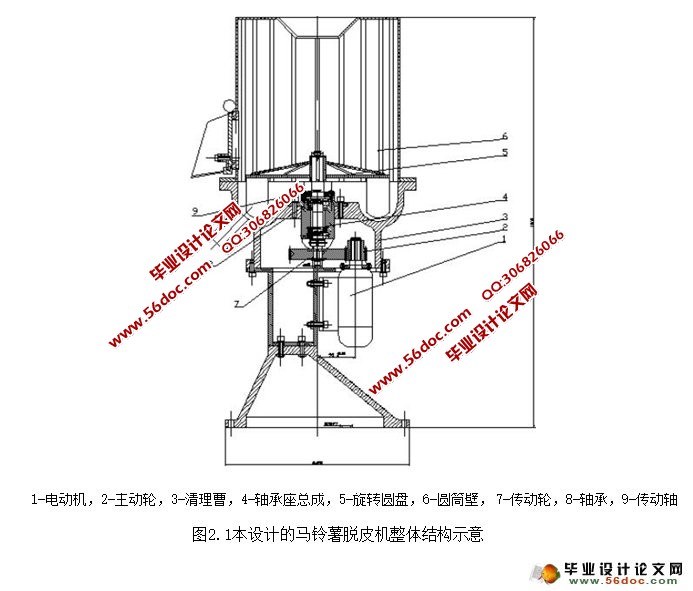

马铃薯(土豆)脱皮机设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书12000字,CAD图纸5张)

摘 要

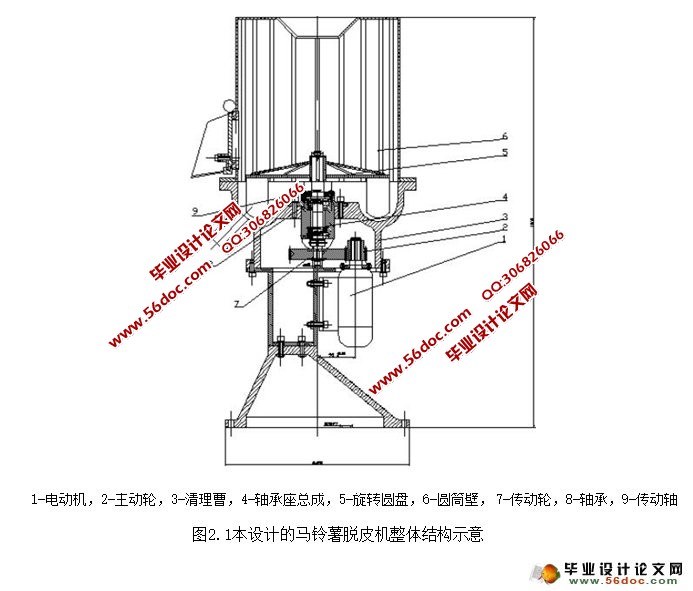

在加工的过程中,许多水果和蔬菜的外表皮是不需要或者不可使用的,需要去除,而且还可以提高成品的外观。主要要注意的是尽可能的去除果蔬材料外表皮并且能减少劳动力,能源和原材料的成本,减少总成本。本文设计介绍是摩擦去皮的方法:将马铃薯在放置在排砂滚筒的内壁,通过摩擦力将水果和蔬菜去皮,然后用大量的水清洗。此方法的优势在于整个脱皮过程不需要加热,故能源的消耗就少,所需的成本相对较少,在常温条件下不造成过热损伤,使加工的食品具备良好的外观特点,但因为食品外层表面的不规则(例如马铃薯表皮上的“孔洞”)会使加工的产品外观破损,故还要附加人工的手动除皮。

关键词:马铃薯;摩擦力;脱皮;清洗;

The design of potato peeling machine

Abstract

In the whole process of the processed foods, most outer layer of skin is

not to need to fruit and vegetable materials or inedible parts, need to

eliminate, and it also can improve the appearance of the finished products

after processing. Mainly need to pay attention to the aspects including the

removal of fruits and vegetables as much as possible the outer epidermis

part, reduce the labor, reduce energy and material spending, so as to

realize the ultimate goal of reducing costs. This design is the method of

using friction peeling: place the potatoes in the sand roller lining, using

the friction to remove the outer epidermis of fruit or vegetable, and then

through the use of large amounts of water for cleaning. This method has the

advantage of the peeling process don't need to be heated, so the energy

consumption is less, the cost is relatively small, at room temperature under

the condition of not overheating damage, make food with good appearance of

the processing characteristics, but because of the food the outer surface of

the irregular (such as potato "holes") on the skin can make the processing

of product appearance, so the human to be manually in addition to the skin.

