城市立体车库结构设计与轻量化优化(含CAD零件图装配图)(任务书,开题报告,外文翻译,文献摘要,论文说明书21000字,CAD图11张)

摘要

伴随城市的城市发展,城市内汽车数量急剧增加,立体车库的发展成为城市立体化的一个必然趋势,在有限的土地资源上充分的利用空间,有效的解决当前大城市停车难的现状。本文主要对升降横移式立体车库进行结构设计并通过有限元的方法对立体车库框架钢结构进行静力学和动力学分析,在保证立体车库安全性和稳定性的前提条件下,对立体车库进行结构优化和轻量化设计,主要内容包括:

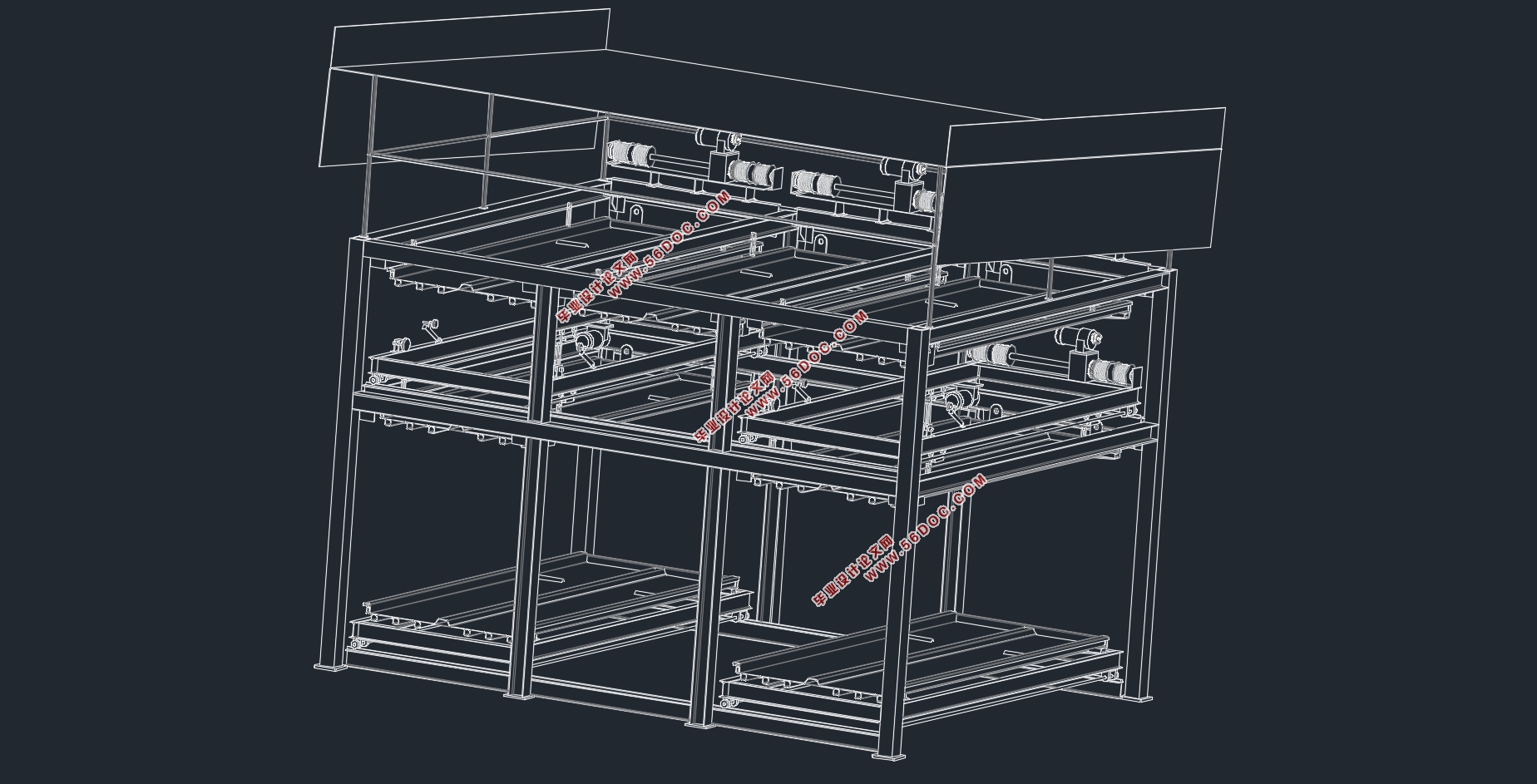

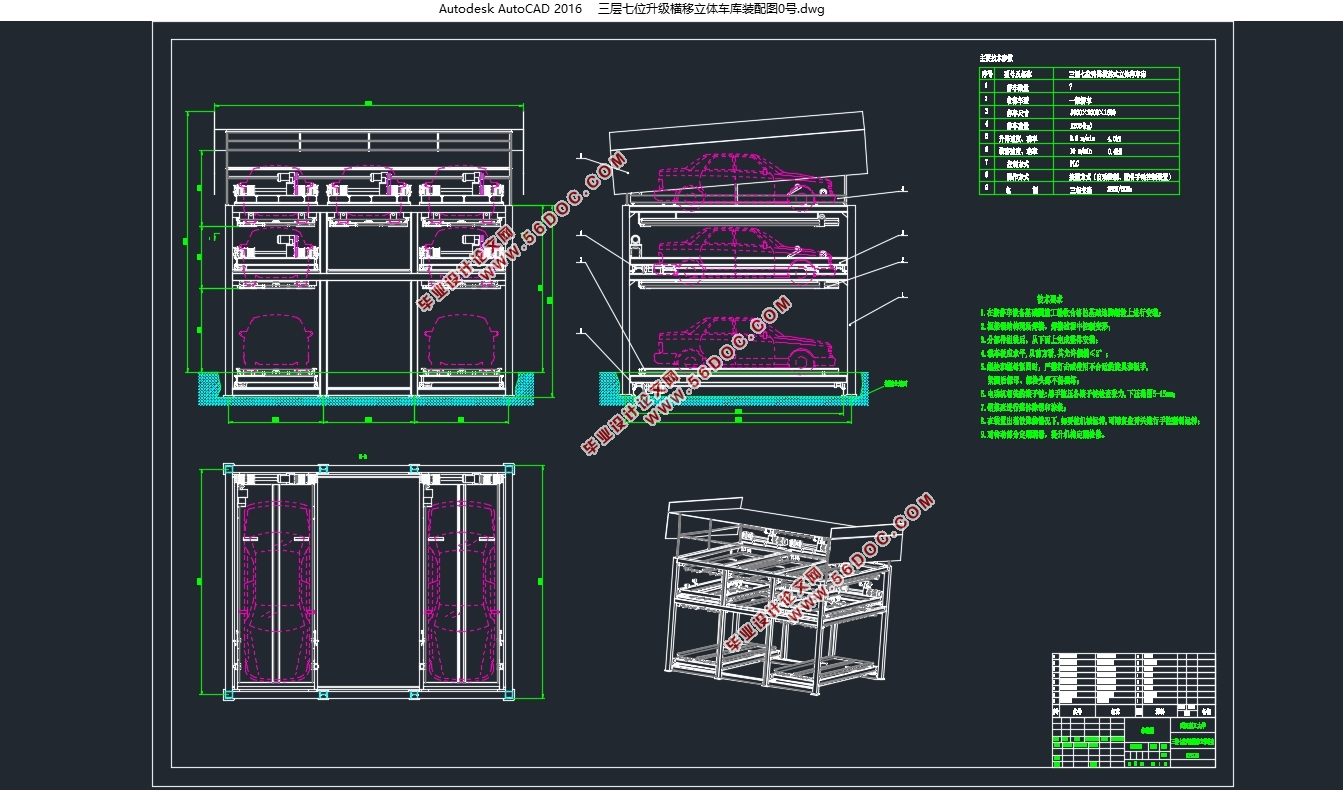

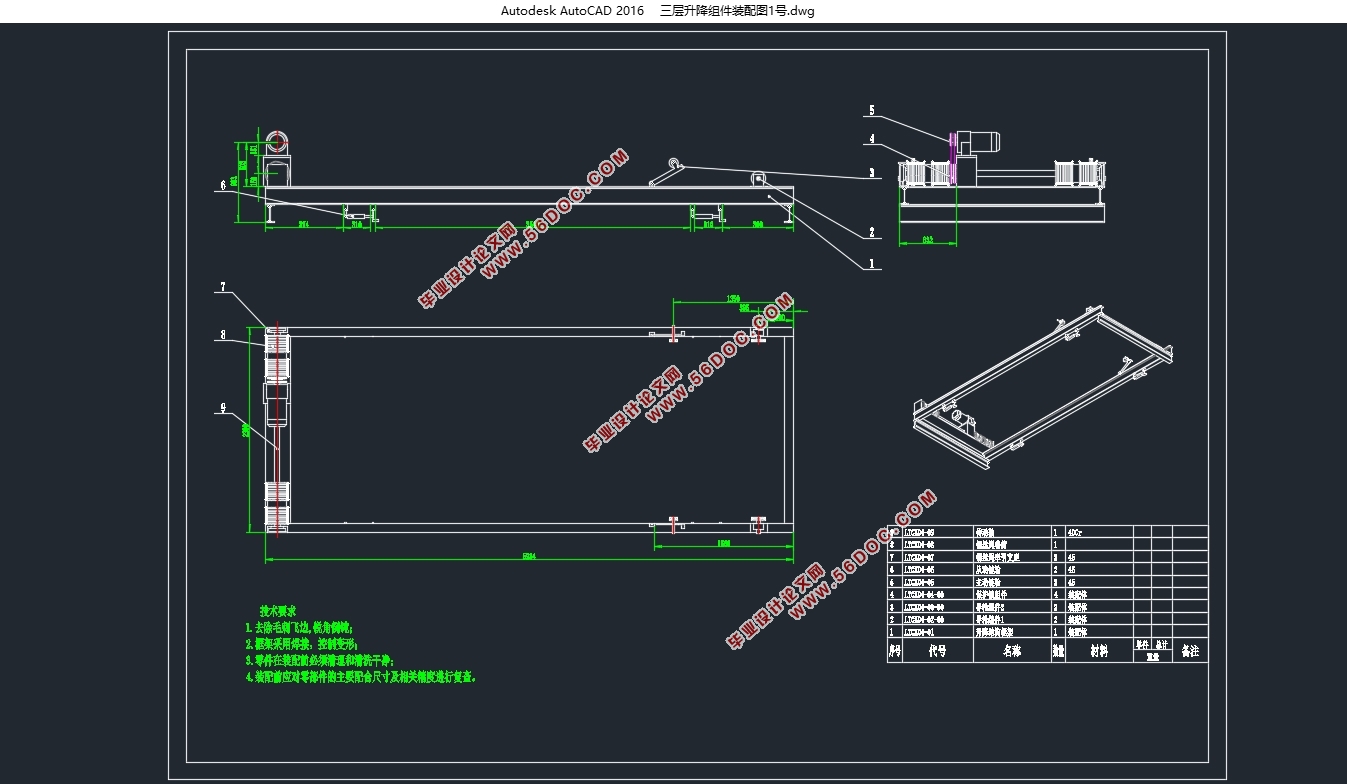

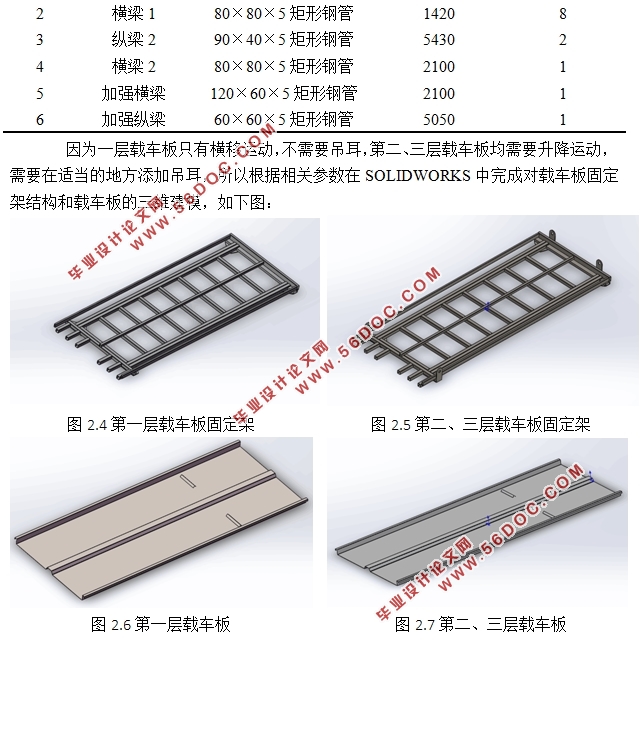

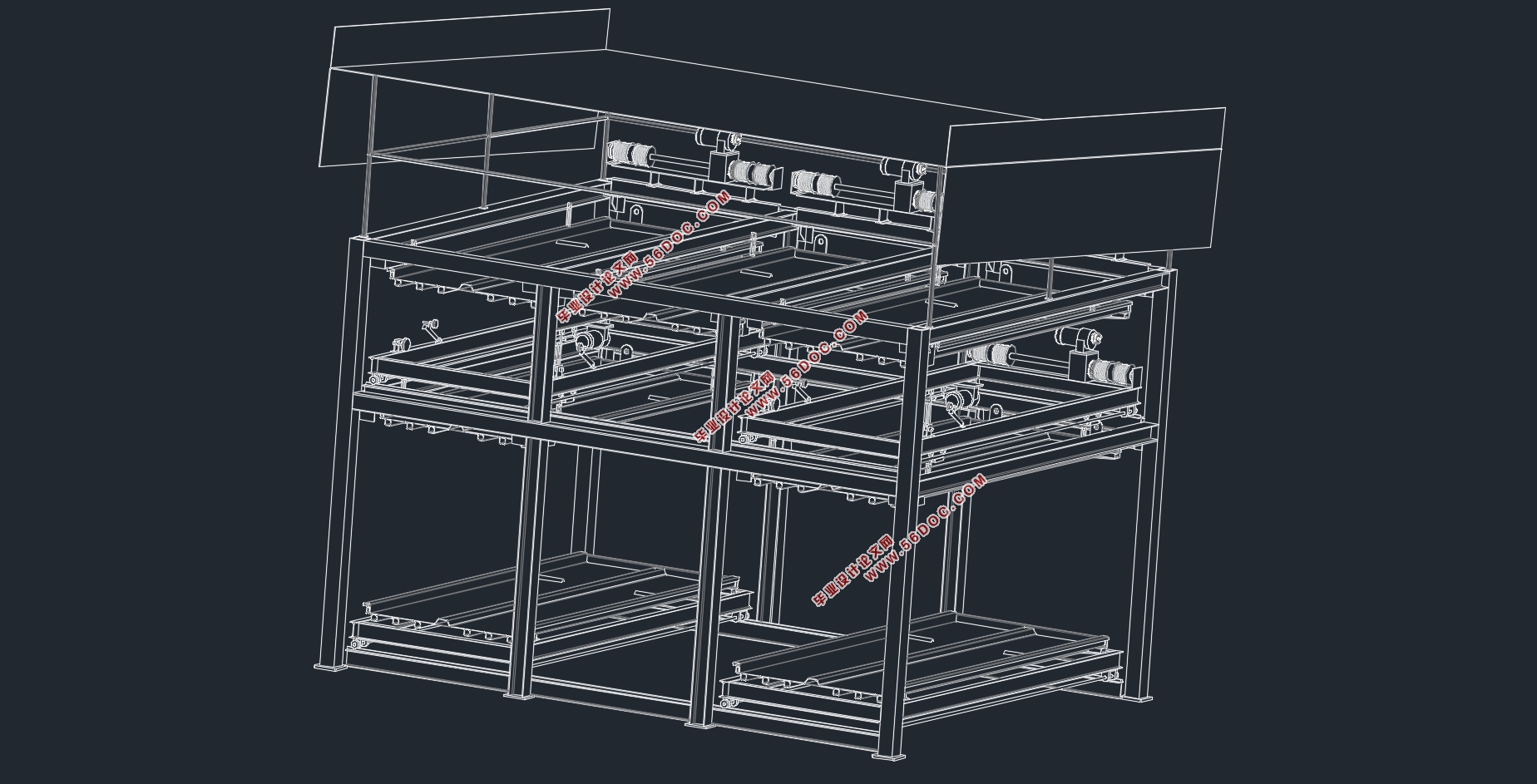

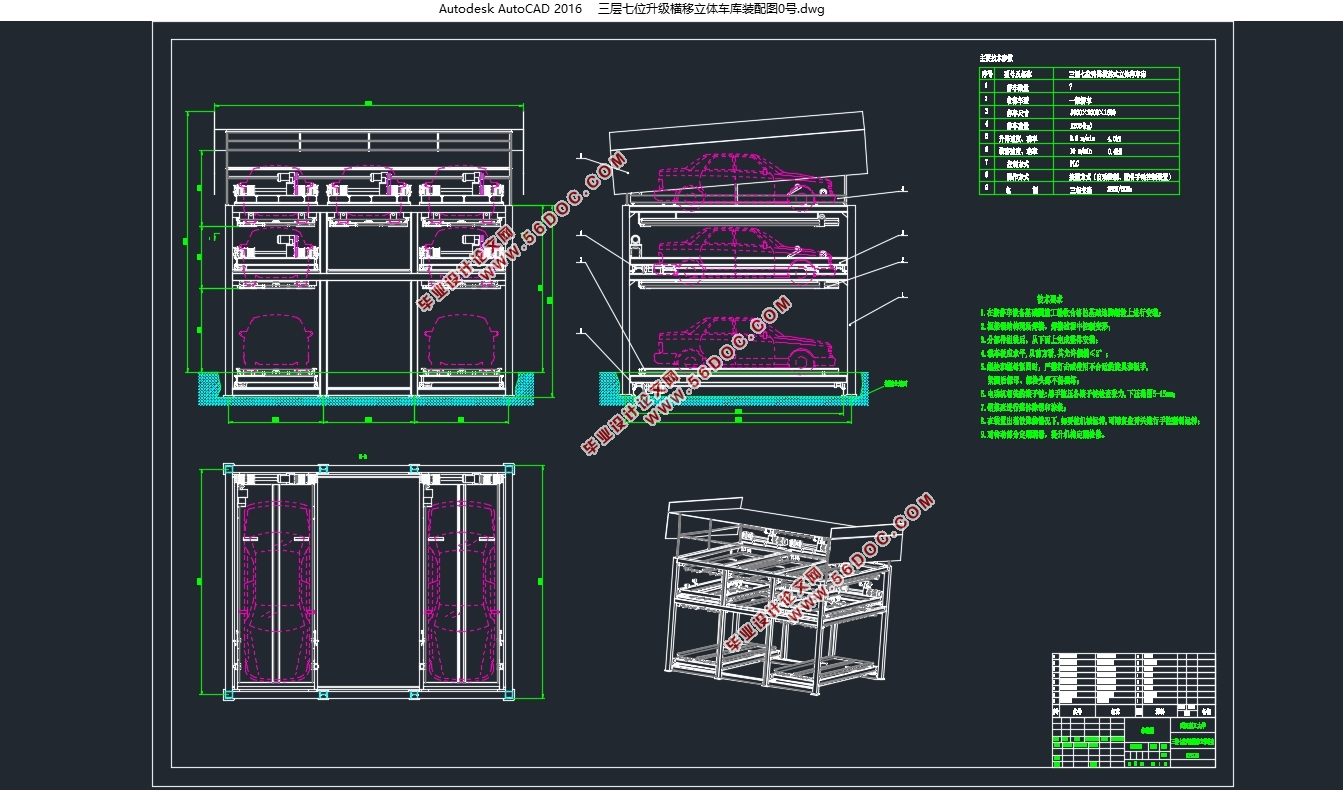

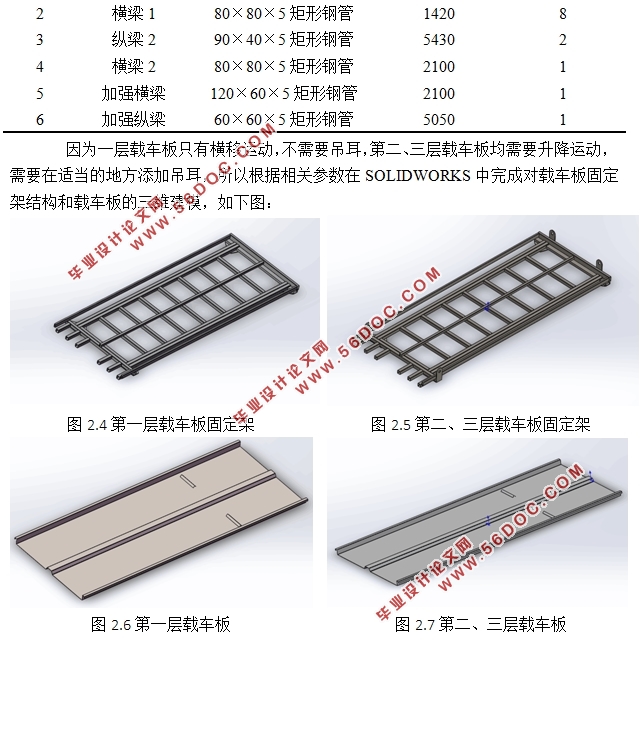

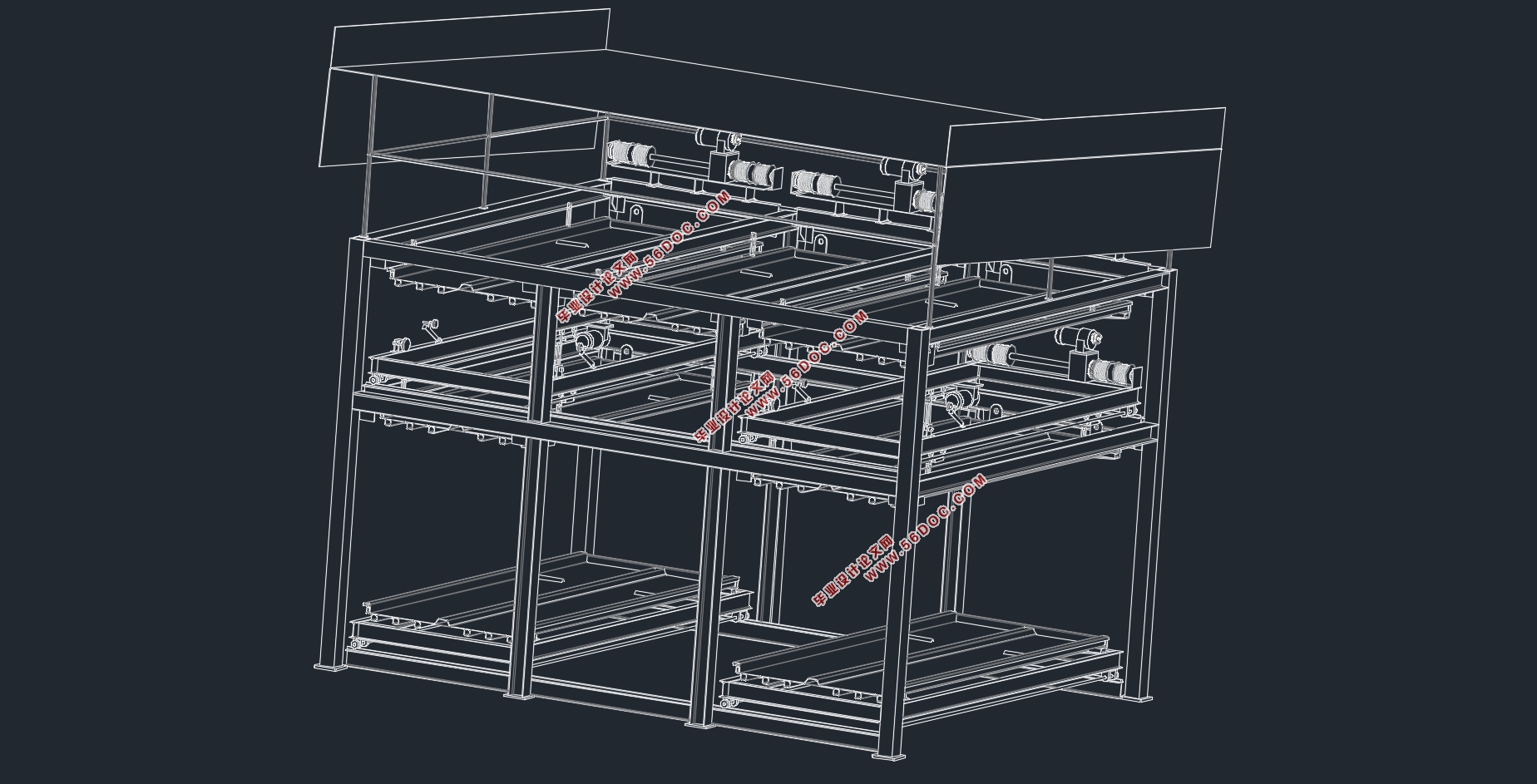

