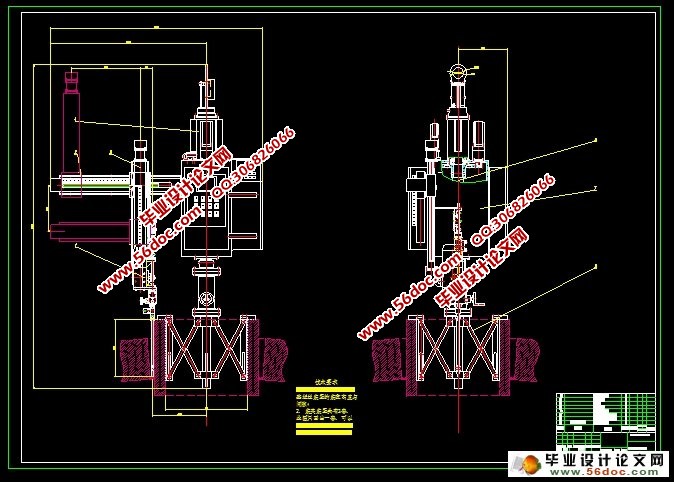

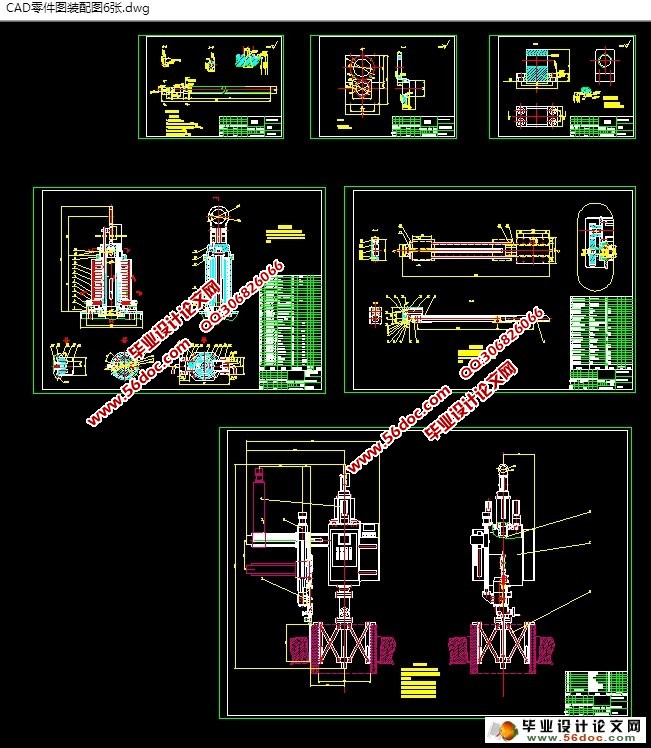

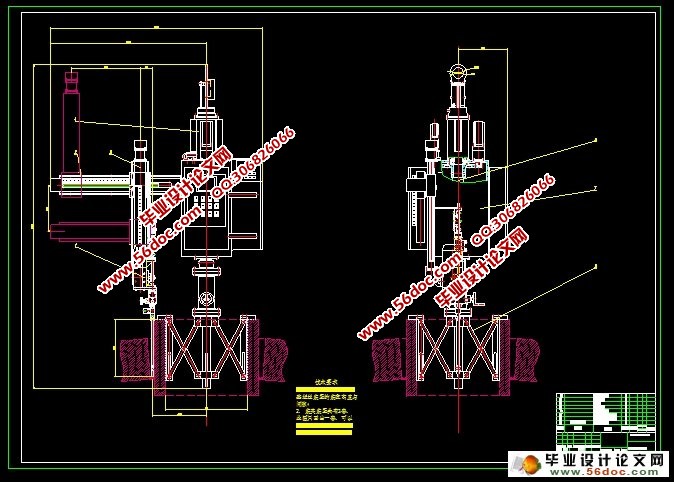

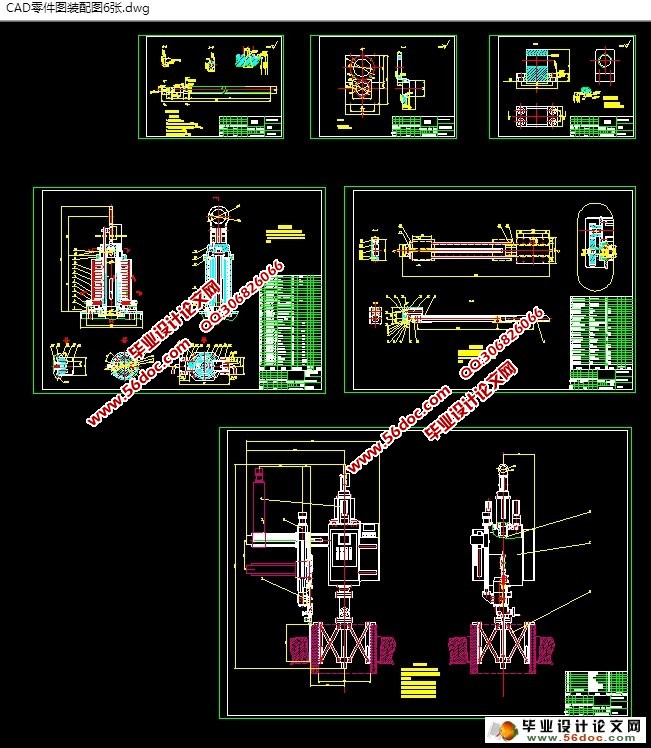

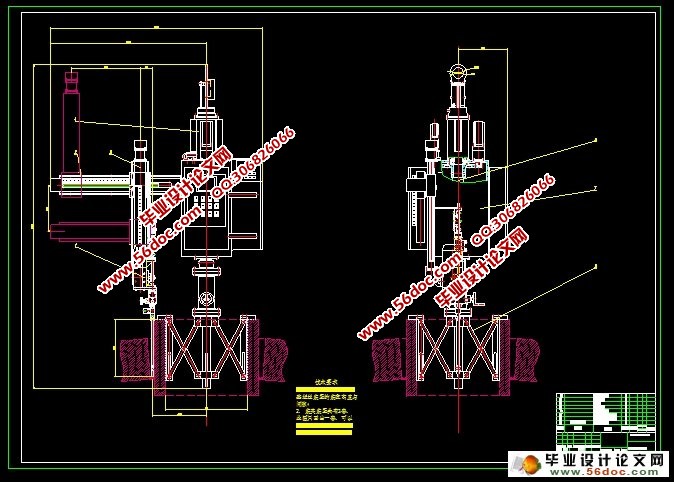

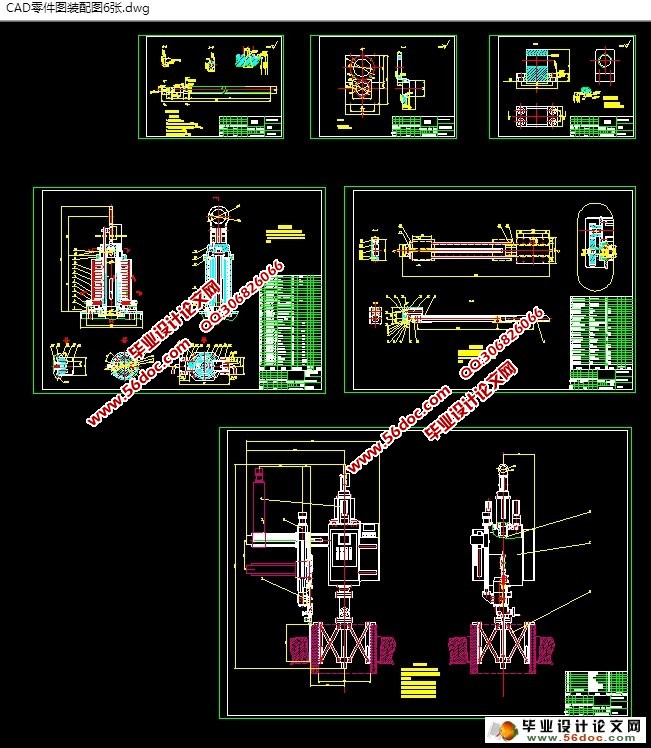

重型压力容器马鞍形自动焊机设计(含CAD零件装配图)(设计说明书18000字,CAD图纸6张)

摘 要

重型压力容器马鞍形自动焊机是用来焊接筒体与接管的智能化焊接设备。很多重大技术装备,如百万千瓦级核电机组设备、超超临界火力发电机组的成套设备、百万吨级大型乙烯的成套设备等,都要实现大厚度、大直径的筒体与接管焊接。其中它们之间的马鞍形曲线焊缝的焊接是制造这些装备的关键所在。马鞍形自动焊机就是针对现有焊接装备难以实现大筒体与接管的自动化焊接而开发研制的,它能够实现大厚度、窄坡口三维复杂焊缝的焊接。

