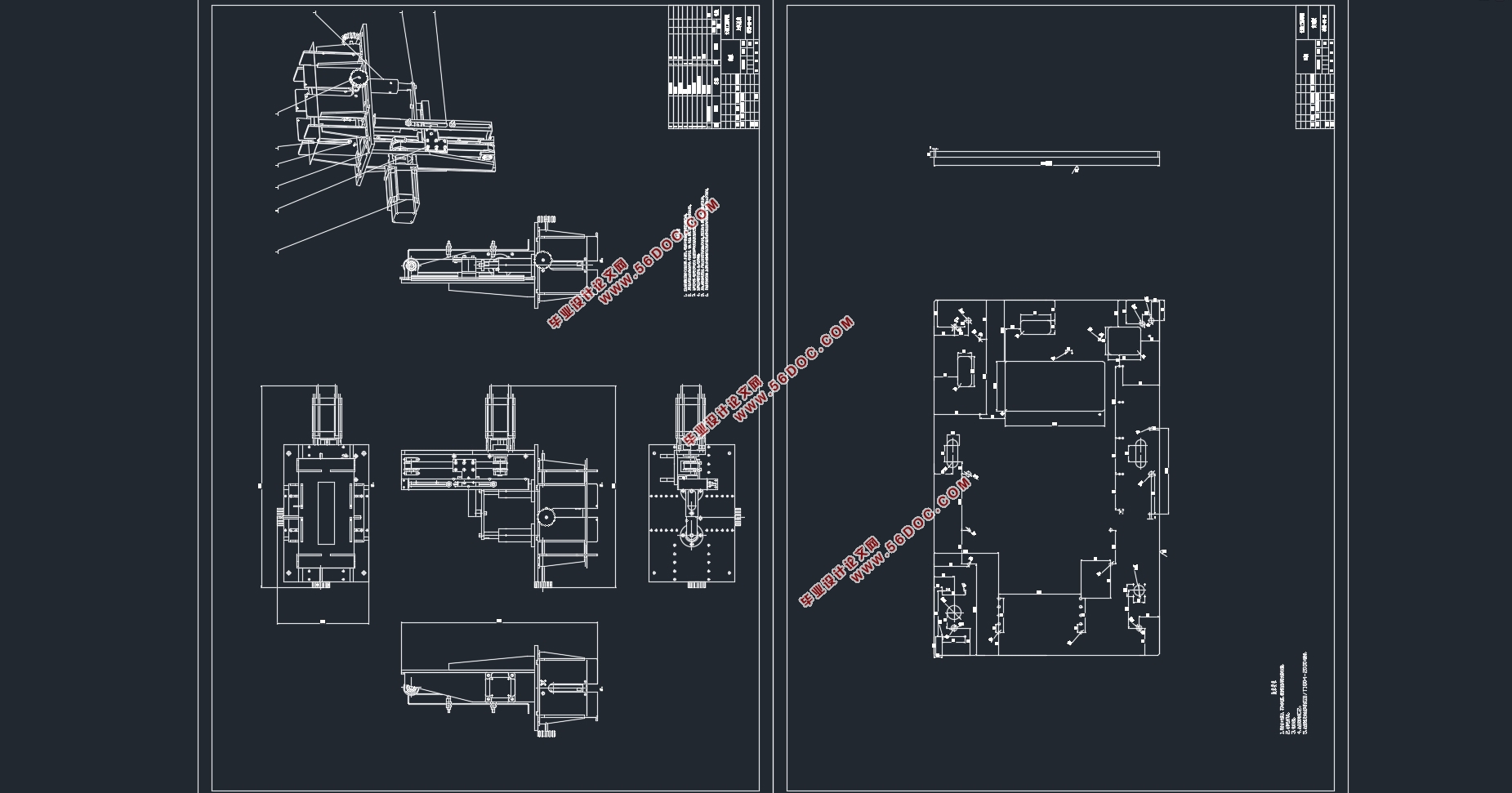

随着新能源汽车产业的发展极大促进了动力锂离子电池行业的发展,极片作为动力锂离子电池的主体,其质量直接影响着电池的性能,传统的人工裁切效率低下且易出现漏切情况,极大的制约着锂离子电池的自动化生产制造效率,因此本课题设计了自动化锂离子电池极片裁切机装置,此机械装置的投入使用将大大提高极片的裁切效率、裁切精度和裁切可靠性。本设计在满足极片裁切工艺要求的前提下提出了整个自动化装置的工作原理,本文电池极片载切机划分为四个具体设计模块:上料系统,送料系统,裁切系统和下料系统;提出了电池极片载切机的总体方案,并对裁切机系统中的主要构件,如裁切气缸、极片吸盘、下料系统电动机和传送带装置进行了选型计算和校核;对电池极片载切机进行了结构设计及建模工作,分别完成了对载切机中工作台结构的设计建模,对上料系统中的传动结构的设计建模,对送料系统中的传动结构的设计建模,对裁切系统中的裁切结构的设计建模,还有对下料系统中的传动结构的计算校核工作。在保证机械系统作业功能的基础上确定了电池极片载切机的结构方案。本文设计的电池极片载切机可达到加工实际应用的目的,为锂离子电池的产业化与自动化生产奠定了实践基础。

关 键 词

锂离子电池;极片载切机;自动化;机械设计

Abstract

With the development of new energy vehicle industry, the development of power lithium-ion battery industry has been greatly promoted. As the main body of power lithium-ion battery, the quality of the pole directly affects the performance of the battery. The traditional manual cutting efficiency is low and it is easy to miss cutting, which greatly restricts the automatic production and manufacturing efficiency of lithium-ion battery. Therefore, this project designs an automatic lithium-ion battery The use of the device will greatly improve the efficiency, accuracy and reliability of the cutting. In this design, the working principle of the whole automatic device is put forward on the premise of meeting the cutting process requirements. In this paper, the battery pole cutting machine is divided into four specific design modules: feeding system, feeding system, cutting system and cutting system. The overall scheme of the battery pole cutting machine is put forward, and the main components