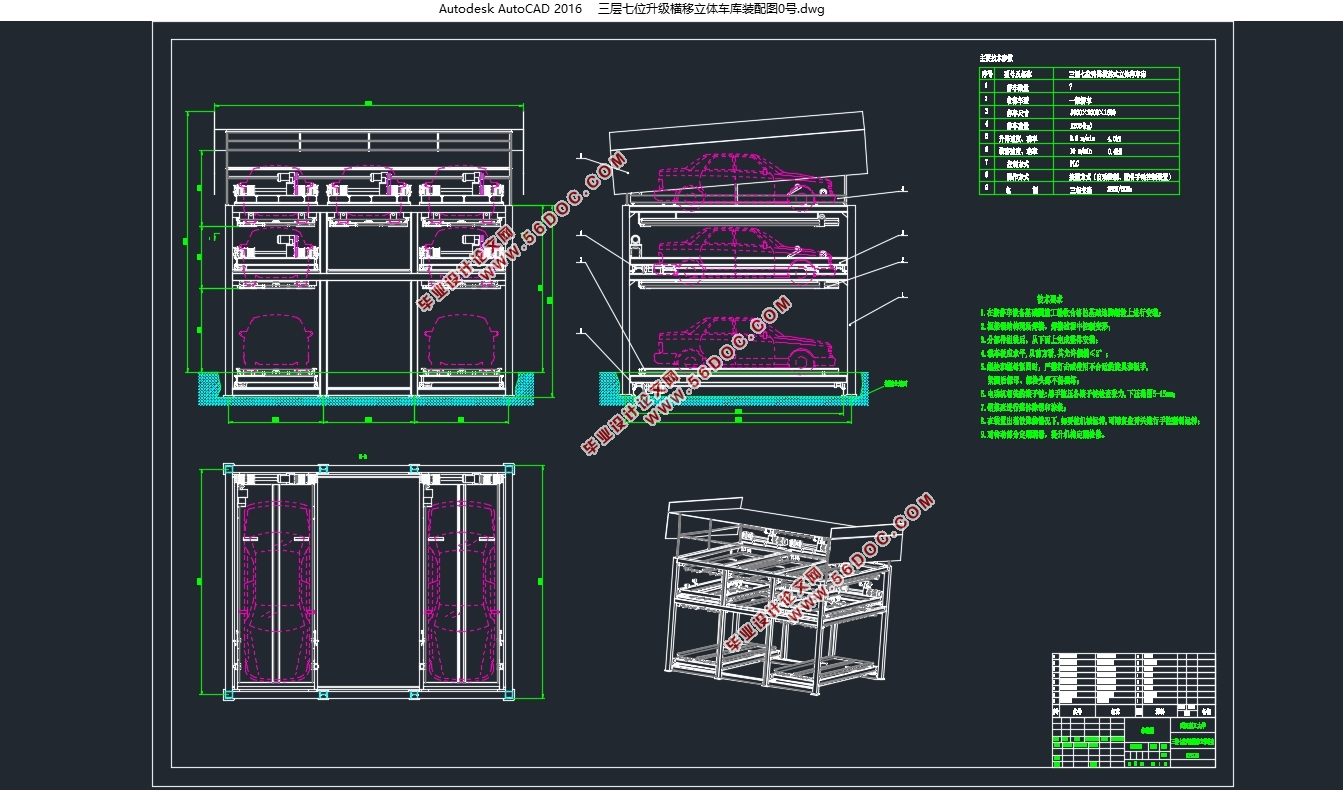

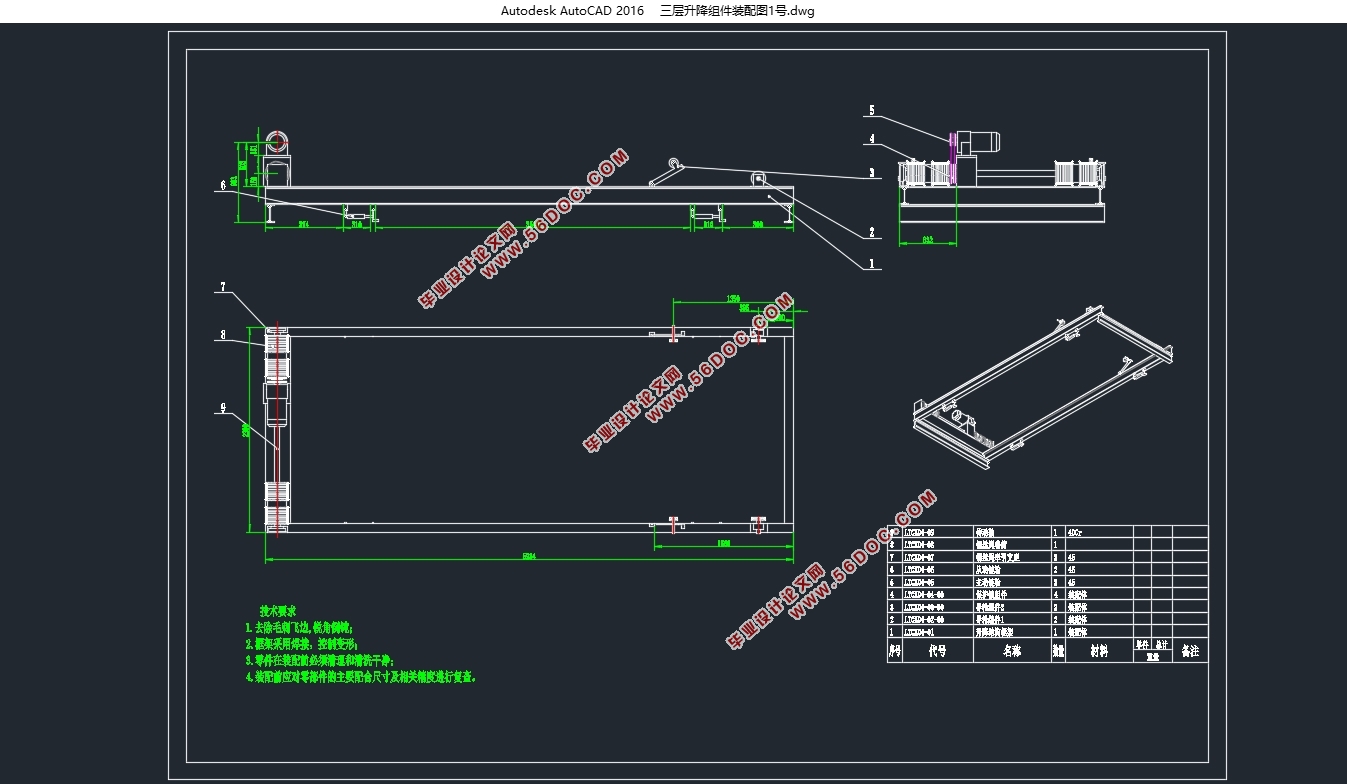

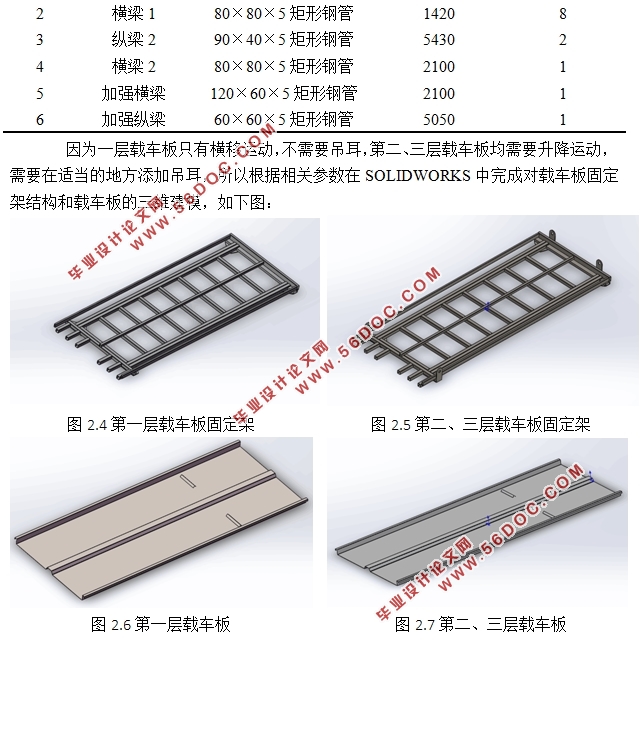

(1)对三层七位升降横移式立体车库分为车库主框架、载车板、横移设备、升降设备等四个部分进行结构设计并在SOLIDWORKS中完成三维建模。

(2)将模型简化后导入HyperMesh中创建有限元模型,然后对有限元模型进行四种典型工况(空载、对称满载、非对称满载、最大偏载)下的静力学分析,并且考虑风载荷对其影响,得到相关的云图,得到最大应力为74.96MPa,最大变形量为1.651mm,均满足设计要求,校核了立体车库的强度和刚度,保证其安全性。

(3)考虑立体车库运行时电机和车辆发动机产生振动的影响,对有限元模型进行模态分析,得到一阶弯曲和扭转所对应的频率在3.46-16.34Hz之间,其满足设计要求,保证了车库运行的稳定性。

(4)利用OptiStruct中尺寸优化的方法对立体车库框架钢结构进行优化设计,使优化后整体结构减重2.58t,减重比占36.49%,并对优化后结构进行校核,且考虑八级强震影响,得出优化后结构仍满足设计要求的结论。

本课题对于立体车库的研究具有一定参考性,对立体车库的广泛应用具有实际意义。