本文根据国内外焊接技术的实际应用情况,在深入了解和分析国内外现有大型焊接装备的前提下,借鉴它们的成功经验,提出了对于窄坡口马鞍形焊缝多层多道循环焊接技术方案。

关键词 重型压力容器;马鞍形曲线;自动焊机;运动仿真

Abstract

The heavy pressure vessel saddle automatic welding machine is used for welding of tube and intelligent pipe welding equipment. A lot of major technical equipment, such as the million kilowatt class nuclear power generating equipment, ultra supercritical thermal power generating units, complete sets of equipment megaton large ethylene equipment, want to realize cylinder thickness, diameter and pipe welding. The welding of saddle shaped seam between them is the key equipment of producing these. Saddle automatic welding machine for welding equipment is available to the cylinder body and the control of automatic welding and welding is developed, it can achieve large thickness, narrow groove weld of 3D complex.

In this paper, according to the practical application of welding technology at home and abroad, in the in-depth understanding and analysis of the existing domestic and foreign large welding equipment under the premise, to learn from the experience, put forward to narrow groove saddle shape weld multipass circular welding technology scheme. Based on this scheme is determined the overall design, the heavy pressure vessel for saddle shaped curve automatic welding machine kinematic and dynamic parameters, and complete the detailed design of each part of the mechanical structure.

Automatic welding machine for saddle shaped curve of heavy pressure vessel designed by this paper has good versatility, high control precision, stable operation, compact structure, simple operation, convenient maintenance, can be very good to meet the large cylinder and pipe welding requirements. Automatic heavy pressure vessel welding, improve production efficiency, to fill the gaps in domestic related fields.In this paper, according to the practical application of welding technology at home and abroad, in the in-depth understanding and analysis of the existing domestic and foreign large welding equipment under the premise, to learn from the experience, put forward to narrow groove saddle shape weld multipass circular welding technology scheme.

