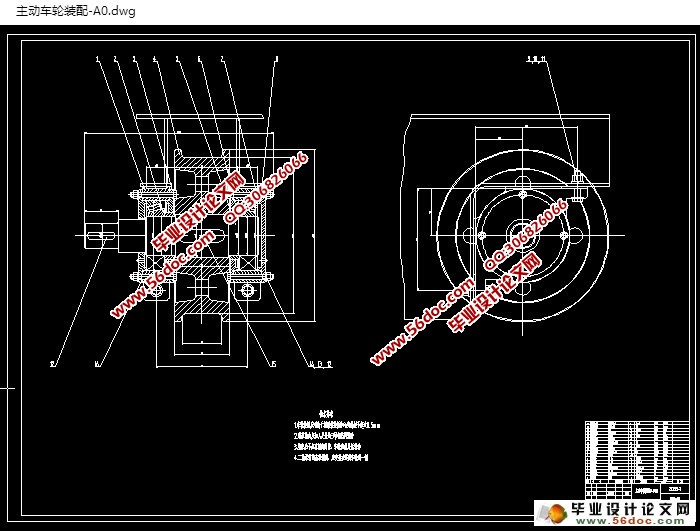

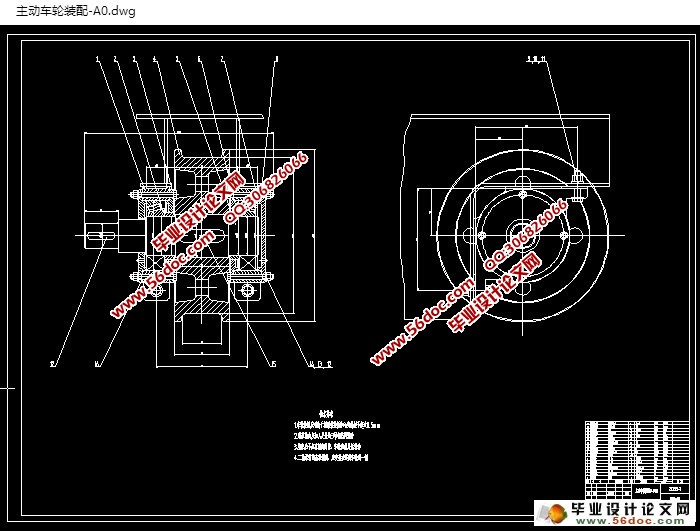

梁式(门式)起重机设计(含CAD零件装配图)(任务书,文献综述,设计说明书9100字,CAD图纸4张)

摘要

随着我国科技建设的不断推进,我国在生产等各个领域的建设规模也在不断扩大,同时促进了我国机械化建设水平的提高。所以,先进的机械设备将会成为促进施工速度的重要保障,同时也是保障工程质量的物质保证。起重机械在煤矿,码头等实现机械化,自动化以及提高劳动生产量方面发挥了重要作用。起重机械一般以间歇,重复的方法进行工作,取物装置的起升,下降或者平移等完成运送货物。在工作进行中,工作范围相对来说较大,且危险因素较多。

因此,在起重机的设计,制造过程中,设计参数和设计要素就相对重要,主要设计参考的几个要素包括:起重绳索,绞车及锚碇,轮胎起重机和汽车起重机,缆索起重机,桩基,构件装卸运输与堆放等。

设备管理是企业经营的重要环节,通过各种技术,经济和组织等措施,对现有设备进行规划,设计,使用,维修,改造,直至完全报废等全过程的管理。

我国对安全生产方面一直都相当重视,但是在执行和客观的条件方面都有许多不确定的不安全因素,尤其是在人为方面,由于生产者忽视安全生产的作用,往往会造成很大的安全事故。我们应该从这些相当重大的生产事故中吸取教训,防患于未然,最根本的最重要的就是从起重机械的设计和管理等一些方面做起,保证产品的质量,尽量减少事故的发生。

关键词:起升机构; 小车运行机构; 门式起重机

Abstract

With the continuous advance of China's economic construction, manufacturing and other areas of the building are getting bigger, while promoting improvement in the level of mechanization. Therefore, advanced machinery and equipment has become an important guarantee to promote the construction speed, but also ensure the quality of the material guarantee. Lifting machinery in the mines, docks and other mechanization, automation, and improve labor productivity has played an important role.

Lifting generally intermittent, repetitive approach to work, extract lifting devices, down or panning, etc. to achieve delivery of goods. In the course of their work, the scope of work is relatively large, and a lot of risk factors.

So, in crane design, manufacturing process, design parameters and design elements is quite important, the main design elements of reference include: lifting rope, all kinds of pulleys, winches and anchor, mast, truck crane stack components such as transportation and handling.

Device management is an important part of business, through a variety of technical, economic and organizational measures for existing equipment planning, design, manufacture, installation, use, maintenance, alteration, until the retirement of the whole process of management. Management objective is to obtain a better job running effect, that is, we

should give full play to the effectiveness of the device, but also the pursuit cycle cost of the most economical.

