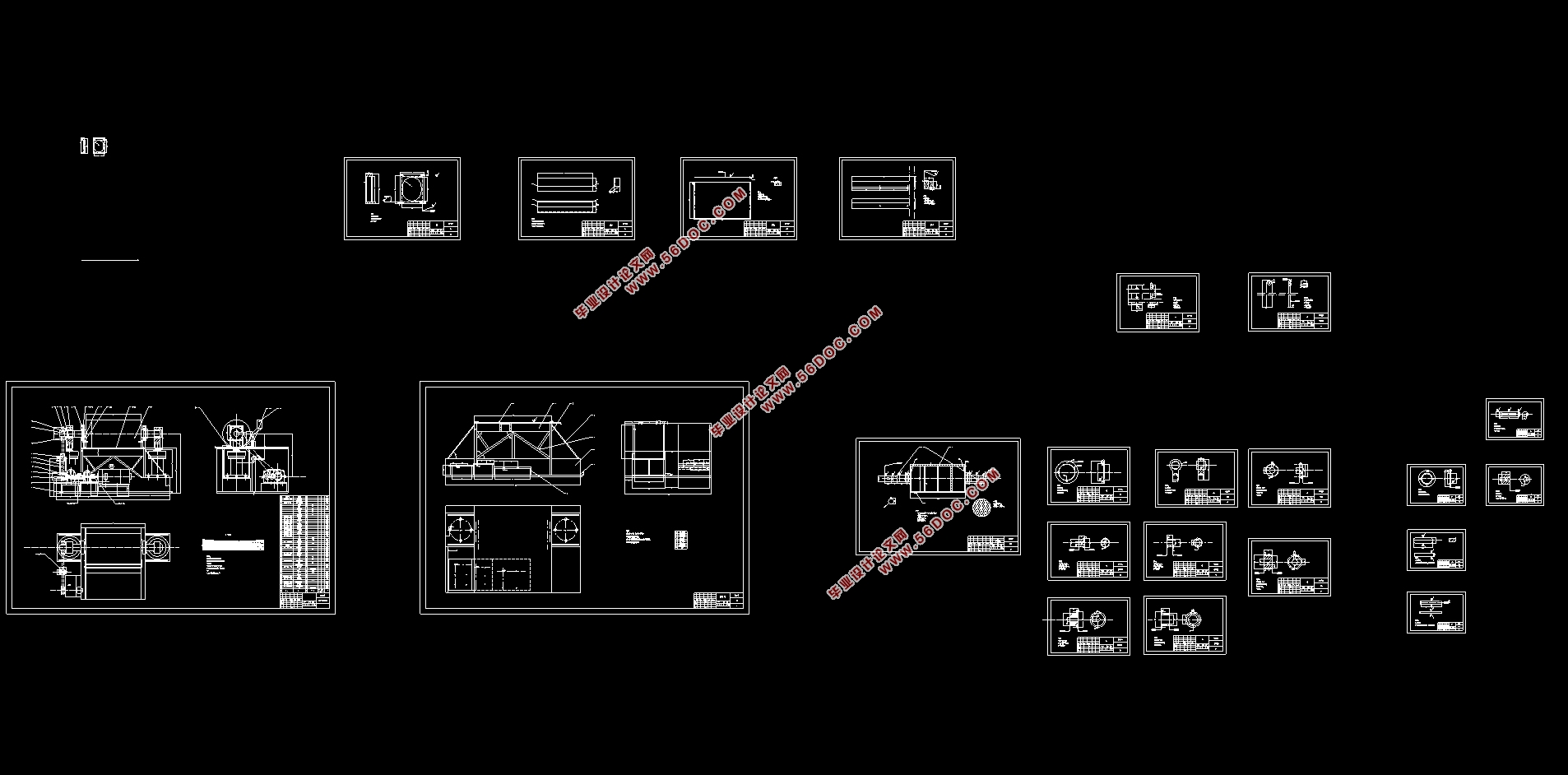

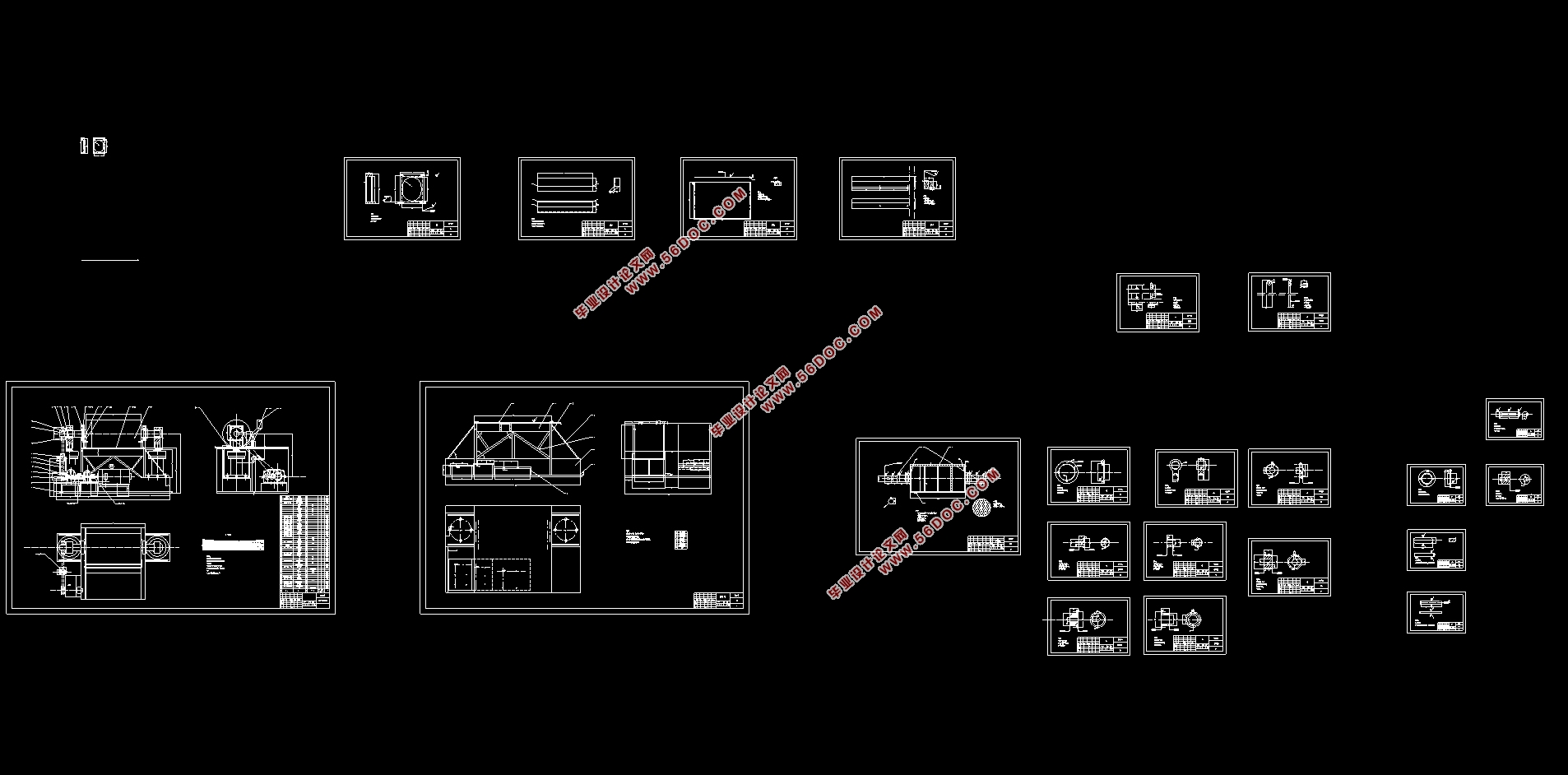

聚四氟乙烯复合板生产装置设计(含CAD零件装配图)(任务书,开题报告,论文说明书10000字,CAD图纸22张)

