药板自动装盒机结构设计(含CAD图)(任务书,开题报告,外文翻译,论文说明书11000字,CAD图纸2张)

摘要

随着社会的不断发展,人们的生活水平不断提高,民众对自身的健康也更加重视,普遍对药品的包装提出了更高的要求。虽然在医药产业新政策和新理念的冲击下,医药产业迎来了新的机遇,但是对比国外老牌包装品牌,我国的包装产业仍存在着制作不精细、适应性单一、故障自我监测和自我修复功能不足等问题。

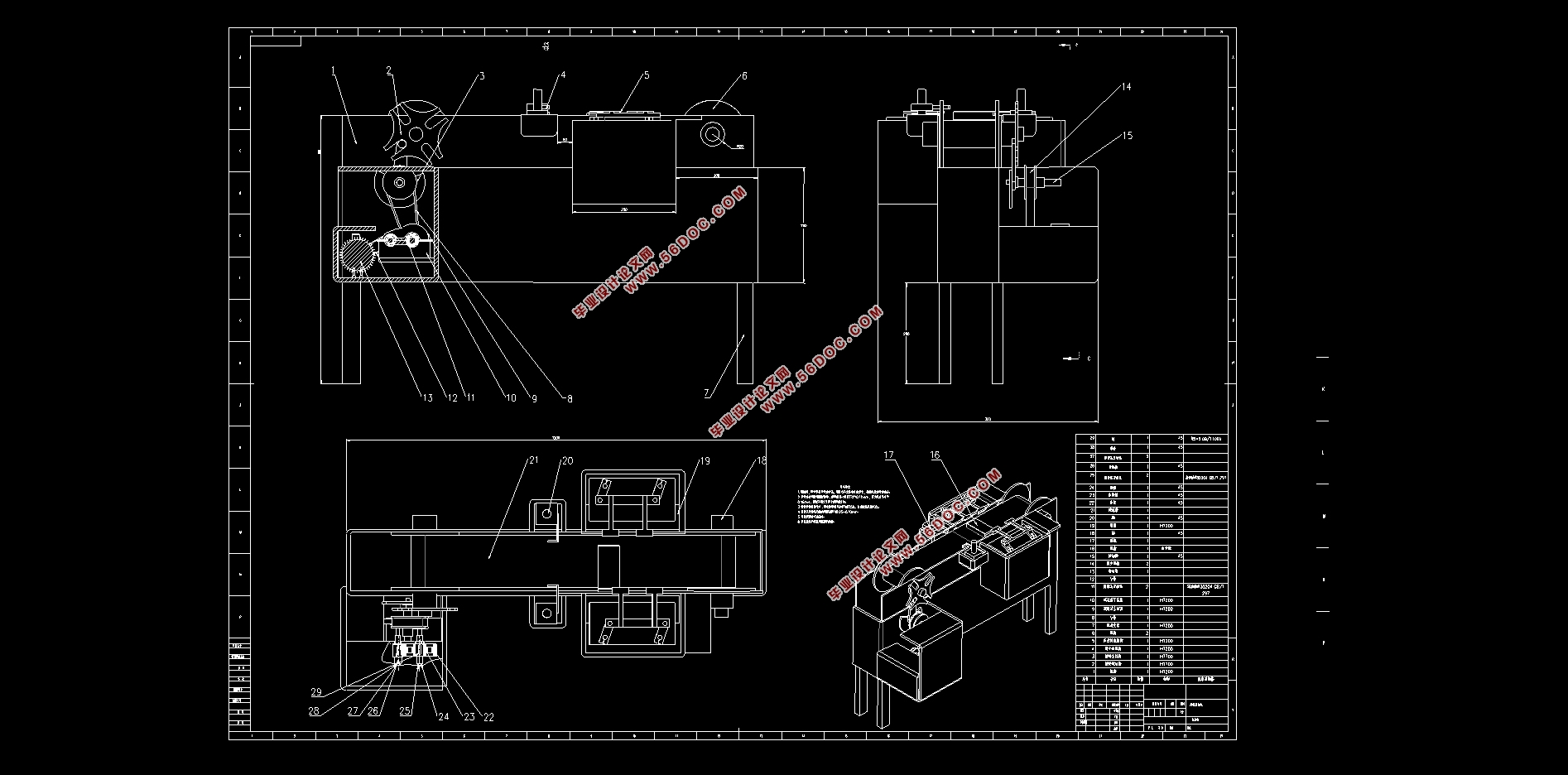

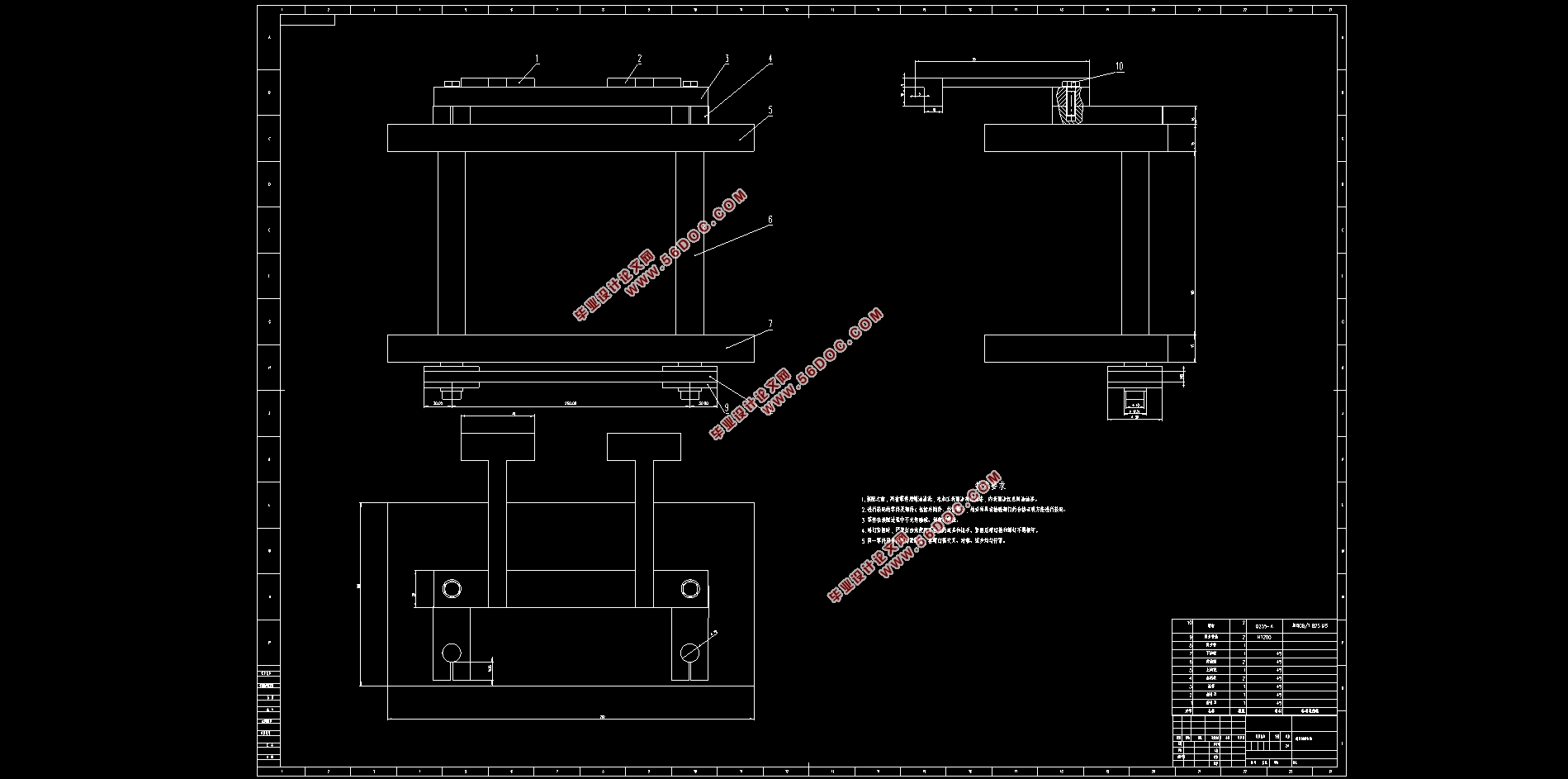

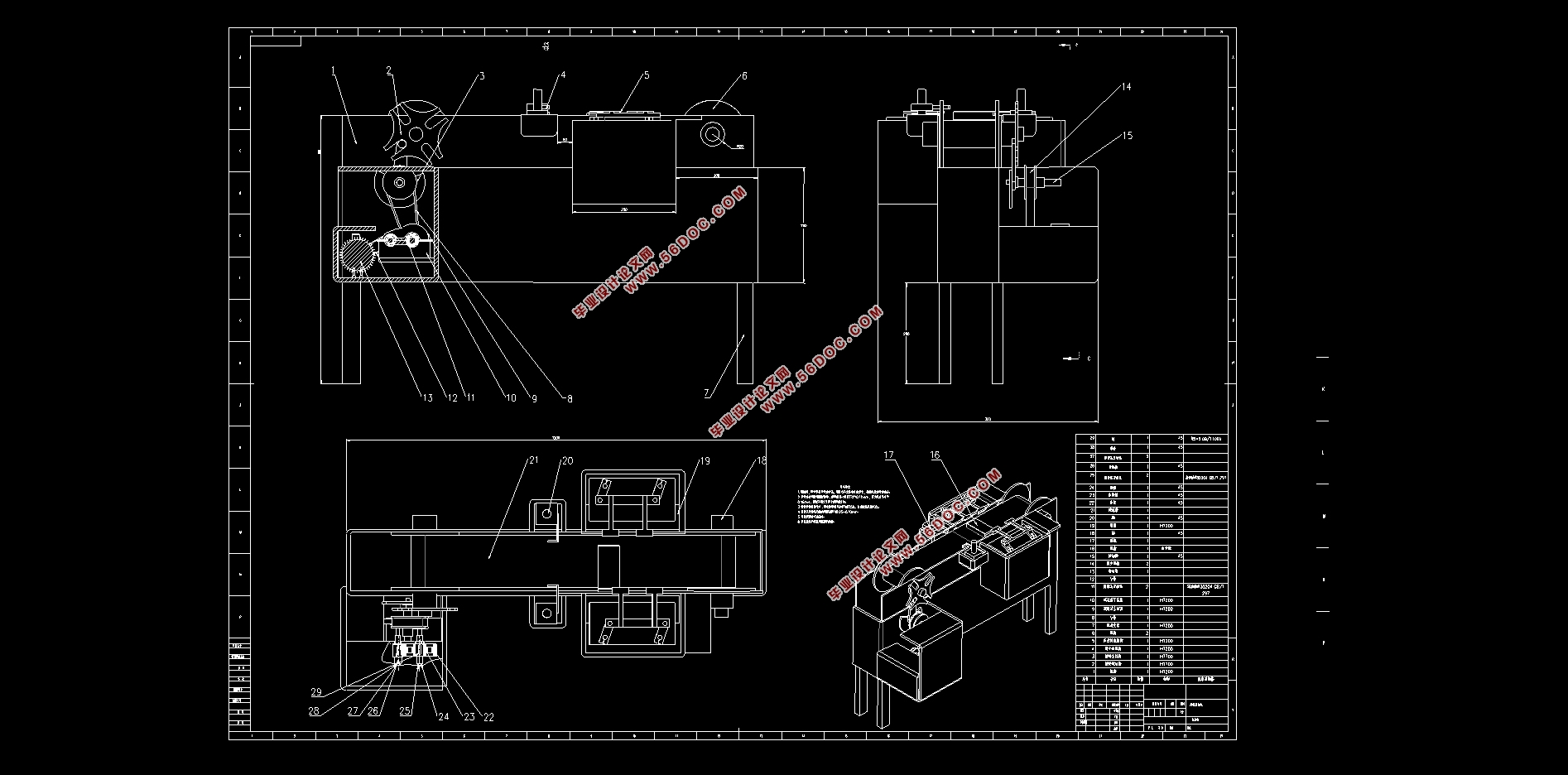

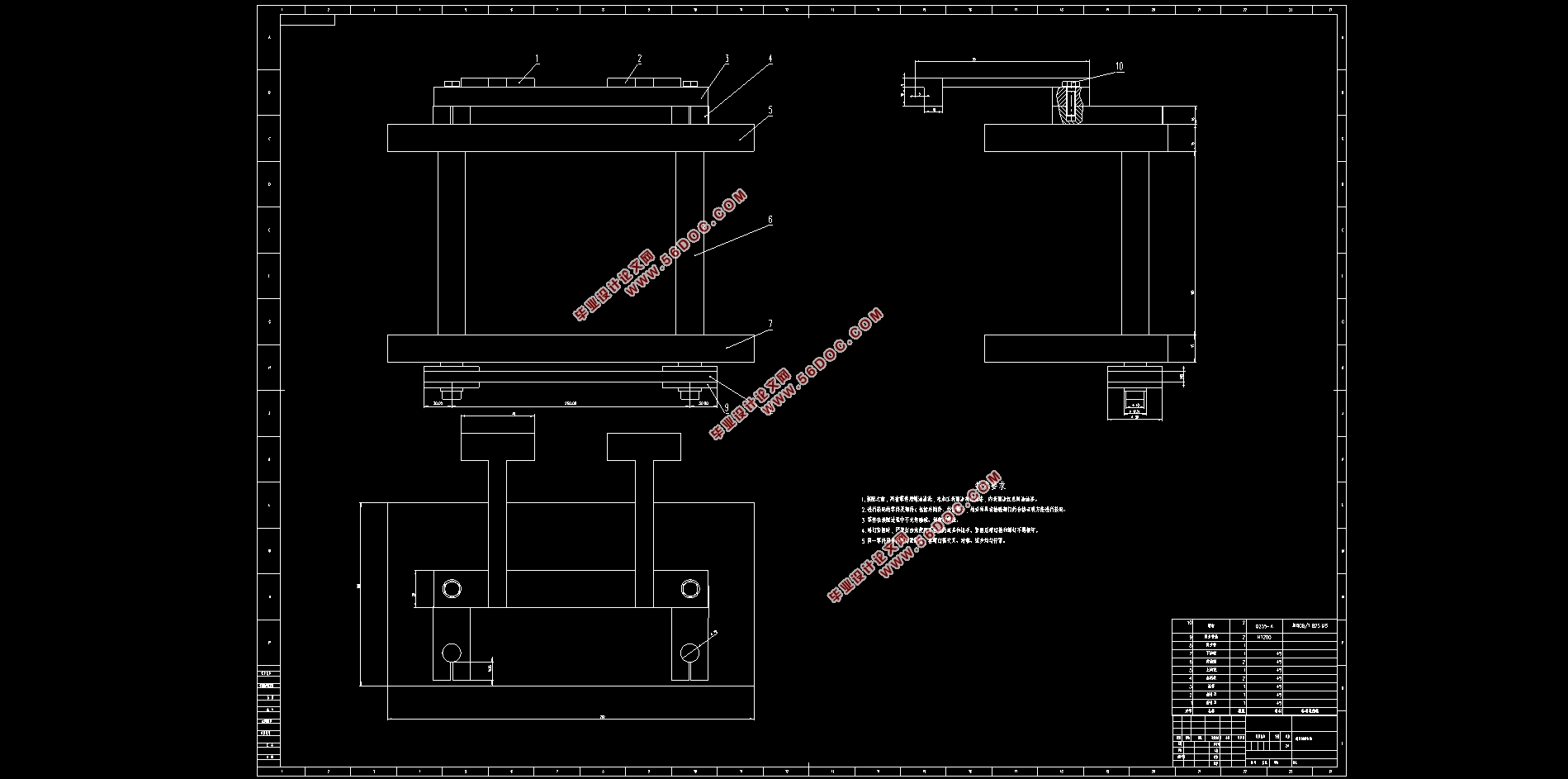

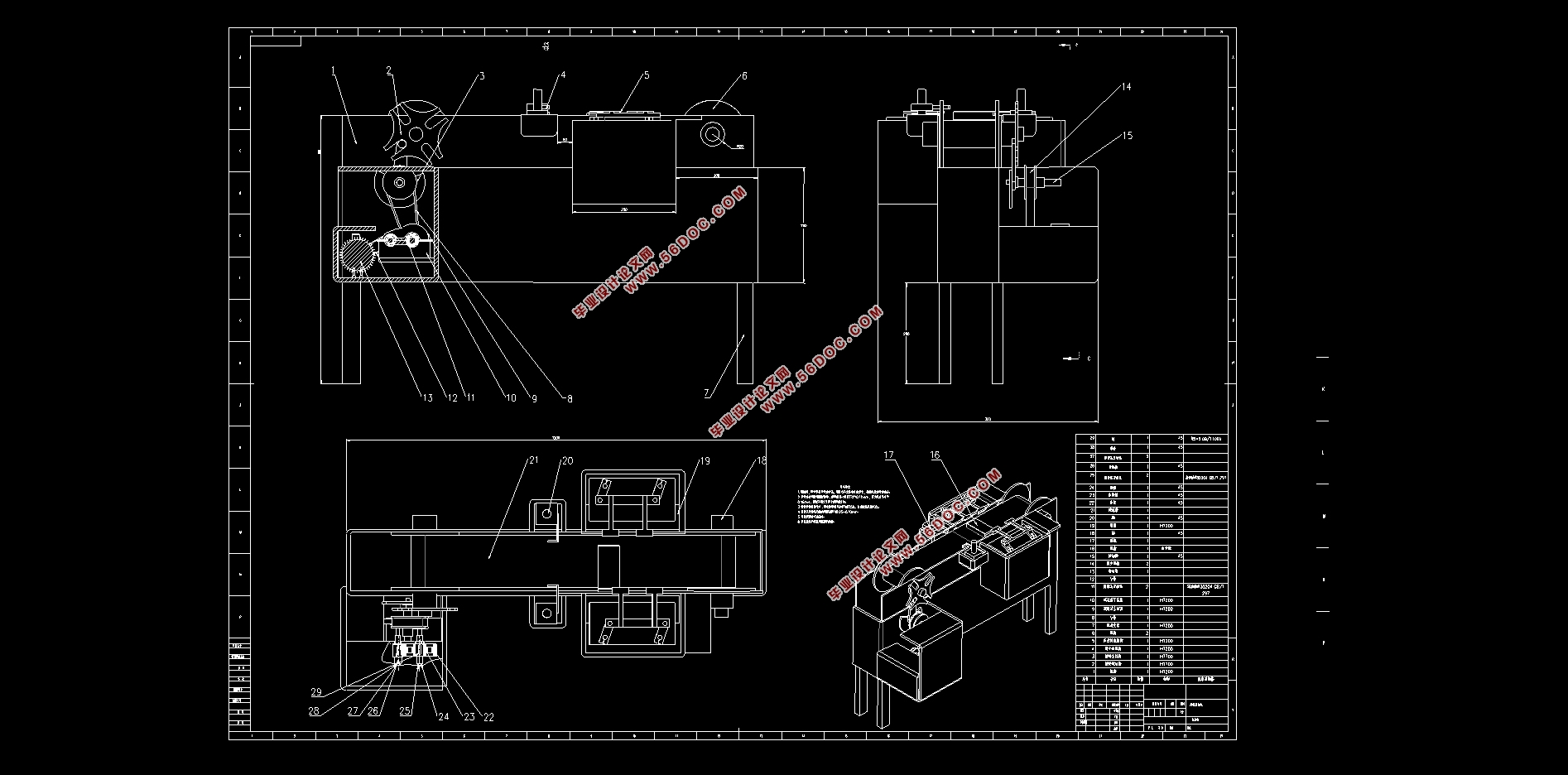

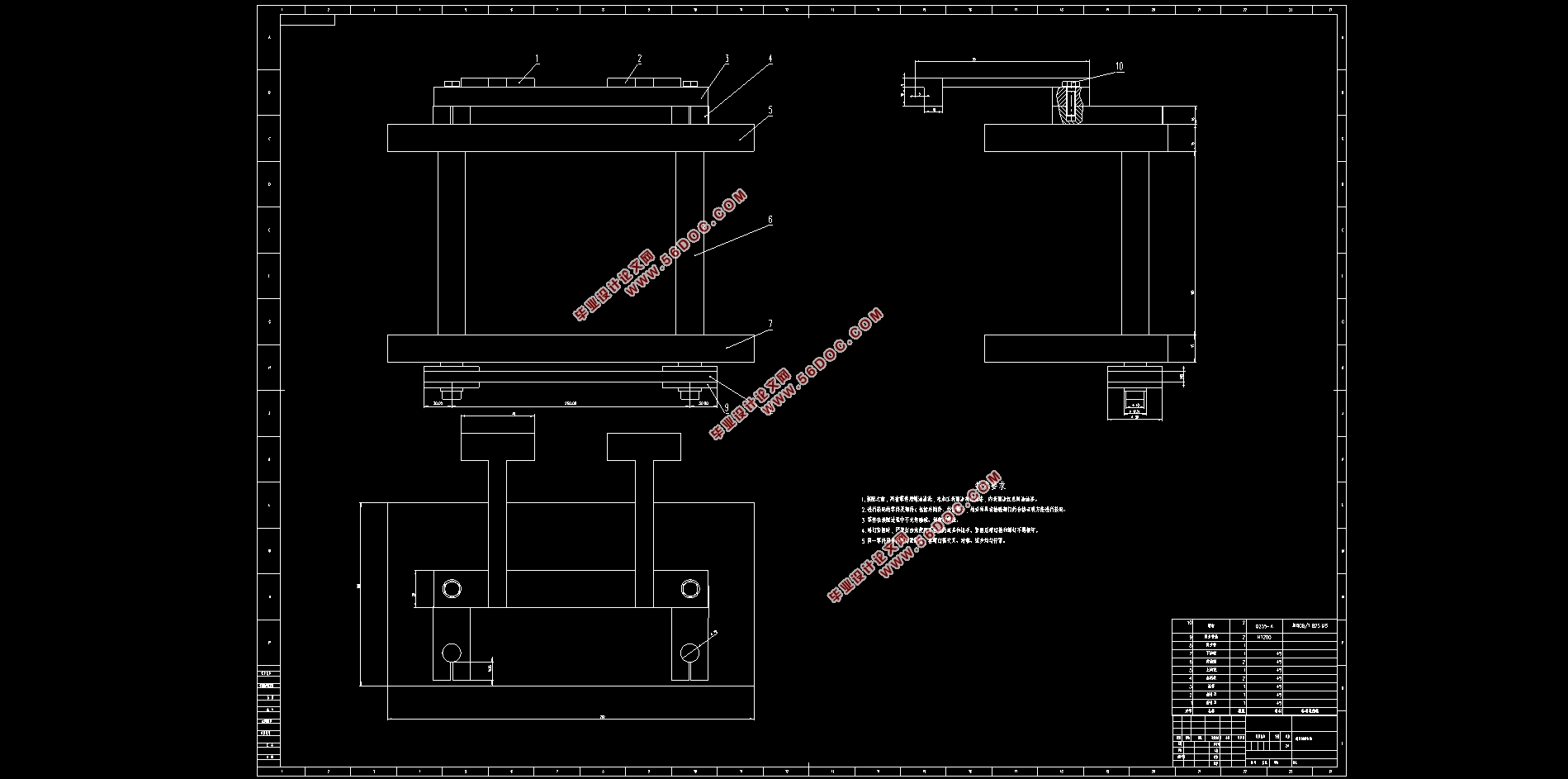

