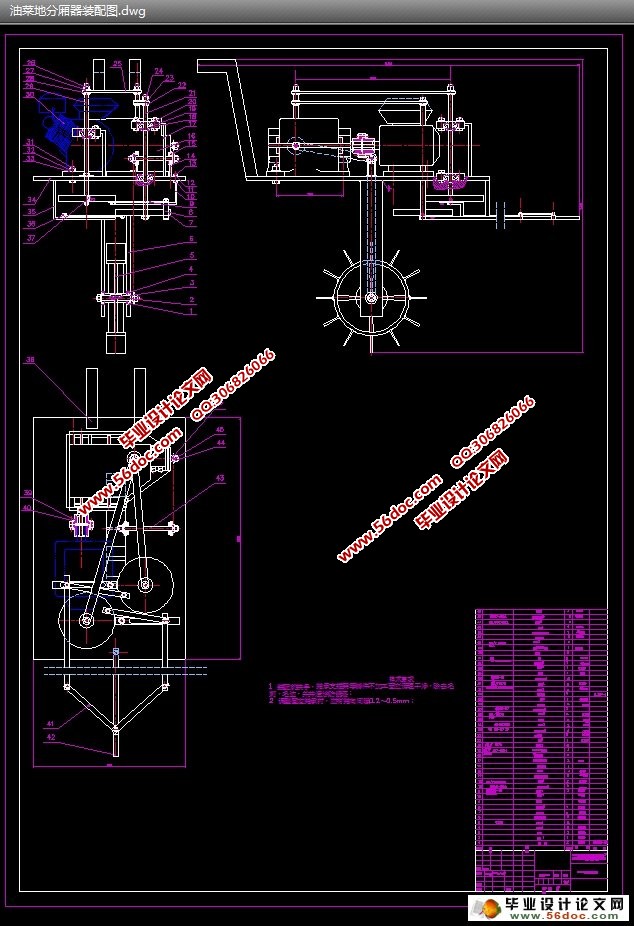

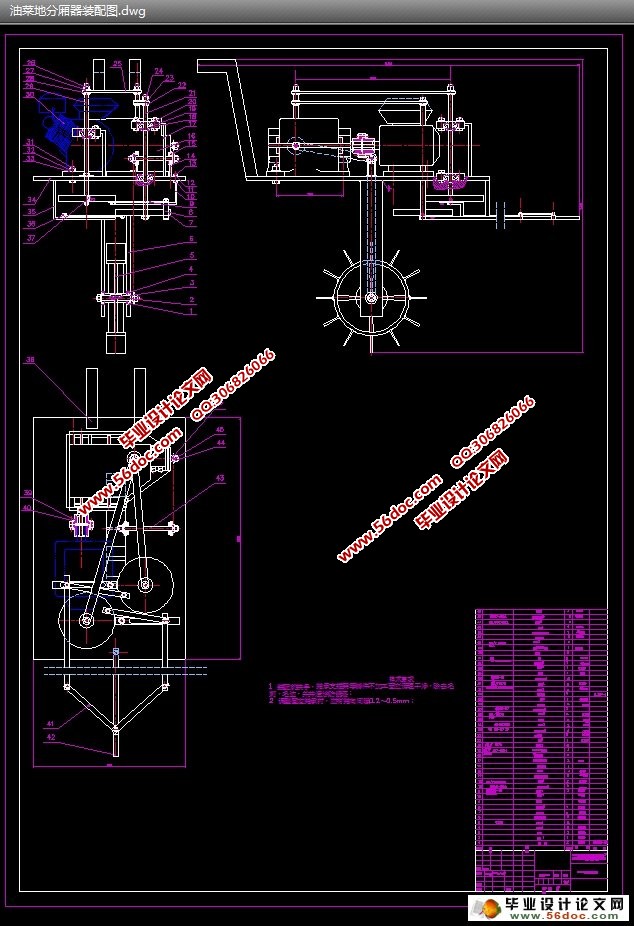

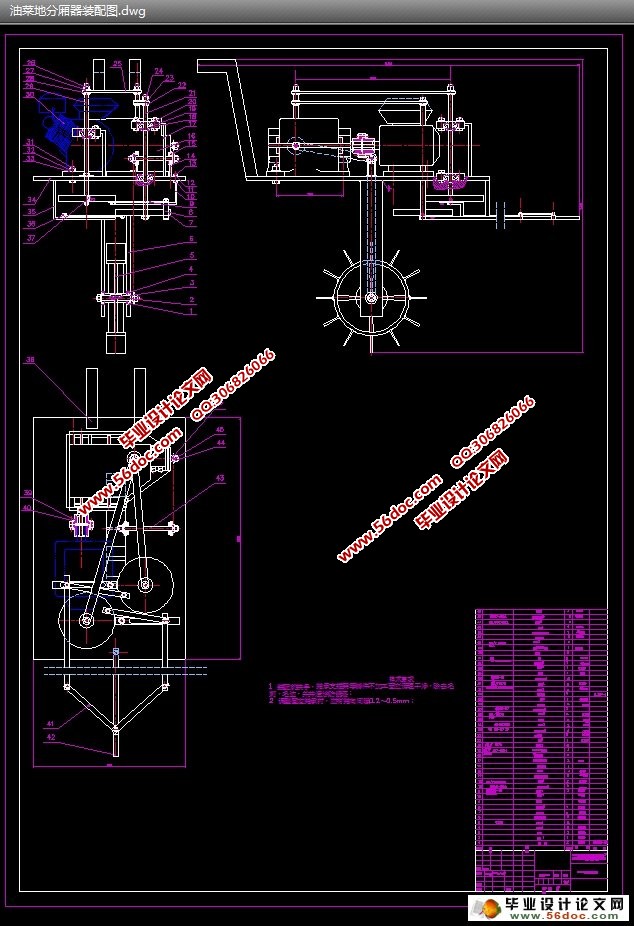

单轮手扶式油菜地油菜分厢器结构设计(含CAD零件图和装配图)(开题报告,中期检查表,论文说明书12600字,CAD图7张)

摘 要:油菜是草本十字花科作物,是我国主要油料作物和蜜源作物之一,其籽粒是制浸油脂原料主要品种之一。栽培遍及全国,分为冬油菜和春油菜两种。其种植面积占全国油料作物总面积的40%以上,产量占全国油料总产量的30%以上,居世界首位。现在要实现油菜产量提升必须使用机械化,油菜联合机械化现在还未普及,同时油菜机械也严重缺少,油菜联合收获机存在着严重脱粒损失,分析发现脱粒损失主要集中在割台损失,约占油菜地收获损失的70%以上,主要是由于油菜枝Y的缠绕。所以,本文设计了油菜地油菜分厢器,在油菜生熟之前对油菜进行分厢,从而避免在油菜成熟后收获时由于分厢造成的脱粒损失,同时可以简化现有的油菜收获机械结构,提高效率。

关键词:分厢器;油菜;机械;

A Structural Design of Rape Points Compartments Device in Single Wheel Hand Type

Abstract:Oilseed rape,a kind of herbaceous cruciferae crops, is the main oil crop and nectar crop planted in our country because its seeds are one of the main raw materials to produce oil. Oilseed rape is planted all over the country which has winter rape and spring rape. Its planting acreage accounts for over 40% of the total area of oil crops, and the production accounts for more than 30% of the total oil production,ranking first in the world. Now ,in order to increase production, we must apply mechanization into practice, but the rape mechanical combine has not been spread, and rape mechanism is also lacking seriously. Meanwhile, there is a serious loss of threshing in rape combine harvesting machine. An analysis was shown that the loss of stripping header was a great part in the threshing loss , which occupied over 70% of the total harvest loss in rape fields, mainly because of the winding of the rape branch Y. Therefore, this thesis designs a Points compartments device to compart rapes before the rapes are mature,so that to avoid the threshing loss owing to compartmentalization when the oil crops are gathered after ripe. And at the same time, the points compartments device also can simplify present rape harvesting mechanical structure and improve efficiency. Key words: Points compartments device ; rape ; machinery;