摘要

随着科学的不断发展,诞生了无数新兴的产业,而塑料工业则是无数新兴产业中极为突出的一个重要产业,它现在已经成为现代工业中不可或缺的部分。与其它工业相比,作为后起之秀的塑料工业无疑具有更为广大的发展前景。

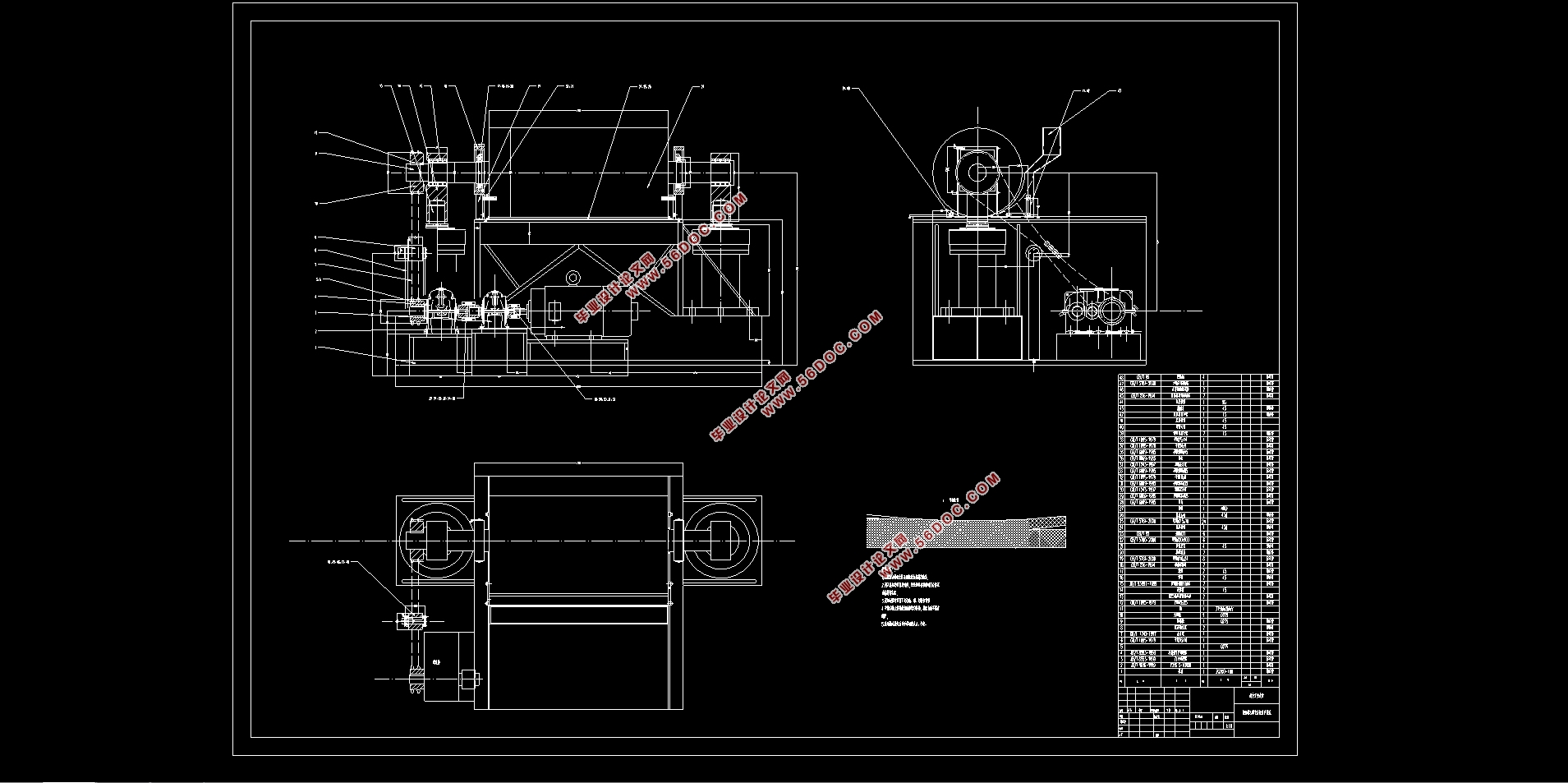

