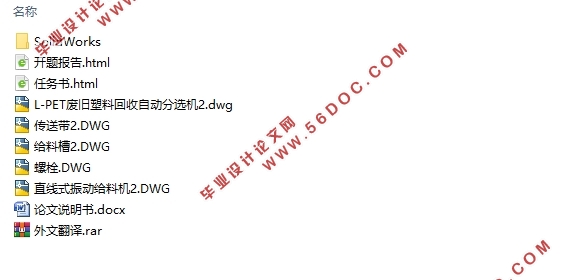

L-PET废旧塑料回收自动分选机(含CAD零件图装配图,SolidWorks三维图)(任务书,开题报告,外文翻译,论文说明书11000字,CAD图5张,SolidWorks三维图)

中文摘要

如今,塑料已经成为人们生活中不可或缺的必需品,塑料行业的发展也越来越快,几乎各行各业都会使用到塑料制品。但是,随着塑料制品的大量被使用,塑料所造成的环境污染越来越严重,废旧塑料的有效回收问题也越来越突出。废旧塑料不仅破坏自然环境和人们的生活环境,同时其自身还蕴藏着巨大的价值,若能够被有效的回收利用,则可以为新塑料制品的制作节省很多材料。目前我国的塑料回收分类技术以人工分拣为主,不仅耗费人力,而且效率较低。相比较之下,采用自动分选装置进行分选不仅可以提高分选效率,而且可以减少对人力的耗费。

