变速箱体自动输送线和可控多循环翻转排屑装置设计(含CAD零件图装配图)(任务书,开题报告,论文说明书12000字,CAD图4张)

摘 要

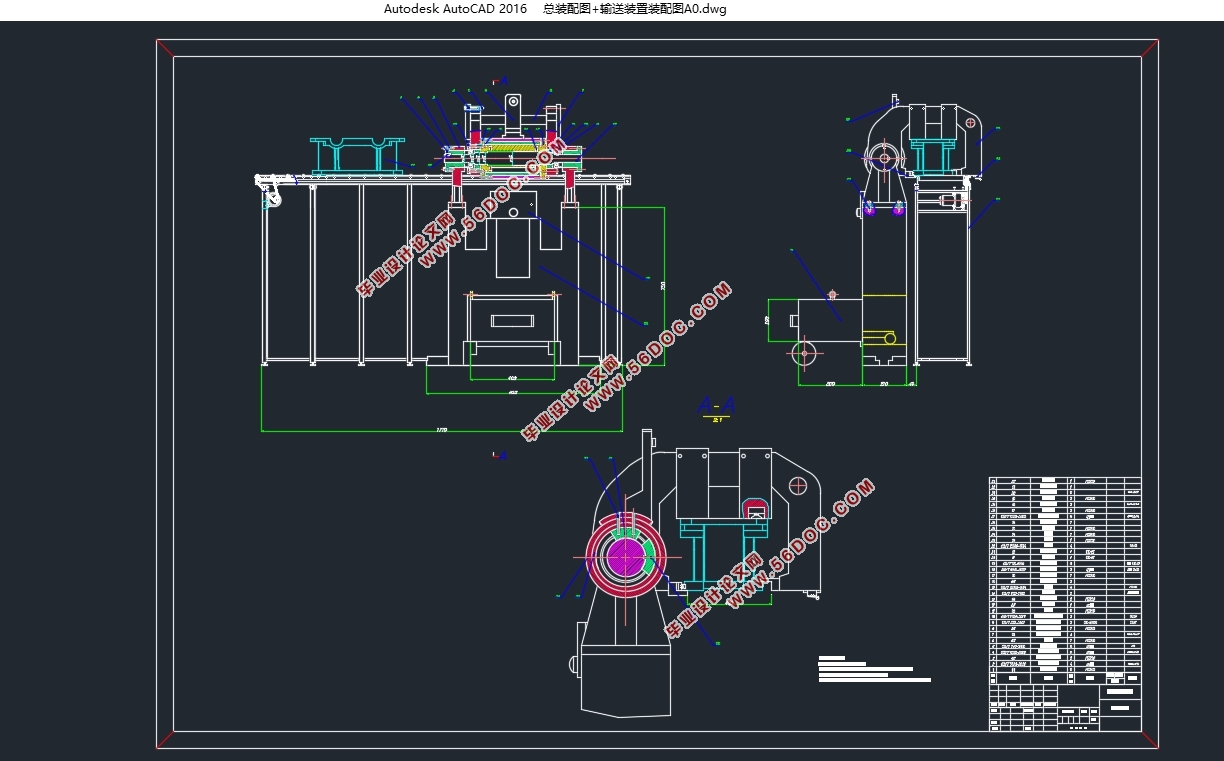

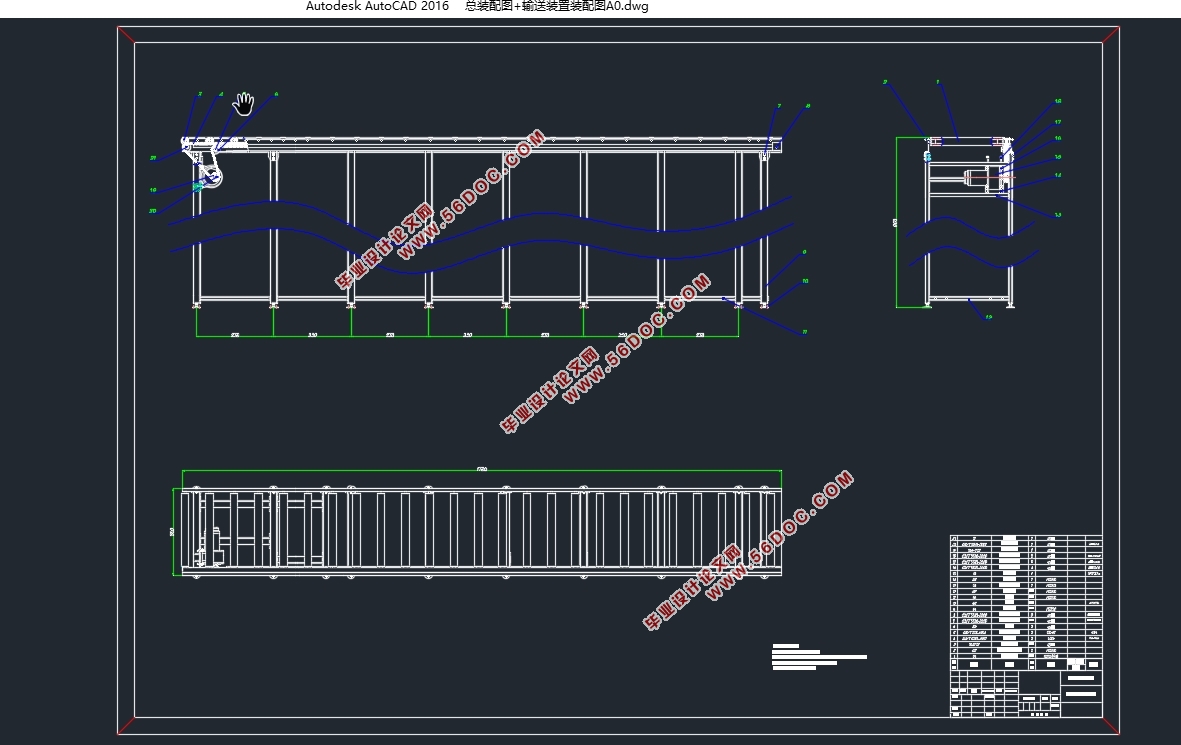

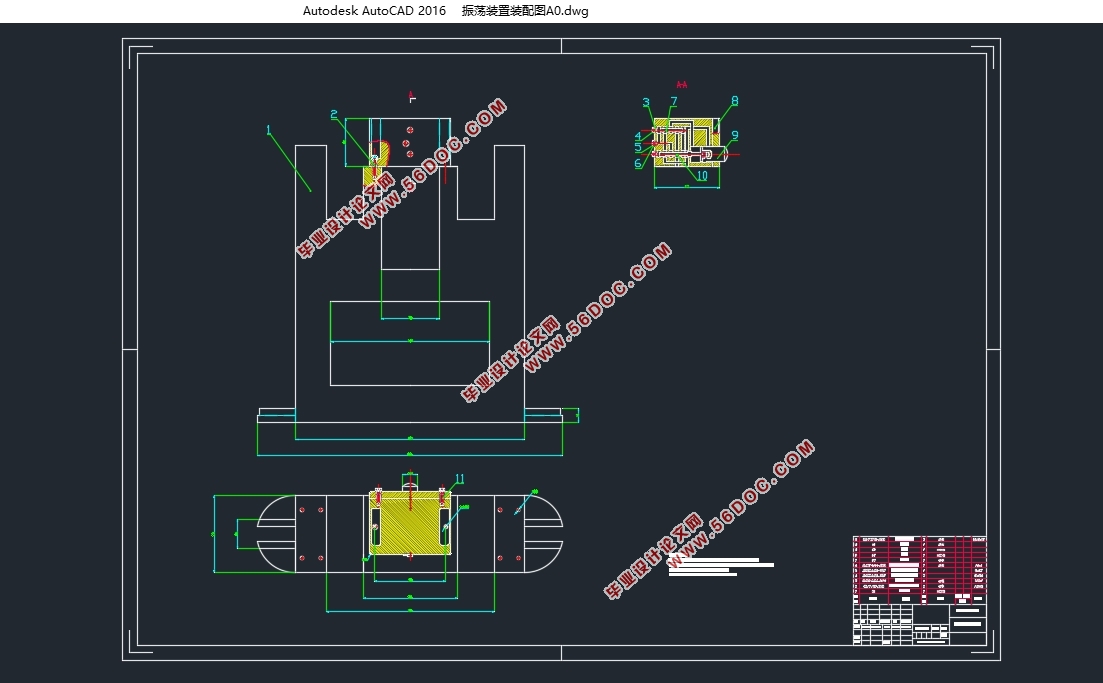

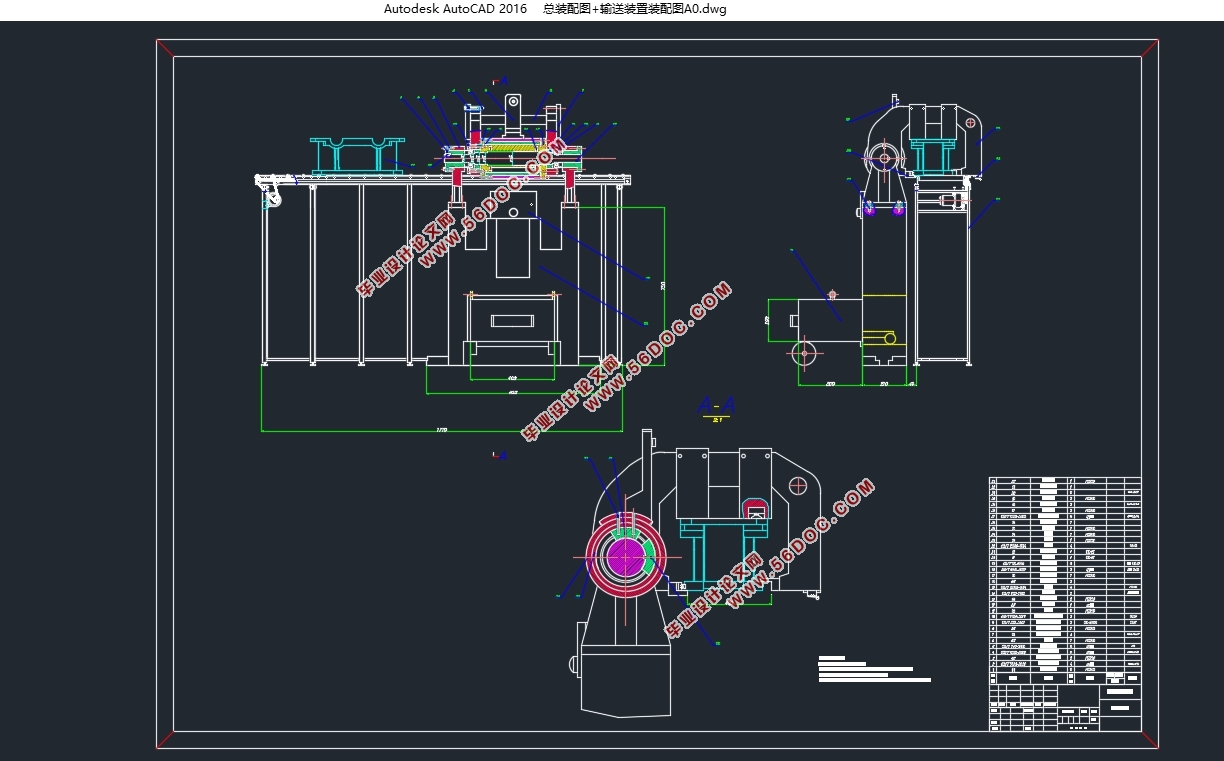

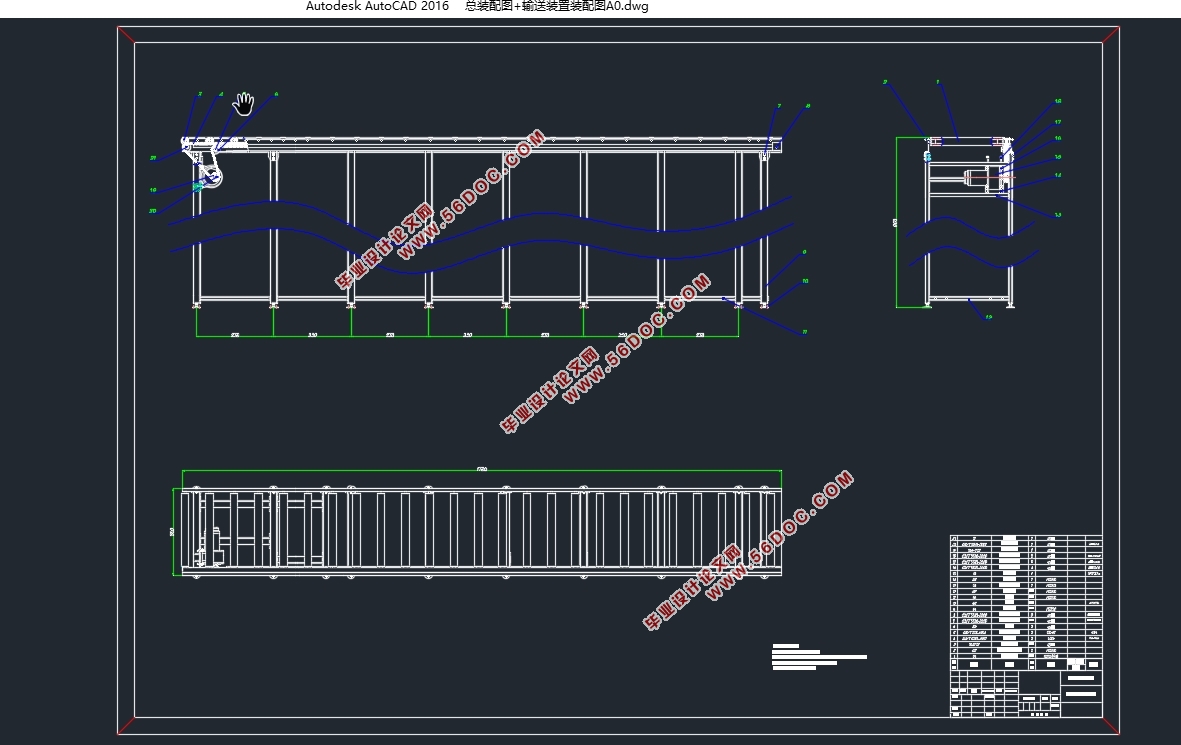

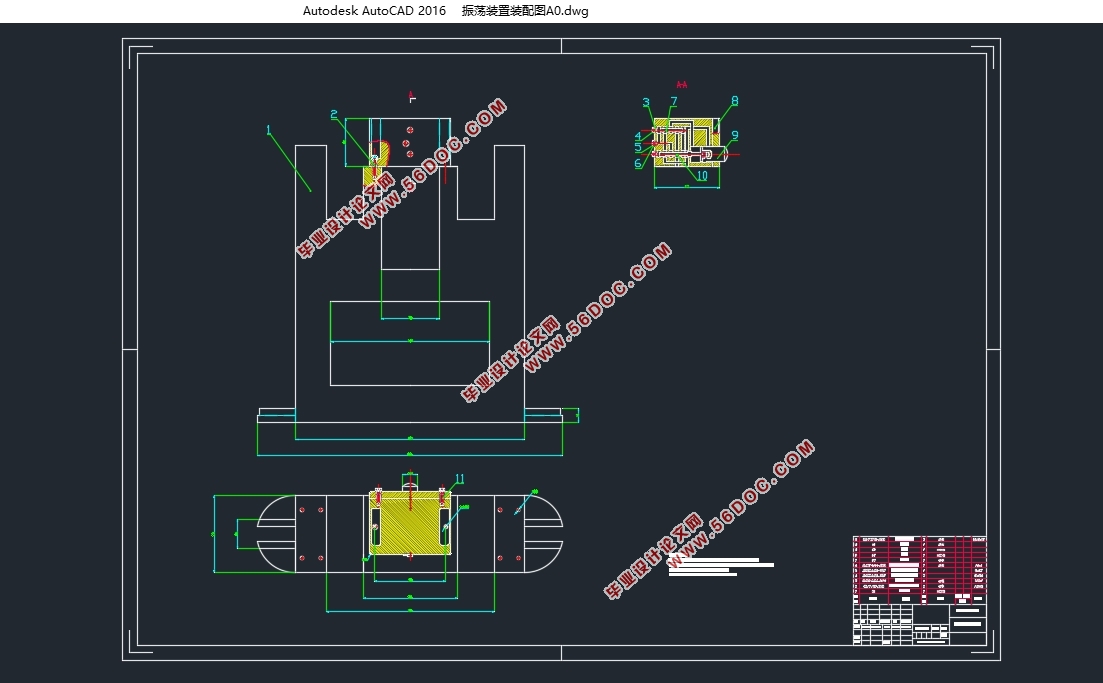

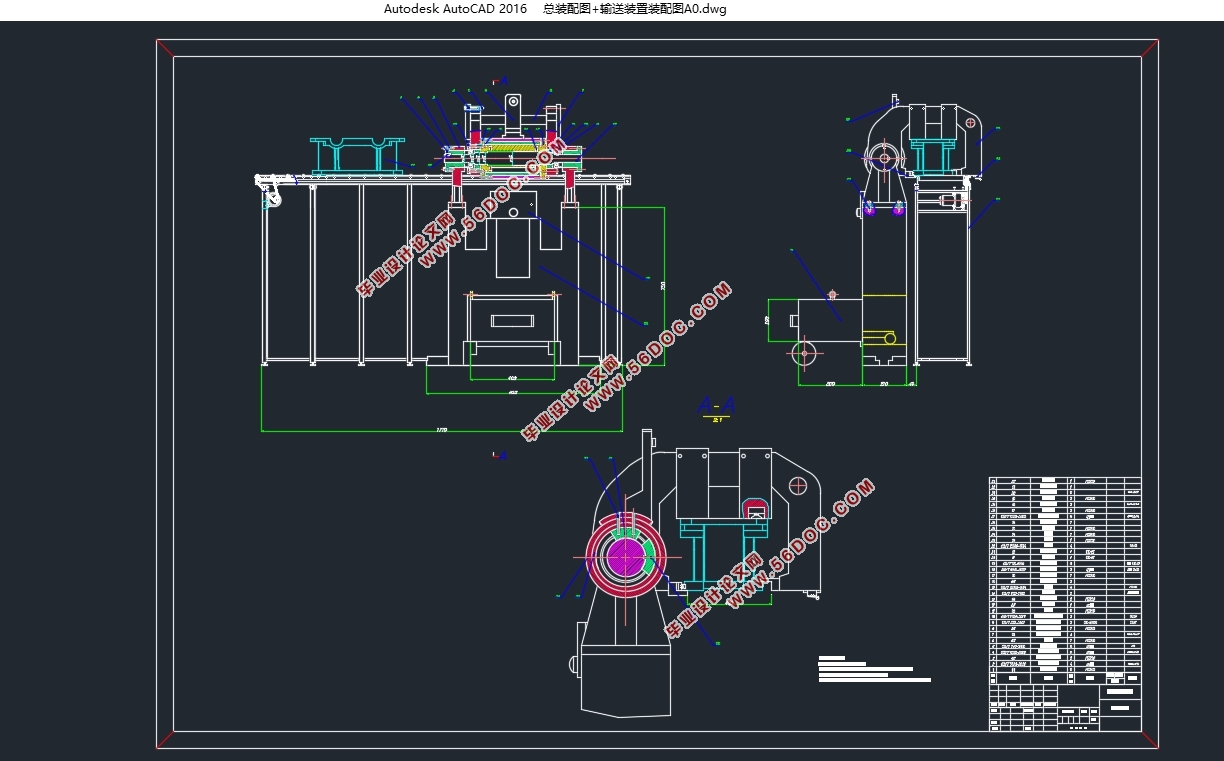

本次设计的装置为变速箱自动输送线及可控多循环翻转排屑装置,此装置用于变速箱自动生产线上解决变速箱体自动运输至指定装置并清理内部或表面残存切屑的问题。本装置分为三个主要装置,分别为翻转装置,振荡装置和输送装置。翻转装置用于实现将变速箱体翻转接近180°的功能;振荡装置实现箱体零件的小角度快速上下振动,帮助其排屑;输送装置用于运送箱体零件至生产线上各个装置的指定位置。

