弯管机的结构设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书12000字,CAD图纸5张)

摘要

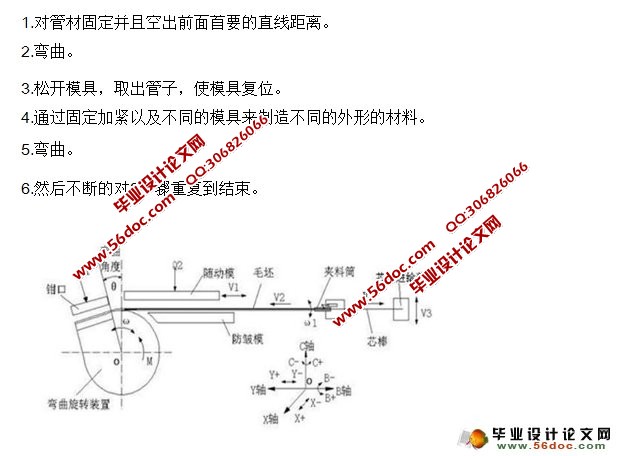

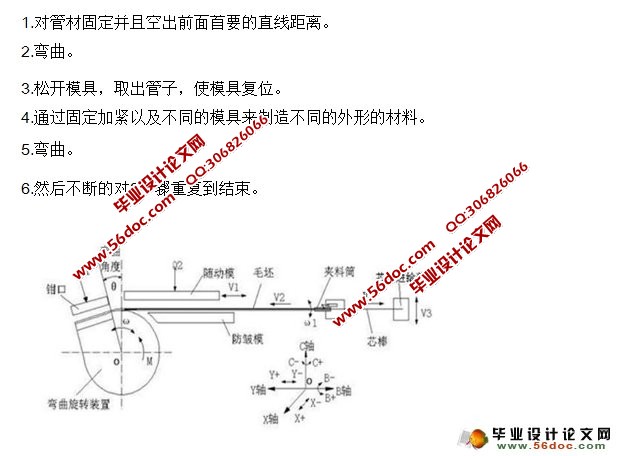

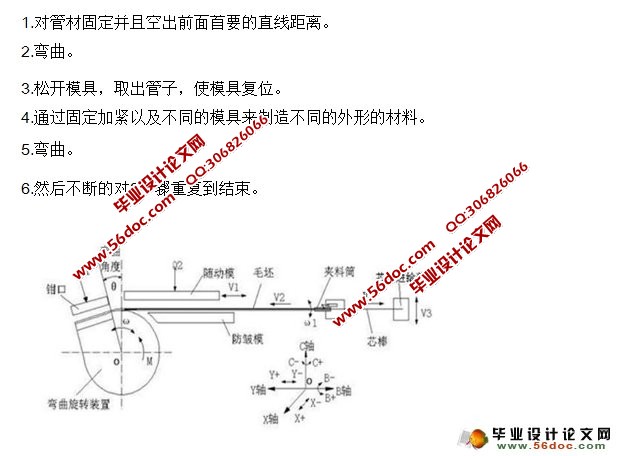

一般来说弯管机的基本原理是利用矢量基准,靠着电脑程序来掌控,来达到能够满足各个自由度方向的弯管的要求,是现今工业发展中必不可少的设备。本次设计的弯管机不仅具有以上的优点,还要实现高效化,自动化,大幅度降低劳动成本。而对于装置的进给装置,选用伺服电机进行驱动,可以实现对进给装置的伺服控制,有利于提高效率以及操作精度。本次设计除了能够满足弯管的要求,也使操作规程变得简单,对其弯管机的结构有了一定的改良,不仅能够达到效率高质量好的效果,而且还能够大大的增加生产效率以及生产成本,提高了能源利用率。对于现代弯管机行业的发展有了一定的推进作用。

关键词:弯管机;伺服驱动;自动化

Abstract

ABSTRACT

Bending machine is a normal mordern curved plastic processing equipment,which is

based on the vector theory,used computer control,to complete any space for three-dimensional

tube to meet user’s requirments..This design elbow not only has the above advantages, but also

realize the efficiency, automation, greatly reduce labor costs.we used proe graphics software for

the preliminary design, it’s size and the relevant requirements of the projections, making

three-dimensional assembly drawings and two-dimensional parts chart. For the feed device of

the device, the servo motor can be used to drive the feed device, and it can improve the

efficiency and operation accuracy.This design improves the bending operation, simplifying the

bending process, improve the pipe bending machine.For improving the yield and quality of

product, improving labor production capacity, reduceding less equipment investment, dynamic

consumption and low production cost,Which is of great significance to achieve high quality and

high yield, low consumption.