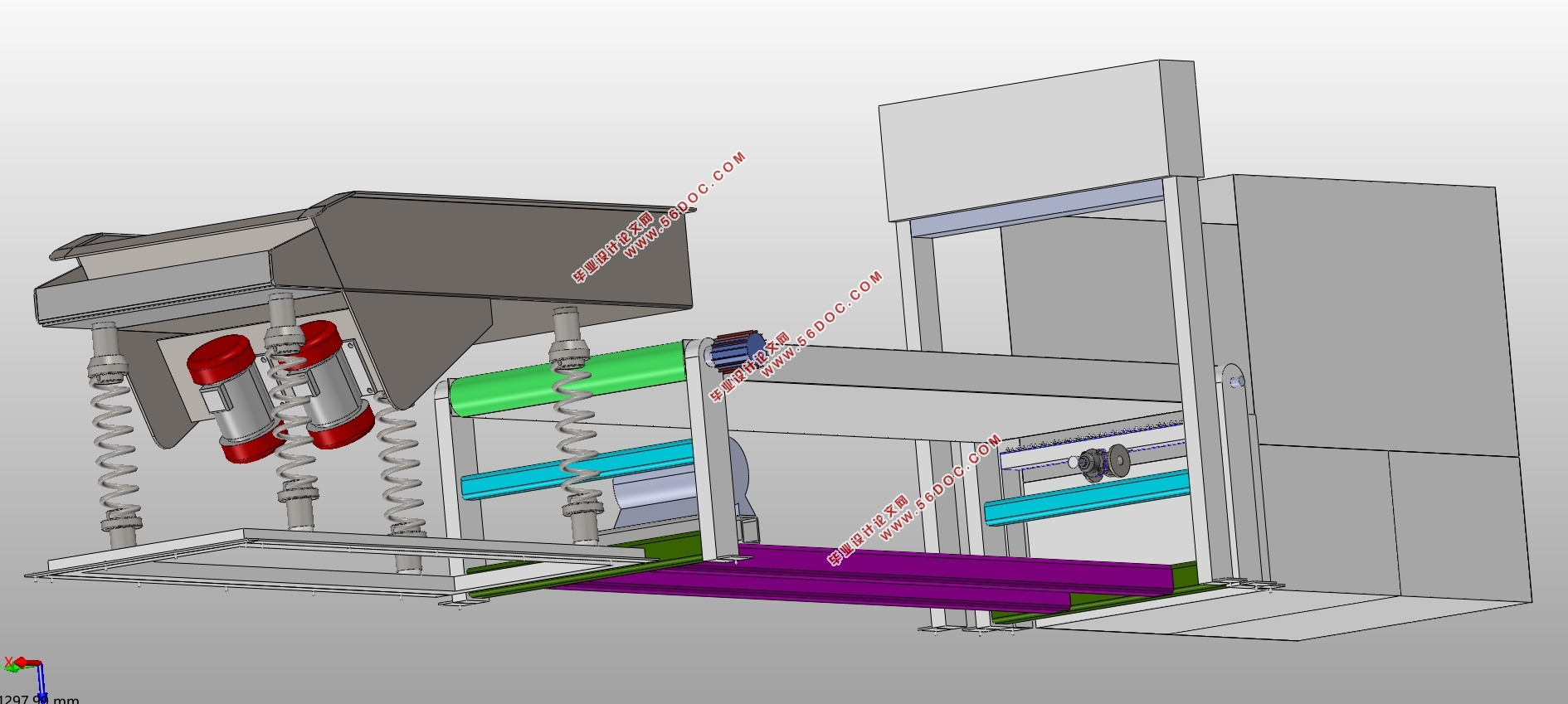

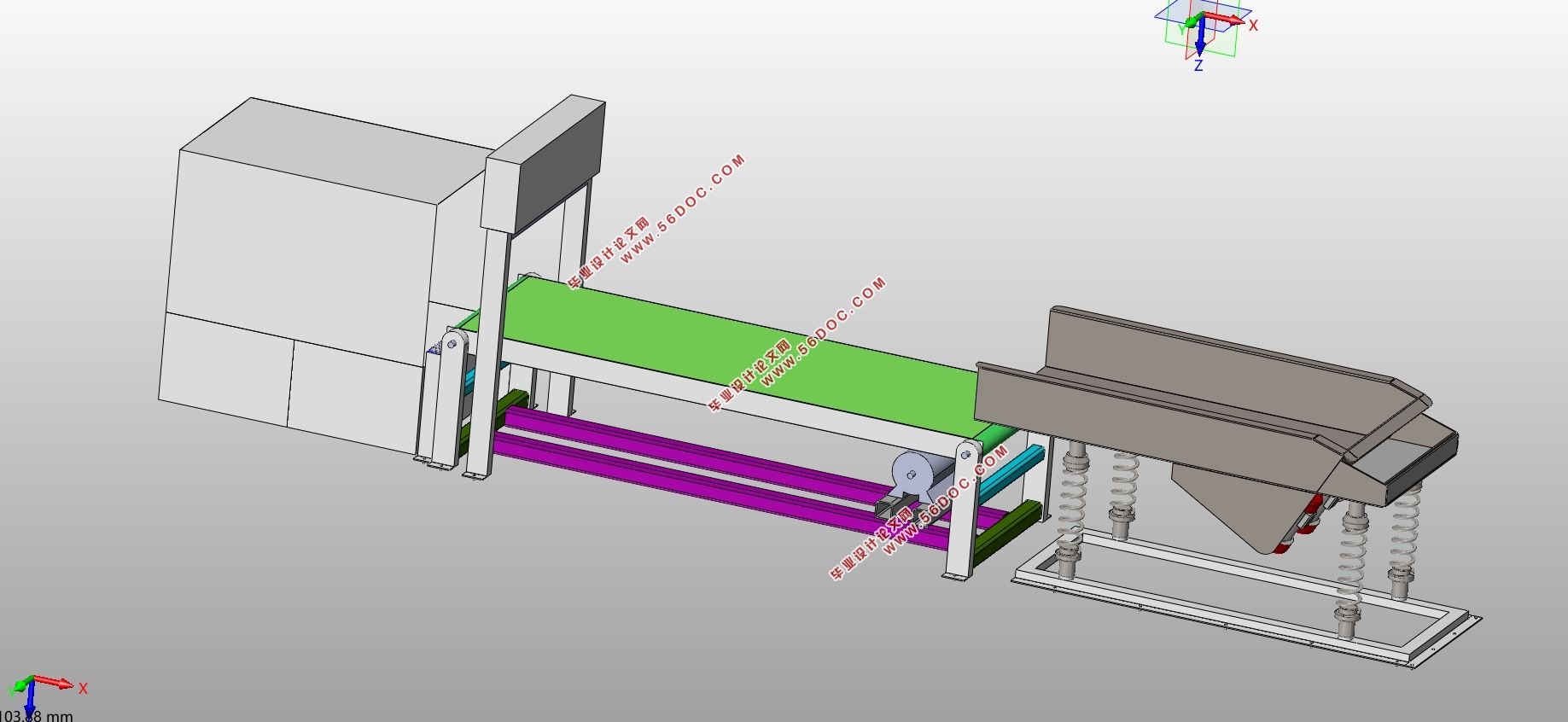

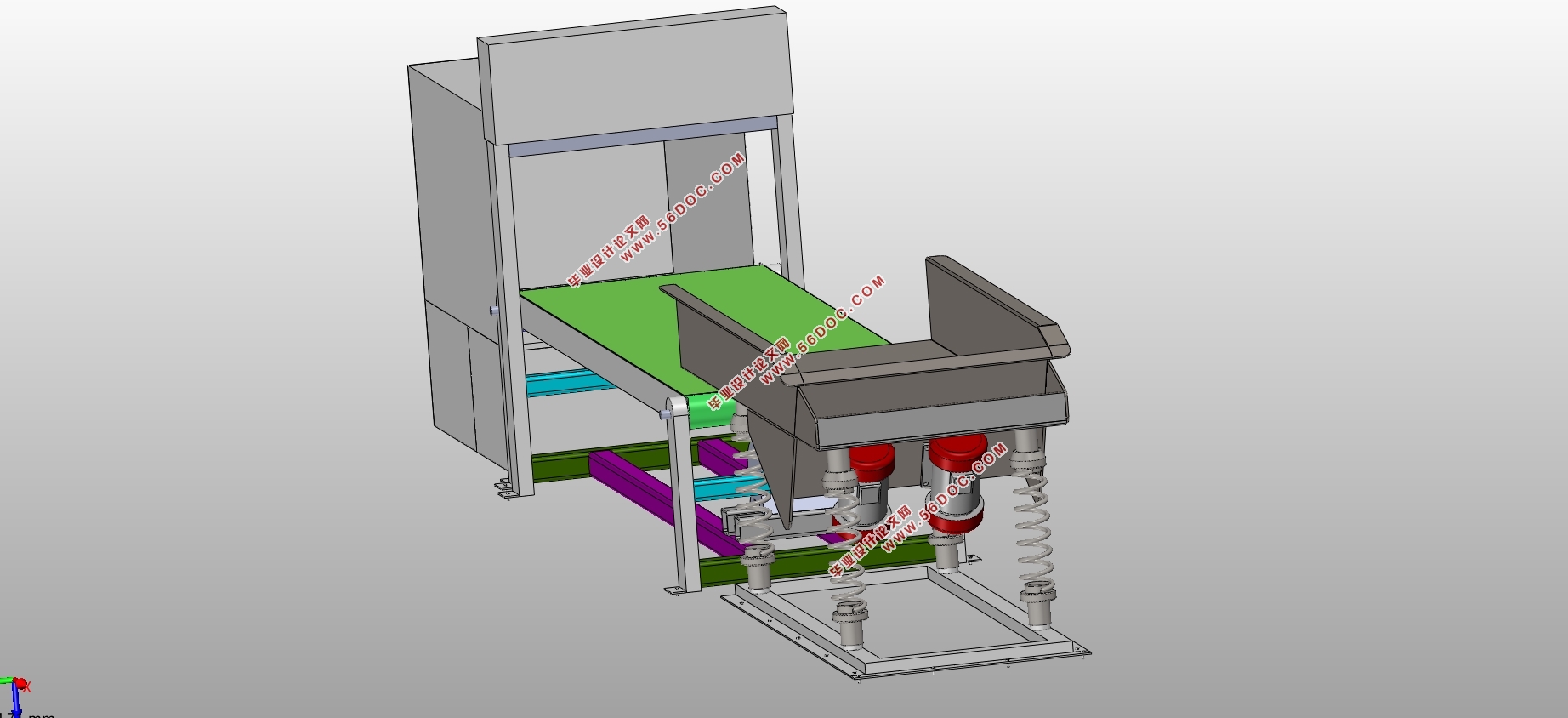

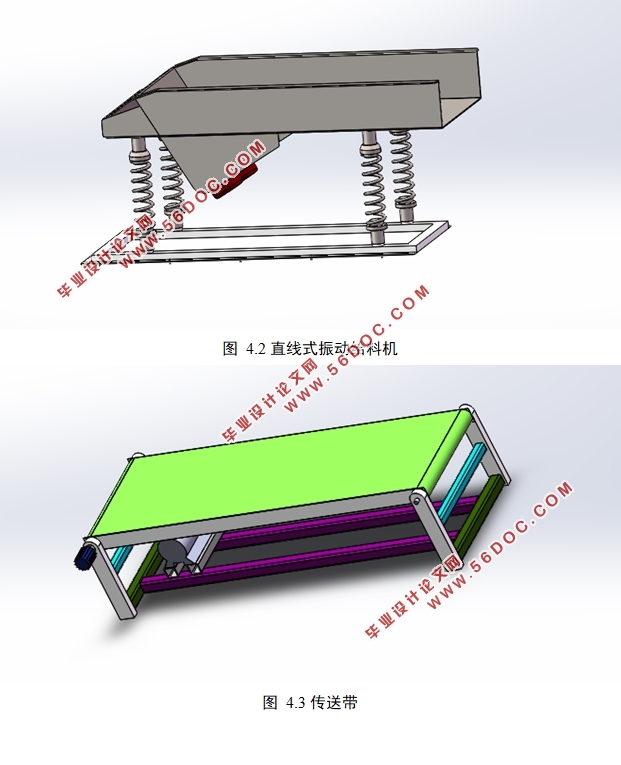

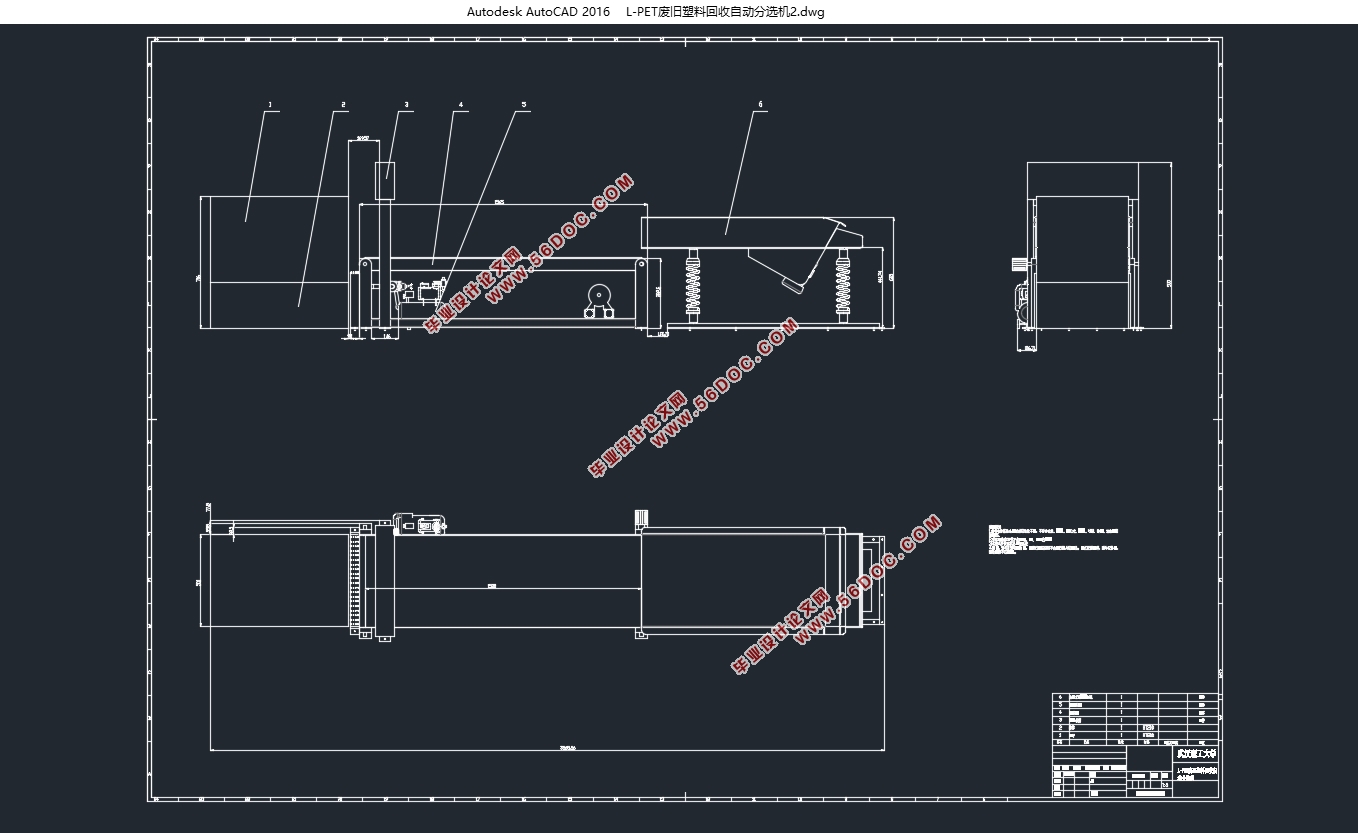

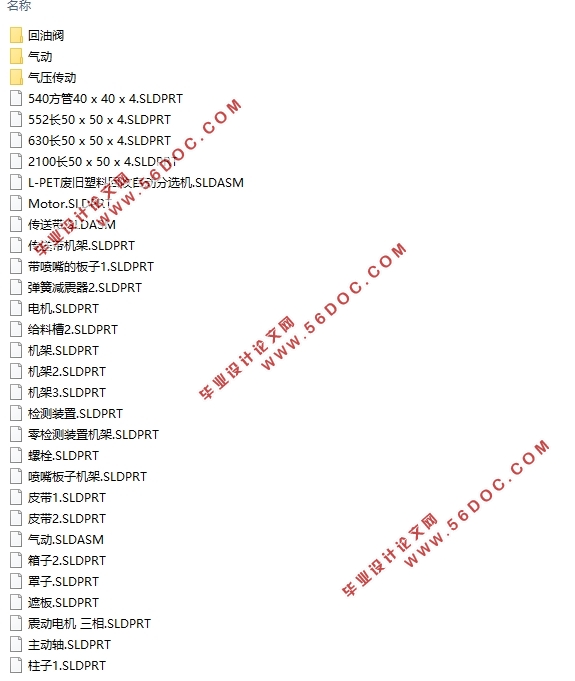

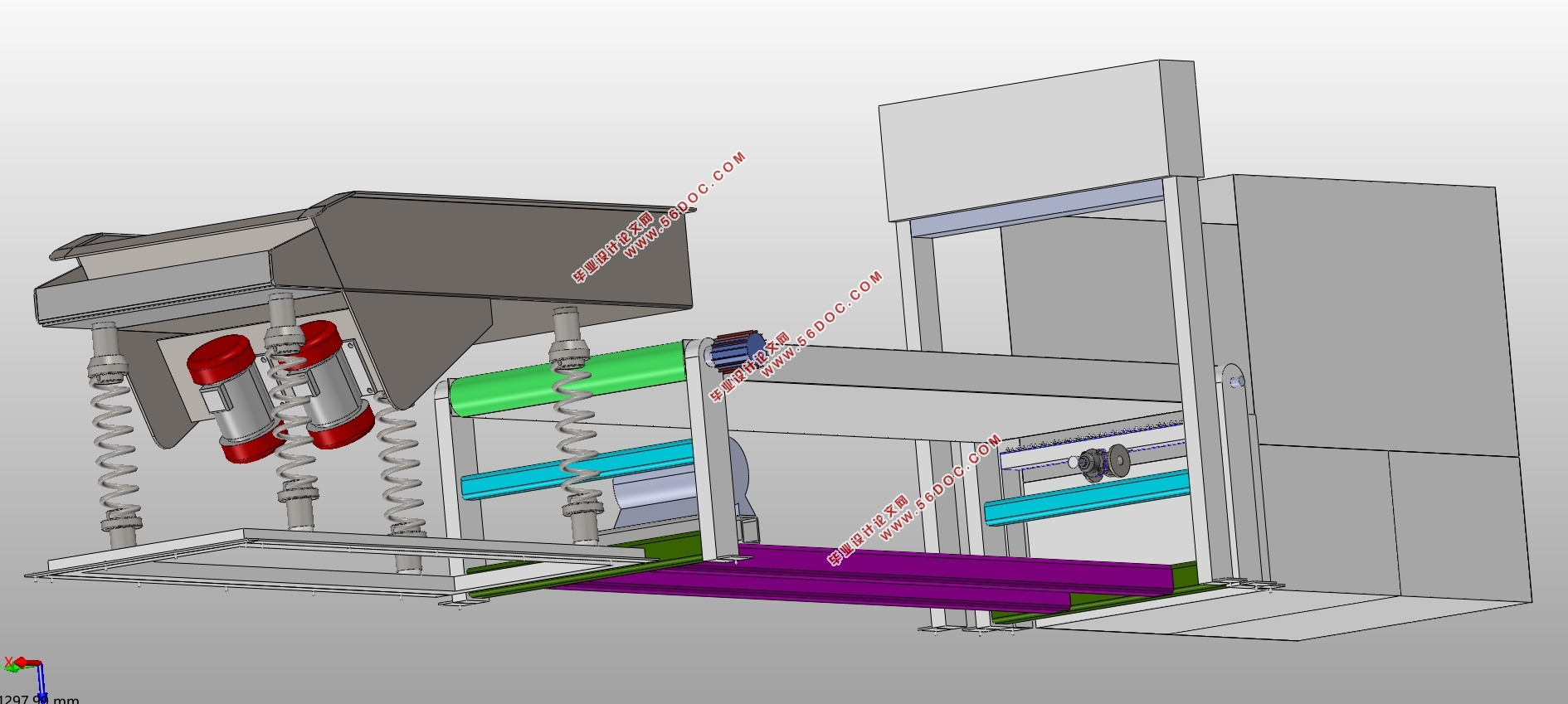

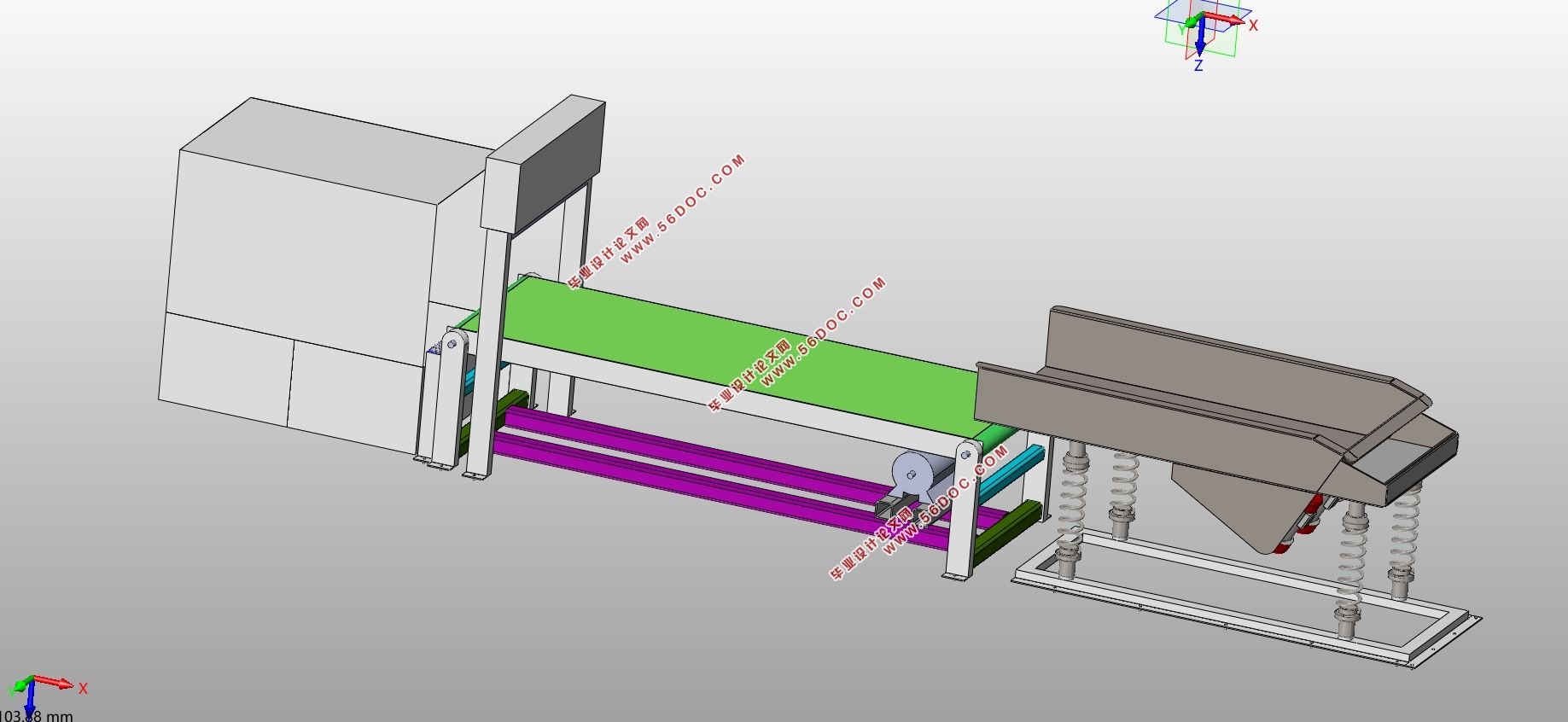

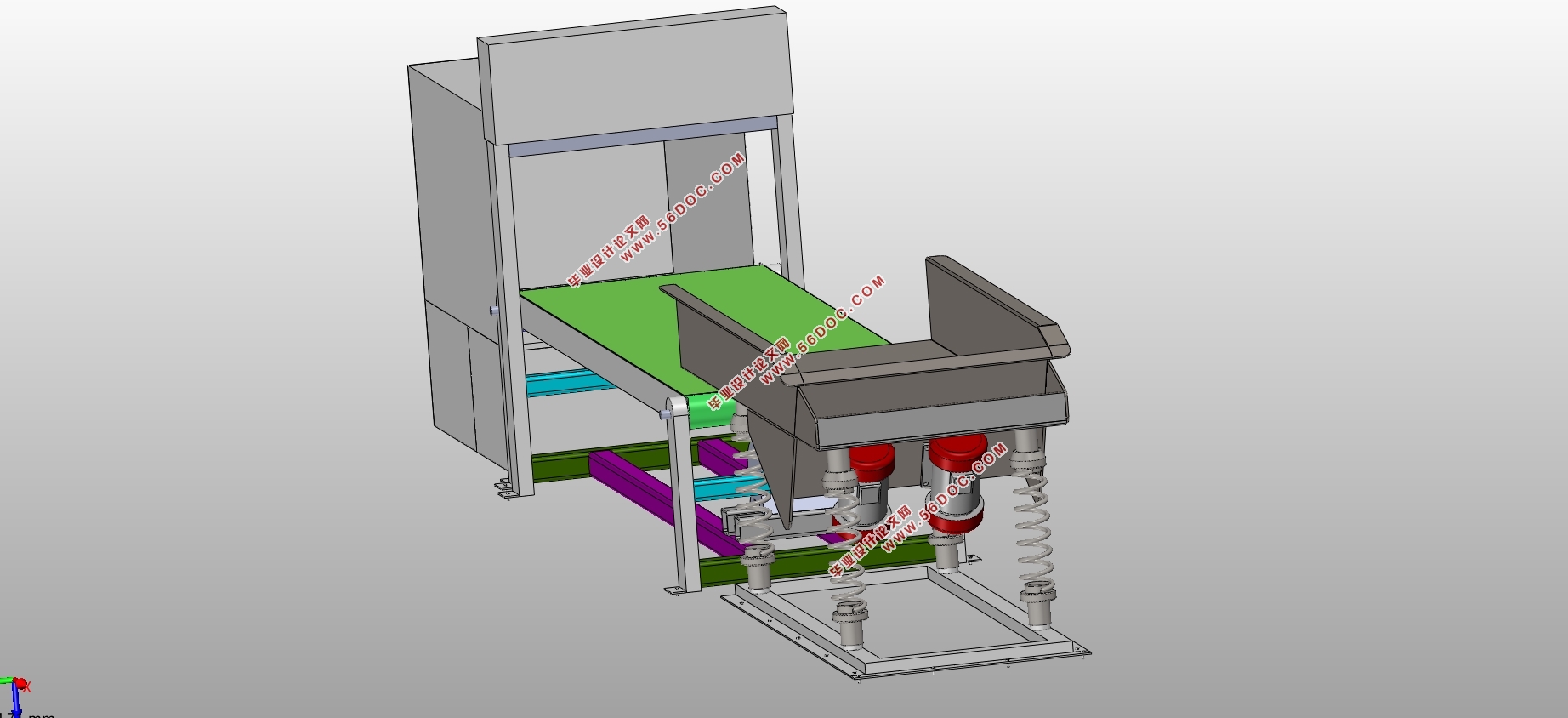

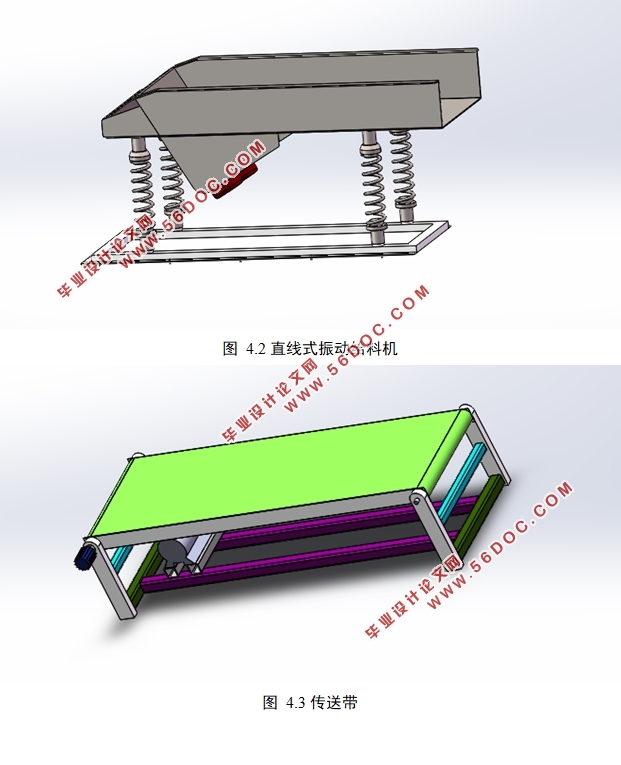

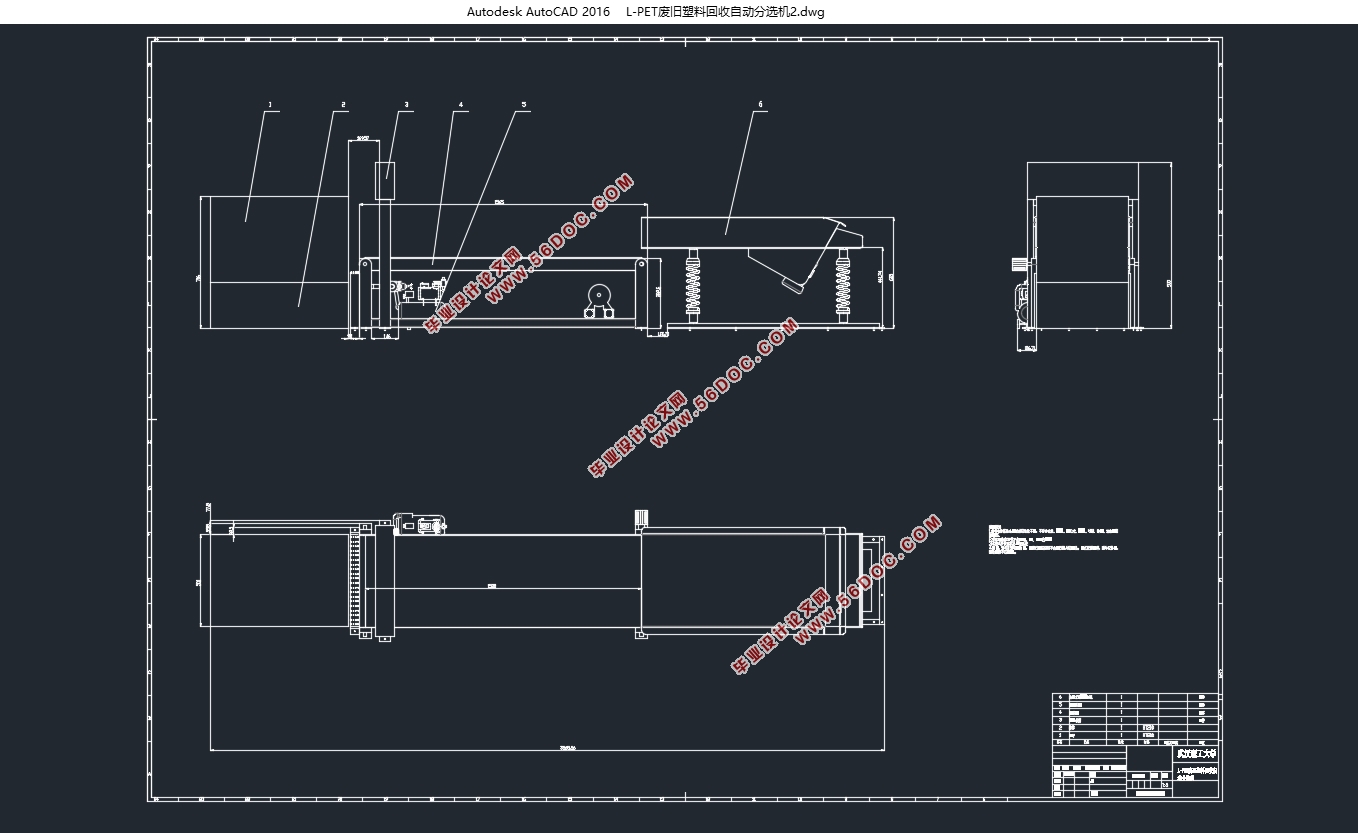

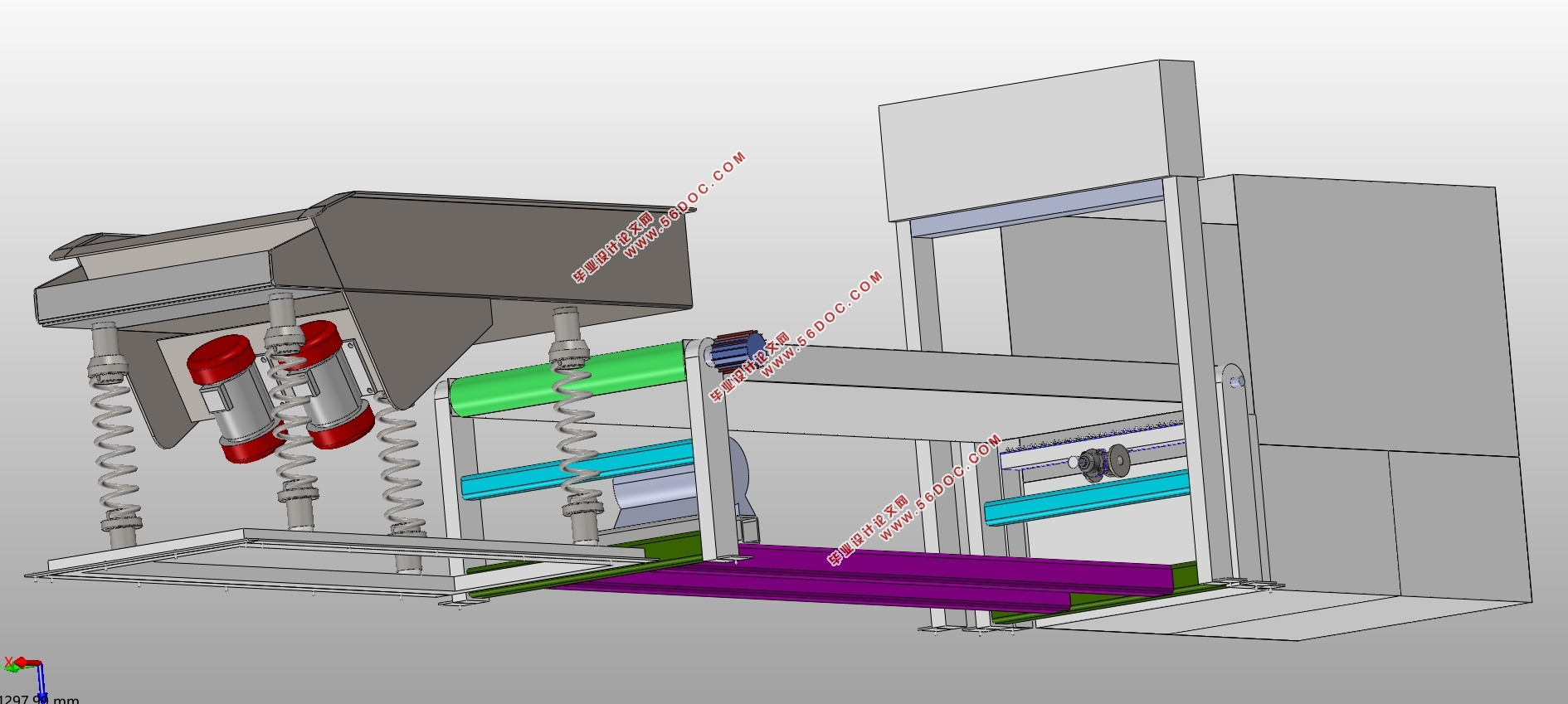

