螺母收口机的设计(论文说明书10200字,CAD图纸9张)

【摘要】

螺母是机械生产制造中的一种常用零件,其应用范围广,种类多,可以配合螺栓螺柱共同使用形成螺纹紧固件.在生产加工中起到连接,紧固作用,自锁收口螺母因其具有良好的防松、抗振效果,并且结构简单,附加重量轻、强度高等特点在生产加工中更受大家欢迎.但是在目前国内的生产中,螺母收口技术还不成熟,设备还不够先进,同时更缺乏可以实现大批量、现代化的生产加工的设备。

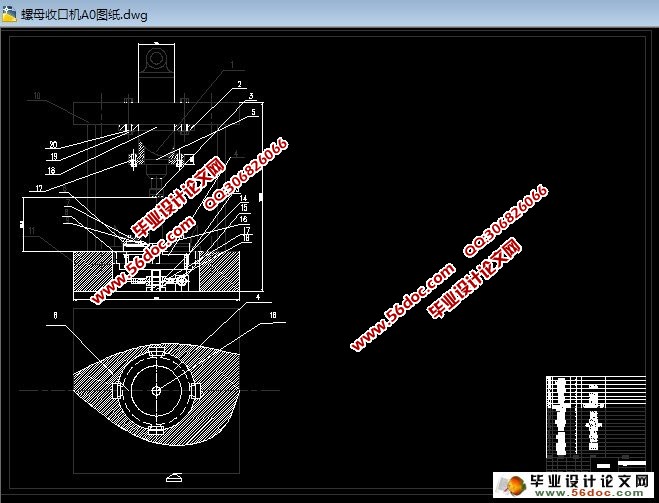

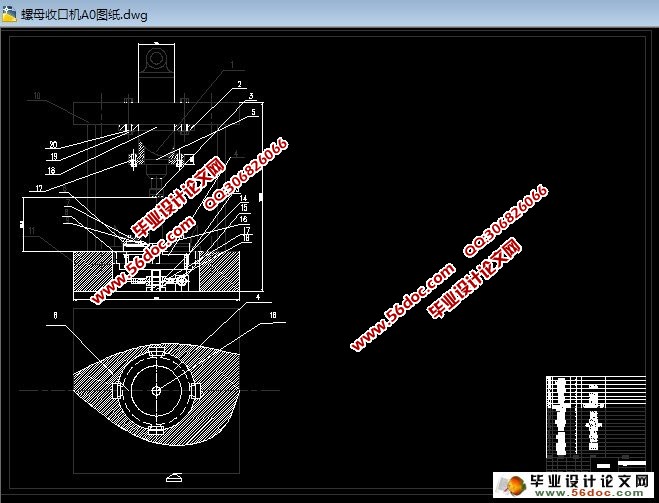

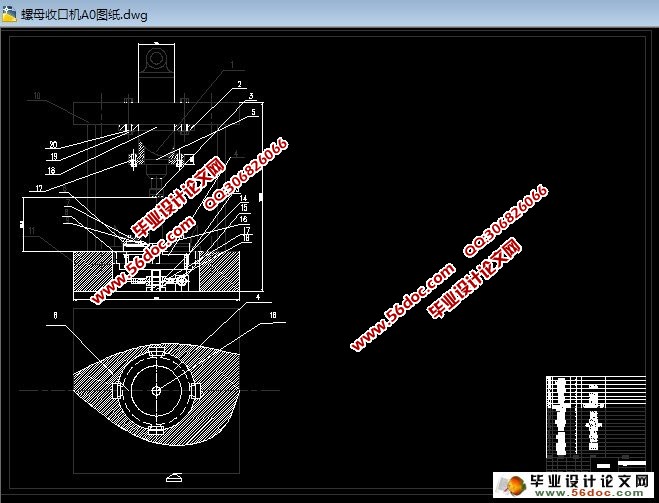

螺母收口机就是一种针对自锁螺母收口加工的设备,本文将在目前已有的螺母收口加工设备的结构基础上,对螺母收口机进行改进设计。主要从其加工的稳定性和精度尺寸定位方面着手改进。并分析研究其在加工过程中因加载而影响的运行平稳.以及在冲压塑性变形过程中影响的精度定位。本结构设计才用液压系统设计主要解决其加载过程中的运行平稳问题、并且设计循环加工过程使操作维护简单易上手,噪音低环境污染少。还适用于各种规格的自锁螺母收口加工及批量生产。