of the cutting machine system, such as cutting cylinder, pole sucker The motor and conveyor belt of the blanking system are selected, calculated and checked; the structure design and modeling of the battery pole cutting machine are carried out, and the design and modeling of the workbench structure in the cutting machine, the design and modeling of the transmission structure in the feeding system, the design and modeling of the transmission structure in the feeding system and the design and modeling of the cutting structure in the cutting system are completed respectively And the calculation and verification of the transmission structure in the blanking system. On the basis of ensuring the operation function of the mechanical system, the structure scheme of the battery pole cutting machine is determined. The cutting machine designed in this paper can achieve the purpose of practical application and lay a practical foundation for the industrialization and automatic production of lithium-ion batteries.

Keywords:

Lithium ion battery; electrode cutting machine; automation; mechanical design

电池极片载切机需要满足的主要技术参数如下:

1、 电源:单相AC220V/50HZ

2、 气压源:≥0.6MPa

3、 设备尺寸(L×W×H):980×700×1300mm

4、 冲切精度:±0.1mm

5、 冲切速度:3.0片/min

6、 毛刺:〈0.01m

3.电池极片载切机工作原理

电池极片载切机的功能是将锂电池的电池极片裁切整齐。本文所设计的电池极片载切机主要由上料系统,送料系统,裁切系统和下料系统共四个主要系统构成。电池极片载切机中的上料系统主要负责将电池极片毛坯运送到电池极片载切机的加工传递的最初位置,进而可以使送料系统接收到所上料的毛坯部件。电池极片载切机中的送料系统负责将被上料系统送来的极片部件毛坯进一步运送到裁切系统位置,以供电池极片载切机对部件毛坯进行裁切作业。电池极片载切机中的裁切系统负责完成对被送料系统送来的电池极片部件毛坯完成裁切加工,完成部件材料由毛坯转变为成型部件的加工过程。电池极片载切机中的下料系统负责将裁剪完成的工件送离裁剪系统位置,从而完成下料过程。

