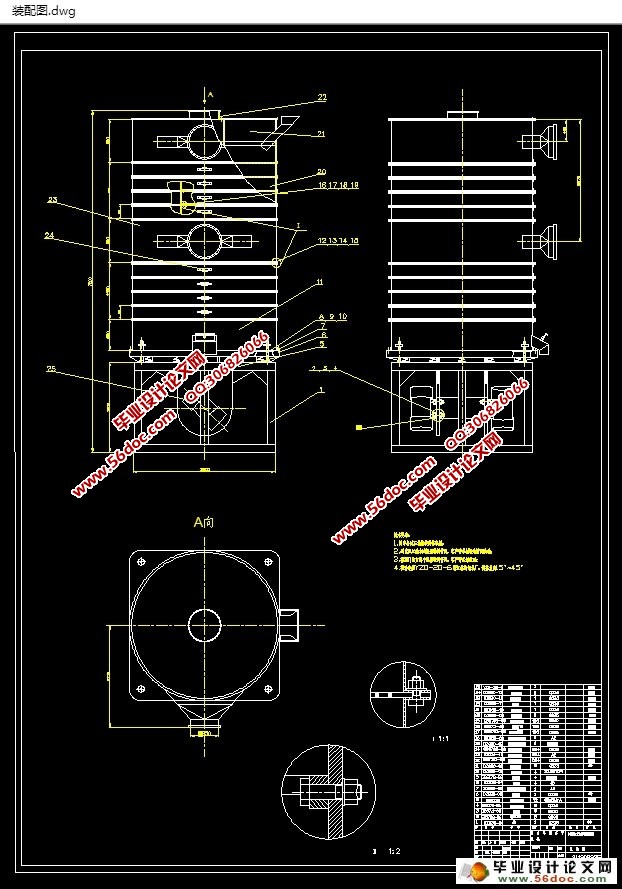

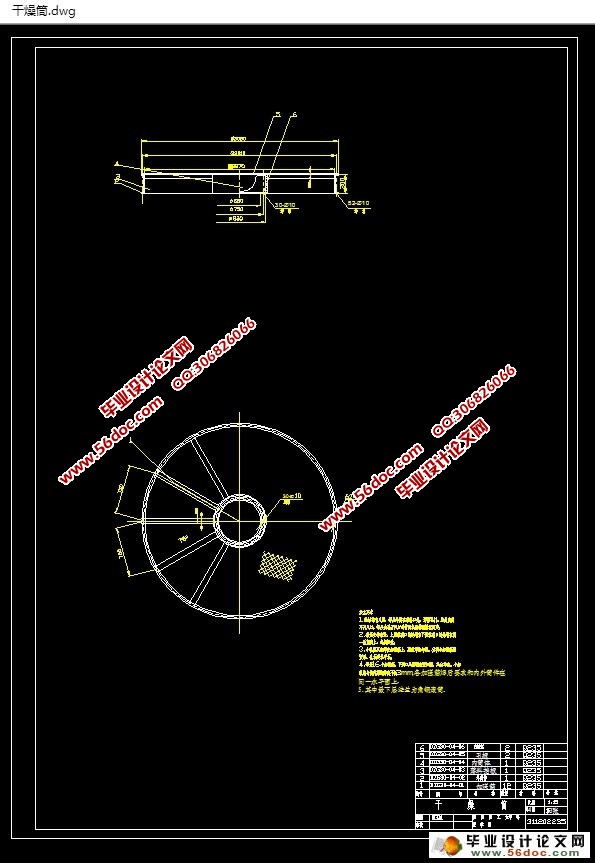

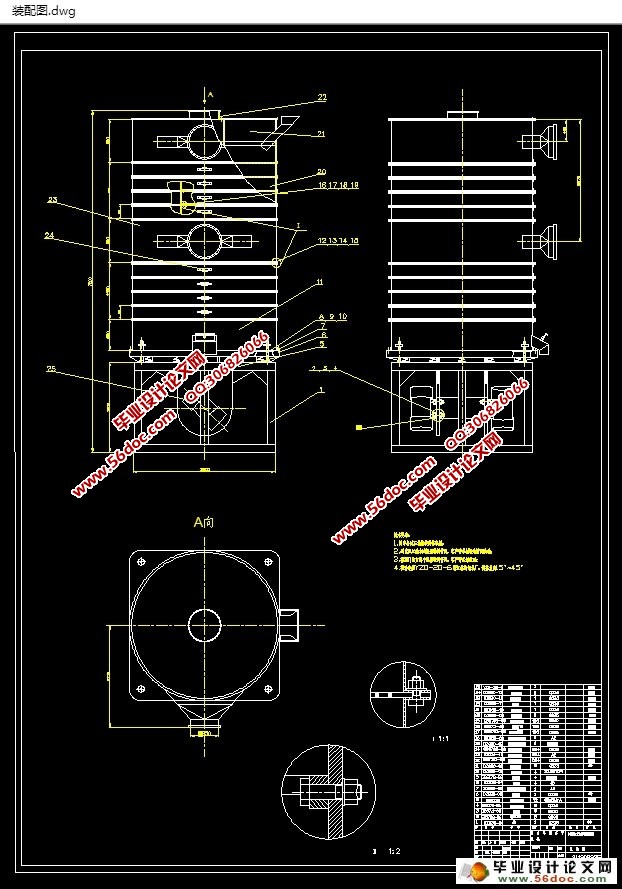

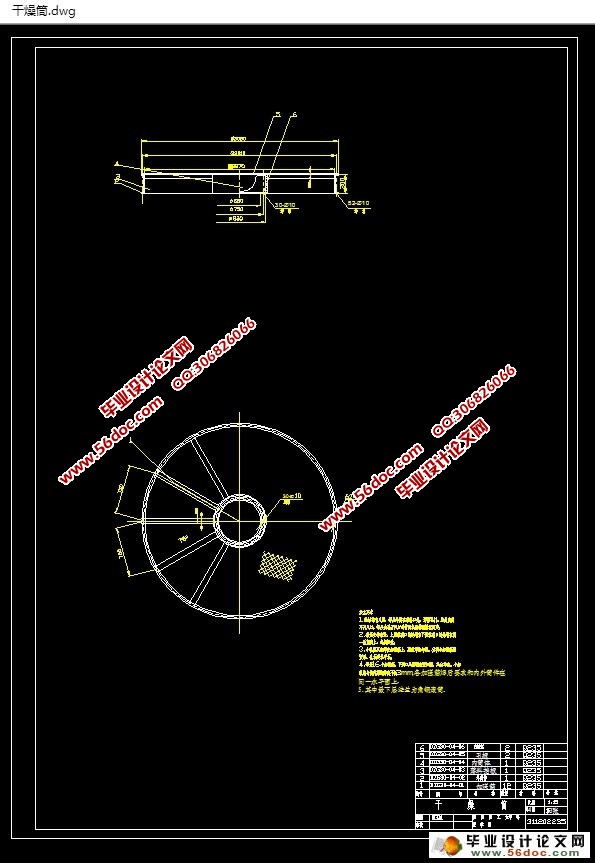

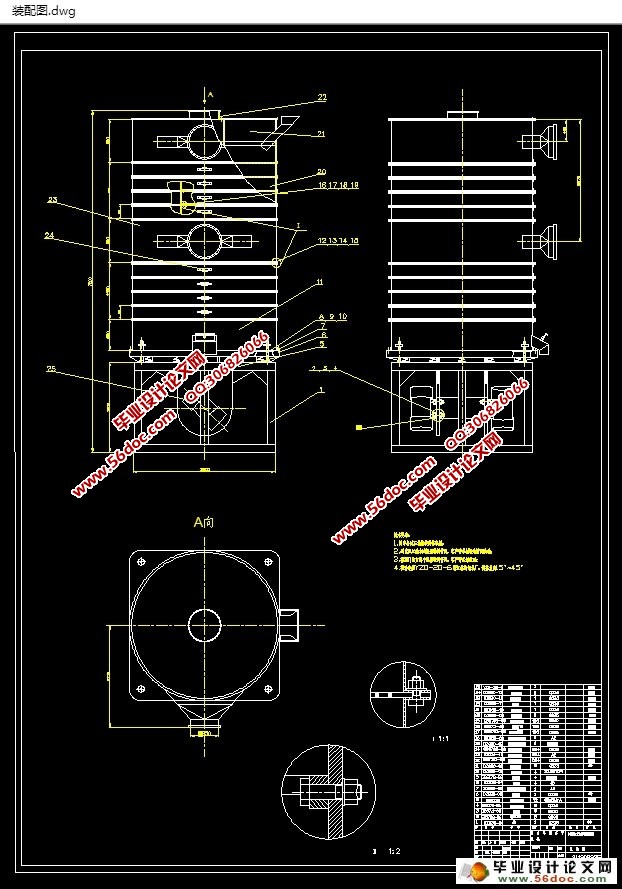

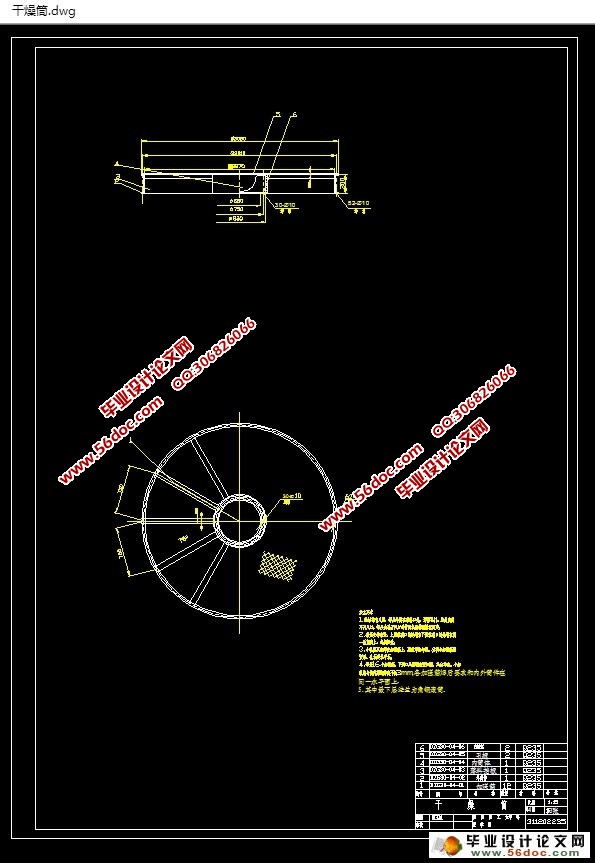

Φ3000振动式单循环干燥机设计(含CAD零件装配图)(任务书,文献综述,设计说明书11000字,CAD图纸4张)