本文为市场常见药板的医用药板装盒机的结构设计,药板装盒的工艺路线包括下盒及纸盒撑开、推药板和说明书入纸盒、折舌和插舌封装的过程,主要做的工作为:对药盒下料机构的结构设计,利用吸盘将压平的纸盒逐个分开,在利用侧壁的压力将纸盒撑开,操作简单,且药盒架具有一定适应性,可以根据不同尺寸的药盒进行调整;药盒折舌机构设计,利用四杆机构带动挡板来回摆动,完成折舌动作;药盒封盒机构的结构设计,利用平行四边形机构带动折舌刀和插舌刀做相同的动作,确保插舌过程中大舌不会滑出,减少失败品等。本文对传动系统进行了选择和校核,包括电机的选择、减速器的设计、带传动的设计计算等。同时利用SolidWorks构建药盒包装机的模型。本设计在保证达到以上动作要求的同时,更加注重防止药品的污染。设计过程中查阅了相关机械结构的设计和一些专利,吸纳其他优秀结构的优点取长补短,最终完成了本设计。

本设计具有机构简单可靠、便于安装、造价不高的优点,同时传动平稳且噪声较小,极大程度上减少人工的操作以避免药品的污染,并且机身高度适宜必要时的人工操作。如今我国的包装产业和制药产业都迎来了快速发展的时期,我国包装机未来的研究应更加注重提高自主创新能力,将技术掌握在自己手中;提高产品的可靠性和适应性;优化人机交互功能。相信通过对现有产品设计不断地改善和对新技术的引用,我国的包装机械产业可以迎来更好的发展,在国际市场上具有更强的竞争力。

关键词:药板装盒机、四杆机构、结构设计。

Abstract

With the continuous development of the society, people's living standards have been constantly improved, people pay more attention to their own health, and generally put forward higher requirements on the packaging of drugs.Under the impact of new policies and new concepts