目录

目录 1

1. 前言 1

1.1 背景 1

1.2 设计的目的和意义 2

1.3 锂电池及其发展 4

1.4 电池极片载切机的国内外发展现状 5

1.5 电池极片载切机的发展趋势 5

2. 电池极片载切机整机设计方案 5

2.1 设计软件 5

2.2 设计要求 6

3. 电池极片载切机工作原理 6

3.1 上料总成工作原理: 7

3.2 送料机构工作原理: 8

3.3 裁切模具工作原理: 9

3.4 下料机构工作原理: 9

3.5 本章小结 10

4. 总体方案设计及主要部件选型计算 10

4.1 电池极片载切机总体方案设计 10

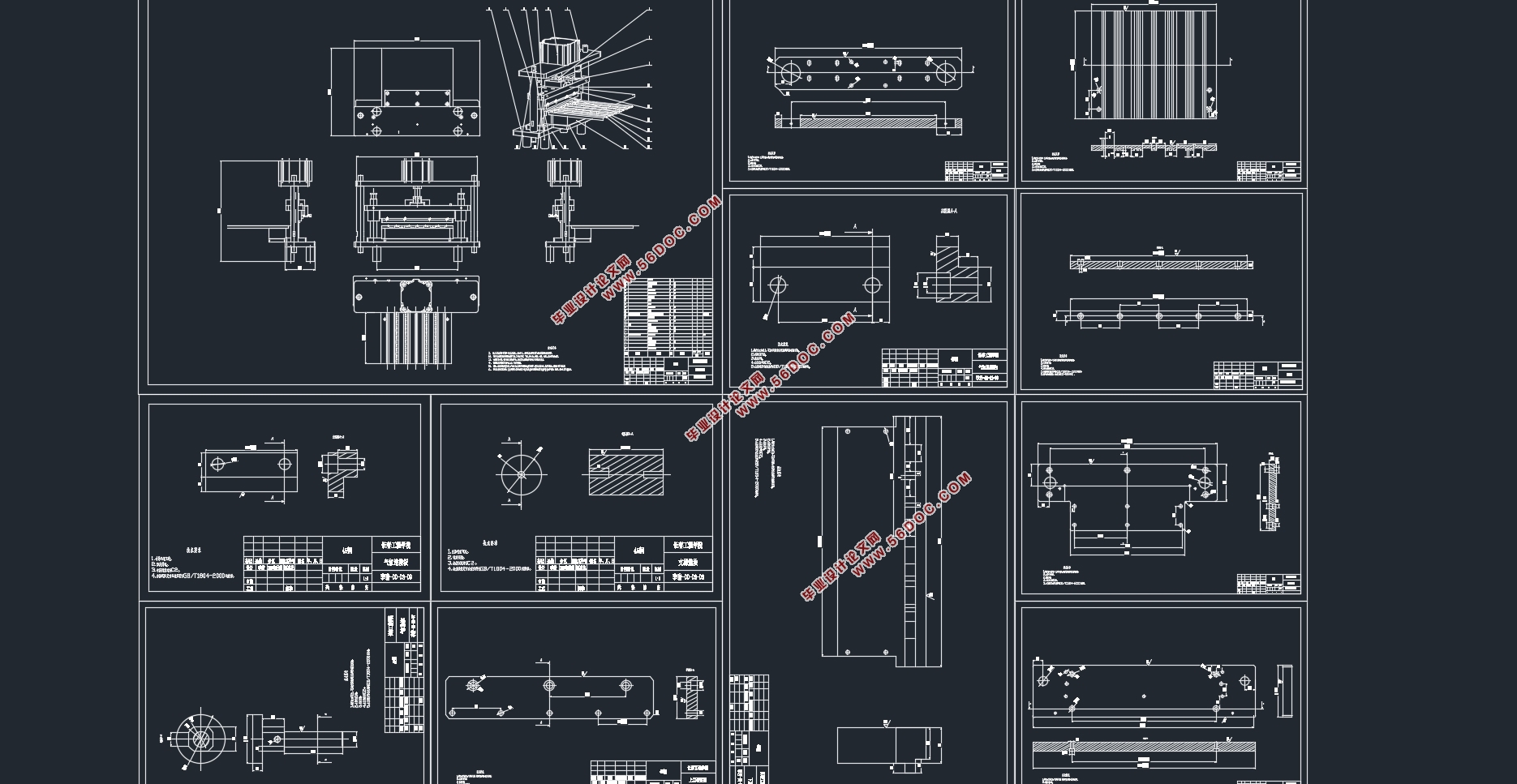

4.2 裁切模具气缸选型 11

4.3 送料机构吸盘的计算选型 16

4.4 皮带接驳组件电动机的计算选型 23

4.5 皮带接驳组件中传送带装置的计算校核 26

4.6本章小结 31

5. 电池极片载切机结构设计建模 32