关键词:立体车库;有限元;HyperMesh;优化设计;轻量化

Abstract

With the urban development of the city, the number of cars in the city has increased dramatically. The development of a three-dimensional garage has become an inevitable trend of the city's three-dimensionalization. It has made full use of space in limited land resources and effectively solved the current status of parking difficulties in major cities. This text mainly carries on the structural design to the lifting and traversing type stereoscopic garage and carries on the static mechanics and the dynamic analysis to the steel structure of the stereoscopic garage frame through the finite element method. Under the premise of guaranteeing the safety and stability of the stereoscopic garage, it carries on to the stereo garage. Structural optimization and lightweight design The main contents include:

(1)The three-story, seven-step, vertically-moving, three-dimensional garage is divided into four parts: the garage main frame, the loading plate, the traversing equipment, and the lifting equipment. The three-dimensional modeling is performed in SOLIDWORKS.

(2)The model is simplified and imported into HyperMesh to create a finite element model. Then the finite element model is subjected to static analysis under four typical conditions (no load, symmetrical full load, asymmetric full load, maximum partial load), and the wind load is considered. For its influence, the related cloud image was obtained. The maximum stress was 74.96 MPa, and the maximum deformation was 1.651 mm. All of them met the design requirements, and the strength and rigidity of the three-dimensional garage were checked to ensure its safety.

(3)Consider the influence of vibration generated by the motor and vehicle engine during operation of the three-dimensional