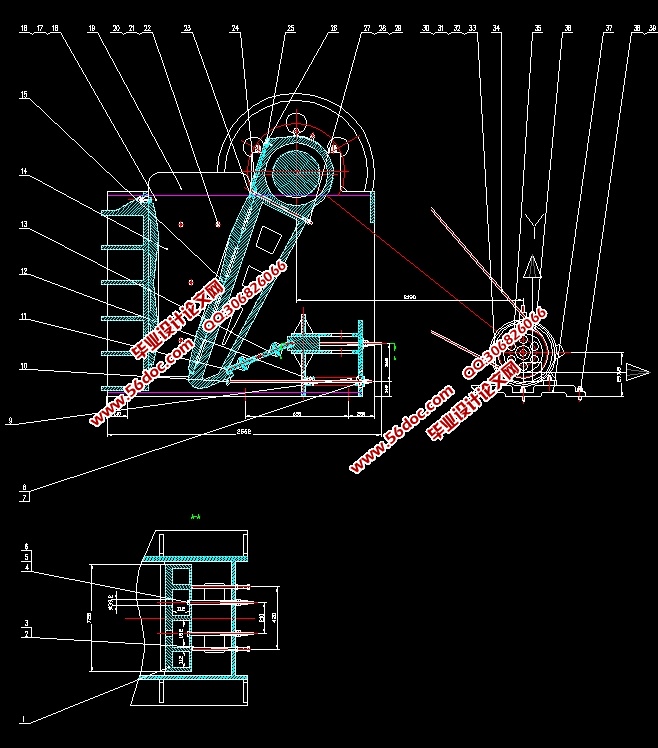

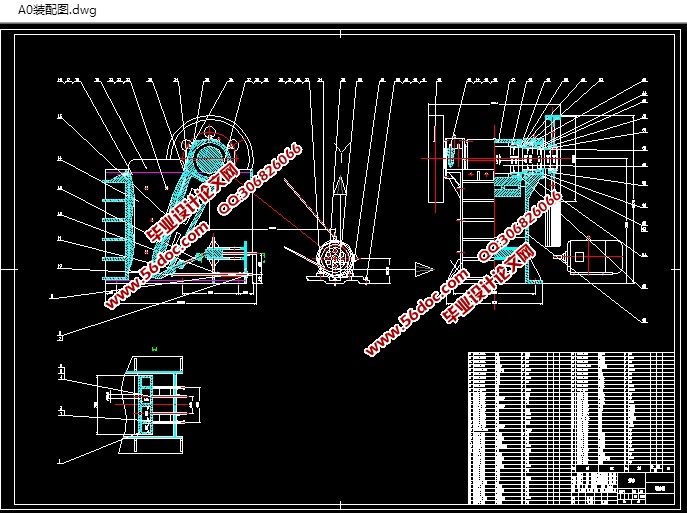

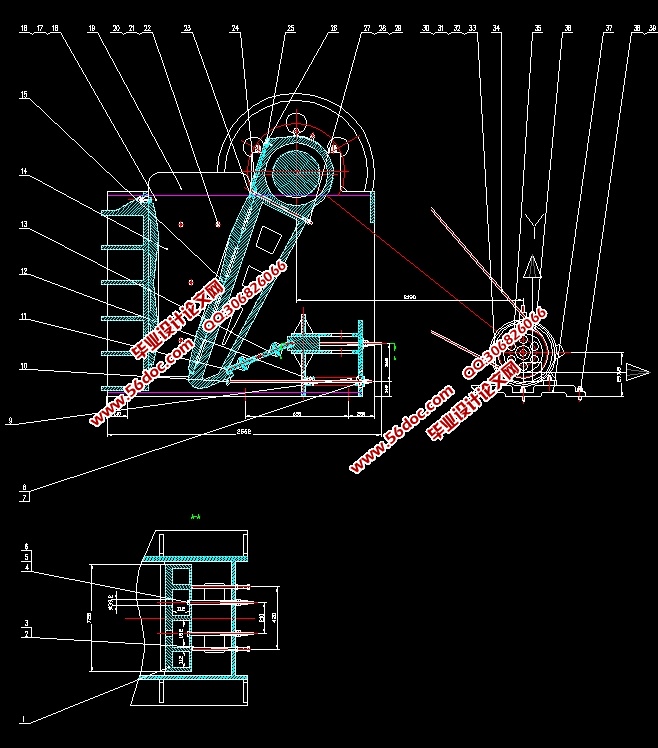

颚式破碎机的设计(含CAD零件装配图)(论文说明书9200字,CAD图纸4张)

