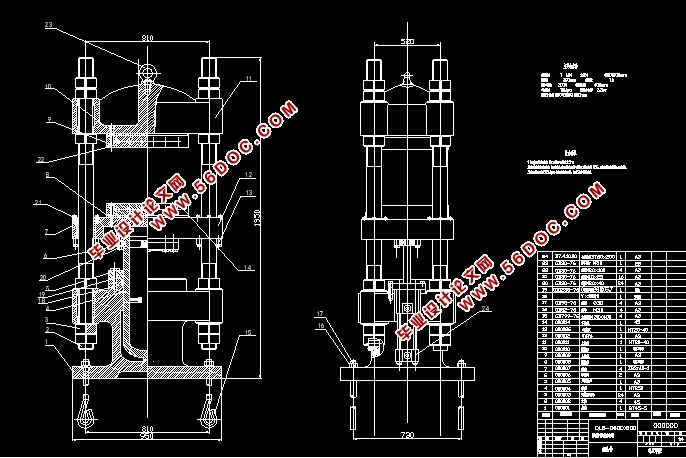

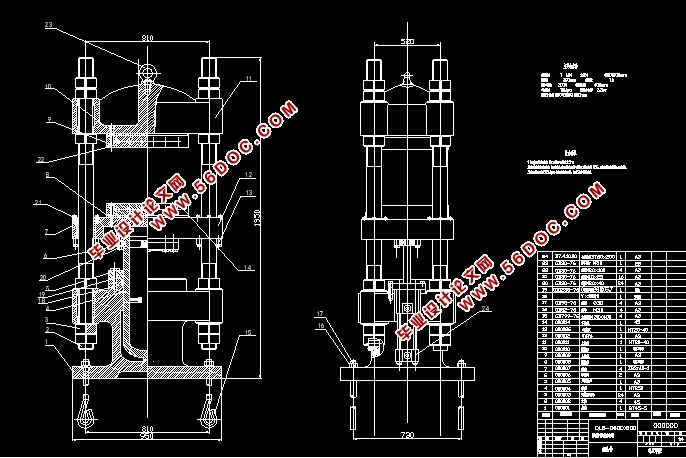

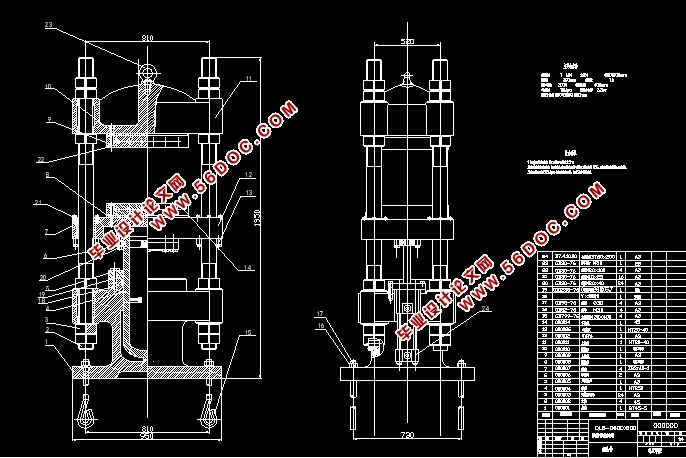

QLB-D600×600快速升降平板硫化机设计(含CAD零件装配图)(论文说明书7000字,文献综述,CAD图纸5张)

摘 要

QLB-600*600快速升降平板硫化机是我本次设计的课题,在本次设计中,我查阅了大量关于平板硫化机的历史同时也计算和校核了QLB-600*600快速升降平板硫化机的各个零部件。

本设计中介绍了快速升降平板硫化机的零部件设计过程,并对部分零件有插图,详细步奏可以参考下文。平板硫化机作为一种工业设备,又柱塞,工作缸,侧板等组成的传递液压能,将其转变成压力能及动能。在硫化机快速发展的时代,硫化机性能的变迁就显得至关重要。

通过接下来的一学期的时间,我将完成QLB-600*600快速升降平板硫化机的设计课程,通过阅读大量的文献使得我对这个原本陌生的机器熟悉起来。国外在生产制造平板硫化机的过程中有着非常先进的技术及其制造理念,可以说他们在对这项机器的把控中显得非常娴熟。而我国作为发展中国家,非常重视技术的创新和发展,科学技术作为第一生产力,我国也掌握着大量的关于平板硫化机的先进技术,很多国内的机械厂都能生产出和国际较高水平等同质量的平板硫化机。但是平板硫化机的生产制造过程中也存在着一定的问题。我们要做的就是发现问题并且寻求解决的办法,不断的引进国外的经验极其先进技术。使得我国的平板硫化机“走出去”,拥有一个强有力的国际市场。

关键词:平板硫化机 ,快速升降。

Abstract

According to different use, transmission, steering system, flat heating, according to different structures, vulcanizing machine can be divided into five categories.

