深孔钻削机床结构设计(含CAD图)(外文翻译,论文说明书18000字,CAD图2张)

摘要

深孔钻削技术是现代工业生产中一种极为重要的加工技术,据统计,整个孔加工行业有五分之二是深孔加工,所以深孔加工在制造业中占有举足轻重的地位。随着工业的进步,传统深孔钻机床逐渐体现出多方面的不足和缺陷,对传统深孔钻床进行改进、提高是现在制造业所需要的。

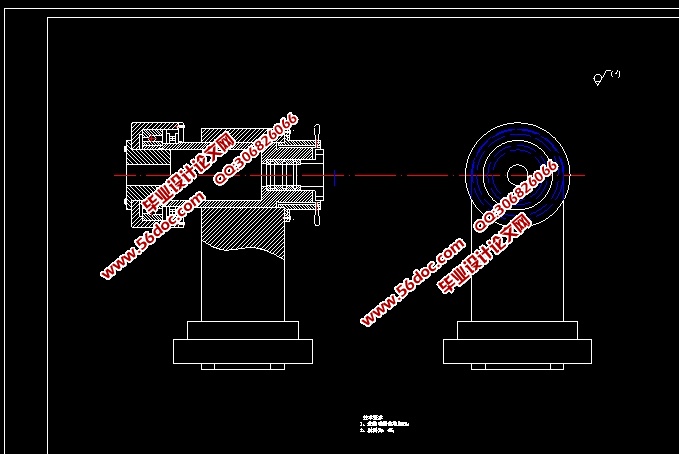

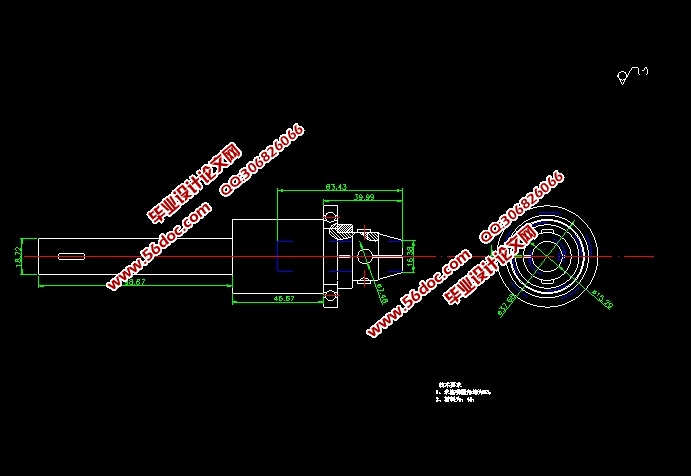

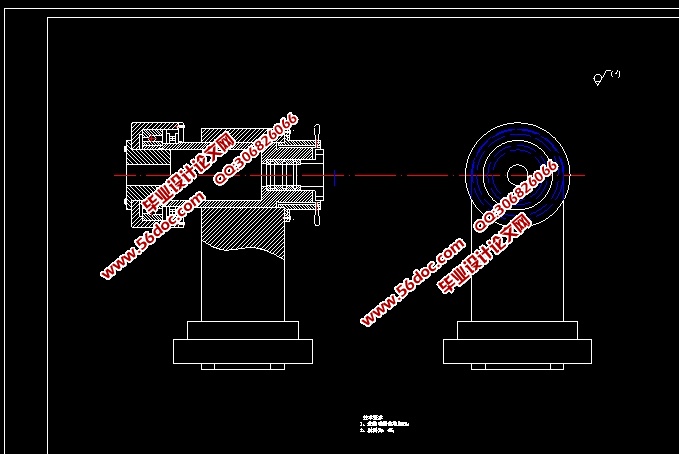

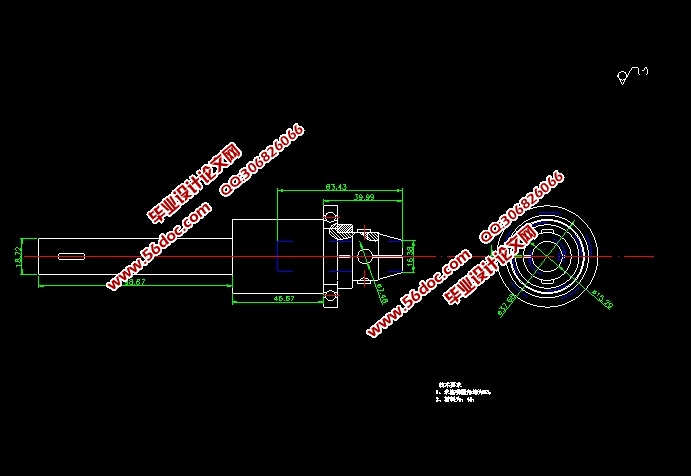

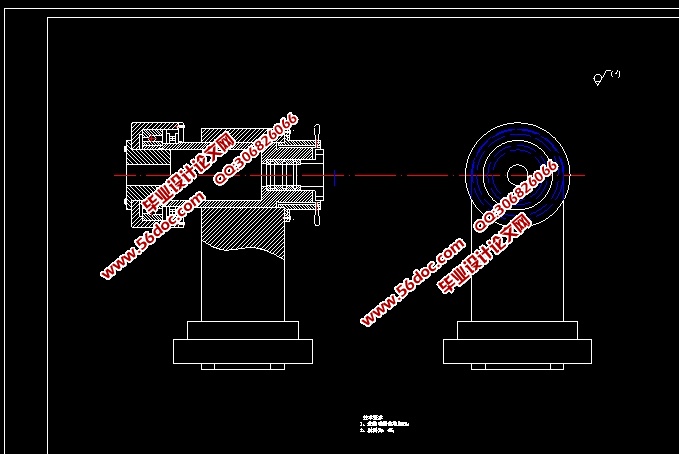

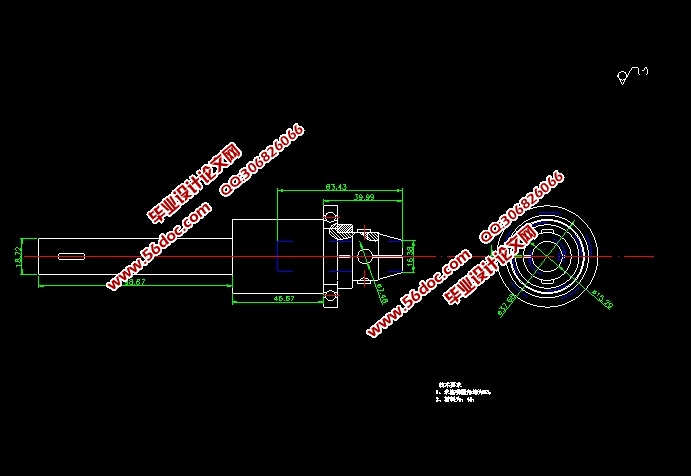

本设计主要针对传统深孔钻削机床所存在的排屑困难、钻削效率低下、刀具磨损、刀具走偏进行分析,找出导致这些问题的原因,并在现有机床的基础之上进行改进和完善。本设计将传统的授油器和导向套结合为一体,很好的解决了刀具走偏问题和授油问题,并且很大缩小了钻床的体积。对切削液进行优化选择,很大程度上提高了钻削效率,并且对钻削方式和刀具几何参数等等问题进行优化,对于传统钻床所存在的问题进行优化设计,并且取得了很好的效果。本设计对深孔钻削机床的主轴、带传动、授油器进行了设计,根据切削功率进行了电机的选择,选出了一套合理的钻床结构。

本设计有效的解决了传统深孔钻床所存在的一系列问题,并且在需要的地方进行画图分析其结构,为工业先现代化做出有效的贡献。

关键词:深孔钻削:钻床;授油器;带传动。

Deep hole drilling machine structure design

Abstract: Deep-hole drilling technology is a very important processing technology in modern industrial production. According to statistics, two-fifths of the entire hole processing industry is deep-hole processing, so deep-hole machining occupies a pivotal position in the manufacturing industry. With the progress of industry, traditional deep-hole drilling machine tools have gradually manifested many deficiencies and deficiencies. The improvement and improvement of traditional deep-hole drilling machines are required by the current manufacturing industry.

This design mainly aims at the difficulties of chip removal, low drilling efficiency, tool wear, and tool misalignment existing in traditional deep-hole drilling machine tools, identifying the causes of these problems, and improving the existing machine tools. And perfect. This