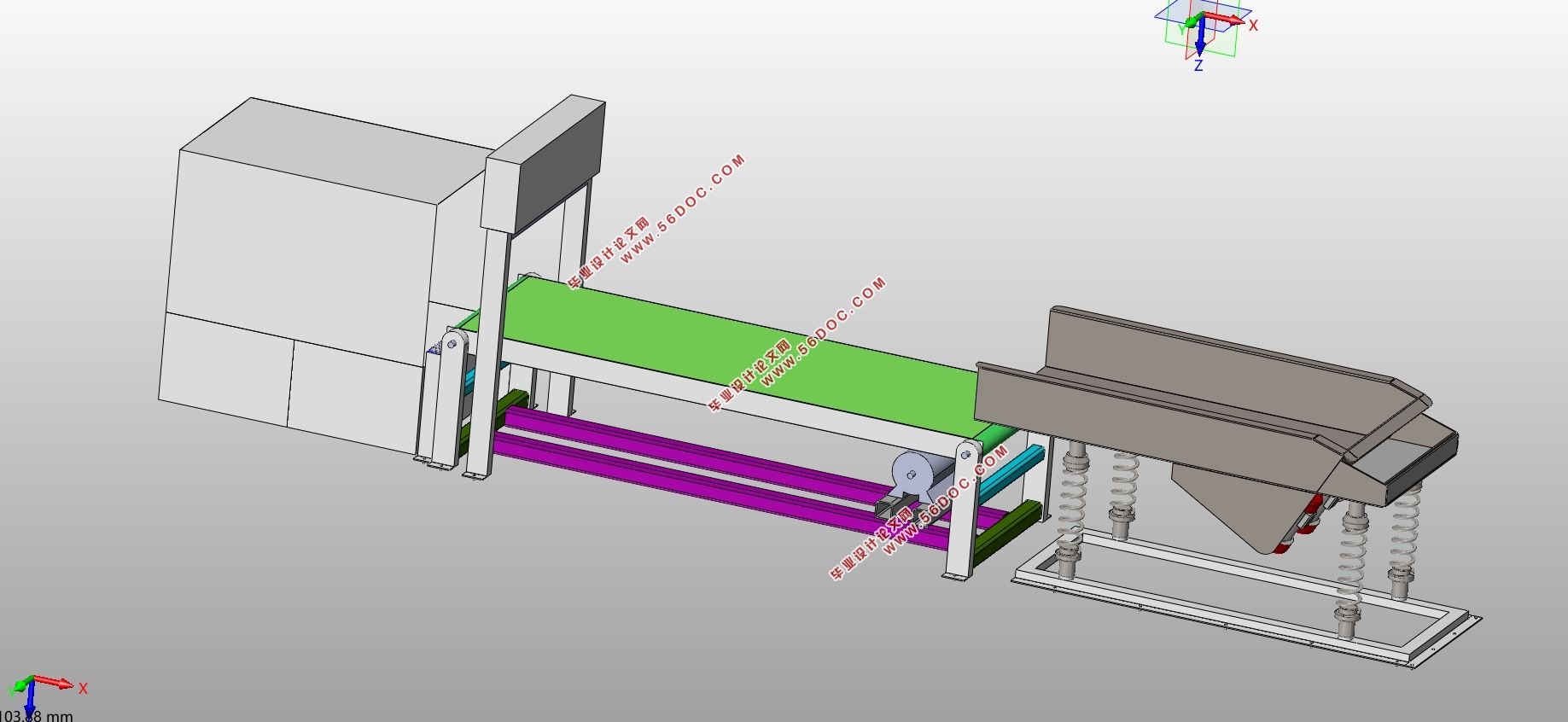

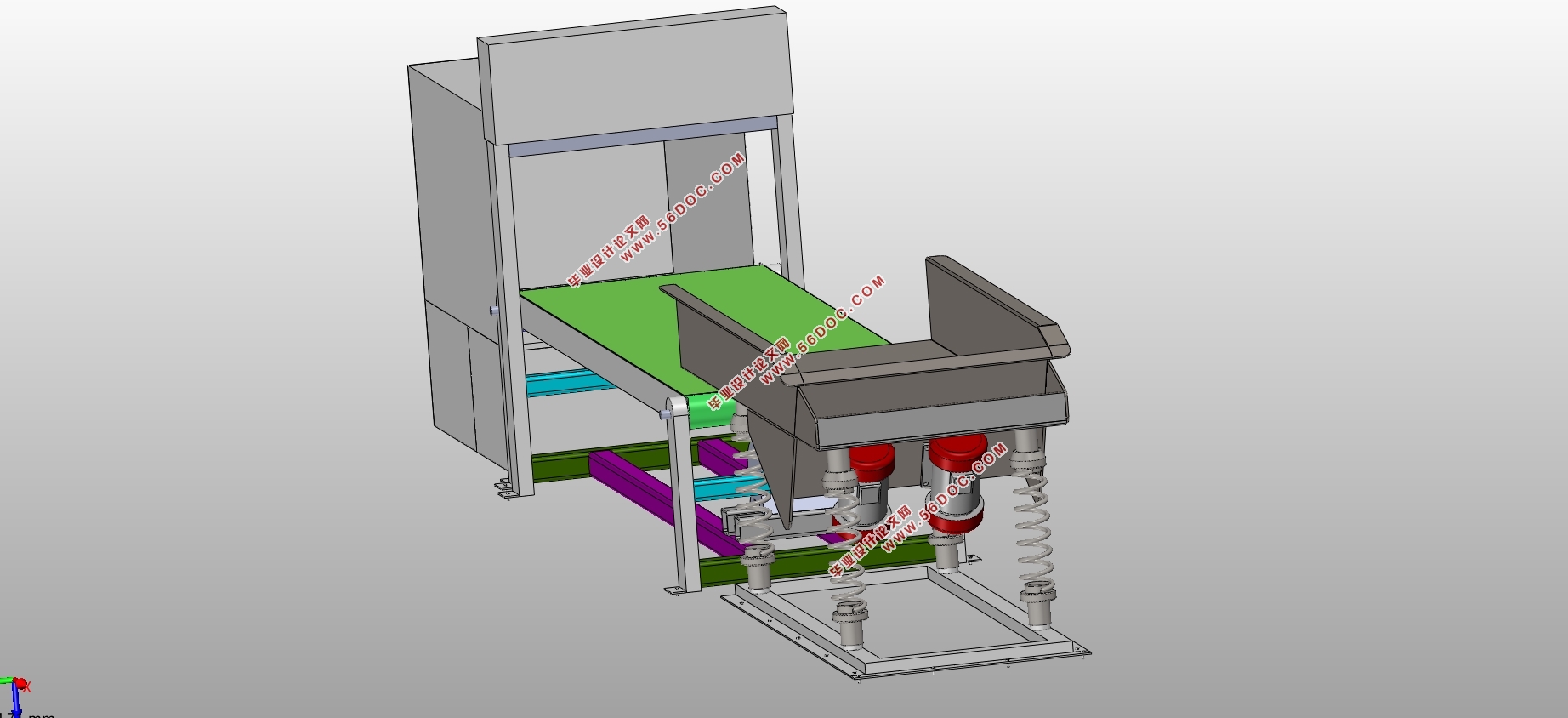

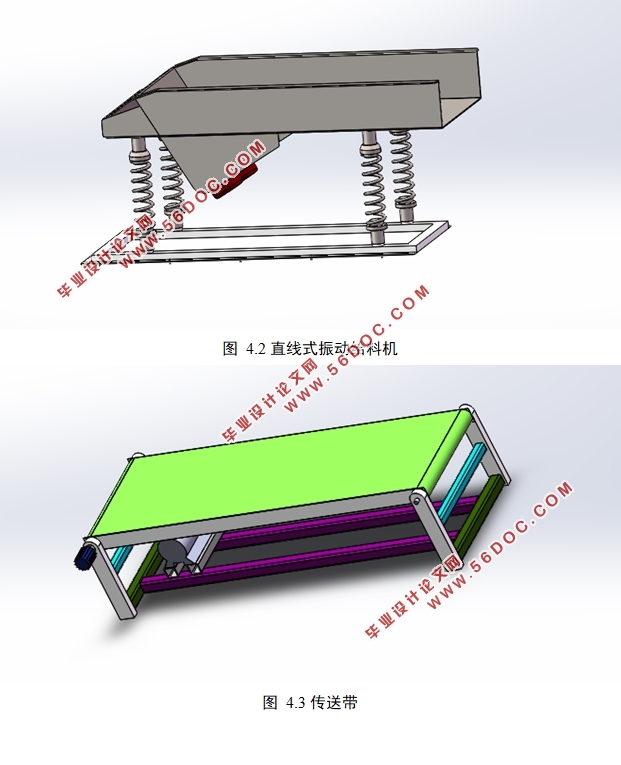

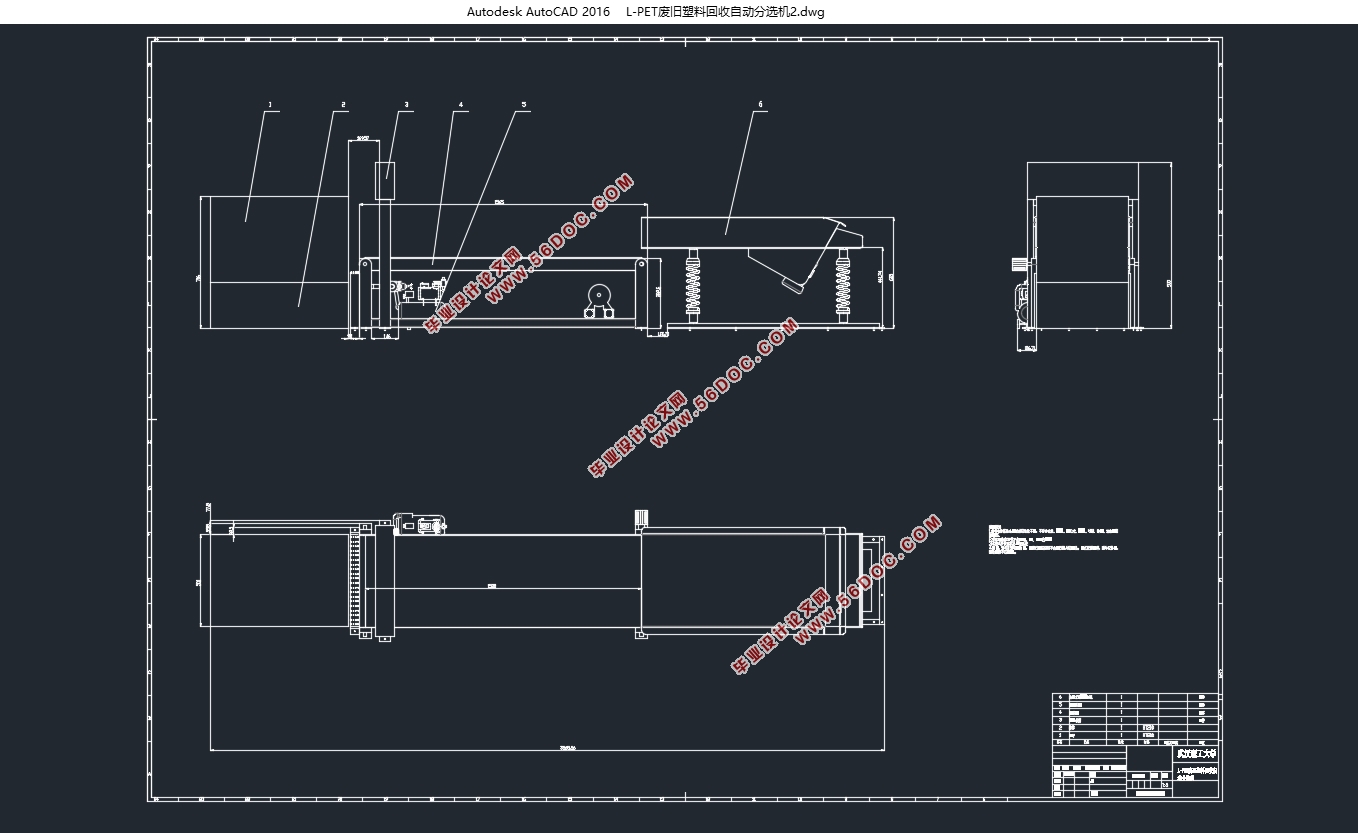

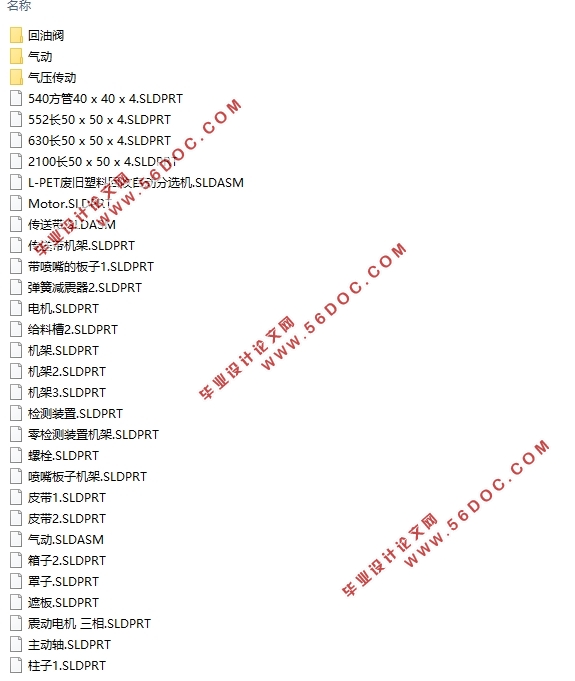

本次设计为L-PET废旧塑料回收自动分选机设计,其主要结构为直线型振动给料器,传送带和气流分选装置,其中以直线型振动给料器和气流分选装置为主。直线型振动给料器设计包括整体的结构设计,槽体的结构设计,减震装置的设计,减震弹簧的校核,振动电机的选择和振动电机的参数计算等。传送带的设计以皮带的尺寸和传送机的高度等为主。气流分选装置的设计包括气压传送系统的设计、相关设备的选型以及箱体的设计等。

关键词:废旧塑料回收;自动分选机;直线型振动给料机;气流分选装置

Abstract

