大枣去核机的设计(含CAD零件图装配图)(课题申报表,任务书,开题报告,中期检查表,外文翻译,论文说明书14500字,CAD图纸10张,答辩PPT)

Design of De-nuclear Machine for Zizyphus jujuba

摘要

随着生活质量的改善,人们对养生保健的需求日益增长,大枣制品被越来越多的人喜爱。如枣泥、枣干、大枣牛奶等等制品。去核是很多果类加工的处理工序,对于大枣而言,去核加工尤为重要。随着加工工业的发展,各类大枣制品需求上升,自然对食品质量也十分注重。因此,大枣去核机,将注重提高去核的效率,以及果肉的干净与完整。以此为目标,去设计合理的机械。要求全自动,多方位。通过分析比对当前市场上的一些大枣去核机,确定要解决的主要问题,即冲击力度太大,导致果肉破碎,亦或者是冲击力度太小,不能完整去核。除此之外,还可能出现一些定位出现偏差,导致整体运动出现衔接不良等等问题。

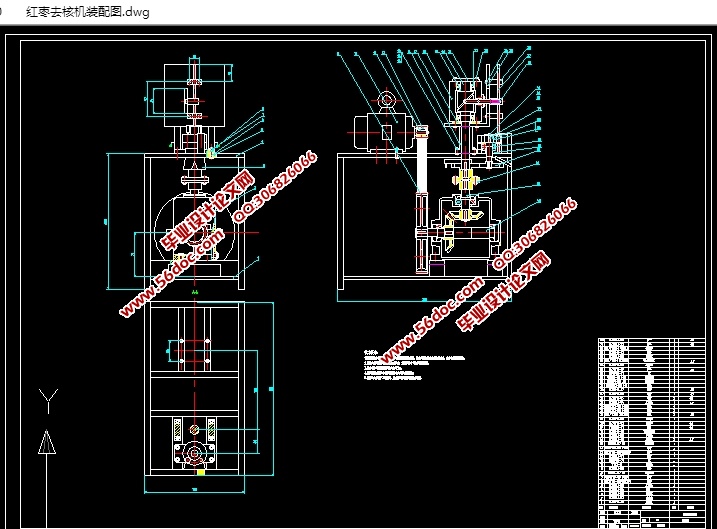

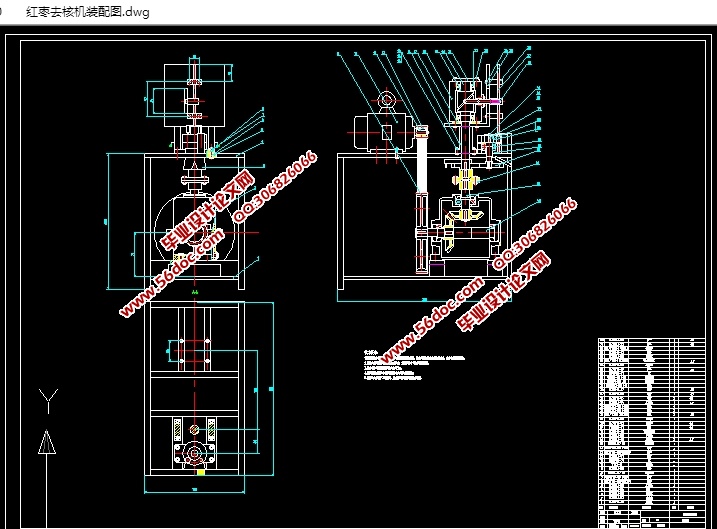

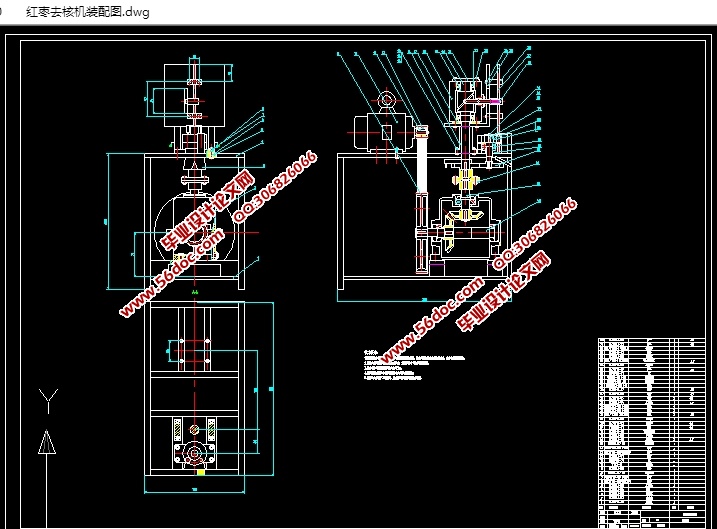

本文主要内容,整体传动方案设定,确定运动方案,对执行机构零件,进行尺寸计算。为了确保去核机的各部分设计的科学性、合理性,利用CAD等绘图软件,对槽轮机构、链轮机构这两部分,作着重研究说明。包括运动特性,配合性等等。