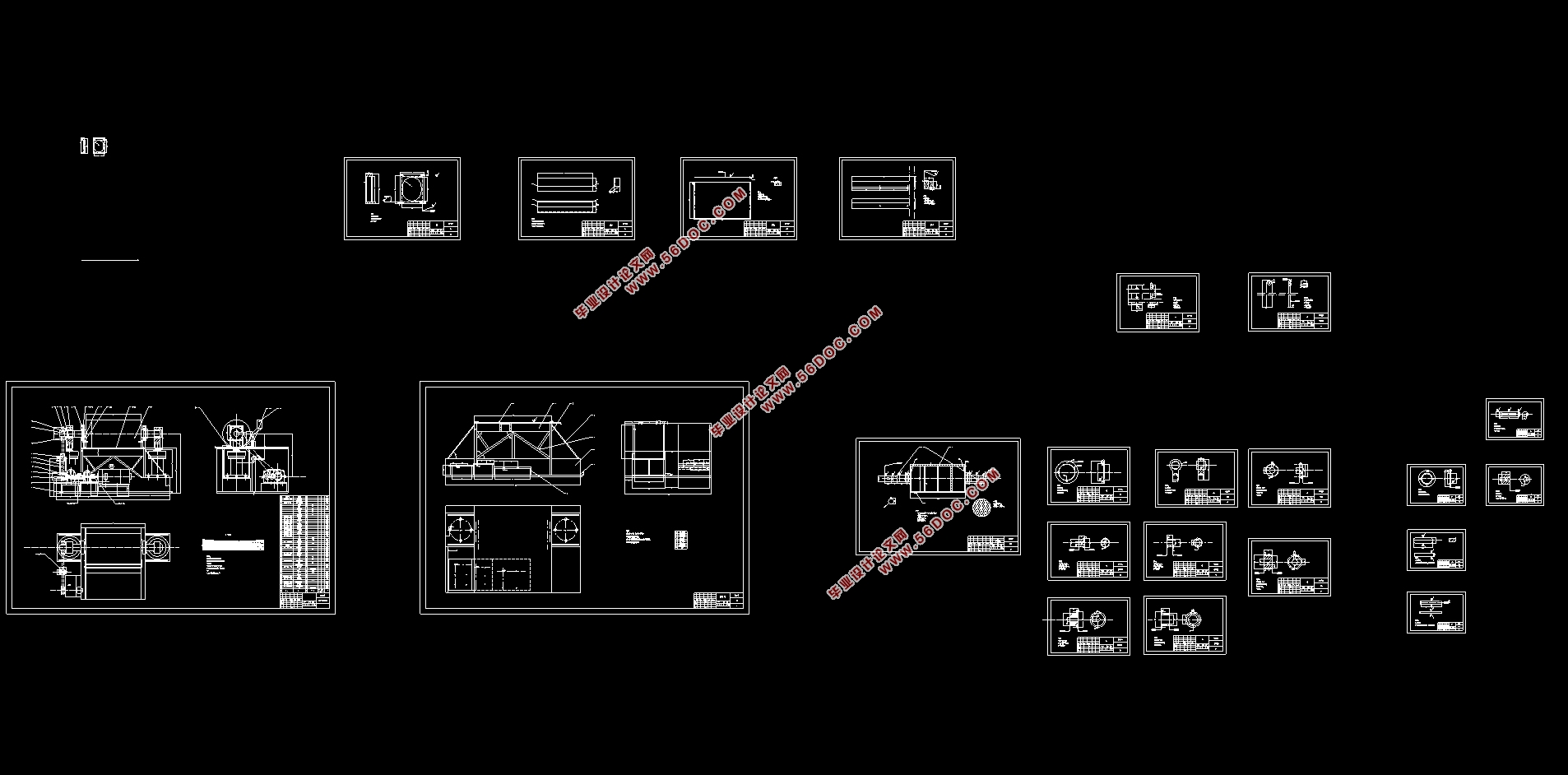

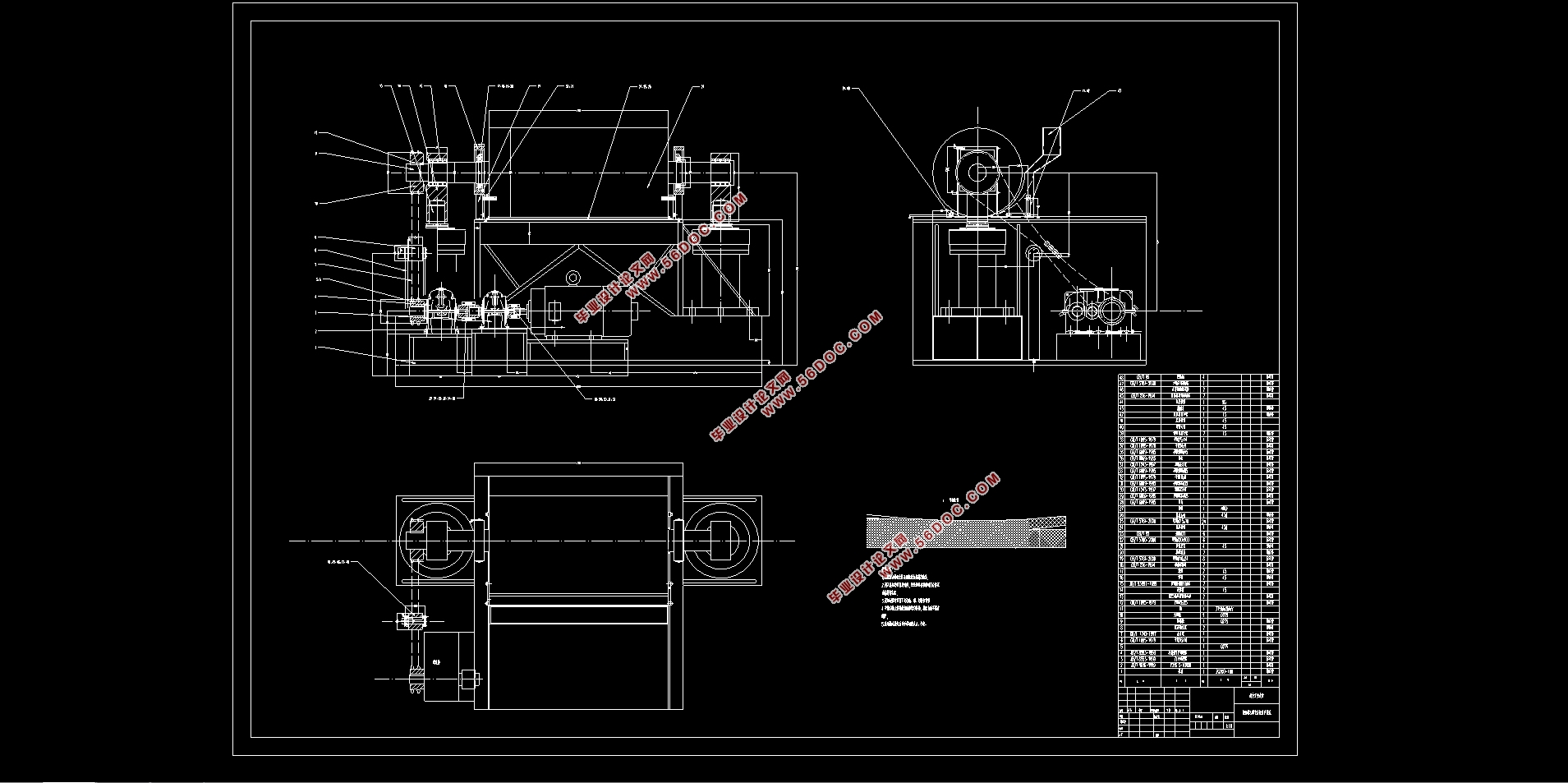

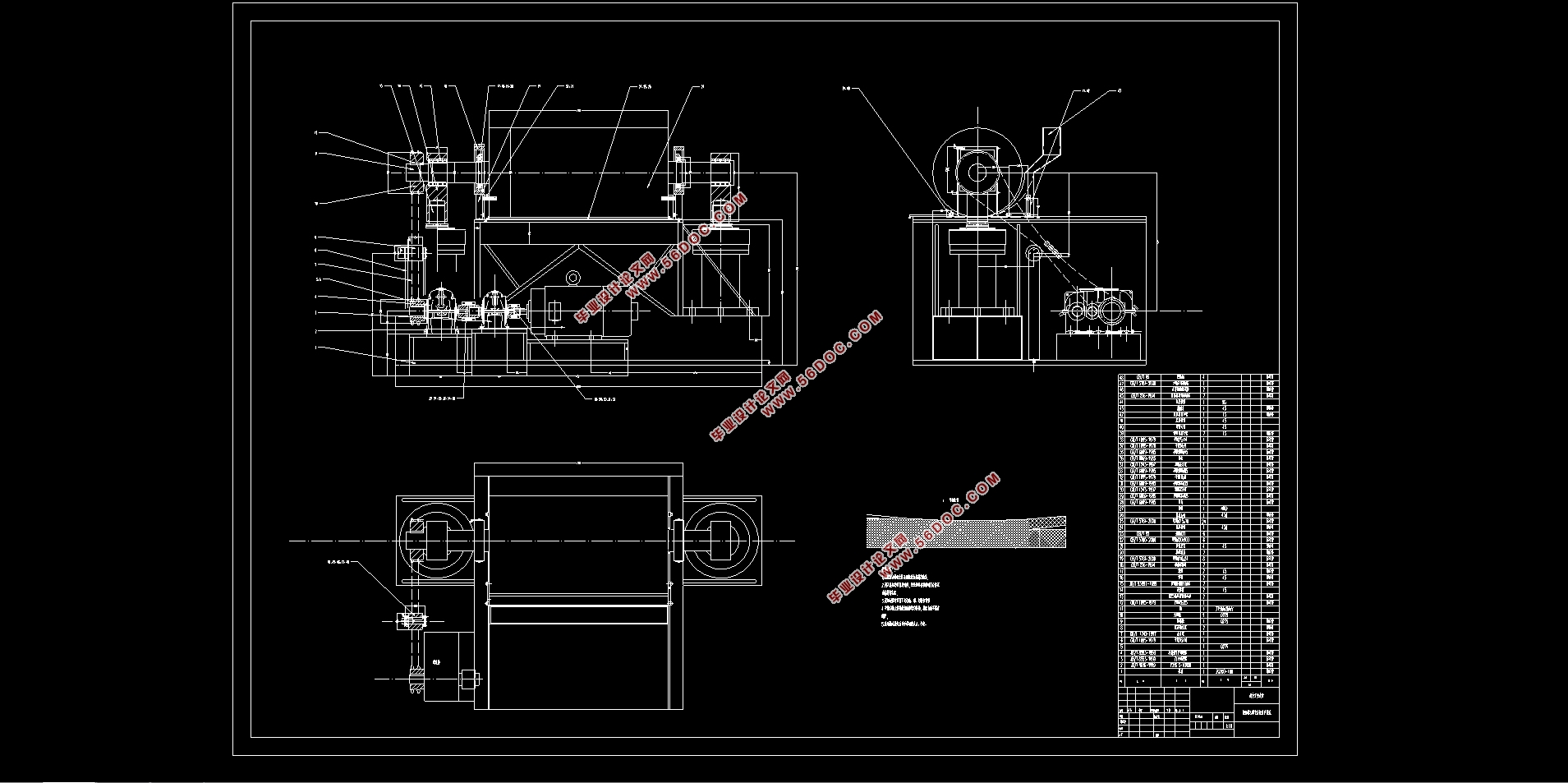

而氟塑料,也就是聚四氟乙烯(简称PTFE),更是有着塑料之王的美称。PTFE 是为国防和尖端技术需要而开发的,尔后逐渐推广到民用。此外聚四氟乙烯复合材料在现实中也被大量应用,PTFE复合材料既能保持PTFE的优良特性,同时又能克服其加工难题,具有广阔的发展前景。本次课题主要是是进行聚四氟乙烯复合板生产装置的设计计算,在实际设计时决定采用滚压法来完成聚四氟乙烯复合版的最终成型。本次设计主要包括工作件压辊的设计计算,压力系统和传动系统的设计计算,以及主要零部件的校核。