本次设计的翻转振荡排屑装置可在无人操控下全自动运行。依靠箱体在输送线上不同位置时,通过触碰限位开关,并与其驱动装置中电磁阀与继电器的配合,控制油泵吸油排油,进而带动翻转装置中回转油缸转动,通过振荡装置中循环油路实现振荡,实现整个装置的全自动运行。本次设计主要分为四个部分:翻转装置部分、振荡装置部分和输送滚道部分和液压回路部分。翻转装置设计部分,主要进行翻转装置中回转油缸的零件参数设计,翻转叶片、翻转轴等零件的参数设计与强度校核。由于翻转轴是非标准件,并通过键连接,所以进行了轴的强度校核与轴上键连接强度校核,以及相应轴承的选用和寿命计算。振荡装置设计部分,主要进行振荡循环油路的结构设计与油路的内径计算。输送装置设计部分,拟定使用链条链轮的传动方式,选用减速电动机驱动,并进行链条的型号选用与强度校核。液压系统设计部分,主要进行液压系统原理图的绘制;液压系统参数的计算以及液压泵,液压阀等液压回路中液压元件的选用。

关键词:翻转排屑;输送道;振荡装置;液压系统

Abstract

The device designed in this paper is the automatic transmission line of gearbox and the controllable multi-cycle turnover chip removing device, which is used in the gearbox automatic production