Key words: The potato; The frictional force; Fruit and vegetable machine;

Cleaning

本次设计的参数:

1、 材料名称:马铃薯

2、 容积800kg/m3

3、 生产形式:间接性生产

4、 工作效率200kg/h

5、 材料大小:80mm

论文大纲

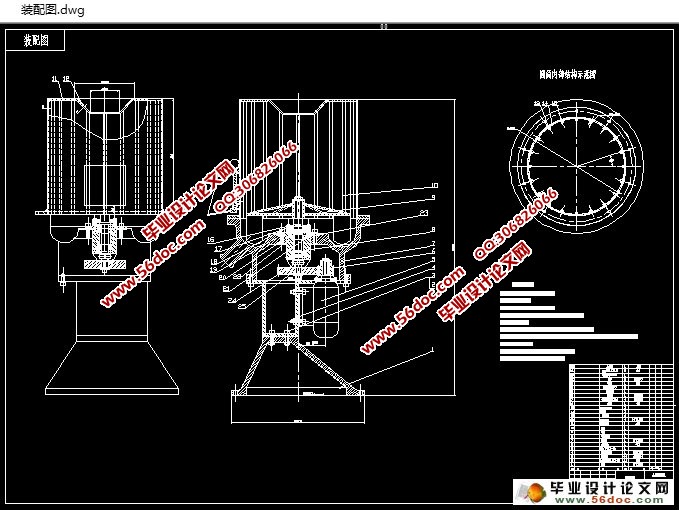

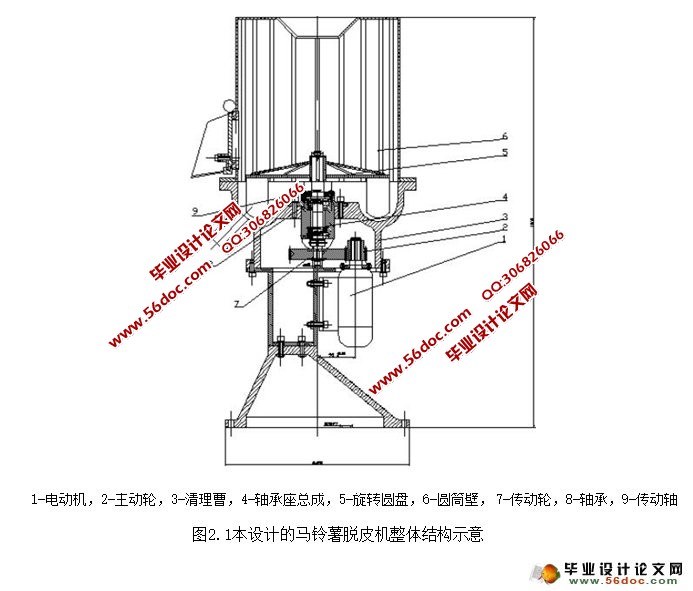

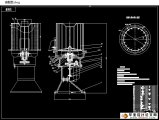

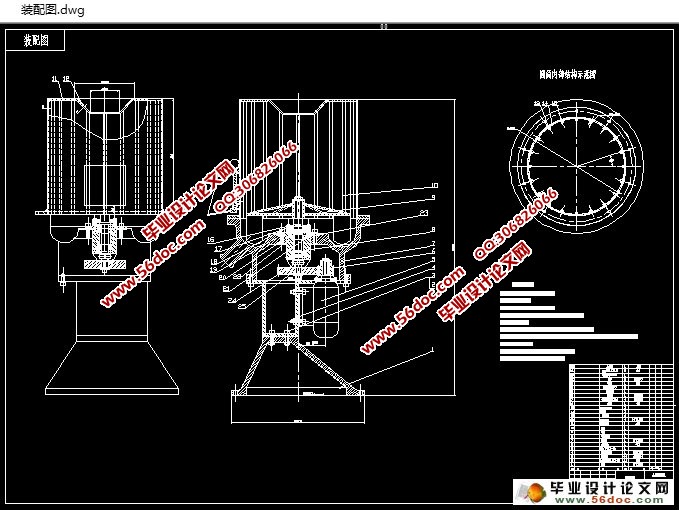

马铃薯脱皮机的发展背景和整体结构