QLB-600 * 600 Fast lifting plate vulcanizing machine is the subject of this design, the history of this kind of flat vulcanizing machine had described in detail, as well as calculating and checking the QLB-600 * 600 Fast lifting plate vulcanizing machine various components

A rubber process principles we know, rubber vulcanization process is working in vulcanizing machine hot plate at a certain temperature, pressure and time and temperature so that the compound was crosslinked rubber molecules, its structure consists of a linear structure into a mesh shape structure, which is obtained with certain physical and mechanical properties of the article, but the plastic material is heated, softened, while the water and volatile substances within the compound to be vaporized, then rely on hydraulic cylinder give enough pressure to rubber full model, and limit the formation of air bubbles, the article dense structure. If the tape laminate, plastic and cloth can firmly sticking. In addition, give sufficient pressure to prevent mold from the seam face appears overflow edge, pattern lack of plastic, porosity sponge and so on.

The design is described in a fast elevator vulcanizing machine parts design process, and some parts have illustrations, detailed step-outs can see below. Vulcanizing press as an industrial equipment, and a plunger, cylinder, side panels and other components of hydraulic energy transfer but not the pressure of the liquid transformed into kinetic energy of motion drive platform and arch made vulcanizer pressure required energy. With the continuous development vulcanizing machine, vulcanizing machine performance to higher demands.

By the time the next semester, I will finish QLB-600 * 600 Fast lifting vulcanizing machine, I will have an updated knowledge of the machine, and an update of the study, over the past few years is the vulcanizing machine development faster time, there are many domestic Rubber Machinery Factory production vulcanizing machine close to the international advanced level, some aspects in the international leading level. As long as we conscientiously sum up the advanced experience, especially learn from foreign advanced design and manufacturing technology aimed at the international market, China's vulcanizing machine will scale a new height.

Key words: flat vulcanizing machine, quick lift.