design integrates the traditional oiler and guide sleeve into a whole, which solves the problem of deviation of the tool and the problem of oil supply, and greatly reduces the size of the drill press. The optimization of the cutting fluid greatly improves the drilling efficiency, and optimizes the problems such as the drilling mode and the tool geometry parameters. It optimizes the problems existing in traditional drilling machines and achieves good results. . The design of the deep-hole drilling machine tool spindle, belt drive, oiler design, according to the cutting power of the motor selection, selected a reasonable structure of the drilling machine.

This design effectively solves a series of problems existing in traditional deep-hole drilling machines, and draws diagrams to analyze its structure where necessary, making an effective contribution to industrial modernization.

Key words: deep hole drilling; drill press; oiler;belt drive.

目录

摘要 I

Deep hole drilling machine structure design II

1 绪论 1

1.1课题研究的意义及背景 1

1.2国内外现状 1

1.3本章小结 2

2 传统深孔钻床的缺点分析 3

2.1 刀具走偏问题分析 3

2.2刀具磨损、折断问题分析 4

2.2.1引起刀具磨损的形式 4

2.2.2引起刀具磨损、折断的原因分析 5

2.2.3传统刀具的钻削方式 5

2.3机床的钻削效率问题分析 6

2.4排屑问题 8

2.5本章小结 8

3 对于钻床存在问题的优化设计 9

3.1 钻床的刀具走偏问题优化设计 9

3.1.1 传统的刀具固定架 9

3.1.2 新型授油器设计 9

3.1.3授油器总体方案的选择 10

3.1.4密封圈的选用 11

3.1.5配合与公差的选用 11

3.2刀具磨损、崩刃问题优化设计 12

3.3 钻削效率低问题的优化设计 13

3.4排屑问题的优化设计 14

3.5 本章小结 15

4 深孔钻床主要部位设计 17

4.1 切削功率的计算 17

4.2 主轴的设计 17

4.2.1轴的分类 17

4.2.2轴的选择 18

4.2.3轴的结构设计 19

4.3带传动设计 24

4.3.1带传动的简介 24

4.3.2带的选择 25

4.4 电机的选择 27

4.4.1电机的作用 27

4.4.2电动机种类的选择 27

4.4.3交流变频调速电机的型号选择 27

4.5 本章小结 28

5 总结和展望 29

参考文献 31

致谢 33

|