250万吨矿井刮板输送机选型设计(含CAD零件图装配图)(论文说明书22000字,外文翻译,CAD图5张)

摘要

刮板输送机是煤矿综采工作面唯一的运输设备。刮板输送机侧面与液压支架联接,为支架的移动提供支点,它沿工作面铺设,以千斤顶与液压支架相联系,为采煤机提供运行轨道,将采煤机落下的煤运入顺槽转载机,再经过可伸缩胶带输送机运送至采区煤仓,完成工作面运煤工序。所以,刮板输送机的可靠、稳定、高效运行将直接影响着矿井的生产能力和煤矿企业的经济效益。随着我国煤炭开采不断地向长壁大采高综采工作面的方向发展,采煤量的不断加大,安全、高产、高效已经成为各煤炭企业的追求目标,因此,各煤炭企业对工作综采设备的性能要求也在迅速提高。需求的增加将激励着国内的煤机生产企业将研制开发的重点转向了大装机功率大运输量、长运输距离、高强度、高可靠性的重型刮板输送机,这也是刮板输送机未来的发展方向。因此,正确选择刮板输送机对采煤工作面高效运转至关重要。

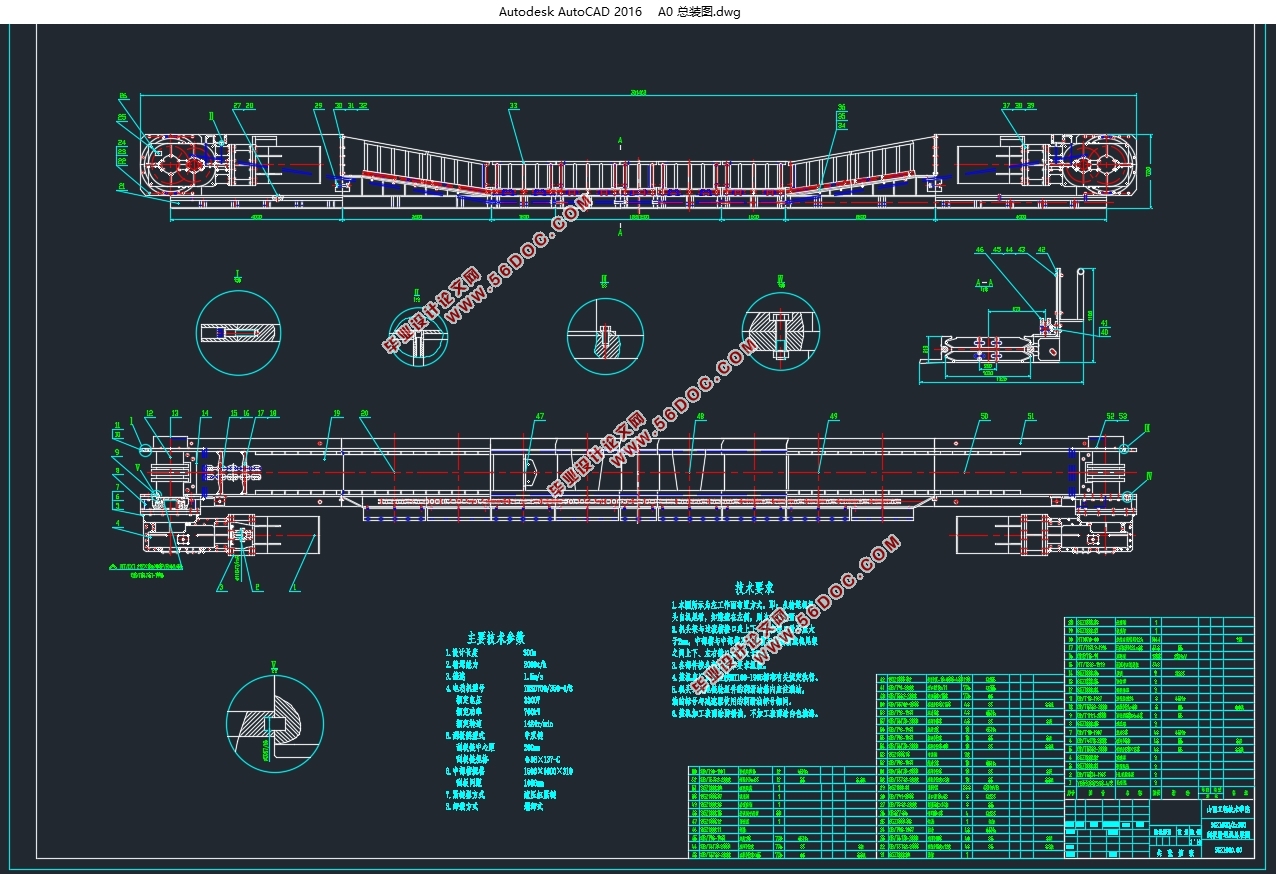

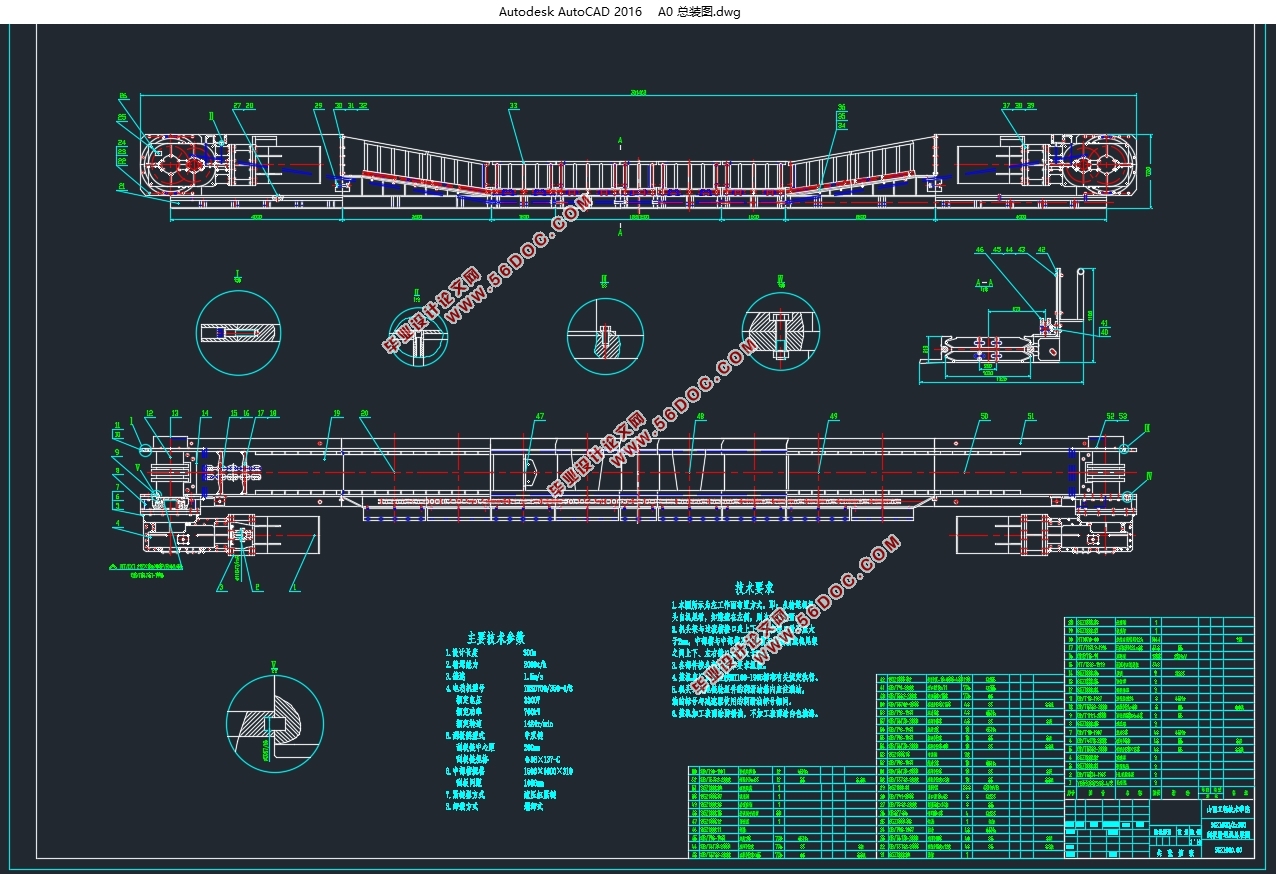