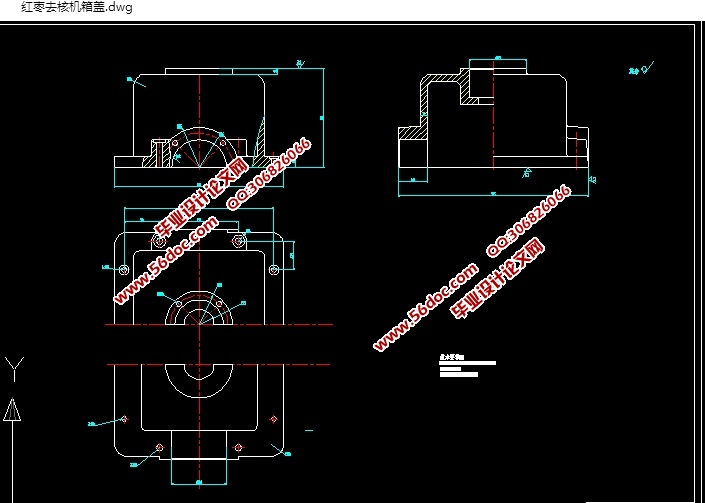

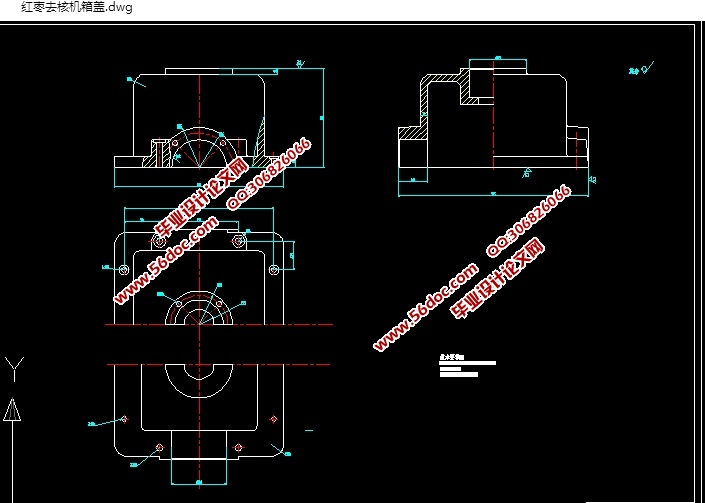

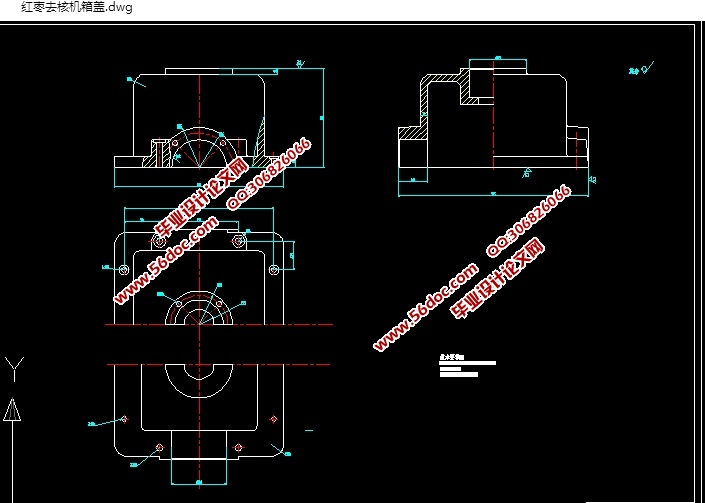

本机主要构成部分有传送带、冲核机构、槽轮机构等。用合理的联结方式,使槽轮机构与曲柄滑块运作,带动冲核杆,对大枣进行精确冲核,提高生产效率。

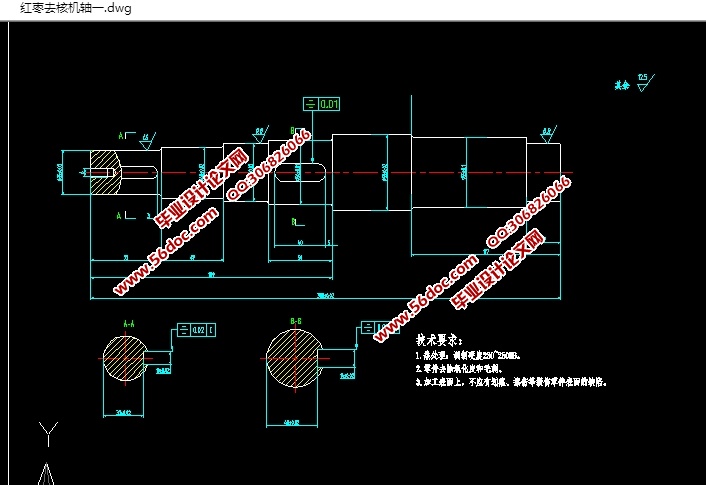

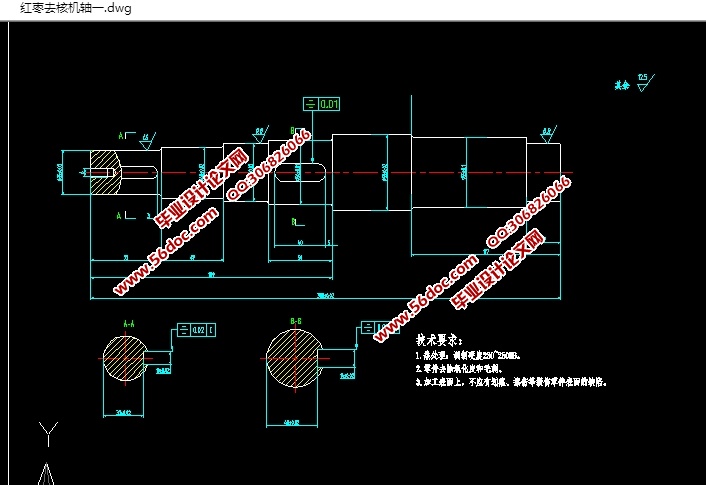

