全自动盘料弯管机弯曲装置设计(含CAD图)(任务书,文献综述,设计说明书13600字,CAD图纸2张)

摘要

伴随着我国加快经济体制改革步伐并顺利加入WTO,中央空调行业及其他各行各业都面临史无前例的挑战和机遇。家用中央空调应用范围为80-800m2住宅,但是随着我国房地产行业的突飞猛进,100m2以上的住宅在如今楼盘建设中比例越来越大。这就直接为中央空调提供了晋级空间。

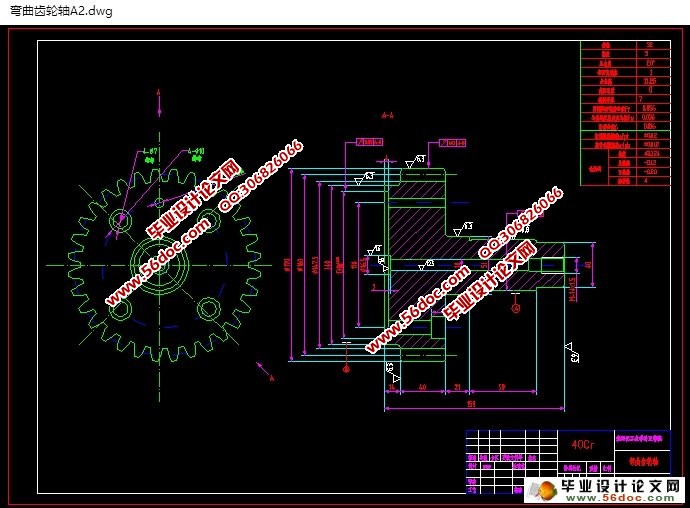

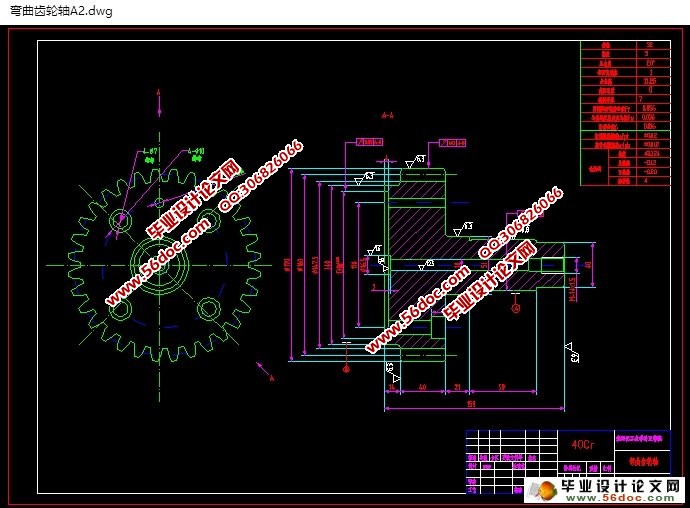

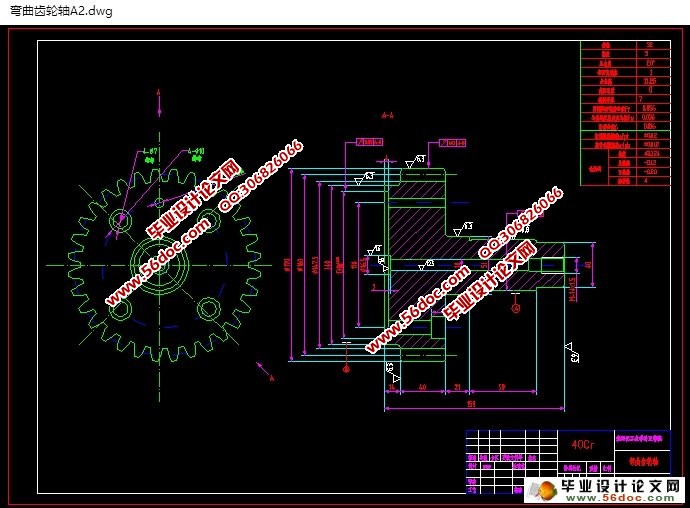

空调核心的制冷部件是冷凝管。制冷装置的重要原材料就是冷凝管,是制冷剂的运输通道。就现在看来冷凝管主要由弯管机生产,全自动盘料弯管机弯曲装置是弯管机不可缺少的一部分,由弯曲模、夹紧模、托架、夹紧油缸、弯曲油缸、托架油缸、弯曲齿条、轴承座、弯曲齿轮等构成。铜管经过导向套筒从弯曲模和夹紧模之间穿入全自动弯管机主机的芯轴杆上,然后夹紧模将铜管夹紧在两模之间,同时托架上升托住铜管,弯曲装置向前翻转作180°弯曲,将铜管弯制成U型管。

本设计对弯管机盘管弯曲装置进行了总体结构、弯曲模、夹紧模的设计、对齿轮齿条进行了计算与校核。对轴承进行了选择与校核。对轴进行了设计与校核。并选取了动力系统,论述了弯管机弯曲装置的调整、故障及其处理方法。