单轮手扶式油菜地油菜分厢器结构设计

1) 人正常行走速度V人=3.5KM/H

2) 沟深200mm 即要求地轮半径应大于200mm,一般取轮的直径 为500~600mm,此处取半径为300mm,沟宽240mm

3) 分厢板分开的最大距离为500mm

4) 油菜分节处离地高度:350~400mm,即要求分厢板距地轮中心为350~400mm

5) 为了使机器转弯方便,应使机器的总长范围为1.5~2m

目 录

摘要: 1

关键词 1

1 前言 2

2 国内外研究现状及意义 3

2.1 国外油菜收获机械现状 3

2.2 国内油菜收获机械现状 4

2.3 选题研究意义 5

3 总体方案拟定 6

3.1 工作参数 6

3.2 制定可行方案 6

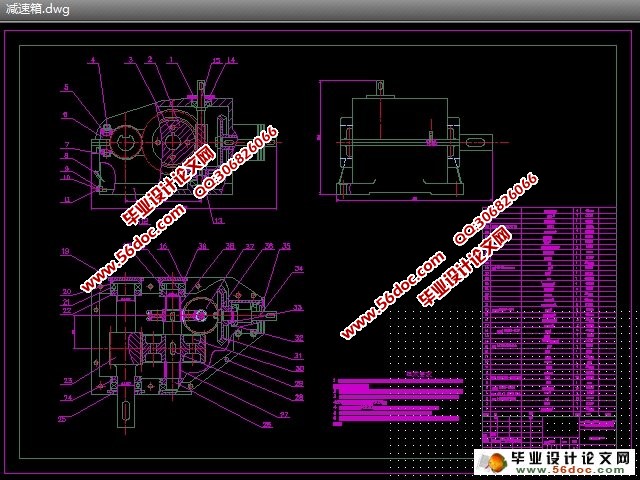

4 总体设计 8

4.1 选择汽油机 8

4.2 工作部件曲柄滑块机构的设计计算 9

4.3 地轮转速的计算 9

4.4 传动装置总传动比计算及各级传动比的分配 9

4.5 计算传动装置的运动和动力参数 9

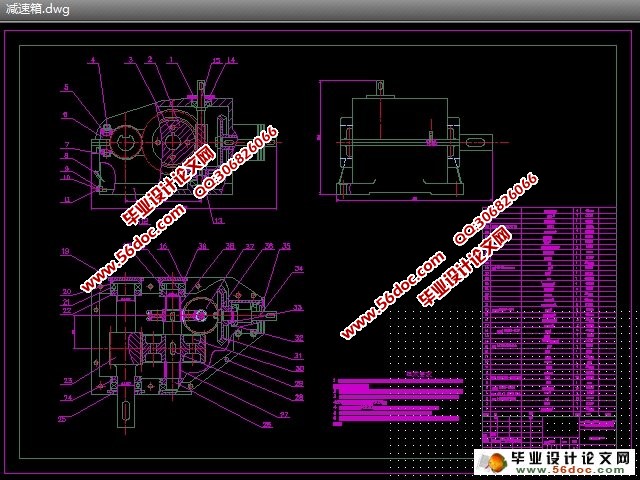

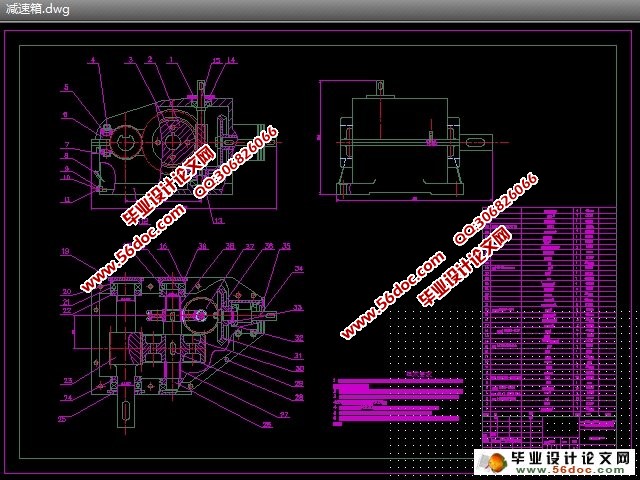

5 关键零部件的设计计算 10

5.1 圆柱齿轮传动的设计计算 10

5.1.1 选定齿轮类型、精度等级、材料及齿数 10

5.1.2 按齿面接触强度设计 10

5.1.3 按齿根弯曲强度设计 12

5.1.4 几何尺寸计算 13

5.2 普通圆柱蜗杆传动的设计计算 13

5.2.1 选择蜗杆传动的类型 13

5.2.2 选择材料 13

5.2.3 按齿面接触疲劳强度进行设计 13

5.2.4 蜗杆与蜗轮的主要参数与几何尺寸 14

5.2.5 校核齿根弯曲疲劳强度 14

5.2.6 验算效率η 15

5.2.7 精度等级公差和表面粗糙度的确定 15

5.2.8 热平衡核算 15

5.3 标准直齿圆锥齿轮传动设计比赛 15

5.3.1 选定齿轮精度等级、材料及齿数 15

5.3.2 按齿面接触强度设计 15

5.3.3 按齿根弯曲强度设计 17

5.3.4 几何尺寸计算 18

5.4 链传动的设计计算 18

5.5 带传动的设计计算 19

5.6 轴的校核计算 20

5.7 键连接的选择及校核计算 24

5.8 减速器的润滑与密封 24

6 结论 25

参考文献 26

致 谢 26

|