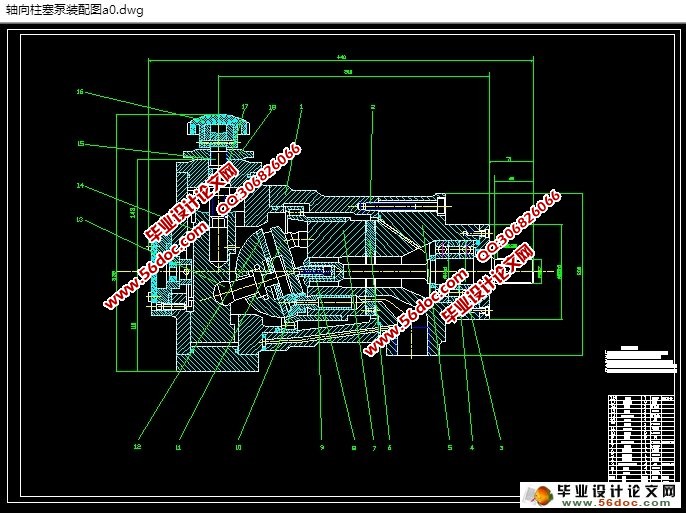

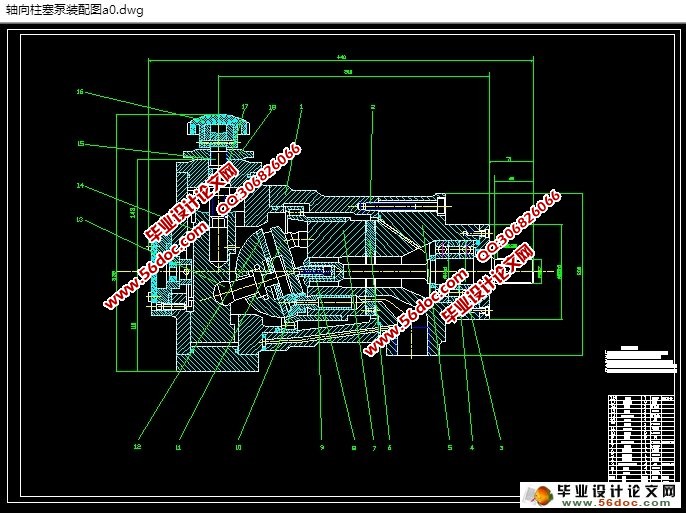

电反馈轴向柱塞泵设计(含CAD零件装配图)(任务书,文献综述,设计说明书11500字,CAD图纸3张)

摘要

液压泵是向液压系统是一种油液的动力元件,是液压系统必备的核心元件,液压泵对于液压系统的能耗﹑提高系统的效率﹑降低噪声﹑提高工作性能都十分重要。随着液压传动的推广液压泵显得十分重要。

本设计对轴向柱塞泵分析,对于轴向柱塞泵的分类阐述,,对于其结构,例如,柱塞的结构型式﹑滑靴结构型式﹑配油盘结构型式等进行了分析以及设计,受力分析,计算.对于缸体的选料,以及变量分类型式进行了缜密分析,对比其优缺.本设计对轴向柱塞泵的优缺点进行了分析,柱塞泵的配流方式有三种,分别为阀配流,轴配流,端面配流,以上配流方式广泛用于柱塞泵中,因为这种独特的配流方式对于柱塞泵抗高压力,高速化起到不可磨灭的重大作用,可以这样说,没有这三种配流方式就没有柱塞泵,但是这些配流方式在其工作中单一使用,液压系统中的核心元件,液压泵,其作用尤其重大,也是其所需的最主要的元件,随着液压传动的推广,液压泵的作用也逐渐显现出来,显得十分重要。同时也造成了一定程度上的不足在于本次设计中对于柱塞泵的一个重要元件滑靴做了相对详细的介绍和分析,它的存在形式分为三种,对于它的缸体以及结构等方面也进行了设计。轴向柱的塞泵是现在我国国内所急需的设计,现有的设计与其他发达地区较比有相对较大的差距。目前,我国在此方面虽有很大的进步。但是我们还是要看清自己的不足之处。并且加以改进,在此之前,我们要先清楚的认识到自己与其他发达地区相比的缺点,例如轴向柱塞泵设计的结构类型、配油盘的结构模式等皆需要进行改进。类型要多样化,规格要多元化。特别是对于其该有的适用的大小尺寸以及是其柱塞的回程结构也做了相应的介绍,柱塞式液压泵是以柱塞在柱塞腔内往复运动,改变其容积而完成吸油和排油的。是容积式液压泵的一个种类,根据其主要零件塞柱和缸体都是圆柱形的,因而其密封性能很好,精准度也很高,在其工作时承受的压力高而呗广泛应用。作为液压系统中不可取代的系统,轴向柱塞泵更有广阔的发展前景,在于其作用以及优劣等方面的考虑,相对于其他的液压系统来说,轴向柱塞泵更具有优势,其在于抗高压力以及高速化等方面有着不可取代的作用。因而我很怀揣希望展望其后发展。

关键词: 柱塞泵; 液压系统; 结构型式; 发展;

Abstract

Hydraulic pump to the hydraulic system is a fluid power components is essential core element of the hydraulic system, the hydraulic pump for the hydraulic system improve energy efficiency of the system to reduce the noise improve performance are very important. With the promotion of the hydraulic drive pump it is very important.