Design of jaw crusher

摘 要

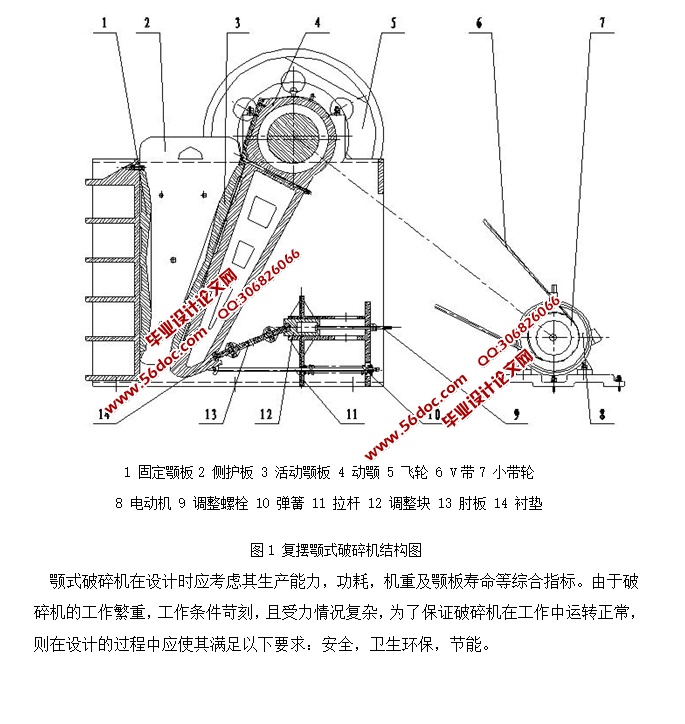

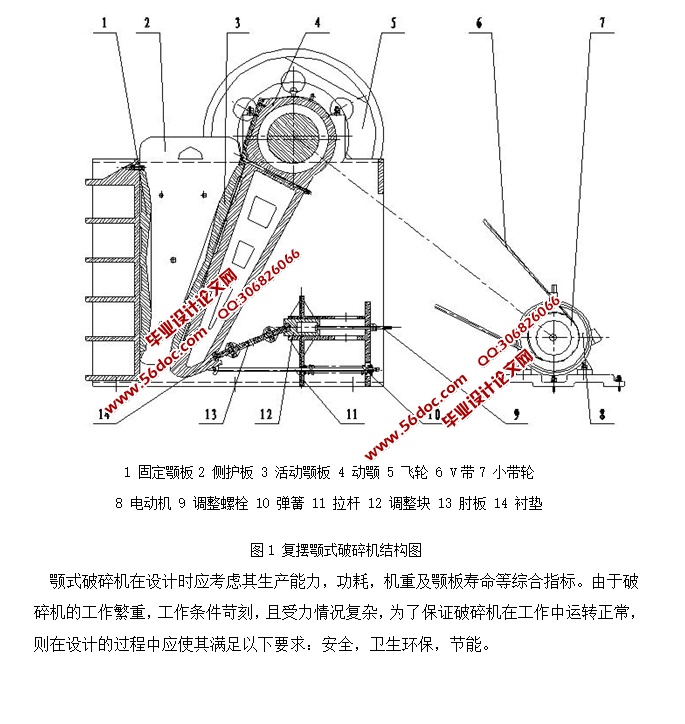

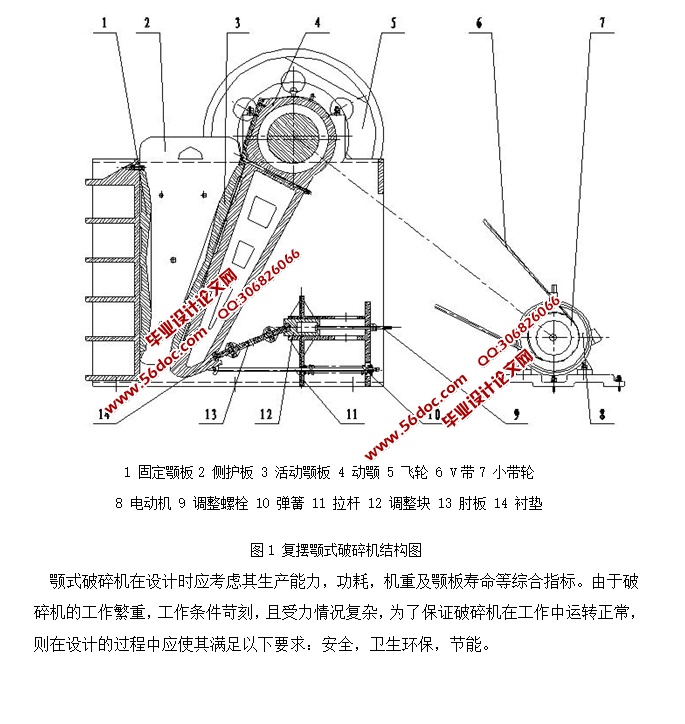

颚式破碎机属于矿山机械的一种,广泛应用于金属矿山、冶金工业、化学工业、建筑工业、水泥工业及砂石行业等,适用于中、细碎普氏硬度f=5-16的各种矿山和岩石,如铁矿石、有色金属矿石、花岗岩、石灰岩、石英岩、沙岩、鹅卵石等。它工作时,电机通过三角带、传动轴、传动齿轮带动偏心套旋转,动锥在偏心套作用下做旋摆运动,使动锥和定锥时而靠近时而偏离。物料在破碎腔内不断受到挤压、冲击而破碎,破碎的物料经筛选靠自重从下部排出。

本次设计的题目是颚式破碎机的设计,本文运用大学所学的知识,提出了颚式破碎机的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,构建了颚式破碎机总的指导思想,从而得出了该颚式破碎机的优点是高效,经济,并且安全系数高,对提高矿石的破碎效率,减少人工投入等等起到了很大的作用的结论。

关键词:颚式破碎机;中心距;弯曲疲劳强度;弯曲许用应力

Abstract

Jaw crusher which belongs to a kind of mining machinery, widely application in metal mines, metallurgical industry, chemical industry, building industry, cement and sand and gravel industry, suitable for various kinds of mines and rocks of medium and fine Platts hardness f=5-16, such as iron ore, non-ferrous metal ores, granite, limestone, quartzite, sandstone, pebbles and other. When the motor works, the electric motor drives the eccentric sleeve to rotate through the triangle belt, the driving shaft and the driving gear, and the moving cone moves in the eccentric sleeve to make the moving cone and the fixed cone sometimes close to the time. The materials in the crushing cavity subjected to continuous extrusion, impact crushing, crushing the material after screening by gravity from the lower discharge.