摘要

目前,干燥技术对大多数工业制造是一个非常重要的过程,它可以直接影响到产品的形式,质量,性能和工艺等。在烘干技术,覆盖面积广,涉及广,即与传热传质原理,和的特点和治疗规模有密切的关系,最终反映在不同的器件结构和制造工艺。目前我国的干燥技术可以追溯到6000多年前的陶器制造业和晒盐技术的沿海地区,自1949年以来,一些现代干燥技术,如喷雾干燥,空气干燥,和流化床干燥,已适用于国内的工业产权;但到目前为止,仍然有必要在生产过程中的创新。七十年代以后,随着烘干技术,装备制造精细化生产和应用的发展,科学技术的迅猛发展,科学技术交流,渗透和增长,干燥技术的各个地区之间也有巨大的发展和进步,一大批优秀的干燥剂进入市场。此外,一些新的设计也慢慢成熟。结果表明,干燥技术在国民经济的好处占据越来越重,并且广泛应用于各种行业。然而,干燥技术的工艺极其复杂,且有此过程中,这也带来了很大的困难在理论研究。从现有的信息看,人们对在干燥操作知之甚少期间许多不同的干燥的差异,但也有工业应用和理论研究..干燥技术的研究方法主要是从宏观方面宣誓和理论推导谴责,宣传的主要因素和干燥的效果进行总结,以提高干燥性能。随着我国经济的发展和世界经济一体化和是生产的需求,一定要理论创新推动机设计,越来越走向经济,高效,可靠,环保的发展方向,标准化,自动化,大型应该是具有非常广阔的前景。