关于自动弯管弯管机底部凹模,模角一般为86〜86°。在行程的底部,集约应具有比之间的间隙的材料厚度略大。为了提高成形角度,因为一个底模弯曲大(约4倍),降低的弯曲半径范围通常导致回弹应力。冲压具有底部弯曲模具弯曲是相同的,只是把打孔处理的前端成为需要的弯曲半径,而密集的间隙小于该材料在冲程的底部的厚度。由于施加足够的压力弯曲(约10倍),力冲前接触材料,基本上避免了回弹。为了选择最小吨位规格,最好是大于所述弯曲半径的材料厚度来规划,并尽可能通过自由弯曲的方法。当弯曲半径是较大,往往不影响片的质量和它在将来使用。精密的弯曲精度要求需要慎重考虑,正是这个因素,决定了你需要考虑数控弯管机或手动弯管机。如果弯曲精度不能改变,必须注重数控机床上。数控弯管机滑块重复精度为 0.0004英寸,形成一个精确的角应该在精确度良好的模具中使用。手动弯管机滑块重复精度 - 0.002英寸,并使用适当的模具的情况下通常产生的加或偏差±2〜3°。

此外,数控弯管机,以装载准备得快,当你需要弯曲,许多小批量零件,这是一个毫无疑问的考虑的原因。即使你有一个完整的模具模架,不要以为这些模具适合于新机。必须检查每模具的磨损和方法是在冲头前端到肩和凹模之间肩长度的长度的量度。对于常规的模具中,偏差应每英尺左右+ / - 0.001英寸,并且偏差不超过0.005英寸正负的总长度。作为用于精磨模具,每英尺精度应+ / - 0.0004英寸,总精度可能不大于+ / - 0.002英寸。最好细磨用于数控弯管机,常规模具用于手动弯管机模具。事实上,我们也常弄得只买新的弯管机,买不到合适的模具来匹配错误。弯曲人们常常被忽略的一个因素是在管弯曲机弯曲长的前方的材料。低碳钢板弯曲90°,7.5吨压力弯管机很可能将被收取的钢顶起来,操作员必须作好准备为280的指标沿5×10英尺10镑的假设直降。可能需要几个强势的工人甚至一台起重机。弯曲弯管机操作员往往需要很长的侧面部分,但不知道他们多么努力工作。现在有适于从事这项工作车间的保持器装置,该装置可根据新的和旧的机器的需求进行修改。使用弯管机模具设备,形成长边的部分。

关键词: 弯曲齿轮; 弯曲齿条; 弯曲模; 轴承座; 油缸

Abstract

With the accelerated pace of China's economic reform and the WTO, central air-conditioning industry with other industries, faced with unprecedented challenges and opportunities. Home central air conditioning is suitable for 80-800mm2 residential, as China's housing industry, 100mm2 or more new residential housing in the proportion is growing. This provides central air conditioning provides a huge space for development.

In the air-conditioned interior, plays an important cooling components are reusable condenser. Condenser refrigeration apparatus is an important raw material, is a refrigerant channel. Condenser tube bending machine depends mainly on the production, automatic plate feeding tube bender bending device is a part of the bending mold, mold clamp, bracket, clamp cylinder, bending cylinders, cylinder bracket, bend the rack , bearing, bent gear and other accessories. Brass through the guide sleeve and clamping mold from bending mode between automatic bending machine host penetration mandrel rod, and then the brass clamping mold mold clamping between the two, while boosting the bracket up brass, flip forward bending device for 180 ° bend, bend the copper tube into the U-tube.

The design of the coil for pipe bender bending device for the overall structure of the bending mold, mold clamping design, rack and pinion were calculated and checked. A selection of the bearing and checked. The shaft is designed and checked. And select the power system, discusses bender bending device adjusting the fault and its treatment.

About the automatic bending pipe bender a bottom concave die, die Angle generally is 86 ~ 86 °. In the bottom of the stroke, intensive should have a slightly larger than the material thickness of the gap between. To improve the forming Angle, because a bottom die bending the large tonnage of bends (about 4 times), reduced the bending radius range usually cause the springback stress. Stamping bending with a bottom bending die are the same, just put the front end of the punch processing became the bending radius of the need, and intensive clearance is less than the thickness of the material at the bottom of the stroke. Due to exert enough pressure bends (about 10 times) force punch front contact material, basically to avoid the springback. In order to select the minimum tonnage specifications, the best is greater than the material thickness of the bend radius to plan, and as far as possible by free bending method. When bending radius is bigger, often do not affect the quality of the pieces and its use in the future. Precision bending precision demand is a need careful consideration, it is this factor, determines the you need to consider a CNC pipe bending machine or manual pipe bender. If bending accuracy + / - 1 ° and cannot be changed, you must focus on CNC machine. CNC pipe bender slider repeat accuracy is + / - 0.0004 inches, forming a precise Angle that should be used in the precision and good mould. Manual pipe bender slider repeat precision of + / - 0.002 inches, and under the condition of using appropriate mould generally produces the deviation of plus or minus 2 ~ 3 °.

