小型绞肉机的设计(含CAD零件装配图)(论文说明书8000字,CAD图纸8张,答辩PPT)

The machine of mini meatcosin

摘 要

本文主要论述了小型肉类加工器具—小型绞肉机的工作原理和它的技术参数,生产能力分析及主要结构设计计算。

此绞肉机采用全封闭联轴器传动方式,具有较高的防护等级,运转平稳,工作可靠,而且拆洗方便,不但可以用于家庭绞肉使用,还可以用来绞碎瓜果,辣椒,碎冰等食物。它所需的功率比较小,采用电力驱动,合理的结构合计能满足普通家庭食品绞碎工作。

此绞肉机主要是依靠绞肉刀高速旋转和挤肉样板上的孔眼刃形成的剪切作用将肉绞碎,并在螺杆的挤压下将原料排出机外。可以根据肉料特性配置不同刀具和孔板,即可以加工出不同尺寸的肉颗和肉泥,满足不同肉类加工需要。

关键词:绞肉机 结构设计 绞刀

ABSTRACT

This paper mainly describes the working principle of small appliances, small meat processing meat grinder and its technical parameters, calculation of production capacity analysis and design of main structure.

The meat grinder using full closed coupling transmission mode, with a higher level of protection, smooth operation, reliable work, and convenient disassembly and washing, not only can used for family meat, can also be used to minced melon, pepper, crushed ice and other food. The power required is relatively small, driven by electric power, reasonable structure can meet the total ordinary family food mincing work.

The meat grinder is mainly rely on the meat knife high-speed rotation and squeeze the meat template on the hole edge formed by shearing action will be minced meat, and in the screw extrusion will be raw material is discharged out of the machine outside. According to the characteristics of different configuration tool and feed plate, can produce different size of meat and minced meat, meat processing to meet the different needs.