line to solve the problem of gearbox body automatically transporting to the designated device and cleaning the residual chip inside or on the surface. This device is divided into three main devices, namely, turnover device, oscillation device and conveying device. The turning device is used to turn the gearbox body nearly 180°. The oscillating device can quickly vibrate up and down with small Angle of the box parts to help them to remove scraps. The conveyor is used to transport the box parts to the designated position of each device on the production line.

The chip removal device designed in this paper can run automatically under unmanned control. When the box is at different positions on the conveying line, the limit switch is touched and the solenoid valve and relay in the driving device are coordinated to control the oil absorption and discharge of the oil pump, which drives the rotary cylinder in the turnover device to rotate and realize the oscillation through the circulating oil circuit in the oscillation device, realizing the full automatic operation of the whole device. This design is mainly divided into four parts: the turning device part, the oscillating device part, the conveying raceway part and the hydraulic circuit part. In the design part of the turnover device, it mainly designs the parameters of parts of the rotary cylinder in the turnover device, as well as the parameters design and strength check of parts such as the turnover blade and the turnover shaft. Since the turning shaft is not a standard part and is connected by keys, the strength check of the shaft and the strength check of the key connection on the shaft are carried out, as well as the selection and life calculation of the corresponding bearing. The design part of the oscillating device is mainly about the structural design of the oscillating circulating oil circuit and the calculation of the inner diameter of the oil circuit. In the design part of conveying device, the transmission mode of chain sprocket wheel is proposed, the reducer motor is selected to drive the chain, and the model selection and strength check of the chain are carried out. Hydraulic system design part, mainly for hydraulic system schematic drawing; Calculation of hydraulic system parameters and selection of hydraulic components in hydraulic circuits such as hydraulic pumps and valves.