【关键词】:自锁螺母 收口 设备

Design of nuts reducing machine Mechanical design manufacture and automation

【Abstract】

The nut is a common part of mechanical manufacturing, wide application range, variety, can fit bolt stud the common use of formation of threaded fasteners. In the production and processing to connect, fasten nut,

self-locking closing because of its loose, anti-vibration effect is good, and the structure is simple, the additional weight lightweight, high strength characteristics are more popular in the production process. But in the current domestic production, nut shell nosing technology is still not mature, equipment is not very advanced, equipment and lack of can realize batch, the modernization of production and processing.

This machine is a kind of nut for self-locking nuts shell nosing processing equipment, this paper will be in the current structure of nuts reducing machining equipment based on existing, improved the design of the nut sealing machine. Mainly from the processing stability and precision positioning to improve. And the research of the machining process and the effect of loading due to the stable operation of the precision positioning effect. And in the stamping process of plastic deformation. The structure design is designed mainly to solve the problem, the smooth operation of the loading process and design cycle process to make the operation and maintenance easy for hydraulic system, low noise, less environmental pollution. Self-locking nut shell nosing process and batch production can be applied to all kinds of specifications.

【Keywords】: self-locking nut nut heal machine

目录

【摘要】 I

1螺母收口机的设计 - 1 -

1.1选题意义及背景介绍 - 1 -

1.2螺母收口机类型 - 2 -

2螺母收口机的工作原理 - 4 -

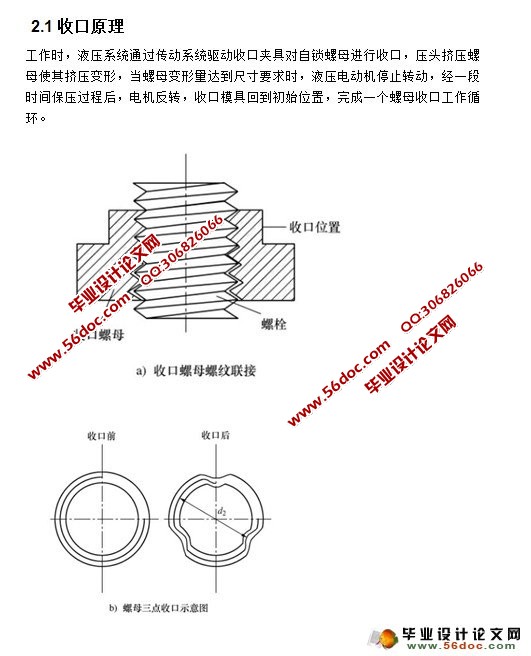

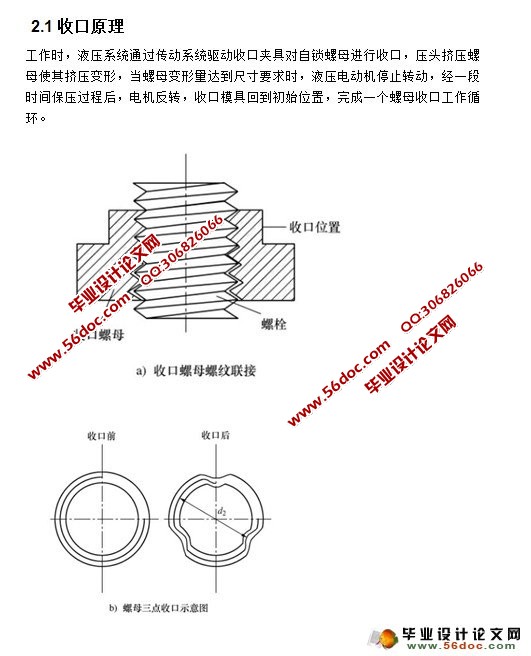

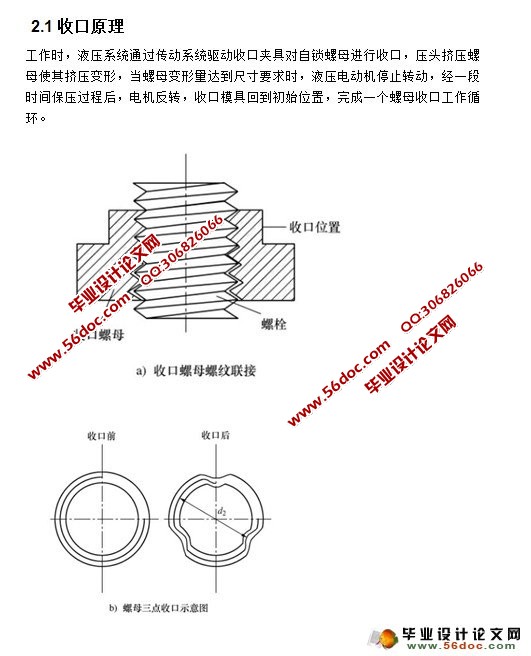

2.1收口原理 - 4 -

2.2收口过程分析 - 5 -

3螺母收口机总体方案确定 - 6 -

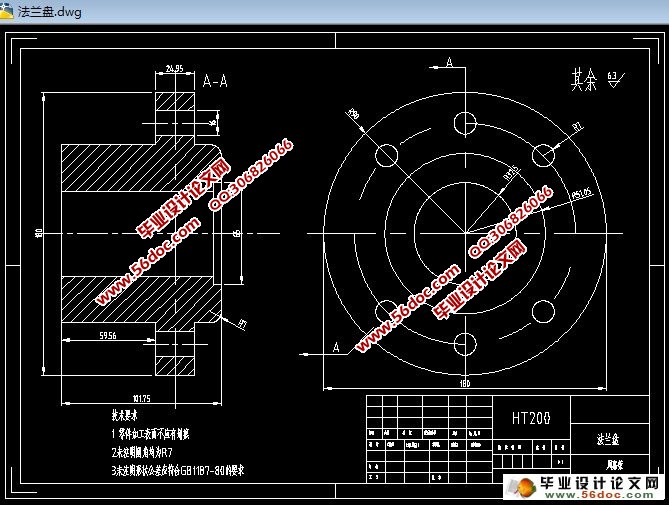

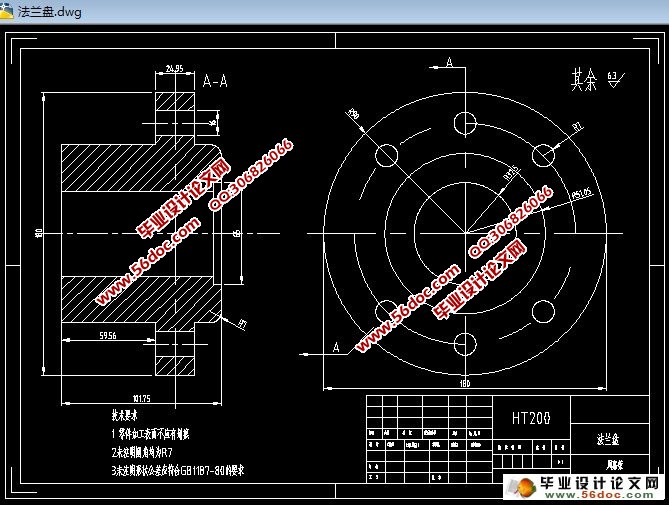

3.1夹具选择 - 7 -

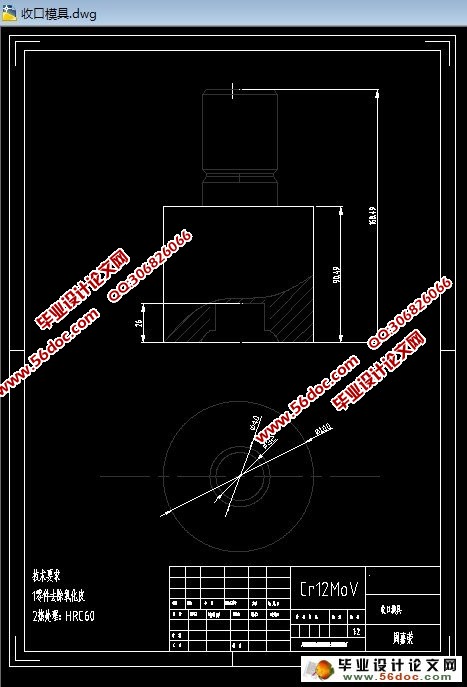

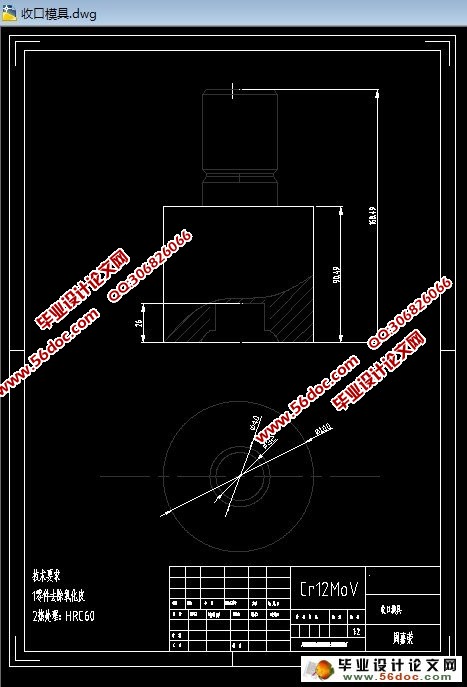

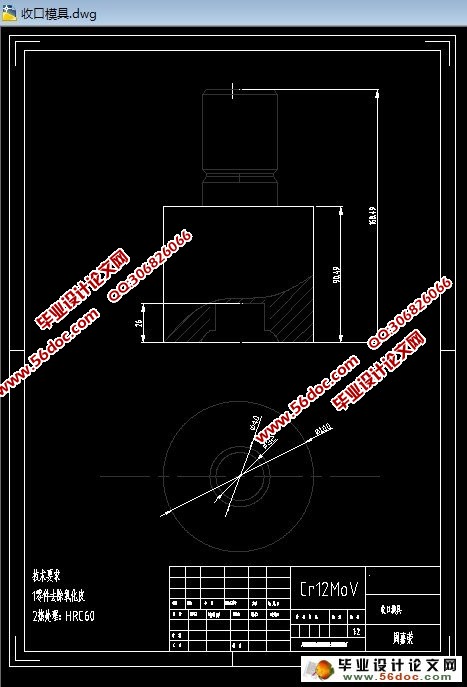