Key words: meat chopper reame processing

目 录

摘要...............................................................I

Abstrac...........................................................II

前言............................................................ 1

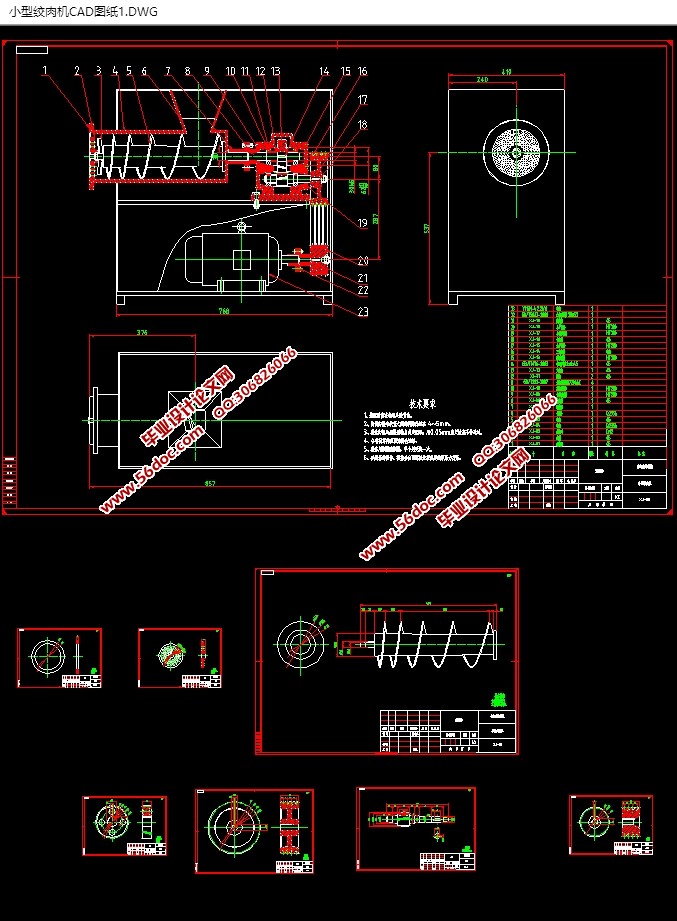

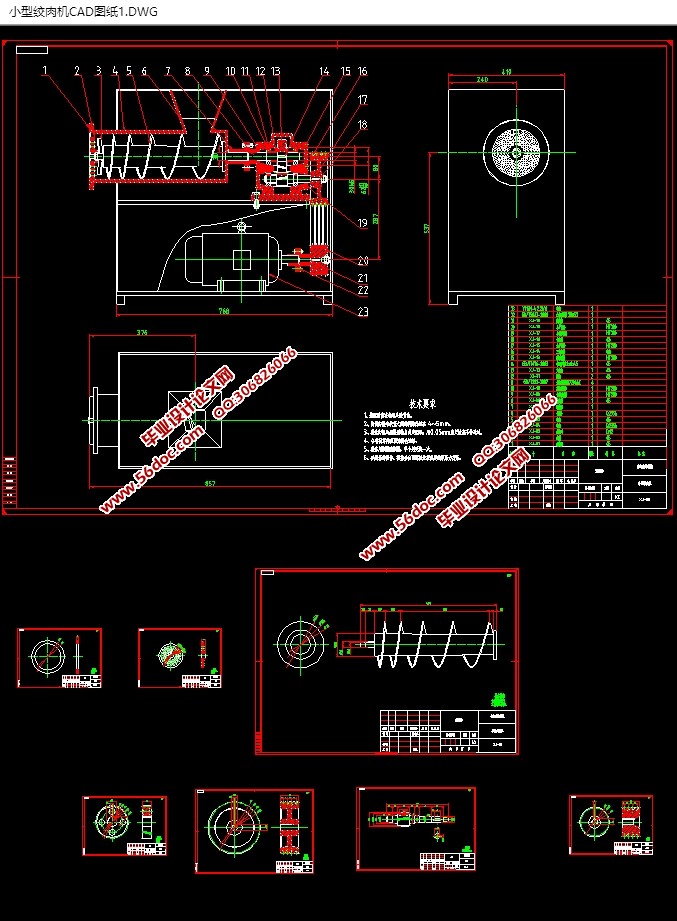

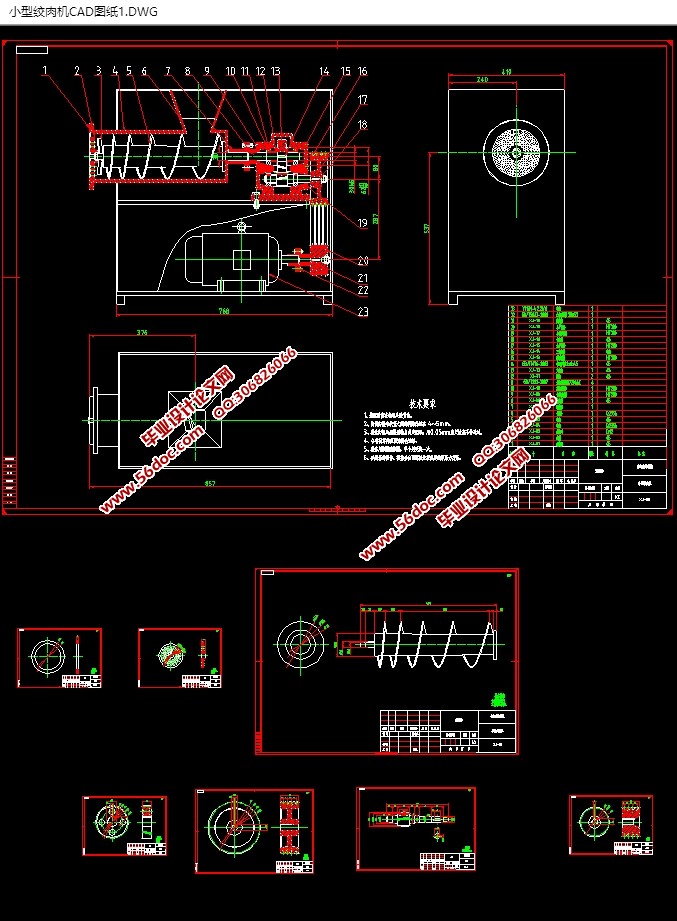

1结构及工作原理.................................................. 2

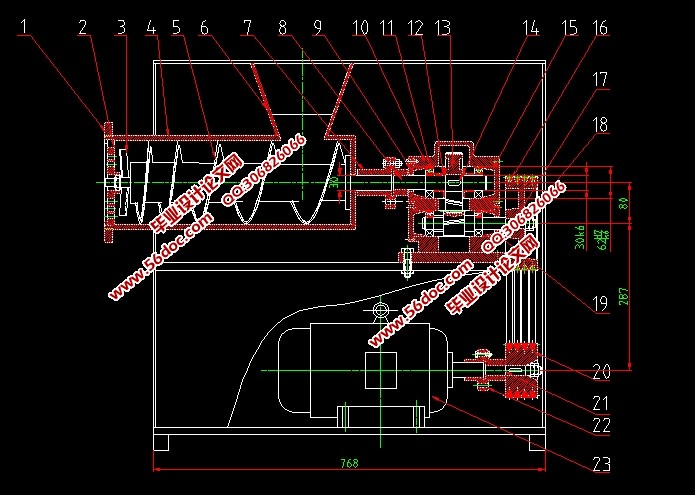

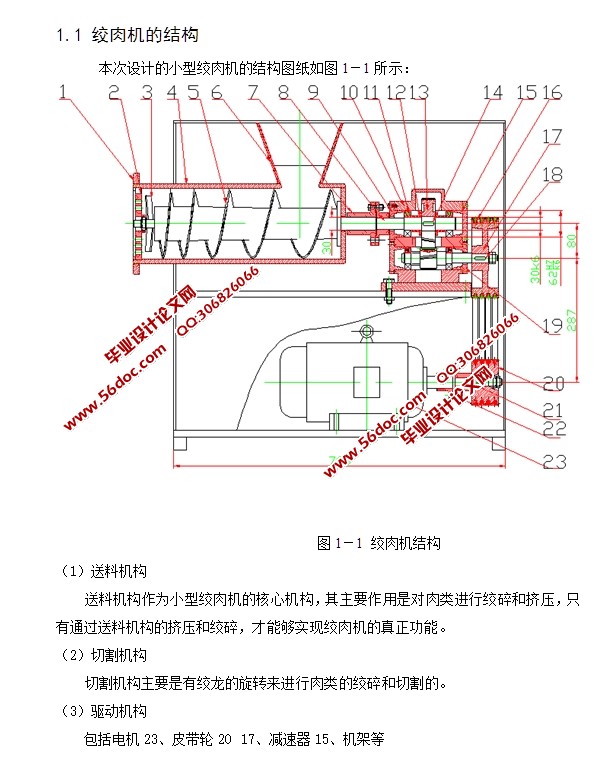

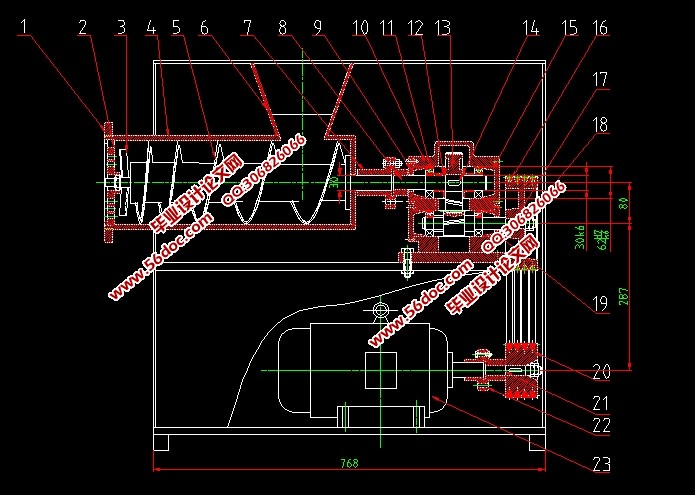

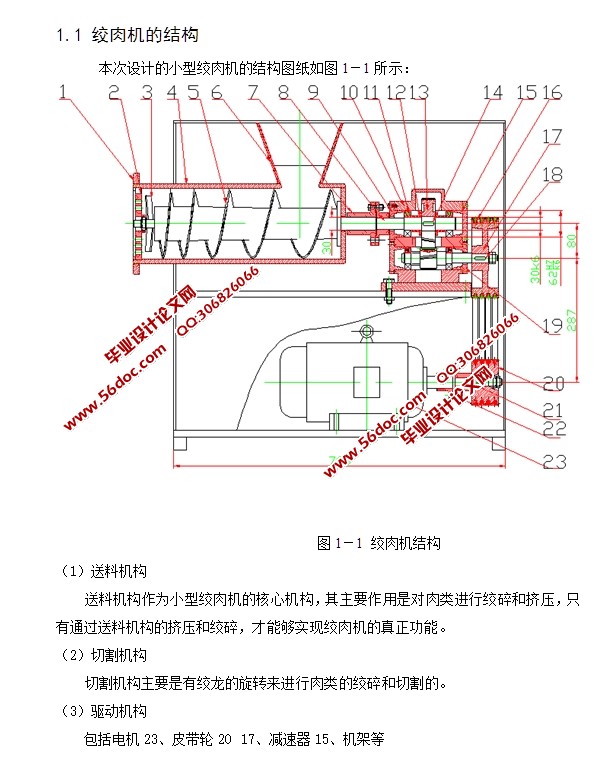