Key Words:Flip chip removal;Delivery way;Oscillation device;The hydraulic system

本章主要进行翻转装置内执行元件参数的设计确定,非标准零件强度校核以及连接方式强度校核。

2.1变速箱体参数确定

由于翻转装置中翻转架的尺寸需要通过变速箱体的尺寸来确定,非标准件的强度校核也与变速箱体的质量有关。所以首先确定变速箱体的各项参数显得尤其重要。

箱体材料:HT250

箱体尺寸:长430mm,宽275mm,高202mm

箱体总体质量:32.43kg

目 录

第1章 绪论 1

1.1本次设计装置的发展现状及趋势 1

1.2本次设计的目的及意义 1

1.3本次设计的主要内容 2

1.4装置的整体运行方案与三维模型示意图 2

第2章 翻转装置整体设计 6

2.1变速箱体参数确定 6

2.2翻转机构设计 7

2.2.1翻转机构中回转油缸设计 7

2.2.2回转油缸主要尺寸的确定 8

2.2.3回转油缸缸筒的尺寸与结构设计 8

2.2.4翻转轴主要参数设计与校核 9

2.2.5定叶片上键连接强度校核 10

2.2.6轴承的选用与寿命计算 11

2.2.7轴承座的选用 11

2.2.8翻转装置中密封零件选用 12

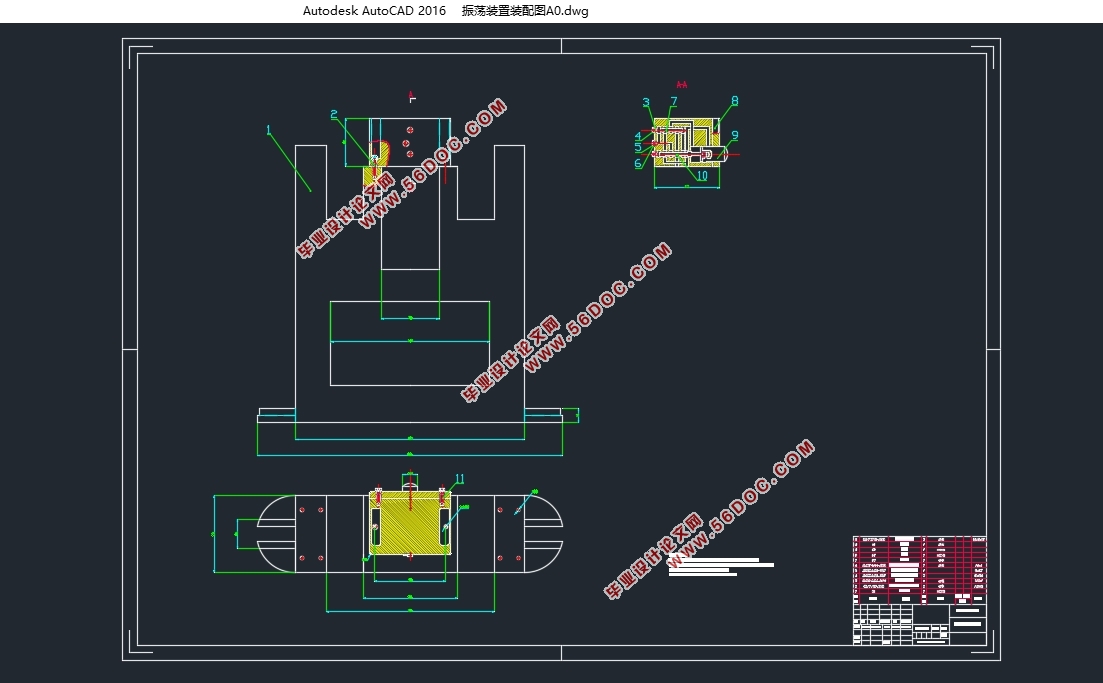

第3章 振荡机构整体设计 12

3.1振荡循环油路整体方案选择与设计 12

3.2振荡机构各项参数确定 13

3.3振荡机构内部结构设计 14

第4章 液压系统设计 14

4.1液压系统特点分析 14

4.2液压系统工况分析 15

4.3确定供油路线 15

4.3.1液压回路设计 15

4.3.2液压系统原理图设计 15

4.4液压元件的计算与选择 17

4.4.1液压泵的选择 17

4.4.2驱动液压泵电动机的计算与选择 17

4.4.3阀类元件及辅助元件选择 18

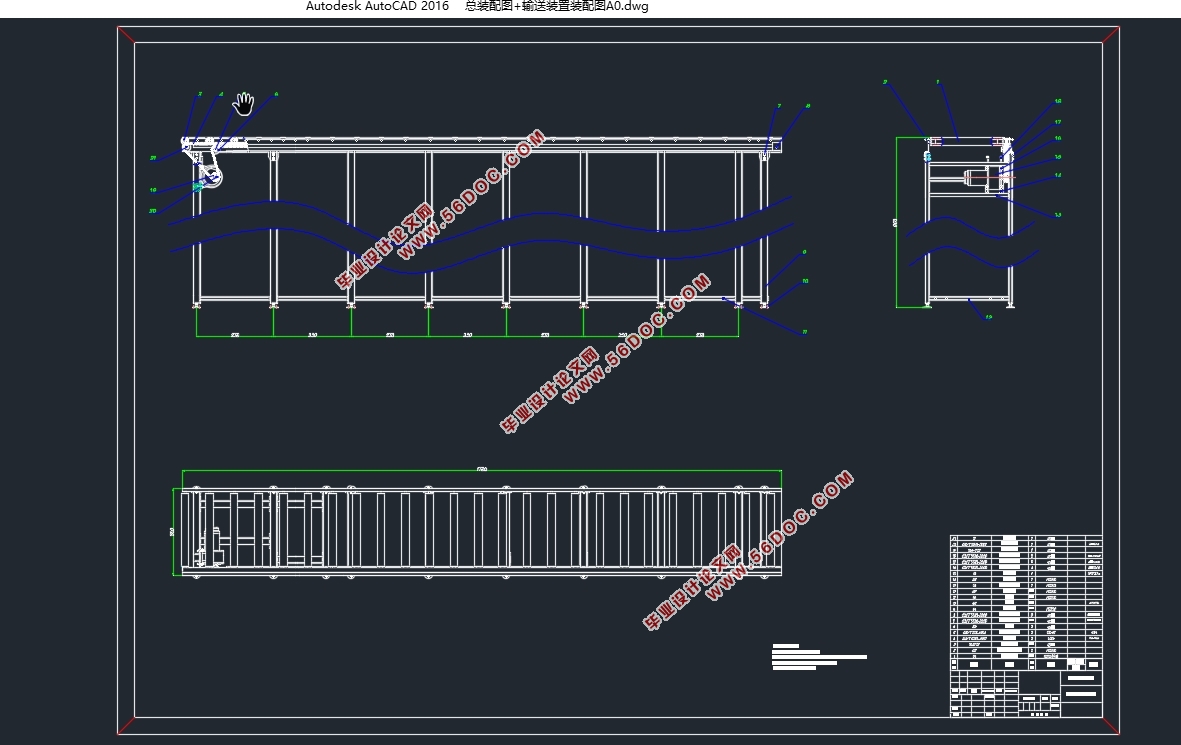

第5章 输送装置整体设计 19

5.1整体输送方案的选择 19

5.2输送装置减速机的选择 19

5.3链条设计与强度校核 19

5.3.1链条的选用 19

5.3.2链条润滑方式的选择 20

5.3.3链传动的强度校核 20

5.3.4链轮的参数确定 20

参考文献 21

致谢 21

|