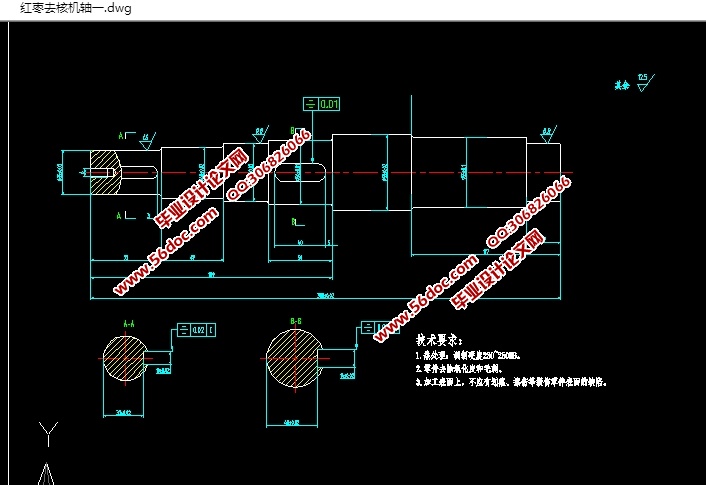

通过根据初始数据的计算,选择合适的电动机。根据所确定的传动比,分析传动零件的具体参数。除此之外,还要对V带传送做进一步分析。根据查表与已知数据相结合,确定中心距、带速、基准长度等参数,进而确定V带的类型。对执行机构中的冲压机构进行分析。大枣从枣斗进入后,首先要进行定位,使做间歇运动的旋转盘工作台与上下往复运动的冲针相互配合,使去核更加准确高效。再依次对轴系零件进行计算并校核,如轴疲劳强度的校核计算,键联结的校核计算,等等,进而选择合适的滚动轴承。