关键词:聚四氟乙烯 复合材料 滚压成型

Design of Production Equipment for Polytetrafluoroethylene Composite Plate

Abstract

With the continuous development of science, numerous emerging industries have been born, and the plastic industry is an extremely prominent important industry among numerous emerging industries, which has now become an indispensable part of modern industry. Compared with other industries, as a rising star of the plastics industry undoubtedly has more broad prospects for development.

And fluorine plastic, namely polytetrafluoroethylene (PTFE for short), it is to have the good name of king of plastic more. PTFE was developed for defense and advanced technology needs and then gradually extended to civilian use. In addition, PTFE composites have been widely used in the real world. PTFE composites can not only maintain the excellent characteristics of PTFE, but also overcome its processing problems, which has a broad prospect for development.This subject is mainly to carry out the design and calculation of ptfe composite board production equipment, in the actual design decided to use rolling method to complete the final shaping of ptfe composite plate. This design mainly includes the design and calculation of the pressure roller, the design and calculation of the pressure system and the transmission system, as well as the check of the main parts.

Key words:PTFE;Compound material;Roll forming

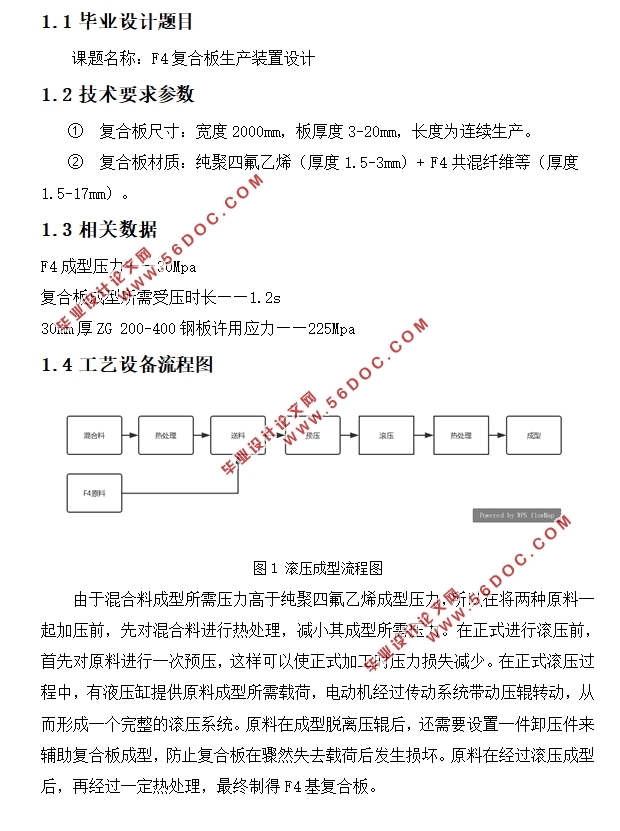

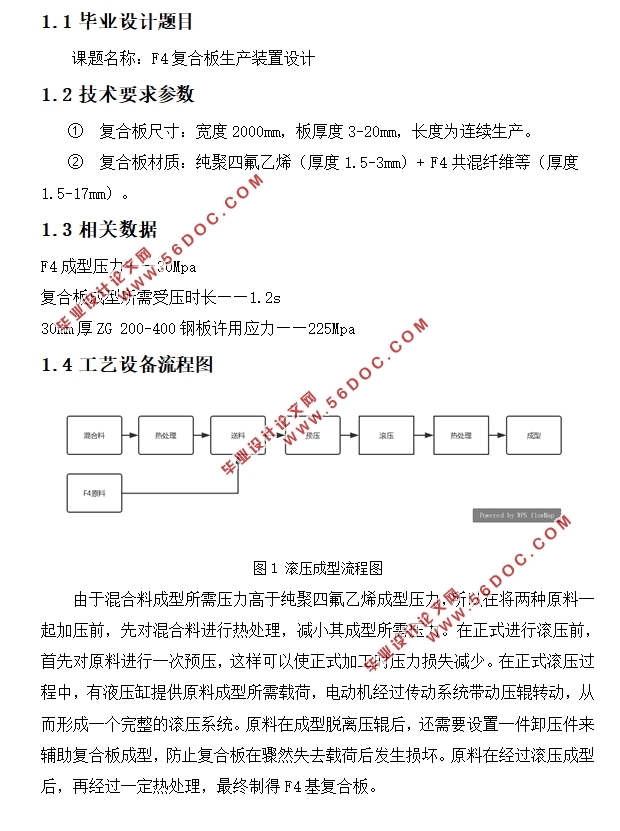

1.1 毕业设计题目

课题名称:F4复合板生产装置设计

1.2 技术要求参数

① 复合板尺寸:宽度2000mm,板厚度3-20mm,长度为连续生产。

② 复合板材质:纯聚四氟乙烯(厚度1.5-3mm)+ F4共混纤维等(厚度1.5-17mm)。

1.3 相关数据

F4成型压力——30Mpa

复合板成型所需受压时长——1.2s

30mm厚ZG 200-400钢板许用应力——225Mpa

