四工位组合机床控制系统的设计(含CAD液压系统图)(论文说明书10000字,CAD图纸2张)

【摘要】

作为现代机械设备实现传动与控制的重要技术手段,液压技术在国民经济各领域得到了广泛的应用。与其他传动控制技术相比,液压技术具有能量密度高﹑配置灵活方便﹑调速范围大﹑工作平稳且快速性好﹑易于控制并过载保护﹑易于实现自动化和机电液一体化整合﹑系统设计制造和使用维护方便等多种显著的技术优势,因而使其成为现代机械工程的基本技术构成和现代控制工程的基本技术要素。液压压力机是压缩成型和压注成型的主要设备,适用于可塑性材料的压制工艺。如冲压、弯曲、翻边、薄板拉伸等。也可以从事校正、压装、砂轮成型、冷挤金属零件成型、塑料制品及粉末制品的压制成型。

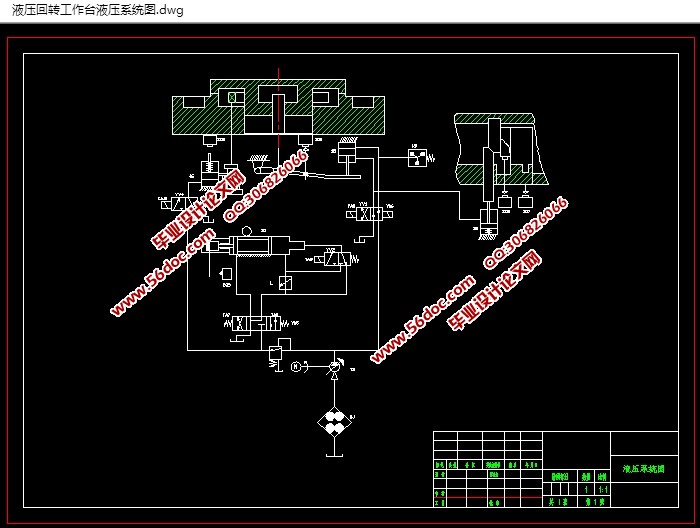

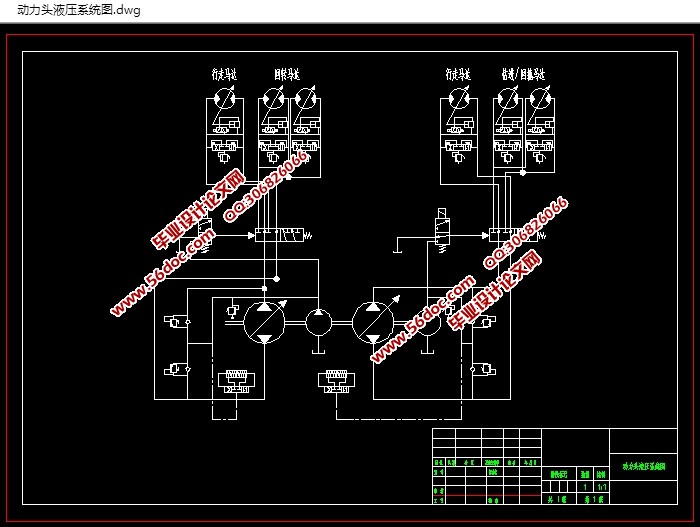

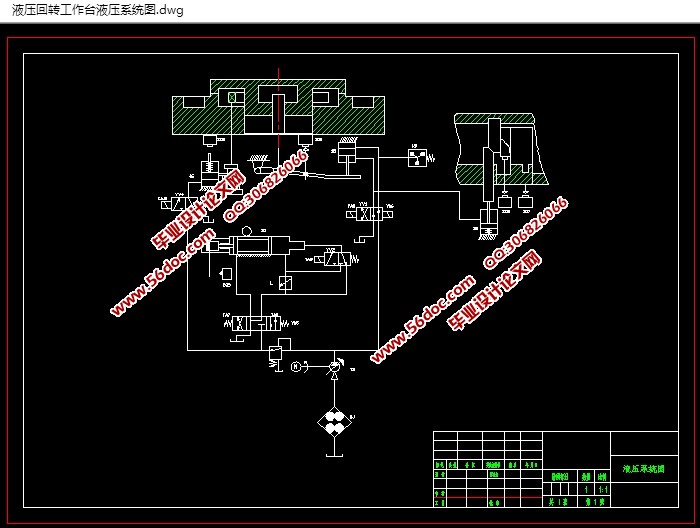

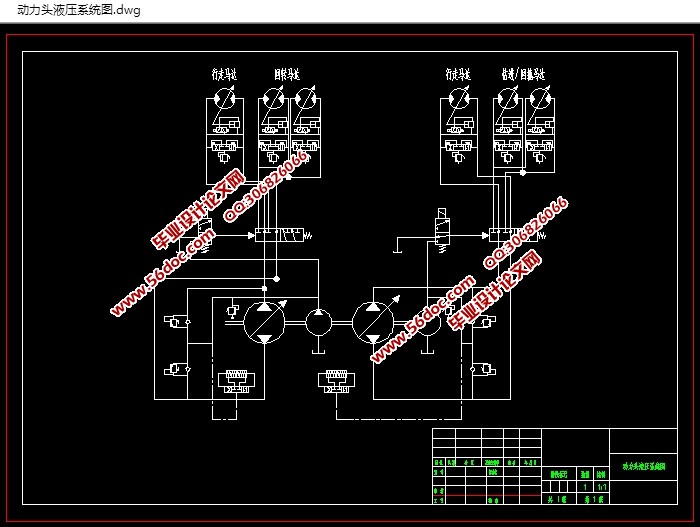

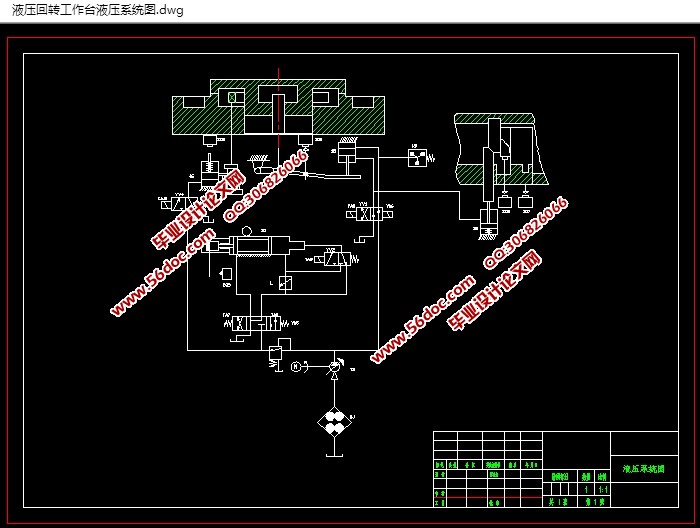

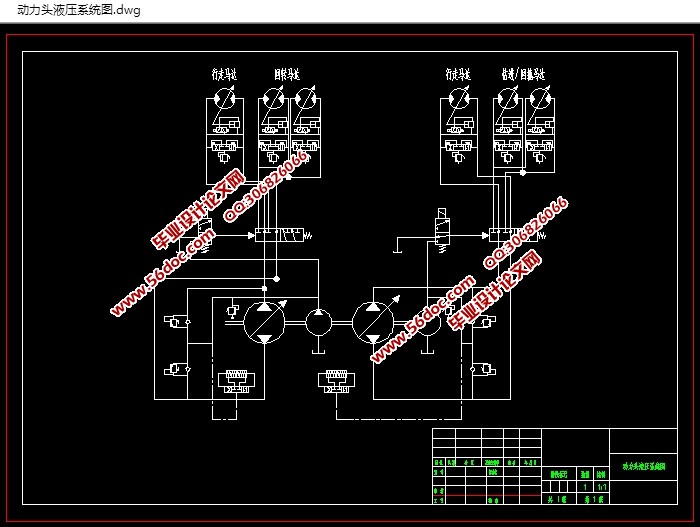

四工位组合机床由四个工作滑台,各带一个加工动力头,组成四个加工工位。除 了四个加工工位外,还有夹具,上下料机械手和进料器四个辅助装置以及冷却和液压系统共四个部分。机床的四个加工动力头同时对一个零件的四个端面进行加工。一次加工完成一个零件。要求具有全自动、半自动、手动三种工作方式,总体的控制流程,当按下启动按扭后,上料机械手向前,将零件送到夹具上, 夹具加紧零件,同时进料装置进料,之后上料机械手退回原位,进料装置放料,然后四个工作滑台向前,四个加工动力头同时加工(洗端面),加工完成后。由四工位加所实现的是加工按次序加工。本次加工按次序分为在一工位装卸、二工位打中心孔、三工位钻孔、四工位加工螺纹。

本文运用大学所学的知识,提出了四工位组合机床的结构组成、工作原理以及液压回转工作台液压系统、动力头液压系统的组成,构建了四工位组合机床机械、液压控制系统总的指导思想,从而得出了该四工位组合机床的优点是高效,经济,并且运行平稳的结论。

关键词:液压技术 四工位组合机床 液压系统 结论

The design of the control system of the four working position combination machine tool

【ABSTRACT】

As one of the modern machinery equipment ransmission and control important technical means, hydraulic technology in the field of national economy has been widely used. Compared with other transmission control technology, hydraulic technology has high energy density, flexible and convenient configuration, large speed range, rapid and smooth work ability, easy to be controlled and overload protection, easily rintegration ,system integration design ,easy maintenance in manufacturing operation and other significant advantages n technology which make it become the basic technology of modern mechanical engineering.