Our country has always attached great importance to production safety, but in the execution, command and objective conditions, there are many uncertain factors of insecurity, especially in human terms, because producers ignore the role of production safety, often cause significant security incidents. We should start with the production of these major accidents learn and take preventive measures, the most important of the most fundamental is from the crane design, manufacture, use and management to start a series of aspects, to ensure product quality, as far as possible reduce accidents.construction, mechanization and automation are also rising, with this adaptation of crane technology is developing rapidly, increasing product range, range more widely.

Key Words:Hoisting mechanism; Trolley run institutions; Gantry crane

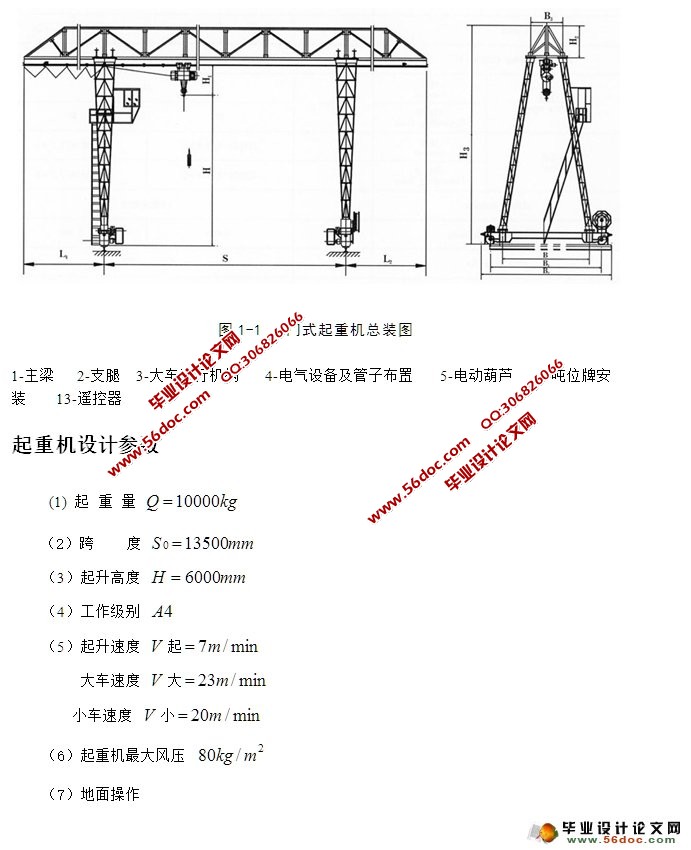

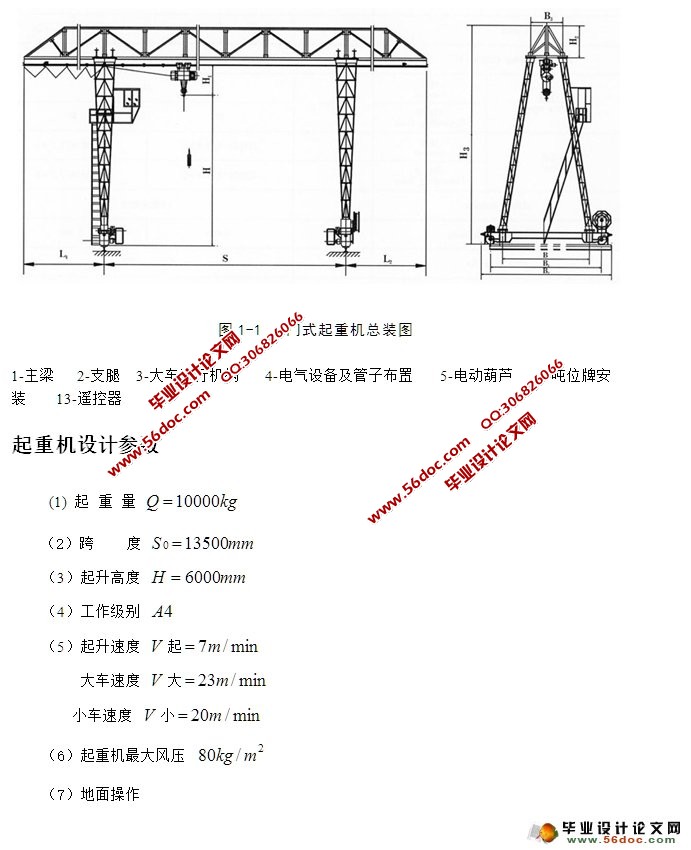

门式起重机的传动过程和工作原理