This design topic is the jaw crusher design. In this paper, the use of university knowledge, the jaw type crushing machine structure composition, working principle and main parts design must have the theoretic calculation and strength check, constructs the jaw crusher total refers to the guiding ideology, and concluded that the jaw crusher machine has the advantages of high efficiency, economy, and high safety factor, to improve the efficiency of the ore crushing, reduce manual input and so on plays a great role in the conclusion.

Key words: jaw crusher; center distance; bending fatigue strength; permissible bending stress

目 录

1 绪论 1

1.1颚式破碎机简介 1

1.2破碎机的发展 2

1.3总体方案设计 3

2 颚式破碎机机构参数设计 5

2.1啮角α 6

2.2动颚摆动行程s和偏心距r 7

2.3传动角 7

2.4肘板摆动角 8

2.5连杆长度 9

2.6肘板设计 10

2.6.1肘板支撑方式选择 12

2.6.2肘板长度计算 13

2.7主轴转速 15

2.8生产能力 16

3 主要零部件计算与选择 17

3.1电动机功率计算和选择 18

3.2带传动设计 18

3.2.1带型选取 19

3.2.2传动比 19

3.2.3大小带轮基准直径 20

3.2.4带速 21

3.2.5轴间距 21

3.2.6所需基准长度 22

3.2.7实际轴间距 22

3.2.8小带轮包角 22

3.2.9单根V带传递的额定功率 23

3.2.10额定功率增量 23

3.2.11V带根数 24

3.3 偏心轴机构设计及尺寸设计 25

3.3.1偏心轴尺寸确定 25

3.3.2作用在动颚上各点力的计算 26

3.4 轴承的选取和校核 27

4 主要零部件的强度校核 28

4.1轴承的选取和校核 29

总结 31

致谢 32

参考文献 33

|