3.2收口模具 - 8 -

4 明确液压系统的设计要求 - 9 -

4.1 负载与运动分析 - 9 -

5 确定液压系统主要参数 - 11 -

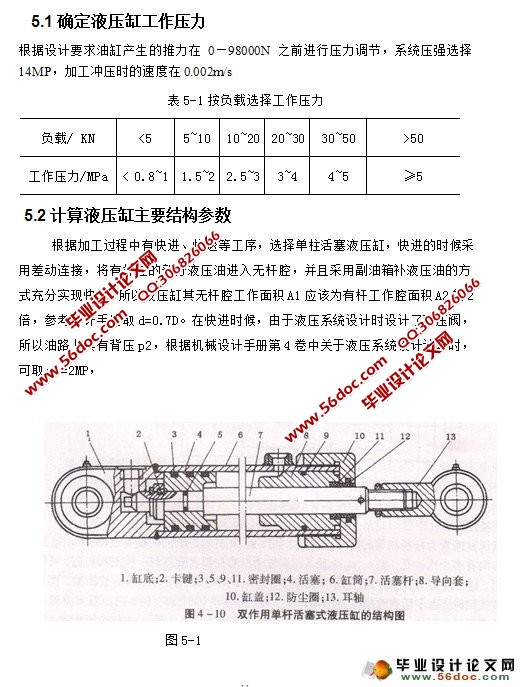

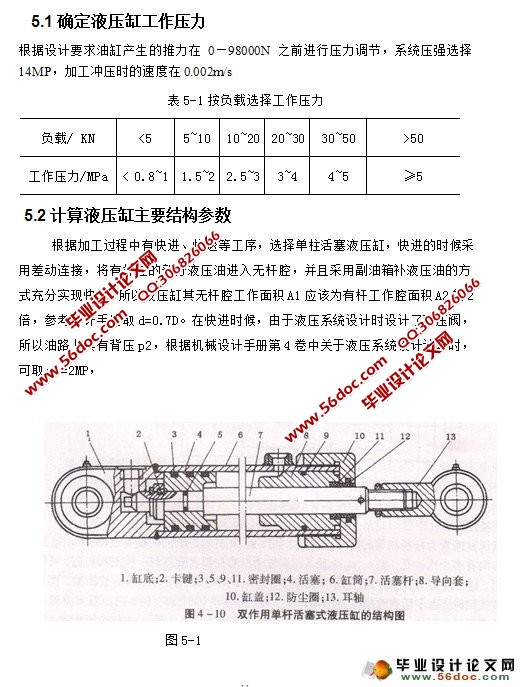

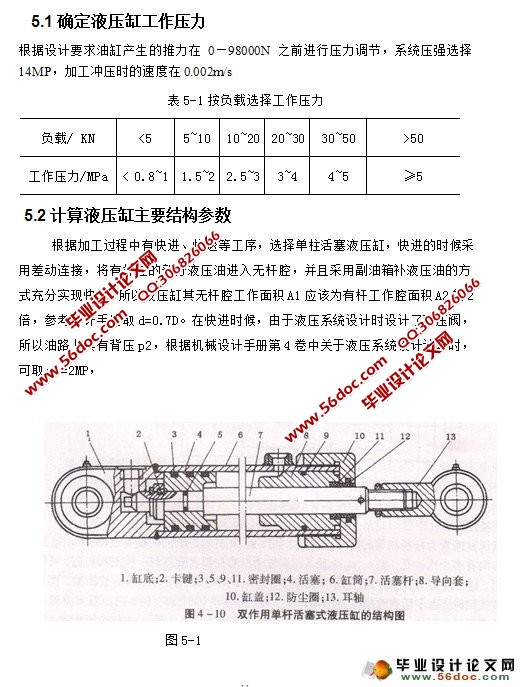

5.1确定液压缸工作压力 - 11 -

5.2计算液压缸主要结构参数 - 11 -

6 液压系统方案设计 - 14 -

6.1选用执行元件 - 14 -

6.2设计自动补油的保压回路回路 - 14 -

6.3设计释压回路 - 15 -

6.4 螺母收口机液压系统原理图拟定 - 17 -

7 液压元件的参数确定和选择 - 19 -

7.1确定液压泵 - 19 -

7.2确定其它元件及辅件 - 20 -

7.2.1油管的选择 - 21 -

7.2.2液压系统的验算 - 22 -

7.3液压缸主要尺寸 - 22 -

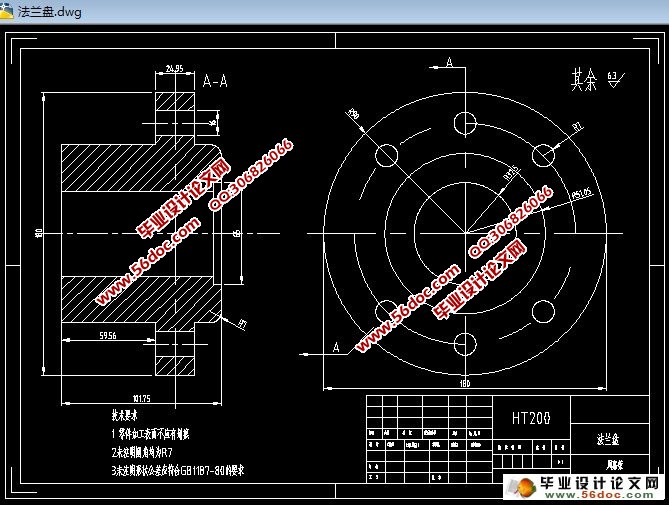

7.3.1液压缸的壁厚和外径的计算 - 22 -

7.3.2最小导向长度以及活塞尺寸 - 23 -

7.3.3液压缸盖的确定 - 24 -

7.4液压缸结构设计 - 24 -

7.4.1缸体与缸盖的连接形式 - 24 -

7.4.2活塞与活塞杆的连接 - 25 -

结束语 - 26 -

参考文献 - 27 -

致谢 - 28 -

|