garage, perform modal analysis on the finite element model, obtain the frequency corresponding to the first-order bending and torsion between 3.46 - 16.34 Hz, which meets the design requirements and guarantees Garage operation stability.

(4)Using OptiStruct size optimization method to optimize the design of the steel structure of the three-dimensional garage frame, so that the overall structure weight loss after optimization 2.58t, weight loss ratio accounted for 36.49%, and check the optimized structure, and consider the eighth-level strong After the earthquake, the conclusion that the structure still satisfies the design requirements after optimization is obtained.

This subject has certain reference for the research of the stereo garage, and has practical significance for the wide application of the stereo garage.

Keywords: 3D Garage;FEM;HyperMesh;Optimization Design;Lightwei

本设计中的车库主要是用来停放轿车或者小型SUV,并根据一般轿车的基本尺寸参数来确定立体车库框架各个结构的基本尺寸。

表2.2立体车库设计基本参数

项目 大小

车长 5000mm

车宽 1700mm

车高 1600mm

车重 2200Kg

载车板长 5500mm

载车板宽 2000mm

车位立柱间距 2500mm

车位长度 6500mm

根据一般立体车库的选材,确定本课题立体车库框架结构材料为Q235,并由数根冷弯矩形空心钢管和工字钢焊接而成,各根据个车位相关尺寸,选择车库框架立柱和和梁的相关尺寸如下表:

表2.3车库框架相关参数

序号 名称 规格 长度(mm) 数量(件)

