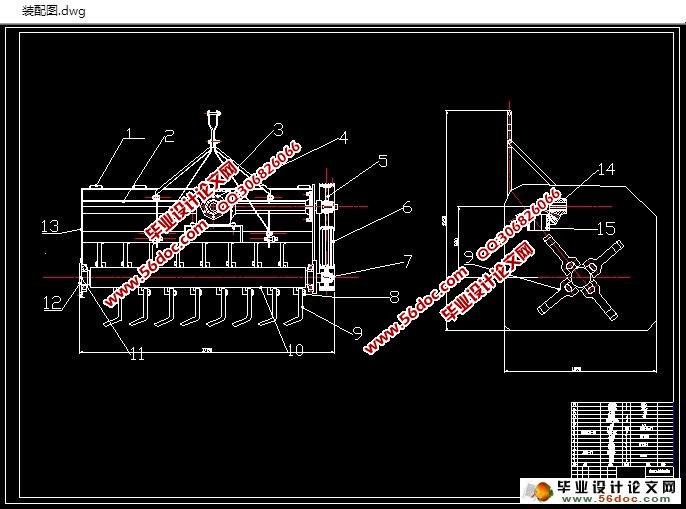

高粱秸秆剪切实验装置设计(含CAD零件装配图)(任务书,设计说明书13200字,CAD图纸6张)

摘要

我国年高粱秸秆产量丰富,但是高粱秸秆的利用率较低,大部分秸秆用于废弃和焚烧,不仅造成了高粱秸秆的浪费,还造成了环境的严重污染。秸秆还田具有增加土壤养分含量、改善土壤物理性状、提高土壤微生物和酶的活性、增加粮食产量等作用,可以增强土壤蓄水保墒能力,减少水土流失有效解决因秸秆废弃焚烧造成的环境污染问题,同时秸秆还田还对保护生态环境、实现农业的可持续发展具有十分重要的意义。

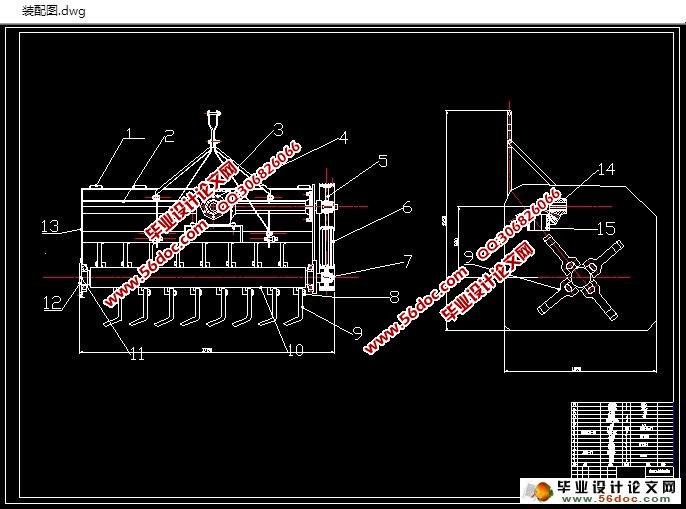

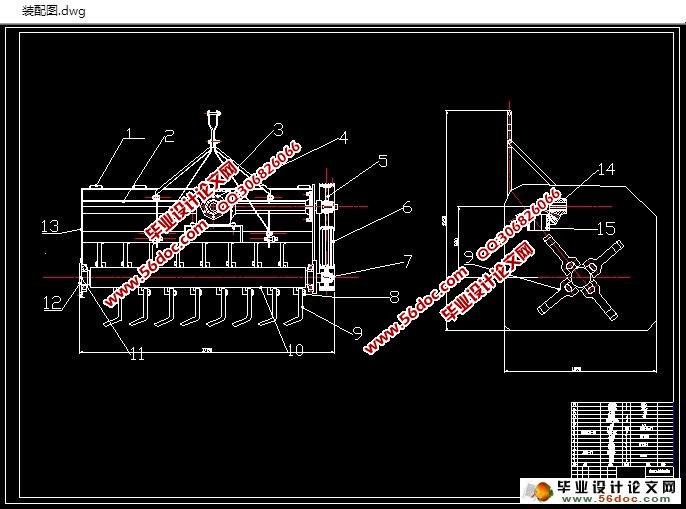

针对解决我国东北黑土区水土流失严重、秸秆焚烧污染环境等问题,结合农机、农艺的要求研发设计了多功能秸秆还田机,该机主要包括秸秆捡拾装置、秸秆切碎装置、根可一次进地完成秸秆捡拾、秸秆切碎、并针对其秸秆探施装置的性能进行试验研究。

关键词 高粱秸秆; 环境污染; 捡拾装置; 切碎装置;

水土流失; 性能研究;

Abstract

Our country is rich in sorghum straw yield, however,the utilization of sorghum straw were lower, most of the straw for abandoned and burned, not only bringing therwaste of the resource, but also making environmental pollute. Straw returning can increase the content of soil nutrient, improve the soil physical properties, increase soil microbial and enzyme activities, increase grain yield and so on. Straw returning also can enhance the soil water holding capacity, reduce soil erosion, can effectively resolve the environmental pollution problems caused by burning of straw. Meanwhile Straw returning has great significance for the protection of the ecological environment and realization sustainable development of agriculture.

To solve the serious problem of soil erosion of Northeast China and environmental pollution caused by straw burning, the mutl functional straw machine was designed combined with there quirements of agrichltural machinery and agronomic. This machine mainly include straw pick-up device, straw cutting device, which can complete straw's pickup, cutting, and experimental study was carried out according to the deep-application device's performance.

Key words: sorghum straw;the environmental pollution;collecting device;

chopped device;soil and water loss; performance study;

目 录

第一章 引言 1

1.1研究的目的与意义 1

1.1.1 土地培肥 2

1.1.2粮食增产秸秆还田是有效的增产措施。 2

1.1.3生态环境改善 2

1.2机械化秸秆还田技术及其国内外研究现状 3

1.2.1国内现状 3

1.2.2国外现状 8

1.3主要研究内容 9

1.4技术路线 11

第二章多功能秸秆还田机总体设计 12

2.1整体结构与工作原理 12

2.2传动系统设计 13

2.2.1秸秆捡拾喂入切碎传动系统设计 13

2.2.2秸秆深施传动系统设计 15

2.3控制系统设计 15

第三章秸秆捡拾与喂入装置设计 20

3.1秸秆捡拾装置设计 20

3.1.1结构设计与工作原理 20

3.1.2捡拾过程运动分析 20

3.1.3受力分析 22

3.1.4主要结构参数和运动参数的确定 23

3.2秸秆喂入装置设计 23

3.2.1结构设计 23

3.2.2受力分析 24

3.2.3主要结构参数和运动参数确定 25

第四章切碎装置设计 27

4.1结构设计 27

4.2主要工作参数确定 28

4.2.1切碎滚筒转速的确定 28

4.2.2定刀配置高度 28

结论 30

参考文献 31

致谢 32

|