Keywords:bending machine;Servo drive;automation

目录

摘要.....................................................................................................1

ABSTRACT..........................................................................................2

第一章绪论...................................................................................... 3

引言........................................................................................... 3

1.2课程的目的及意义........................................................................4

1.3课题内容........................................................................................ 4

第二章弯管机系统设计总体方案..................................................5

2.1弯管机工作原理概述....................................................................5

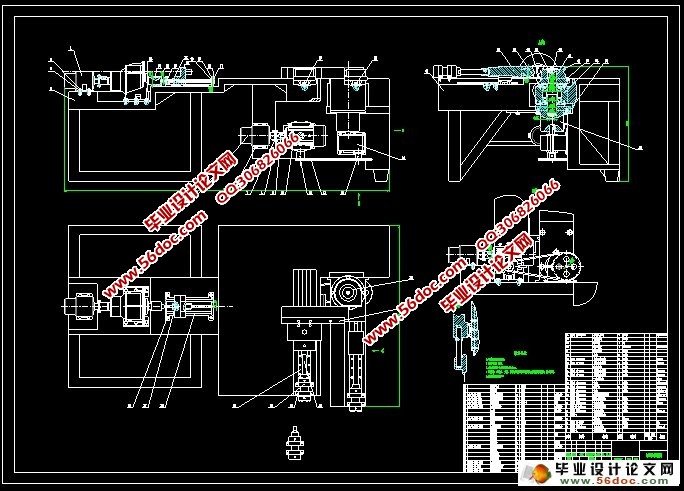

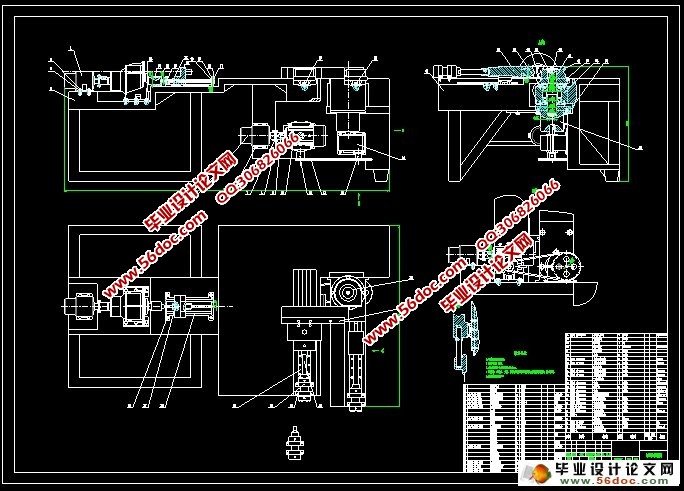

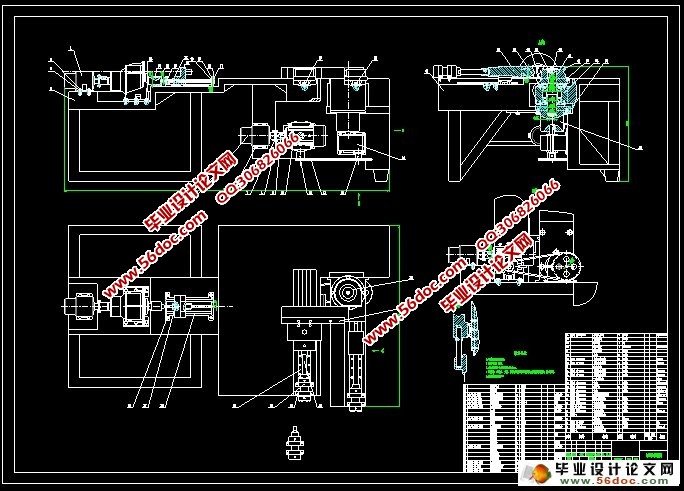

2.2总体结构设计................................................................................6

2.2.1设计的总体思路..................................................................6

2.2.2盘上夹紧装置设计..............................................................6

2.2.3总体方案设计.......................................................................7

第三章

弯管机关键组成部分的设计............................................8

3.1前言......................................................................................... 8

3.2驱动装置部分.........................................................................8

3.2.1、驱动弯管方案的确定................................................8

3.2.2、管材弯曲力矩的相关计算........................................8

3.2.3、电动机的选择............................................................9

3.2.4、电动机选择的相关计算..........................................10

3.2.5、蜗杆减速器的特点..................................................11

3.2.6、蜗杆减速器的选择..................................................11

3.2.7、一级减速器的选择..................................................12

3.2.8、一级减速箱的特点..................................................12

3.2.9、转动平台内用轴承的选择与计算..........................13

3.2.10、滚子链传动的设计与计算....................................14

3.2.11、轴的结构设计与计算校核....................................17

3.3随动模夹紧装置部分...........................................................18

3.3.1、液压的优点..............................................................19

3.3.2、随动模部分..............................................................19

3.4进给部分的总体设计与计算...............................................19

3.4.1进给设计方案.............................................................19

3.4.2、电机的选择..............................................................20

3.4.3、滚珠丝杠的选择......................................................20

第四章

液压系统的设计以及相关计算......................................21

液压系统的设计计算......................................................21

4.1.1、明确设计要求,分析工况......................................21

4.1.2、确定液压系统的主要参数......................................23

4.1.3、液压执行元件的工况图..........................................24

第五章总结与展望........................................................................28

参考文献............................................................................................ 29

致谢...................................................................................................30

|