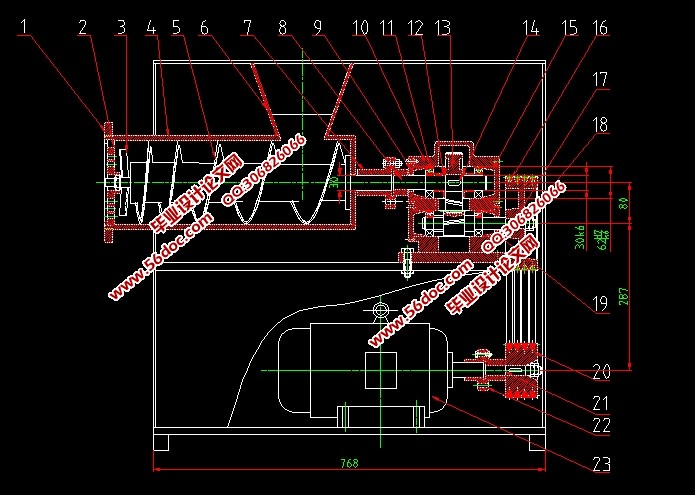

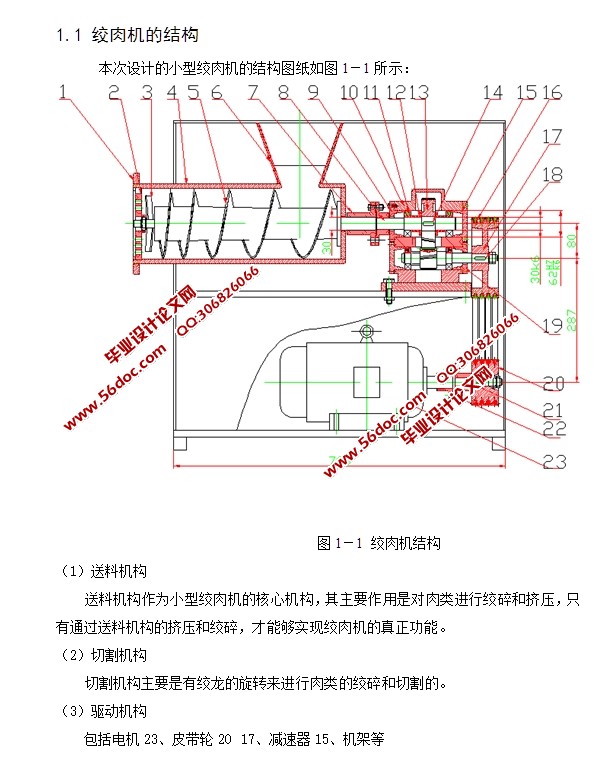

1.1绞肉机的结构................................................ 2

1.2绞肉机的工作原理............................................ 3

2 螺旋供料器的设计................................................ 3

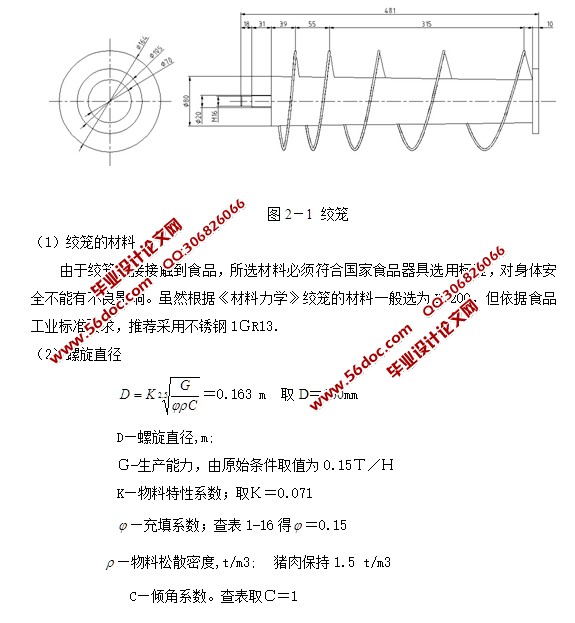

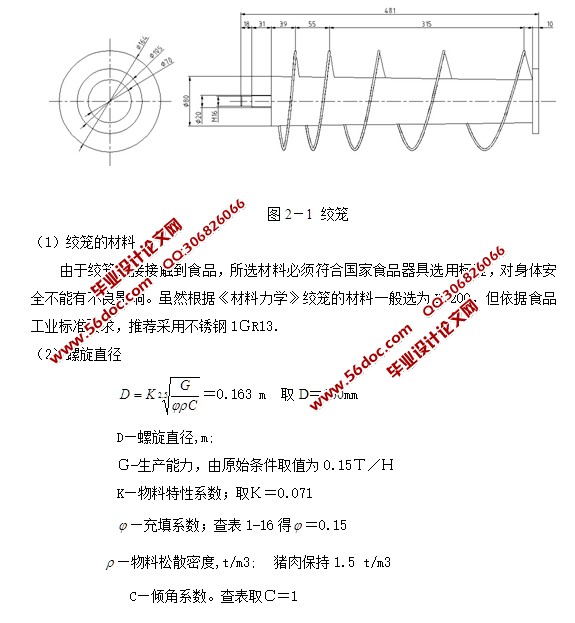

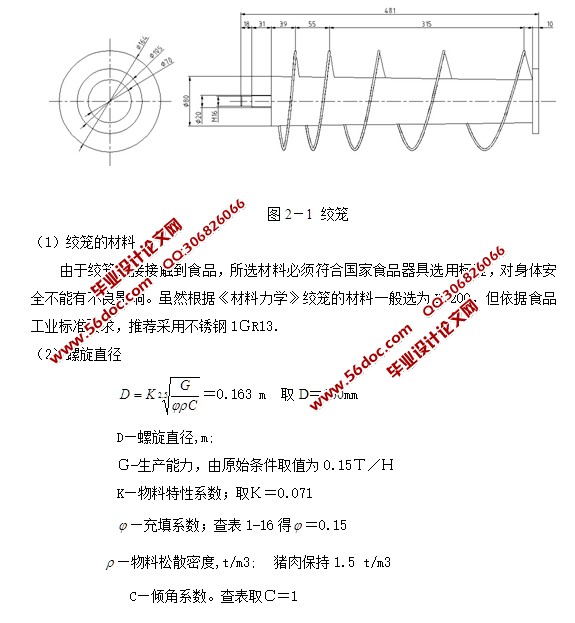

2.1绞笼的设计.................................................. 3

2.2绞筒的设计................................................. 4

3 传动系统的设计.................................................. 4

3.1电机的选择.................................................. 5

3.2带传动的设计................................................ 5

3.3齿轮传动设计................................................ 10

3.3.1选择材料,确定 和 及精度等级...................... 10

3.3.2按接触强度进行初步设计................................... 10

3.3.3校核齿面接触强度......................................... 12

3.3.4校核齿根的强度........................................... 14

3.3.5齿轮副精度的检验计算..................................... 15

3.4轴的设计..................................................... 16

3.4.1按扭转强度计算........................................... 16

4 绞刀的设计...................................................... 18

4.1绞刀的设计.................................................. 18

5 生产能力分析................................................... 25

5.1绞刀的切割能力.............................................. 25

5.2 绞肉机的生产能力............................................ 25

5.3功率消耗.................................................... 26

总结.............................................................. 27

参考文献.......................................................... 28

致谢.............................................................. 29

|