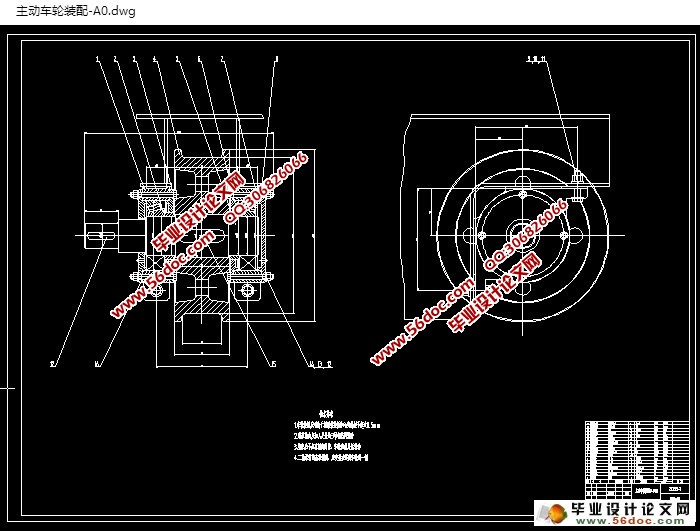

主要组成结构:电动机、齿轮联轴器、传动轴带、齿轮、联轴器、减速器、齿轮联轴器、卷筒、钢丝绳、定滑轮组、吊钩组

当起升机构接通电源后,制动器自动松闸,在控制电动机的正转或者反转时,动力就会通过联轴器、制动轮联轴器传递给减速器,电动机所输出的高转速通过减速器将迅速减速,在之后,就会出现低转速大转矩,然后就会拖动卷筒转动。当整条钢丝绳两端穿过装有滑轮组的吊钩后,分别固定在卷筒的两端,随着卷筒的正反转动吊钩组就会达成升降,货物就会实现上下降落。如果在工作过程中切断电源,电动机断电从而失去动力,进而制动器就会立刻制动,抱紧闸门,货物就会被悬吊在半空。电动机和制动器一般都实行电气联锁装置,只需要切断电动机电源,制动器就会依靠自身弹簧的张力作用而发生制动,以便于可以保证工作中的安全。

目 录

第一章 引言 1

1.1 门式起重机的用途以及工作特点 1

1.2 门式起重机分类及其应用 1

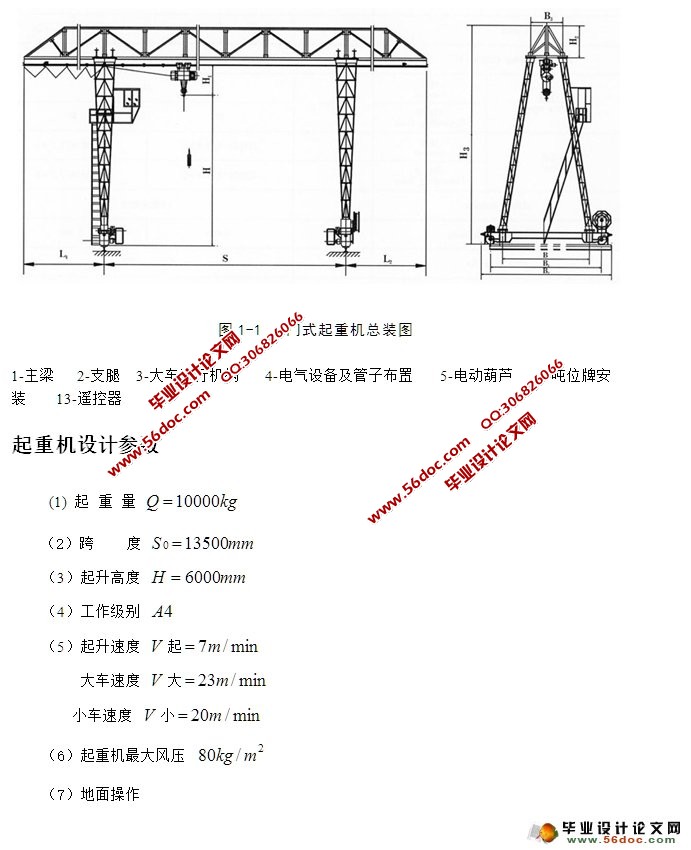

1.3 门式起重机的主要参数 2

1.4 门式起重机的表示方法 3

1.5 门式起重机的选用 3

1.6 门式起重机的传动过程和工作原理 4

1.7 门式起重机国内外研究历史与现状 4

1.8 本次起重机设计的结构图 5

第二章计算 6

2.1 载荷情况 6

2.1.1 正常的载荷 6

2.1.2 工作最大载荷 7

2.1.3 非工作最大载荷 7

2.2 起重机设计算依据 8

2.2.1 起重机设计依据 8

2.2.2 起重机设计参数 8

2.3 起重机截面特性设计计算 9

2.31 主梁截面几何设计 9

2.3.2 支腿截面特性 10

2.4 主梁设计计算及校核 12

2.4.1 主梁计算载荷与内力 12

2.4.2 主梁强度计算 16

2.4.3 主梁工字钢下翼缘局部集中应力 16

2.4.4 合成应力 17

2.5 支腿设计计算及校核 19

2.5.1 支腿几何参数 19

2.5.2 支腿强度计算 20

2.5.3 主梁刚度计算 23

结束语 24

致谢 25

参考文献 26

附录 27

|