基本性能参数

公称合模力:1MN

热板规格:600×600mm

电加热板最高温度:200℃

最大热压力:2.5Mpa

柱塞行程:400mm

外形尺寸:950×850×1950mm

目 录

第一章 绪论 1

1.1 平板硫化机的最新进展 1

1.1.1用平板硫化机进行模压成型及硫化 1

1.2 平板硫化机的用途、类型及工作原理 2

1.2.1用途和类型 2

1.2.3工作原理: 2

1.3 基本性能参数 2

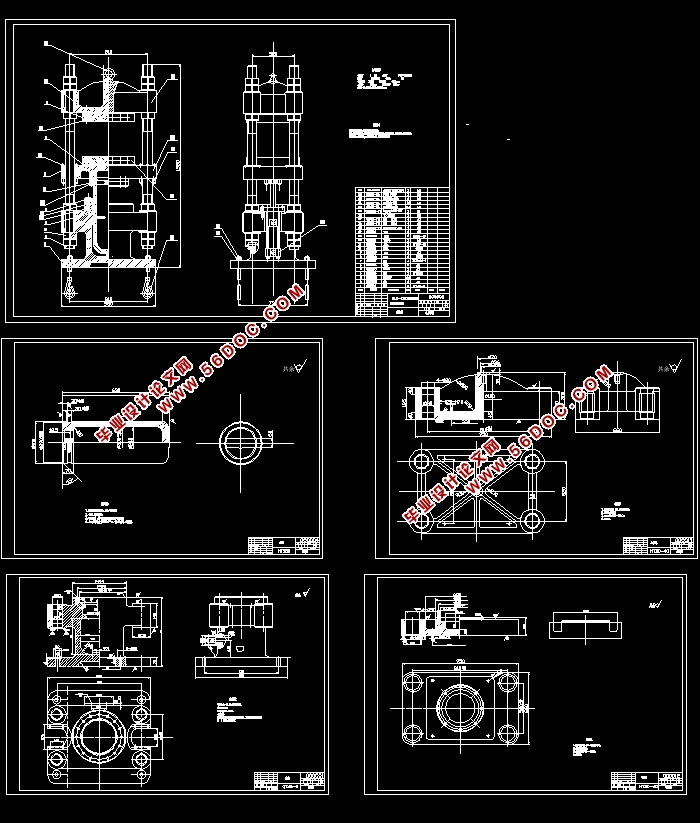

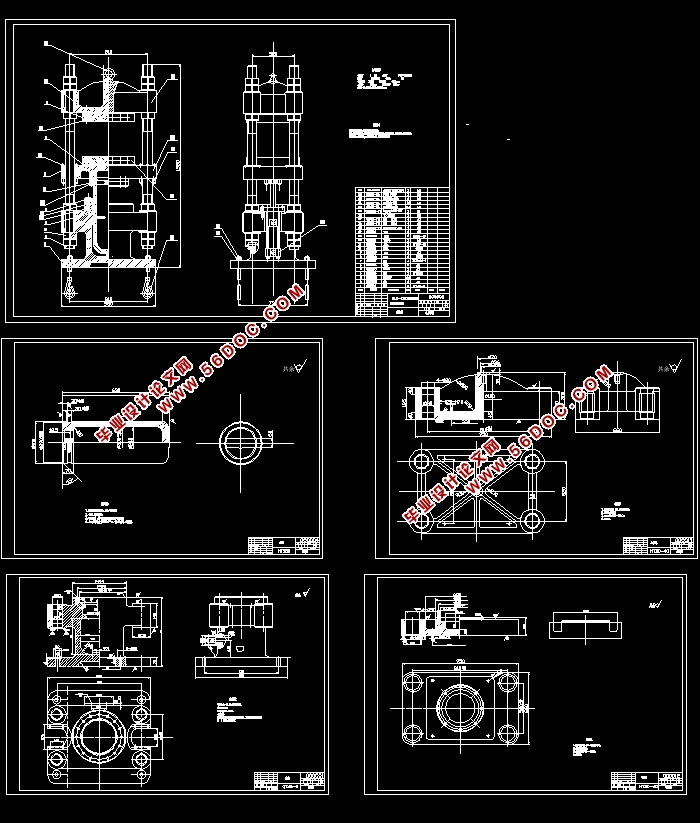

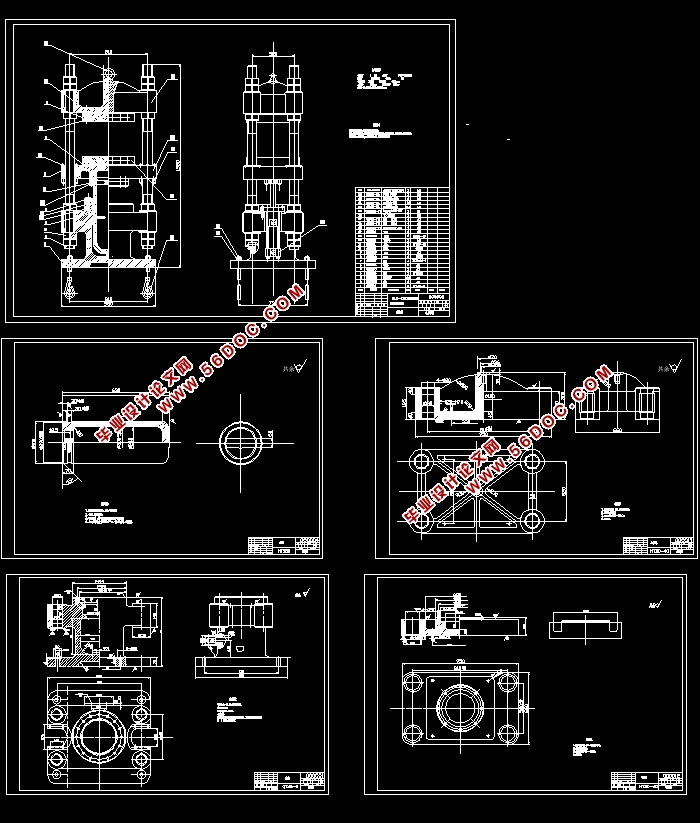

第二章 主要零部件的设计与校核 4

2.1 柱塞 4

2.1.1 结构形式 4

2.1.2 柱塞的选材 4

2.1.3 结构尺寸及强度计算 4

2.2 工作缸 6

2.2.1 结构形式 6

2.2.2 材料 6

2.2.3 结构尺寸 6

2.3密封装置 9

2.3.1定义 9

2.3.2 对密封装置的要求 9

2.4 可动平台 9

2.4.1 平台负载荷及弯矩受力情况 9

2.5 上横梁 11

2.5.1材料 11

2.5.2弯矩及弯曲应力 12

2.6 底座 14

2.6.1 结构及尺寸 14

2.6.2 材料 14

2.6.3 计算 14

2.6.4 强度校核 17

总 结 20

参考文献 21

致 谢 22

|