The design analysis of axial piston pump, axial piston pump for classification set forth ,, for its structure, for example, structure type plunger slipper structure type oil pan structure type were analyzed as well as the design, stress analysis, calculation of election materials to the cylinder, and variable types were classified careful analysis, comparison of their advantages and disadvantages. The advantages and disadvantages of axial piston pump design were analyzed, piston pump with flow in three ways , respectively, with a flow valve, axial flow, end with the flow, or more widely used in piston pump with flow mode, as this unique feature flow mode for resistance to high pressure piston pump, high-speed play a major role in indelible, it can be said there was no assignment of these three ways, there is no piston pump with flow mode but these core elements in their work single-use, hydraulic system, hydraulic pumps, and its role is particularly relevant, but also its most important components required, With the promotion of hydraulic transmission, hydraulic pump effect is gradually revealed, it is extremely important. But also caused a shortage to some extent, this design is an important element for the piston pump shoe made a relatively detailed description and analysis of its existing form is divided into three, for its cylinder and structure It has also been designed. Axial piston pump is now urgently needed China's domestic design, existing design and other developed regions than over a relatively large gap. At present, despite great progress in this regard. But we still want to see their own shortcomings. And to improve, in the meantime, we must first clear understanding of the shortcomings of its own compared to other developed areas, such as structural type axial piston pump design, oil pan structure model needs to be improved mused. Type should be diversified, specifications should be diversified. Especially for its size that some suitable size and structure of their return plunger also made the corresponding presentation, piston reciprocating plunger pump is in the plunger cavity, changing its volume and complete suction and drain the oil. It is a kind of positive displacement pump, according to its main parts are cylindrical plugs and cylinder, and thus a good sealing performance, accuracy is also high, when its working pressure is high and chant widely used. As the hydraulic system irreplaceable system, axial piston pump more broad prospects for development, given its role in other aspects as well as the pros and cons, relative to other hydraulic systems, axial piston pump has more advantages, its resistance to high pressure and that the speed and so has an irreplaceable role. Therefore I hope that carries the prospect of subsequent development.

Keyword: The pillar fills a pump; the liquid presses system; structure pattern; will develop from now on ;