In addition, CNC pipe bender to prepare for loading die quickly, when you need to bend, many small batch parts, this is a no doubt consider the reasons. Die even if you have a shelf full of die, don't think that these mould is suitable for the new machine. Must be checked every mould wear and method is a measure of the length of the punch front-end to shoulder length between the shoulder and concave die. For conventional mold, deviation should be per foot around + / - 0.001 inches, and the deviation is not more than plus or minus the total length of 0.005 inches. As for fine grinding mould, per foot accuracy should be + / - 0.0004 inches, the total accuracy may not be greater than + / - 0.002 inches. Best to fine grinding mould used for CNC pipe bender, conventional mold for manual pipe bender. Indeed, we are often made to buy only the new pipe bender and don't buy the right mold to match error. Bending side people often ignored one factor is the material in front of the tube bending machine bending length. Assumptions along a 5 x 10 feet 10 - the gauge of low carbon steel plate bending 90 °, 7.5 tons of pressure pipe bender probably will be charged on the steel top up, and the operator must be geared up for the 280 - pound straight down. Make the parts may need several strong workers even a crane. Bending the pipe bending machine operator often need long side parts, but don't realize how much they work hard. Now there is a retainer device suitable for the workshop engaged in this work, the device can be modified according to the needs of new and old machine. Using the pipe bending machine mould device, forming long side parts only one operator.

Keywords: bending gear; bending rack; flexural modulus; bearing;

cylinder

全自动盘料弯管机弯曲装置的组成及工作原理

弯管机盘管弯曲装置是将铜管弯曲180°的装置,可以同时对4根铜管进行弯曲。通过调整模具、拖架等的位置可以加工其他型号的铜管。弯管机盘管弯曲装置由弯曲模、夹紧模、托架、夹紧油缸、弯曲油缸、托架油缸、弯曲齿条、轴承座、弯曲齿轮等构成。弯曲模具、夹紧模具、托架三点一线。铜管经过导向套筒从弯曲模和夹紧模之间穿入全自动弯管机主机的芯轴杆上,然后夹紧模将铜管夹紧在两模之间,同时托架上升托住铜管,弯曲装置向前翻转作180°弯曲,将铜管弯制成U型管。为防止铜管弯曲部的变形,有万向活动芯轴在铜管内,在弯曲的同时向弯曲处自动喷油润滑。

2.2全自动盘料弯管机弯曲装置的规格

⑴材料的材质:T2、TP2脱氧铜管;材料状态:软(按GB8895-88选用);

⑵材料的尺寸:9.52×t0.35mm 盘管(光管及内螺纹管)下料长度:300-600mm;

⑶下料长度: L=Min.300~Max.20001.0mm,端部不齐度:Max.1mm;

⑷循环时间:L=1000mm时 18秒/每循环;

⑸弯曲部椭圆度:Max.15%;

⑹弯曲部壁厚减薄率: Max.35%。

目 录

引 言 1

第一章 弯管机概述 4

1.1弯管机的发展概况 4

1.2弯管机研究的意义和价值 5

1.3弯管机构成及工作原理 5

1.3.1弯管机的构成 5

1.3.2弯管机的工作原理 5

第二章 全自动盘料弯管机弯曲装置概述 6

2.1全自动盘料弯管机弯曲装置的组成及工作原理 6

2.2全自动盘料弯管机弯曲装置的规格 6

第三章 全自动盘料弯管机弯曲装置的结构设计 7

3.1全自动盘料弯管机弯曲装置总体的结构设计 7

3.2弯曲模和夹紧模的设计 8

3.2.1回弹角的计算 8

3.2.2影响回弹的因素 8

3.2.3弯曲模和夹紧模工作原理 9

3.3齿轮齿条的设计 10

3.3.1齿轮传动的优点 10

3.3.2齿轮的几何尺寸计算 10

3.3.3齿轮的接触疲劳强度校核 11

3.3.4齿轮的弯曲疲劳强度校核 12

3.4轴承的选择与校核 13

3.4.1.轴承的选择 13

3.4.2所选系列轴承的性能特点 13

3.4.3轴承的寿命校核 13

3.4.4轴承的静强度校核 14

3.4.5轴承的极限转速校核 15

3.5轴的设计 15

3.5.1轴的直径计算 15

3.5.2轴的校核 15

第四章 全自动盘料弯管机弯曲装置的结构设计 19

4.1 全自动盘料弯管机弯曲装置油缸的选择 19

4.2全自动盘料弯管机弯曲装置液压泵的选择 19

4.2.1液压泵的选择 19

4.2.2 V型柱塞泵的参数 21

4.2.3 V型柱塞泵的特性 21

第五章 全自动盘料弯弯曲装置的调整管机 22

5.1弯曲角度的调整 22

5.2托架高度的调整 23

5.3压力调整 23

5.4速度调整 24

第六章 可能出现的故障及原因 25

6.1不夹紧的原因 25

6.2不弯管的原因 25

6.3弯曲形状差的原因 26

结 论 27

参考文献 28

致 谢 29

|