in the pharmaceutical industry, the pharmaceutical industry has ushered in new opportunities. However, compared with foreign established packaging brands, China's packaging industry still has problems such as imprecise production, single adaptability, failure self-monitoring and self-repair.

This paper describes the structural design of medical cartridge packing machine for common cartridge plates in the market. The technological route of cartridge packing includes the process of opening the lower box and the carton, pushing the cartridge plate and putting the instruction into the carton, folding tongue and inserting tongue.The main works include the structure design of the medicine box blanking mechanism, which use suction cup to separate the flattened carton one by one,and use the pressure of the side wall to open the carton,The operation is simple, and the medicine box holder has certain adaptability, which can be adjusted according to different sizes of medicine boxes;the tongue folding mechanism of the medicine,the four-bar mechanism is used to drive the baffle to swing back and forth to complete the tongue folding movement;The structure design of the medicine box sealing mechanism uses the parallelogram mechanism to drive the tongue folding knife and tongue inserting knife to do the same action, so as to ensure that the tongue will not slip out during the tongue inserting process and reduce the number of failed products.Also use SolidWorks to build models.The design in order to ensure that the above action requirements, at the same time pay more attention to the prevention of drug pollution.During the design process, the design of the relevant mechanical structure was reviewed, and combined with the advantages of other mechanical structures to complete the design.

