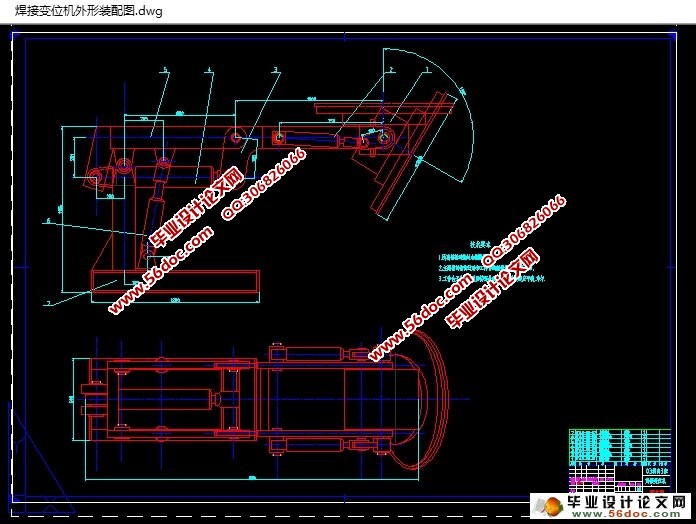

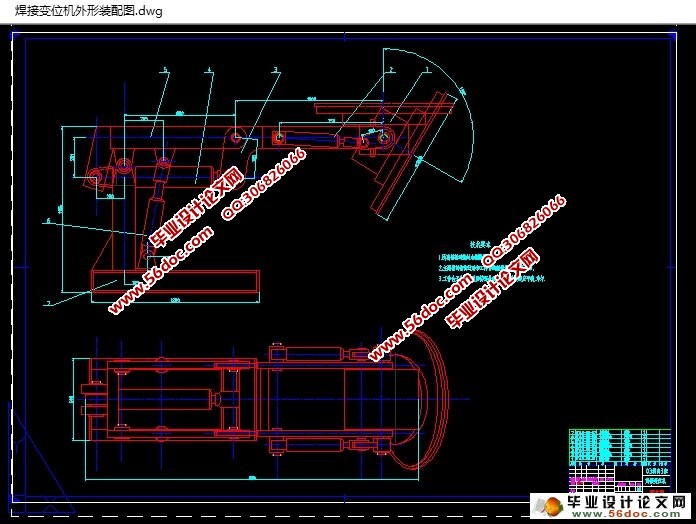

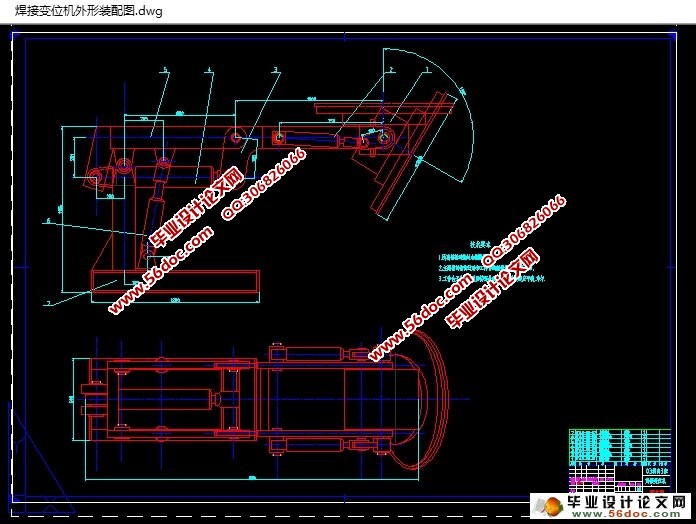

焊接变位机的设计(含CAD零件图装配图)

来源:wenku7.com 资料编号:WK713770 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK713770

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

焊接变位机的设计(含CAD零件图装配图)(论文说明书9000字,CAD图纸8张)

摘 要

本次设计是以焊接变位机作为主要的研究对象。在焊接变位机中采用全液压系统,使之重量减轻,自动化程度增强,变位机中的传动部分是由一个油泵机组分别驱动油马达和三组油缸带动工作台进行回转和倾斜,并使主,副臂产生俯仰动作调节工作台的高低。本次设计对焊接变位机的传动机构的特点和组成都做了详细的介绍,对机构中的主要零部件做了具体的设计。本次设计采取了独特的设计,使得产品更为先进、实用,设计后制造出来的焊接变位机主要应用在焊接行业上,这样可以缩短焊接辅助时间,提高工人的劳动生产率,减轻工人劳动强度,改善焊接质量,并充分发挥各种焊接方法的效能。

在焊接生产中,经常会遇到焊接变位以及选择合适的焊接位置的情况,针对这一实际需要,我们设计的焊接变位机,它可通过工作台的回转和倾斜,使焊缝处于易焊位置.焊接变位机与焊接操作机配合使用,可实现焊接的机械化、自动化,提高了焊接的效率和焊接质量。焊接变位机可应用于化工、锅炉、压力容器、电机电器、铁路交通、冶金等工业部门的自动焊接系统。

关键词:

焊接变位机;液压系统 ;回转; 倾斜;

Abstract

The design is subject to Weld change site equipment .The Weld change site equipment,which the hydraulic system been used to lighten its weight and achieve highly automatically. The transmission part of the equipment is powered by one group of oil pump,several hydraulic motor and three hydrocylinder drive the work table to achieve rotation, incline and Vice-arm to adjust work table the height. The detailed system feature and components have been introduced in this design to emphasis the cutting edge and reality feature which been enhanced by the specialty design of its major component。Weld change site equipment is mainly for welding industry to reduce the Welds the assistance period, enhance work efficiency, reduce utility of labour and improve quality of welding. Most importantly, Weld change site equipment could enhance the effect of almost every sort of welding。

In the welding production, it can meet the welding frequently to transition and to choose the appropriate welding position the situation, in view of this actual demand. I design the Weld change site Equipment. It has been possible through the work table rotation and incline. It causes the welded joint to be in easily to weld the position. The Weld change site equipment and the welding operation machine coordination use, can realize the welding mechanization, the automation, enhanced the welding efficiency and the welding quality. Weld change site equipment can be applied in the industrial section of the chemical engineering, boiler, pressure container, electrical engineering electric appliances, rail communication, metallurgy...etc. to weld system automatically.

Keywords:

Weld change site equipment;hydraulic system;rotation;incline

本次设计的具体参数:

最大的工作载1000N;工作台的回转速度为0.2r/min;回转角度为360°;工作台倾斜速度为0.5r/min,倾斜角度为120°。工作台回转轴的转矩为200N•m。

目 录

引言 3

1焊接变位机的总体设计 5

1.1焊接变位机的类型 5

1.2焊接变位机械应具有的性能 5

1.3焊件变位机械的功能 6

2焊接变位机工作台运动方案的拟定和选择 8

2.1工作台回转运动方案的拟定和选择 8

2.2工作台倾斜运动方案的拟定和选择 9

3回转机构的设计与计算 10

3.1减速器的选择 10

3.2液压马达的选择 10

3.3齿轮的设计与计算 12

3.4软件校核齿轮的强度 16

3.5 回转轴的强度计算 18

3.6 联轴器的选取和校核 22

3.7轴承的选取和校核 23

3.8键的选取和校核 23

3.9 导电与导气装置 24

4 倾斜机构的设计与计算 25

4.1 液压缸的设计计算 25

4.2活塞杆稳定性校核 26

4.3选用的回路 27

5 结论 28

致谢 29

参考文献 30

|