关键词: 干燥; 振动; 物料; 多层; 扭振

Abstract

At present, drying technology is a very important process for most industrial manufacturing, which can directly affect the form, quality, performance and process of the product.. In drying technology, covering a wide area, involving wide, that is, the principle of heat and mass transfer, and the characteristics and the size of the treatment have a close relationship, and ultimately reflected in the different device structure and manufacturing process. The drying technology in China can be traced back to 6000 years ago pottery manufacturing and solar salt technology of coastal areas, since 1949, some modern drying technology, such as spray drying, air drying and fluidized bed drying, has been applied to the domestic industrial property right; but so far, it is still necessary to have in the production process of innovation. Since the seventies, with drying technology and equipment manufacturing fine production and application development, the rapid development of science and technology, science and technology exchange, penetration and growth, drying technology in various regions are also a great development and progress, a large number of outstanding desiccant into into the market. In addition, some of the new design is slowly mature. The results show that the benefits of drying technology in the national economy become more and more important, and it is widely used in various industries.. However, the process of drying technology is extremely complex, and this process, which also brings a lot of difficulties in theoretical research. From the existing information, the people to the drying operation know very little during many different drying of difference, but there are also industrial applications and theoretical research. Drying technology research method is mainly from the macro aspects of the oath and the theoretical condemnation and publicity of the main factors and the drying effect were summarized in this paper. In order to improve drying performance. With the development of China's economy and integration of world economy and the needs of production, be sure to theory innovation promote machine design, more and more towards economic, efficient and reliable, environmentally-friendly direction of development, standardization, automation, large-scale should be has very broad prospects.

Keyword: Dry; Vibration, Supplies; Multi-layer; sprain and shake

本次设计的题目是振动式单循环干燥机的机械设计,主要是设计了干燥机的机体;

主要技术参数如下;

干燥管直径:3000mm

电机功率:1.5kw

电机型号:GB5218

材料:

圈数:n 10

干燥过程:

过程1:液体有一蒸汽形式从表面排除,此过程的速率取决于温度,空气温度,湿度和空气流速,暴露的表面积和压力等外部条件,洗过程称外部条件控制过程,也称恒温干燥过程.

过程2:无聊的内部 湿分的迁移是无聊性质,温度和湿含量函数,细过程称为内部条件控制过程.也称降速干燥过程。

目录

第一章 绪 论 1

1.1干燥技术的现状及前景 1

1.2干燥的基本原理 1

1.3干燥的目的 2

1.4干燥的方法 2

第二章 流化床干燥技术 4

2.1流化床干燥机 4

2.2 优点 4

第三章 振动干燥技术 6

3.1振动干燥的过程 6

3.2多层振动流化床干燥器 7

3.2.1 多层振动流化床干燥器的工作原理 7

3.2.2性能特点 8

3.3论文所做的工作 10

第四章 振动式单循环干燥机的计算 11

4.1干燥过程 11

4.2干燥物料 11

4.3实验参数的调节和测试 12

4.4机体的计算 13

4.5振动电机的选择 19

4.6弹簧的核算 20

4.7 干燥机的力学分析 24

结 论 25

参 考 文 献 26

致 谢 27

|