目 录

摘 要 I

第1章 绪论 1

1.1 课题背景 1

1.2 国内外研究现状 2

1.2.1 国内研究现状 2

1.2.2 国外研究现状 4

1.3本文研究内容 6

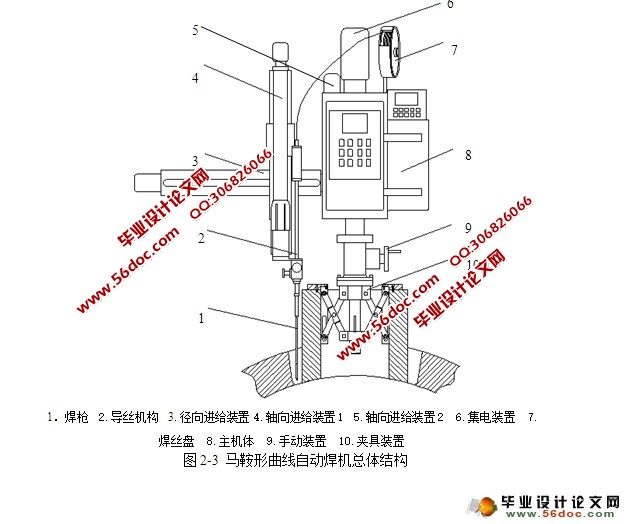

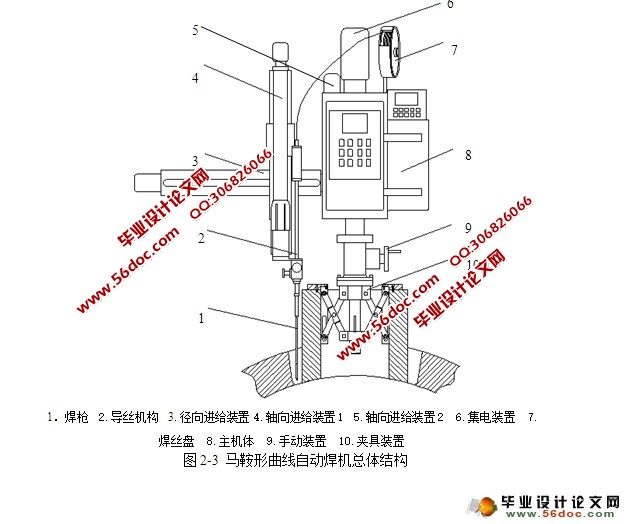

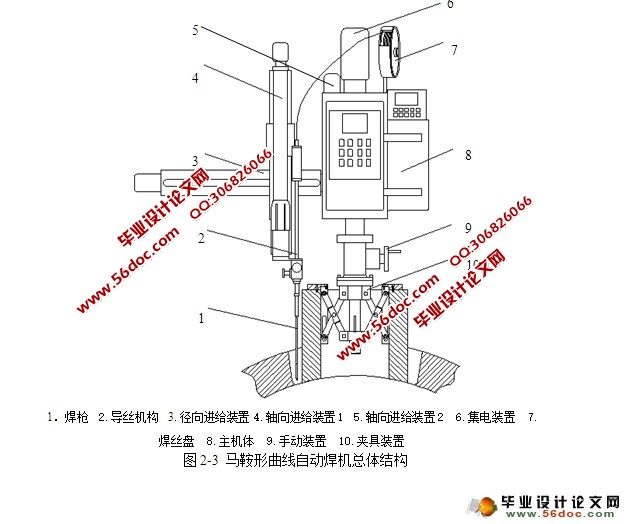

第2章 总体设计 8

2.1设计要求 8

2.2 设计原则与总体布置 10

2.1.1 设计原则 10

2.1.2 总体布置 10

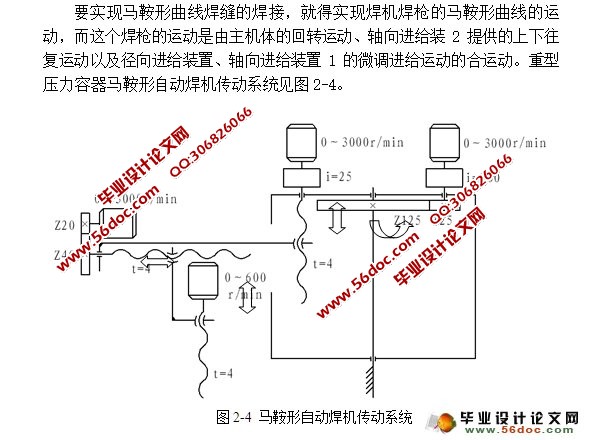

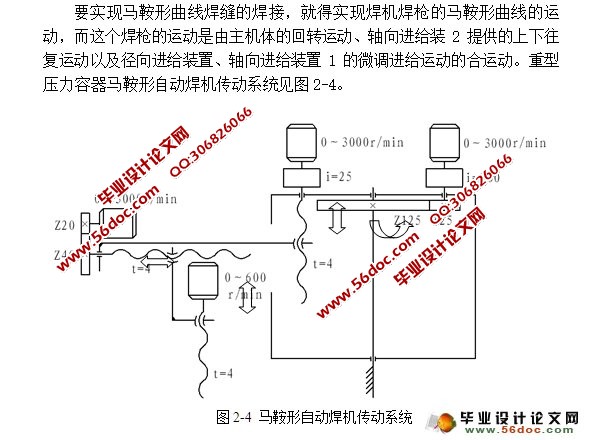

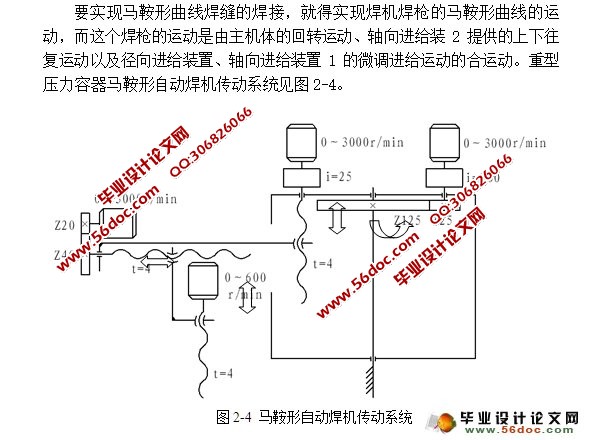

2.3 主要参数的确定 13

2.3.1 传动原理 13

2.3.2 运动参数确定 14

2.3.3动力参数确定 15

2.4 本章小结 17

第3章 主要部件设计 18

3.1 电动机选择 18

3.2 集电装置 19

3.3 进给装置 22

3.4 非任务的主要部件的设计 25

1.1 本章小结 32

结 论 33

参考文献 34

致 谢 37

附录I 38

附录II 46

|