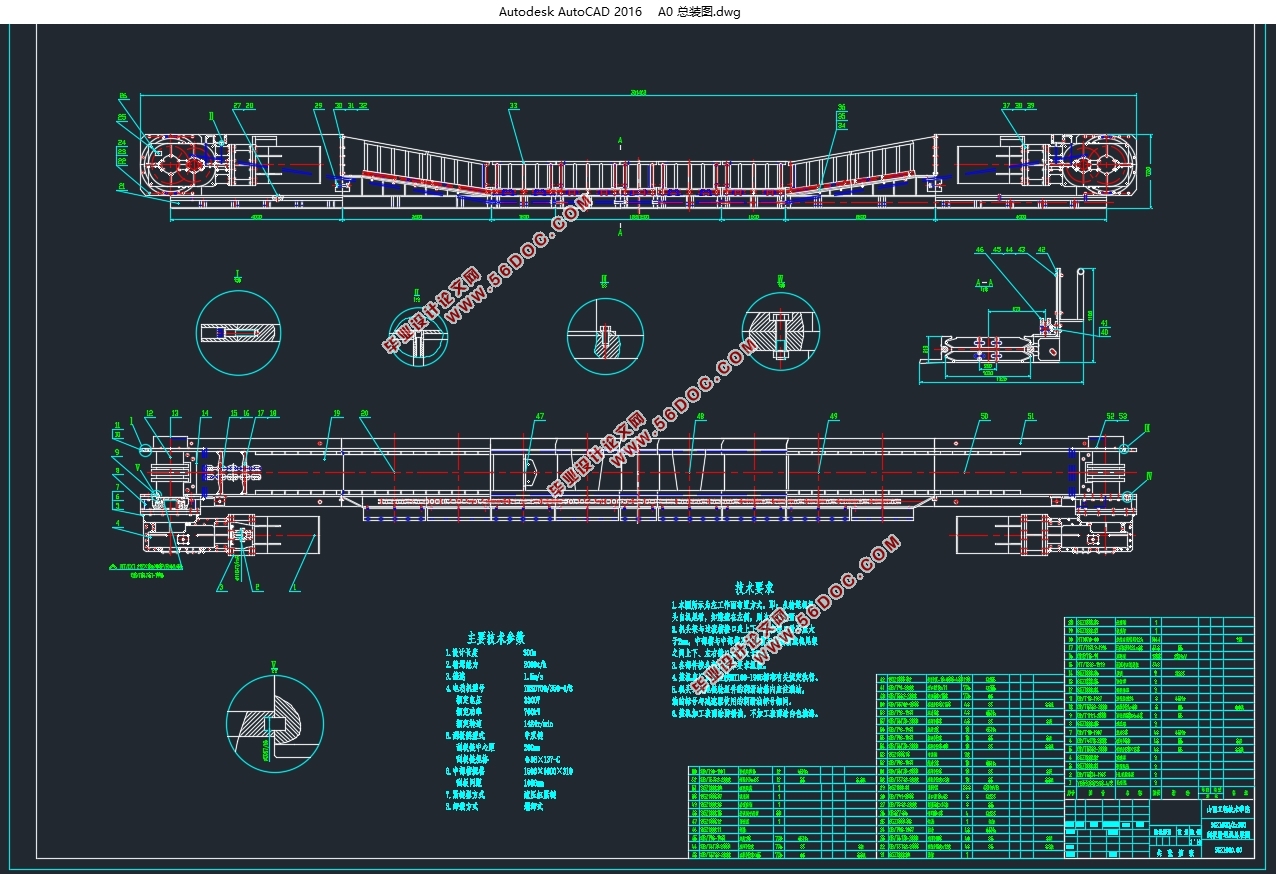

本文中从中部槽的设计选用、运行阻力的计算、计算电动机功率、计算刮板链的预紧力和紧链力、验算刮板链的安全系数、减速器设计等入手,在设计中刮板输送机采用了机头、机尾双驱动,传动部平行布置的总体设计。本文还对传动部的齿轮进行了设计计算和校核,对重要的轴、键进行了强度校核,对主要轴承进行了寿命校核,对其他部分进行了选用,从多个方面对250万吨矿井刮板输送机进行选型计算,具有一定参考价值。