Nowadays, plastics have become an indispensable necessities in people's lives. The development of the plastics industry is also getting faster and faster. Plastic products are used in almost every industry. However, with the large number of plastic products being used, the environmental pollution caused by plastics has become more and more serious, and the problem of effective recycling of waste plastics has become increasingly prominent. Waste plastics not only destroy the natural environment and people's living environment, but also contain huge value. If they can be effectively recycled, they can save a lot of materials for the production of new plastic products. At present, China's plastic recycling classification technology is mainly manual sorting, which not only consumes manpower but also has low efficiency. In contrast, the use of automatic sorting devices for sorting not only improves sorting efficiency, but also reduces manpower cost.

This design is designed for L-PET waste plastic recycling automatic sorting machine. Its main structure is linear vibrating feeder, conveyor belt and air flow sorting device, among which linear vibrating feeder and air flow sorting device are the main ones. The linear vibrating feeder design includes the overall structural design, the structural design of the tank body, the design of the damping device, the check of the damping spring, the selection of the vibration motor and the calculation of the parameters of the vibration motor. The design of the conveyor belt is mainly based on the size of the belt and the height of the conveyor. The design of the air separation device includes the design of the air pressure transmission system, the selection of the relevant equipment, and the design of the tank.

Keywords: waste plastic recycling; automatic sorter; linear vibrating feeder; air separation device

目录

中文摘要 1

Abstract 2

目录 3

第1章 绪论 5

1.1目的及意义 5

1.2国内外现状 5

1.2.1国外研究现状 5

1.2.2国内研究现状 6

1.3研究内容 6

1.3.1研究内容 6

1.3.2研究目标 6

1.3.3技术方案及措施 7

第2章 给料机和传送带的设计 8

2.1直线型振动给料器的设计 8

2.1.1振动给料器的概述 8

2.1.2组成部分和工作原理 9

2.1.3给料机槽体的设计 10

2.1.4减震装置的设计 11

2.1.5机座的设计 13

2.1.6电机的选择和参数的计算 13

2.1.7紧固螺栓的选择 16

2.2传送带的设计 17

第3章 气流分选装置设计 18

3.1气流分选装置的概述 18

3.1.1气流分选装置的用途 18

3.1.2气流分选装置的组成 18

3.1.3气流分选装置的优点 19

3.2气流分选装置的结构及设计 19

3.2.1气源装置 19

3.2.2空气过滤器 20

3.2.3压力控制阀 20

3.2.4单向阀 20

3.2.5喷嘴 21

3.2.6箱体的设计 21

3.2.7风力分选的相关参数计算 22

第4章 建模与仿真 24

4.1废旧塑料回收自动分选机的建模 24

4.1.1建模软件的简介 24

4.1.2废旧塑料回收自动分选机的建模模型 24

4.2废旧塑料回收自动分选机的仿真 26

第5章 结论和展望 27

参考文献 28

致谢 28

|