(一)马铃薯脱皮机工作的原理。

(二)马铃薯脱皮机结构特点。

马铃薯脱皮机轴的设计

(一)轴的材料选用。

(二)轴的尺寸选择。

(三)轴的强度校核。

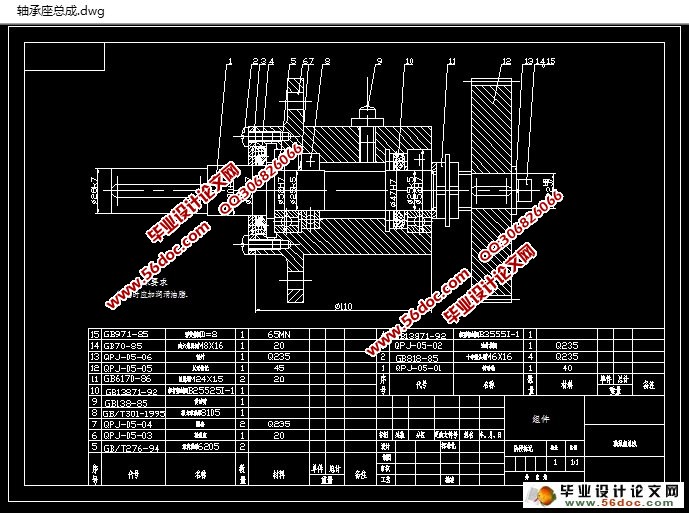

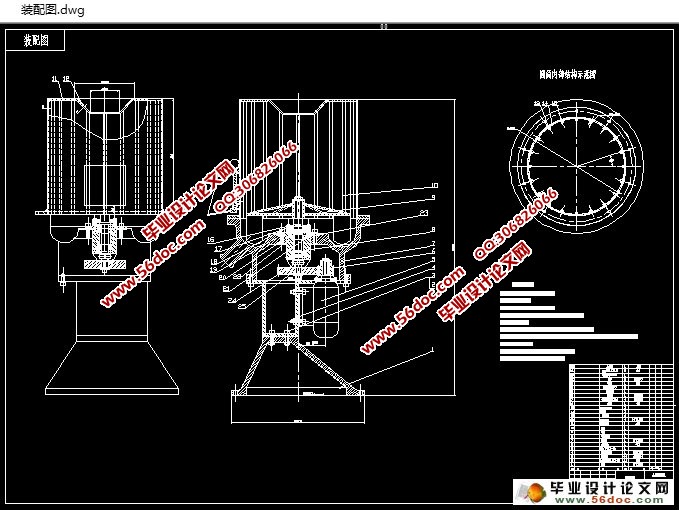

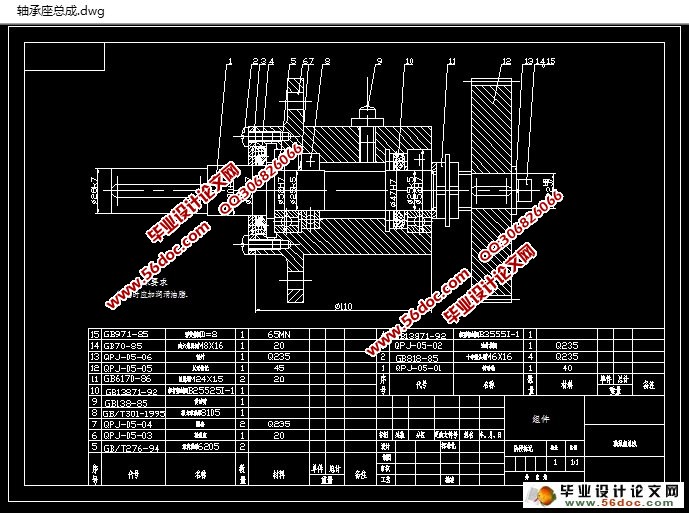

马铃薯脱皮机轴承的设计

(一)轴承类型的选用。

(二)轴承部件的组合设计。

马铃薯脱皮机电动机的选用

马铃薯脱皮机齿轮的结构设计

(一)齿轮的材料选用。

(二)齿轮相关参数的选用。

(三)齿轮强度的校核。

圆筒、轴承座以及圆盘的结构设计

八、结论

参考文献

致谢 |