关键词:刮板输送机;运行阻力;减速器;选型

Selection Design of 2.5 Million Tons Mine Scraper Conveyor

Abstract

Scraper conveyor is the only transportation equipment in the fully mechanized coal mining face. The side of the scraper conveyor is connected with the hydraulic support to provide a fulcrum for the movement of the support. It is laid along the working face, connected with the hydraulic support by a jack, to provide a running track for the shearer, to transport the coal falling from the shearer into the trough transfer machine, and then transported to the coal bin of the mining area through the retractable belt conveyor to complete the coal conveying process of the working face. Therefore, the reliable, stable and efficient operation of the scraper conveyor will directly affect the production capacity of the mine and the economic benefits of the coal enterprises. With the continuous development of coal mining in our country towards the long wall and large height fully mechanized coal face, the increasing of coal mining volume, safety, high yield and high efficiency have become the pursuit goal of all coal enterprises. Therefore, the performance requirements of all coal enterprises for fully mechanized coal mining equipment are also rapidly increasing. The increase of demand will encourage the domestic coal machinery manufacturers to turn the focus of research and development to the heavy-duty scraper conveyor with large installed power, large transportation capacity, long transportation distance, high strength and high reliability, which is also the future development direction of scraper conveyor. Therefore, the correct selection of scraper conveyor is very important for the efficient operation of coal face.

In this paper, starting from the design and selection of the middle slot, the calculation of running resistance, the calculation of motor power, the calculation of the pre tightening force and the tightening force of the scraper chain, the calculation of the safety factor of the scraper chain, the design of the reducer, etc., in the design, the scraper conveyor adopts the overall design of the head and tail double drive, and the transmission part is arranged in parallel. In this paper, the design calculation and check of the gear in the transmission part, the strength check of the important shaft and key, the life check of the main bearing, and the selection of other parts are also carried out. The selection calculation of the 2.5 million ton scraper conveyor in the mine from various aspects has certain reference value.

Key words: scraper conveyor; running resistance; reducer; selection

刮板输送机设计计算

刮板输送机设计输送能力2000t/h,设计长度300m,链速1.5m/s。

在查取相关资料后决定选用弧齿锥齿轮,斜齿圆柱齿轮和行星齿轮三级减速传动。输送机与截深0.8m无链电牵引采煤机配套使用,可适应缓倾斜、左右综采工作面,工作倾角≤10°。刮板输送机在工作过程中其槽间水平弯曲角度为3°,采用φ38×137-C级圆环链的中双链式刮板链,单位长度质量29kg/m,双机头驱动。

目录

摘要 i

Abstract ii

1绪论 1

1.1刮板输送机的组成 2

1.1.1机头部 2

1.1.2中部槽及附属部件 3

1.1.3刮板链 4

1.1.4紧链装置 4

1.1.5推移装置 5

1.1.6锚固装置 5

1.2 刮板输送机的分类 5

1.3 刮板输送机的应用 5

1.4 刮板输送机的工作原理 6

1.5 刮板输送机的特点 6

1.6 刮板输送机的发展现状和趋势 6

1.7新型刮板输送机 7

2 总体设计 8

2.1刮板输送机设计计算 8

2.1.1中部槽的设计选用 8

2.1.2运行阻力的计算 10

2.1.3计算电机功率 11

2.1.4计算刮板链的预紧力和紧链力 12

2.1.5验算刮板链的安全系数 12

2.2传动方案的设计 13

2.2.1传动方案的确定 13

2.2.2总传动比及传动比分配 13

2.2.3传动装置运动参数的计算 14

2.3减速器传动件设计计算 15

2.3.1传动部弧齿锥齿轮设计计算 15

2.3.2 中速级斜齿圆柱齿轮设计计算 26

2.3.3传动部行星机构的设计计算 34

2.3.4圆环链链轮设计计算 40

2.4 SGZ1000/2×700中双链刮板输送机技术特征 42

3零部件的设计及校核 43

3.1轴的设计及校核 43

3.1.1高速轴的设计校核 43

3.1.2第二轴的设计计算 48

3.1.3初算第三轴轴径 55

3.1.4初算行星轮系各轴径 55

3.1.5初算链轮轴径 55

3.2轴承的寿命校核 56

3.2.1高速轴轴承寿命计算 56

3.2.2第二轴轴承寿命的计算 57

3.3键的设计与强度校核 59

3.3.1高速轴普通平键设计校核 59

3.3.2链轮轴渐开线花键校核 60

3.4联轴器的选用 61

4刮板输送机的使用和维修 63

4.1刮板输送机的安装与试运转 63

4.1.1刮板输送机零部件的存放 63

4.1.2安装与调试 63

4.1.3刮板输送机的使用与维护 65

4.2刮板输送机的润滑 67

4.3常见故障及处理方法 68

附录 70

参考文献 76

外文文献 78

中文翻译 84

致谢 89

|