目录

摘要....................................................Ⅰ

Abstract................................................Ⅱ

第一章 绪论.............................................2

1.1 毕业设计题目...............................................................................................2

1.2 技术要求参数................................................................................................2

1.3 相关数据........................................................................................................2

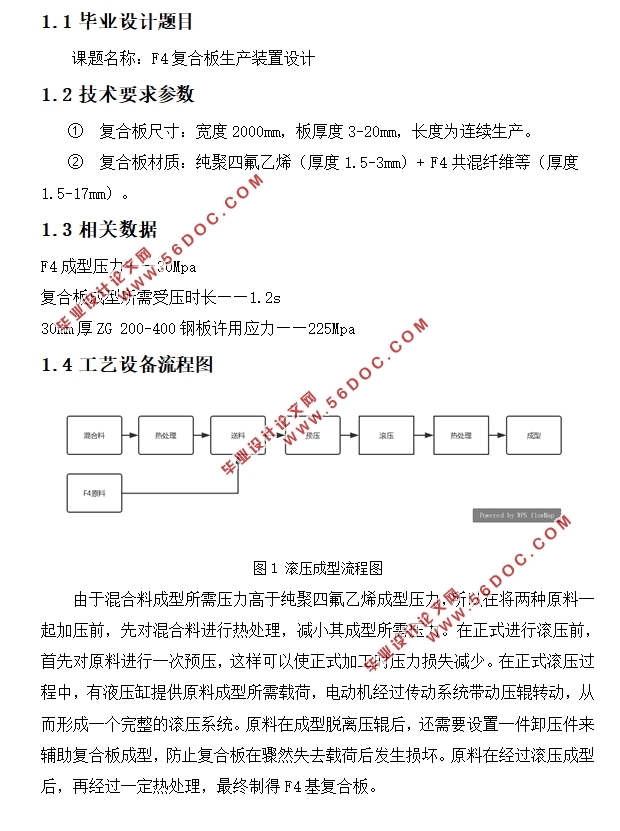

1.4 工艺设备流程图............................................................................................2

第二章 分系统的功能结构的设计计算.......................3

2.1 滚压系统........................................................................................................3

2.1.1 工作件滚子.............................................................................................3

2.1.2 压力系统.................................................................................................8

2.1.3 传动系统.................................................................................................12

2.2模具系统.........................................................................................................19

2.3 杆架设计........................................................................................................20

第三章 校核计算.........................................22

3.1 压辊轴的校核................................................22

3.2 支撑板的校核................................................23

第四章 设备的经济性分析.................................23

参考文献................................................24

结束语与致谢............................................27

|