it can be engaged in the adjustment, the mounting indentation, the grinding wheel formation, the swaging metal parts formation, the plastic products and the powder products suppressed formation.including the choice of motor, a crank connecting rod transmission design, shaft design, bearing design, selection of the key and the design of the frame, trying to through the design, so that the transport mechanism of walnut is simple, and can improve the efficiency, and also can reduce the energy consumption.Vibrating conveyer is the eccentric wheel drives a connecting rod to generate centrifugal force, the materials can be separated. This paper is divided into several parts to illustrate the design process, so I did about graduation design walnut vibration conveying equipment.

Graduation project this time is a tube axial compressive loading machine. This paper introduces the theoretical calculation to design sleeve pressing machine structure, working principle and main parts of the strength check and the advantages of the sleeve, pressing machine is efficient.

Keywords: enery operation intergrtin design modern advantages

目 录

1 绪论................................................................................1

1.1 课题的意义、背景及现状............................................................1

1.2 组合机床概述......................................................................2

1.3 液压系统的基本组成................................................................3

2 组合机床液压系统的工况分析..........................................................7

2.1 负载分析...............................................................................8

2.2 运动分析...............................................................................9

3 液压系统主要参数的确定..............................................................10

4 确定液压系统方案和拟定液压系统原理图................................................13

4.1 确定液压系统方案.......................................................................14

4.2 确定基本回路............................................................................15

4.3将液压回路综合成液压系统................................................................16

5 选择液压元件.......................................................................17

5.1 液压泵..................................................................................18

5.2 阀类元件及辅助元件......................................................................19

5.3 油管....................................................................................19

5.4 油箱....................................................................................20

5.5 密封件的选择............................................................................21

6 液压缸在实际中的应用情况分析........................................................22

结 束 语......................................................................................23

谢 辞.........................................................................................24

参 考 文 献...................................................................................25

|