最后选择合适的润滑方式,对传动系统零部件进行润滑与密封。

关键词 去核;传动方案;执行机构;槽轮机构

Abstract

With the improvement of quality of life and the increasing demand for health care, jujube products are loved by more and more people. Such as jujube mud, dried jujube, jujube milk and other products. The core removal is the processing procedure of many fruit processing, especially for the red jujube. With the development of processing industry, the demand for all kinds of jujube products is rising. Therefore, jujube denuclearization machine, will focus on improving the efficiency of de-nucleation, as well as pulp clean and complete. With this as the goal, to design reasonable machinery. Full automatic, multi-directional. By analyzing and comparing some jujube denuclearization machines in the current market, it is determined to solve the problem. The main problem is that the impact is too strong, resulting in pulp broken, or too small to be completely demineralized. In addition, there may also appear some positioning errors, resulting in the overall movement of poor cohesion and other problems.

The main content of this paper, the overall transmission scheme setting, determine the motion plan, the actuator parts, size calculation. In order to ensure the scientific and reasonable design of each part of the denuclearizer, this paper mainly studies and explains the slot wheel mechanism and the sprocket mechanism by using CAD and other drawing software. Including the characteristics of motion, coordination, and so on.

The main components of the machine are selected roller, conveyor belt, punching mechanism, trough wheel mechanism and so on. Using reasonable connection way, the groove wheel mechanism and crank slider operate, drive the punching rod, carry on the accurate punching of the red date, and improve the production efficiency.

According to the calculation of the initial data, the suitable motor is selected. According to the determined transmission ratio, the specific parameters of the transmission parts are analyzed. In addition, V-band transmission should be further analyzed. According to the combination of look-up table and known data, the parameters such as center distance, band velocity and datum length are determined, and the type of V-band is determined. To carry on the analysis to the punching mechanism in the executive mechanism. After entering the jujube bucket, the jujube should be positioned first, so that the rotating table with intermittent movement can cooperate with the punching needle of the reciprocating movement, so that the nucleation can be more accurate and efficient. Then the shafting parts are calculated and checked in turn, such as the fatigue strength of the shaft. Key connection check calculation, and so on, and then select the appropriate rolling bearing.

Finally, the proper lubrication method is chosen to lubricate and seal the parts of transmission system.

Keywords: denucleate transmission scheme actuator geneva mechanism

功能

大枣去核机的去核过程,是把是把做往复运动的枣核冲针,与间歇运动的旋转盘,通过合理的机构。进行联结,来完成大枣的去核。总的步骤大体上可以分为以下四个:人工送料、冲核、回程、落枣。

原始数据

(1)待加工的大枣,直径为15mm~20mm;

(2)大枣去核时,负责冲核的冲针,针头压力在3KN左右;

(3)冲针每运动一次,自上而下,负责旋转的旋转盘,进行一次间歇运动,转角为90°;

(4)大枣去核机大约有10多年的使用寿命,每天的工作时长大约10小时,对载荷而言,有轻微的震荡和冲击。

目 录

摘要 I

Abstract II

1 绪论 1

1.1研究背景及意义 1

1.2 研究内容 1

1.3 研究方法 1

2 方案设计 3

2.1 概述 4

2.2 执行系统 4

2.3 传动系统 6

3 传动装置 8

3.1 电动机的选择 8

3.2 确定传动比 9

3.3传动装置的动力参数 9

3.3.1 各轴转速 9

4传动零件 10

4.1普通V带传送 10

4.2 直齿锥齿轮 11

4.3 联轴器 14

5执行机构 16

5.1冲压机构 16

5.2槽轮机构 18

6轴类零件 21

6.1轴1的结构设计 21

6.2滚动轴承设计计算 26

6.3键联结校核 29

总结 30

致谢 31

参考文献 33

|