This design has the advantages of simple and reliable mechanism, easy installation, low cost, stable transmission and small noise, greatly reduce the manual operation to avoid drug pollution, and the body height is suitable for necessary manual operation.Now China's packaging industry and pharmaceutical industry have ushered in a period of rapid development, China's packaging machine research in the future should pay more attention to improve the ability of independent innovation, technology in their own hands;Improve product reliability and adaptability;Optimize human-computer interaction.It is believed that through the continuous improvement of the existing product design and the introduction of new technology, China's packaging machinery industry can usher in better development and have stronger competitiveness in the international market.

Key Words:Medical Cartridge Packing Machine; The Four-bar Mechanis ; Structural Design.

2.1装盒机设计的基本要求

机器总体的方案设计很大程度上决定了机器的使用对象、性能及结构布局,是结构设计中的关键环节。因此,根据药板的形状特征和使用要求,充分考虑各种影响因素,因此方案的设计需要满足以下要求:

(1)药板装盒机的结构布局设计。在保证操作方便,各个功能能够充分发挥的基础上,实现结构紧凑合理,并达到减震减噪的目的。使整机尽可能的节约空间、便于安装和维修。

(2)药板装盒机的准确性设计。取盒时可以准确的吸取进一个纸盒,准确的将药板和说明书运送到填装工位,准确的将药板和说明书放入盒内,不出现卡机现象。

(3)药板装盒机的连贯性设计。可以连续完成下盒及纸盒撑开、推药板和说明书入纸盒、折舌和插舌封装等动作。

(4)可一次性使用5年。在布局合理不影响功能的前提下,尽可能方便制造和维修。

(5)使用电源电压为380V/50Hz。

(6)噪声不大于70dB。

(7)尽可能减小制造成本,减少功率消耗,环境友好。

2.2功能与应用范围

功能:完成纸盒封盒的动作,包括折小舌、折大舌和纸盒的传送。

应用目标的基本参数为:

(1)纸盒规格(长×宽×高):最大尺寸120×60×20mm,最小尺寸90×40×14mm;

(2)纸签(说明书)规格(折叠后,长×宽):最大尺寸100mm×50mm,最小尺寸60mm×30mm;

(3)包装物(药板)规格(长×宽):最大尺寸100×50mm,最小尺寸70×30mm;

(4)包装材料:白卡纸

(5)生产能力:90-120盒/分,1-2板/盒。

目录

第1章 绪论 1

1.1研究背景 1

1.2国外包装机械概述 1

1.3我国包装机械业的发展 2

1.4药品装盒机发展中面临的问题研究 3

1.5研究意义 3

第2章 药板装盒机的总体方案设计 4

2.1装盒机设计的基本要求 4

2.2功能与应用范围 4

2.3执行机构方案设计 5

2.3.1传送方案选择 5

2.3.2纸盒上料结构设计 5

2.3.3折小舌结构设计 6

2.3.4折大舌结构设计 7

第3章 传动系统主要机构的选择和校核 8

3.1电动机的选择 8

3.1.1电机种类的选择 8

3.1.2电动机功率的确定 8

3.1.3选择电机 9

3.1.4计算总传动比和分配各级传动比 9

3.2减速器高速轴直径及强度校核 10

3.3齿轮传动设计计算 10

3.3.1选择齿轮材料,确定许用应力 10

3.3.2按接触疲劳强度设计 11

3.3.3校核齿根弯曲疲劳强度 11

3.4V带传动的设计计算 12

3.4.1初选中心距 12

3.4.2确定带长 12

3.4.3确定中心距 13

3.4.4验算小轮包角 13

3.5键的选择和校核 13

3.6传送带带轮参数设计 14

第4章 主要工作构件的结构设计 15

4.1四杆机构设计 15

4.2插舌设计 15

4.3箱体设计 16

第5章 结论 18

参考文献 19

致谢 21

|