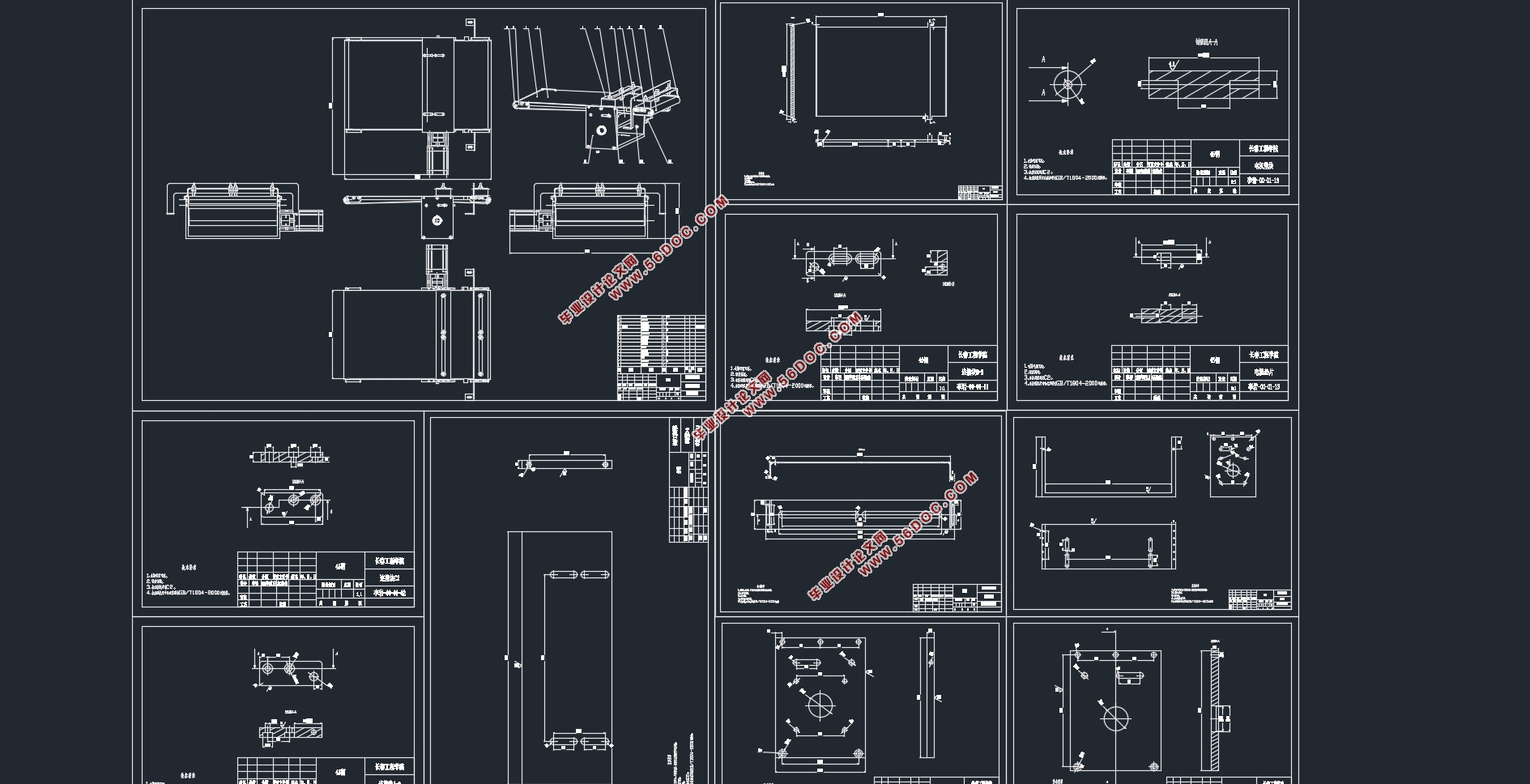

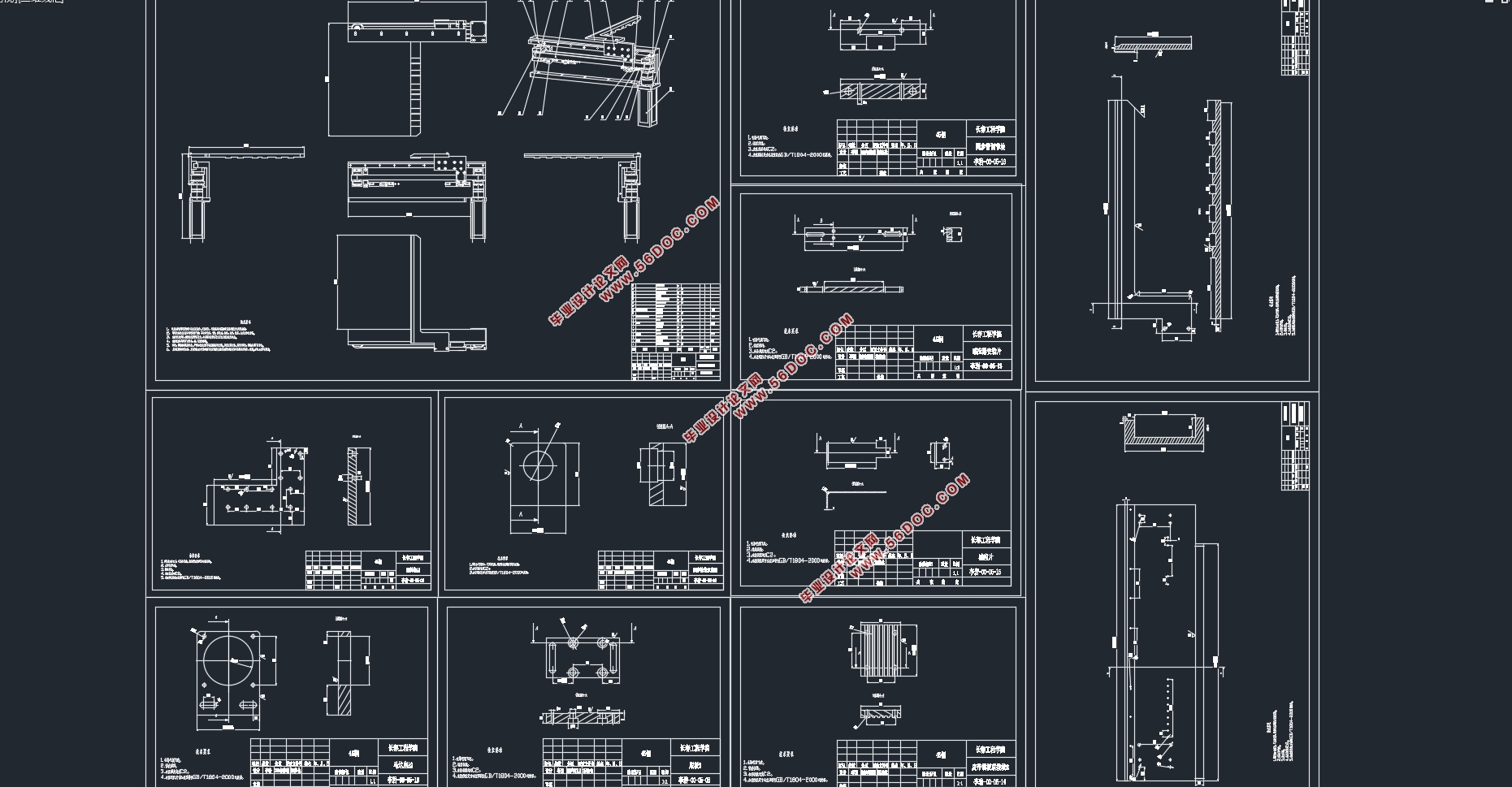

5.1载切机工作台结构设计 32

5.2上料总成传动结构设计 32

5.3送料机构传动结构设计 33

5.4裁切模具裁切结构设计 34

5.5皮带接驳组件传动结构设计 35

5.6本章小结 36

6. 总结 36

参考文献 36

致谢 38

|