1 两侧立柱 200×200×12矩形钢管 4610 4

2 中间立柱1 20b工字钢 1672 4

3 中间立柱2 20b工字钢 2548 4

4 横梁 200×200×12矩形钢管 7500 6

5 纵梁 20b工字钢 6000 4

目录

第1章绪论 1

1.1课题背景 1

1.2研究目的及意义 1

1.3国内外研究状况 2

1.3.1国外研究现状 2

1.3.2国内研究现状 2

1.4本课题研究内容 3

第2章立体车库的结构设计 4

2.1立体车库整体设计方案 4

2.2升降横移式立体车库的结构设计 5

2.2.1车库主框架结构设计 5

2.2.2载车板设计 6

2.2.3横移设备设计 8

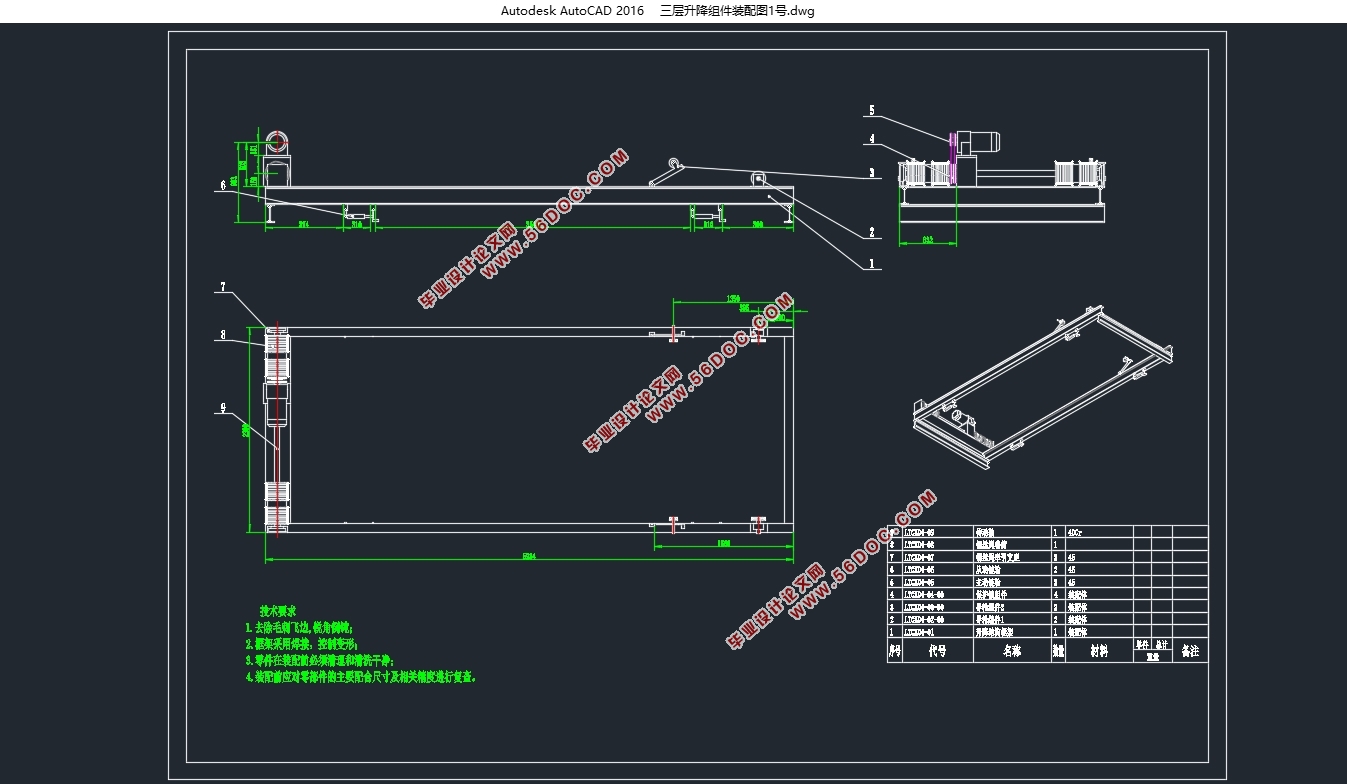

2.2.4升降设备设计 10

2.2.5车库整体结构设计 11

2.3本章小结 12

第3章立体车库框架钢结构有限元建模及静力学分析 13

3.1有限元分析基本原理和步骤 13

3.1.1有限元基本原理 13

3.1.2有限元基本步骤 13

3.2立体车库框架钢结构有限元建模 15

3.2.1立体车库三维模型的简化 15

3.2.2简化模型的导入 16

3.2.3几何清理与中面抽取 16

3.2.4网格划分及连接处理 17

3.2.5车库框架钢结构边界条件的确定 21

3.3立体车库框架钢结构各工况下静力学分析 22

3.3.1立体车库不同载荷工况的确定 23

3.3.2计算结果和分析 24

3.4本章小结 35

第4章立体车库框架钢结构有限元模态分析 37

4.1模态分析理论简介 37

4.2车库框架的模态分析 38

4.3模态结果分析 43

4.4本章小结 43

第5章立体车库框架钢结构轻量化优化设计 44

5.1尺寸优化设计理论 44

5.2车库框架的轻量化优化设计 44

5.3轻量化优化结果分析 47

5.4轻量化优化后的校核 48

5.5本章小结 51

第6章结论与展望 52

6.1结论 52

6.2展望 52

参考文献 54

致谢 56

|