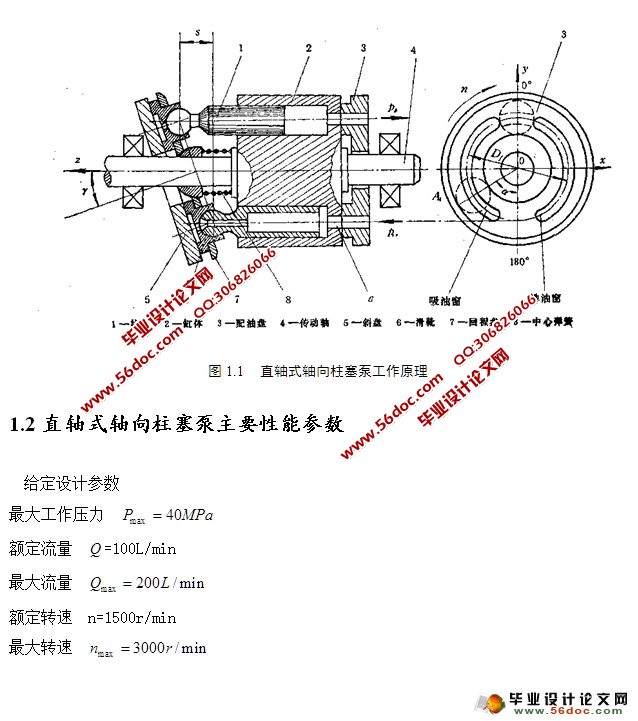

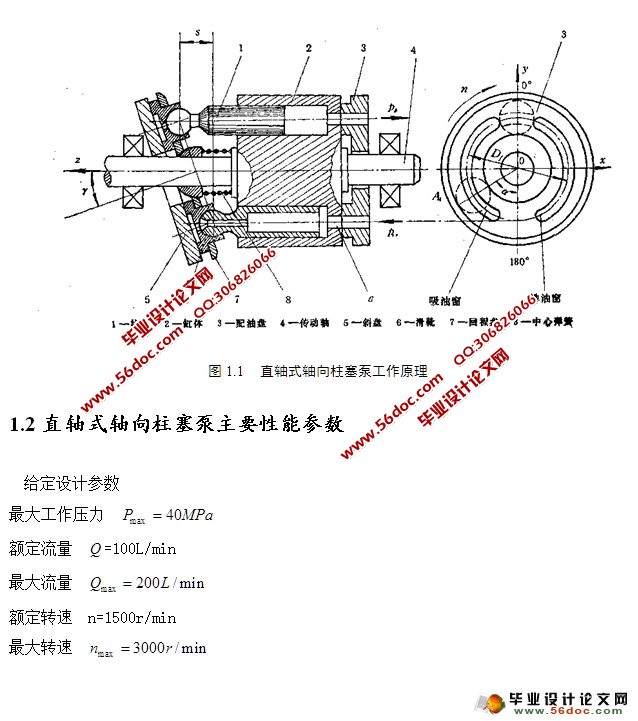

直轴式轴向柱塞泵主要结构示意图1.1。柱塞头装有滑靴,滑鞋底和斜板的平面运动。气缸驱动柱塞旋转,由于斜板表面相对汽缸(xoy方面)有一个坡度角,迫使活塞柱塞腔作为直线往复运动。如果根据图形缸体n方向,范围内的~,柱塞的下死点(位置)开始不断,柱塞腔体积增加,直到上死点(位置)。在这个过程中,柱塞腔恰逢配油盘吸油窗口是相互联系的,油柱塞腔吸,这是吸油的过程。范围内筒旋转,~,柱塞斜板从上死点的限制下不断进入空腔.

目 录

绪论 1

第一章 直轴式轴向柱塞泵工作原理与性能参数 3

1.1直轴式轴向柱塞泵工作原理 3

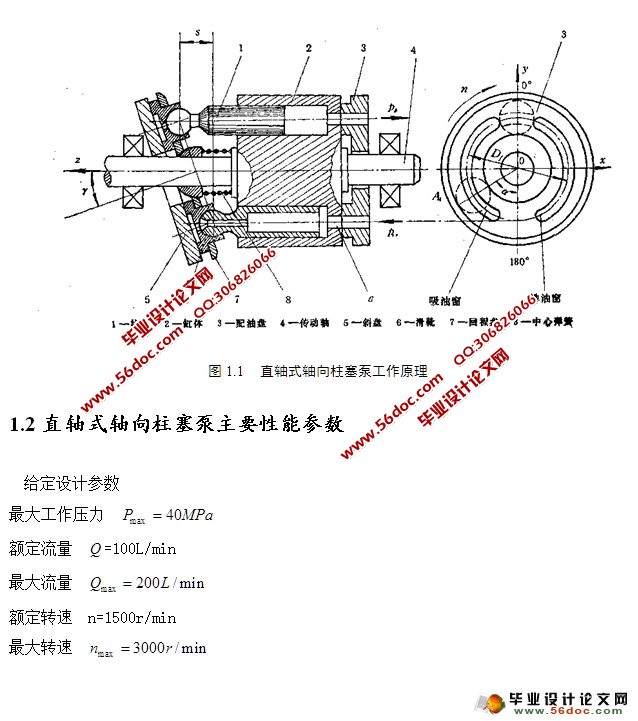

1.2直轴式轴向柱塞泵主要性能参数 4

1.2.1排量﹑流量与容积效率 4

1.2.3功率与效率 6

第二章 柱塞受力分析与设计 8

2.1柱塞受力分析 8

2.1.1柱塞底部的液压力 8

2.1.2柱塞惯性力 9

2.1.3离心反力 9

2.1.4斜盘反力N 9

2.1.5柱塞与柱塞腔壁之间的接触应力 和 9

2.2柱塞设计 11

2.2.1柱塞结构型式 11

2.2.2柱塞结构尺寸设计 13

2.2.3柱塞摩擦副比压P﹑比功 验算 15

第三章 滑靴受力分析与设计 17

3.1滑靴受力分析 17

3.1.1分离力 17

3.1.2压紧力 19

3.1.3力平衡方程式 19

3.2滑靴设计 20

3.2.1剩余压紧力法 20

3.3滑靴结构型式与结构尺寸设计 21

3.3.1滑靴结构型式 21

3.3.2结构尺寸设计 23

第四章 配油盘受力分析与设计 26

4.1配油盘受力分析 26

4.1.1压紧力 27

4.1.2分离力 27

4.2配油盘设计 30

4.2.1过渡区设计 30

4.2.2配油盘主要尺寸确定(图4.3) 30

4.2.3验算比压p﹑比功pv 32

结论 34

参考文献 35

致 谢 36

|