颗粒包装机自动供料系统的设计(开题报告,中期报告,外文翻译,论文说明书18800字,CAD图4张)

摘要

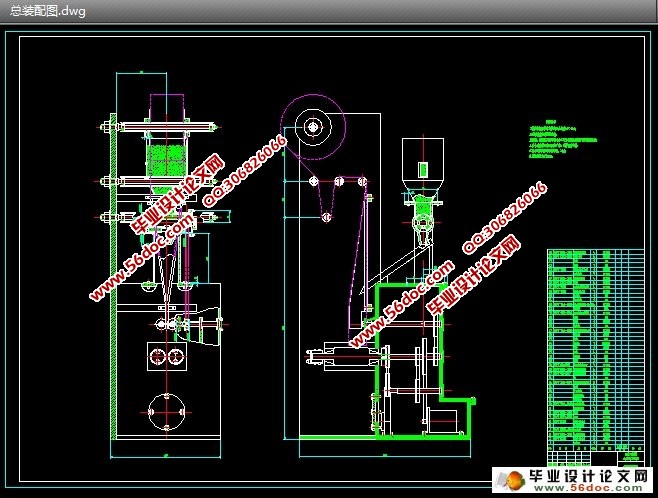

本设计是关于颗粒包装机自动供料系统的设计。颗粒包装机是将小颗粒产品通过计量装入包装袋内,再进行封装的包装机械。能较大提高生产效率、降低人工劳动强度。

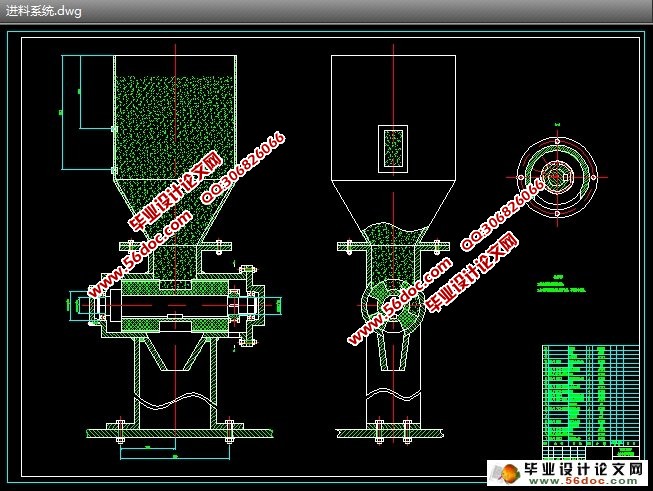

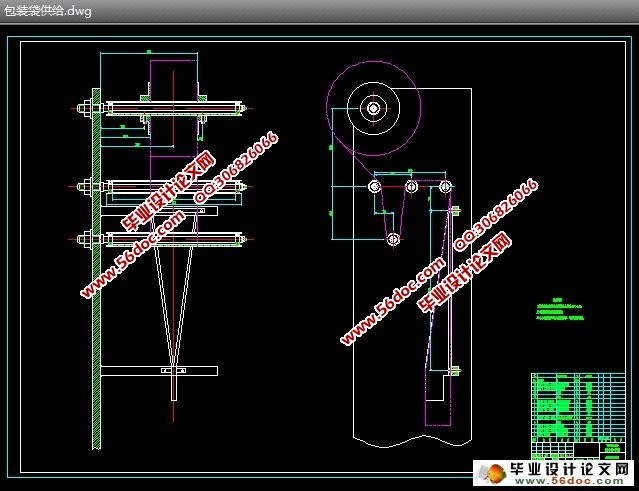

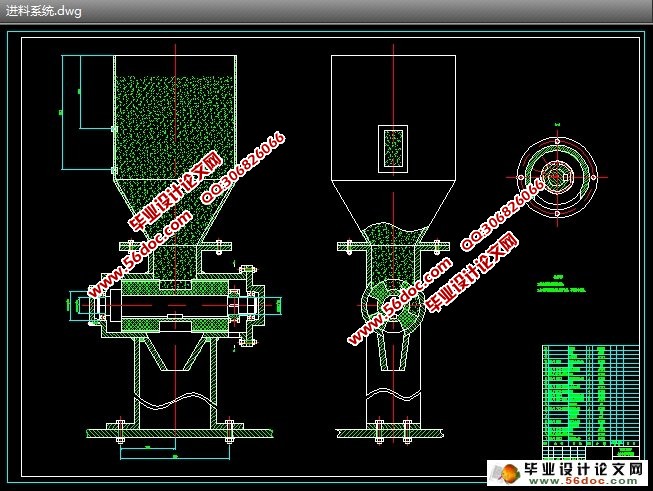

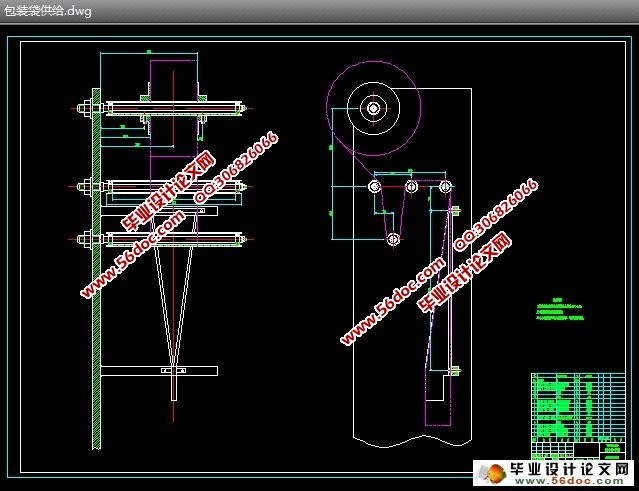

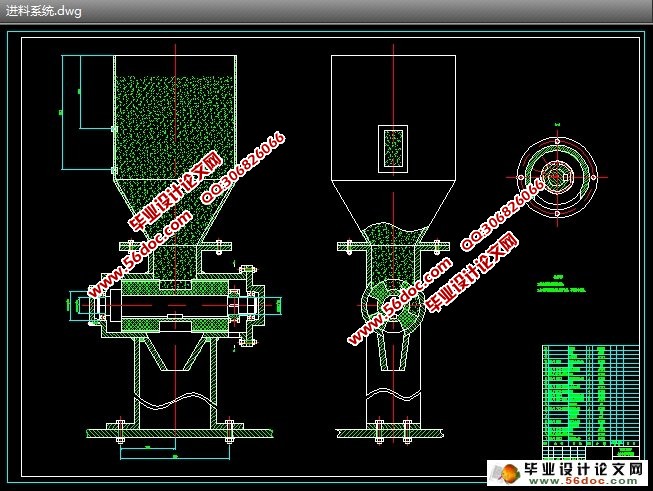

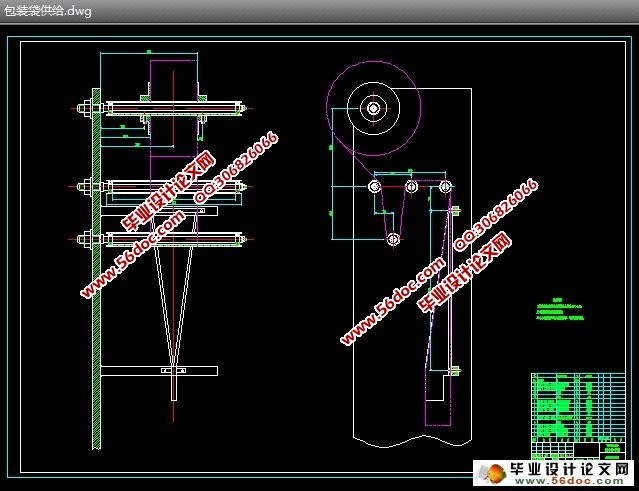

本设计主要研究物料供送系统的结构设计和包装材料供送机构的设计。首先由包装机的生产能力确定计量装置的大小来完成物料的计量,从而完成物料的供送。其次由包装材料的传送路线确定引导辊的位置来完成包装材料的供送。

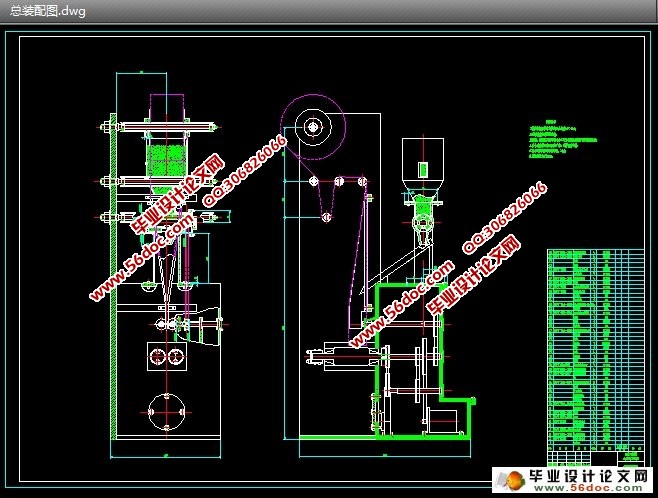

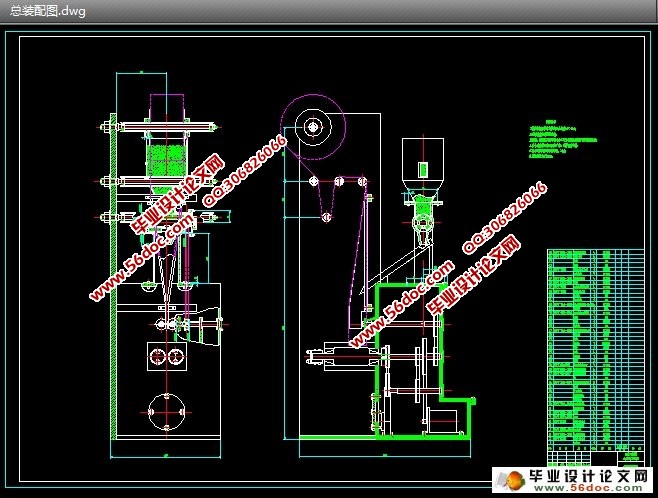

本设计主要设计颗粒包装机的包装材料成型与供送系统,包括供送包装材料的辊子,引导辊,成型器;物料供给系统,包括料斗,计量器,导流槽;以及计量器的传动系统。本次设计采用了象鼻成型器和改进后的转鼓式计量装置。

本设计能进一步提高其包装性能,结构简单、重量轻、外形尺寸小、设备费用低、运转安全,操作方便、便于维修和管理。

关键词:颗粒包装机;成型器;计量器

A design of the automatically feeding system for Granule packing machine

Abstract

This design is about automatic feeding system of packaging machine. Granule packaging machine feeds small products through the measurement into the packing bag, and then packaging system to finish packing. It could greatly improve the production efficiency,and reduce labor intensity.

This design mainly research materials for structure design and packaging material feeding system. Determined firstly by packing machine production capacity to complete material metering device size, thus completing the material supply. To determine the route followed by packaging materials to finished packaging material guide roller position feeding.

Packaging material forming the main design particles this design packaging machine and feeding system, including the supply roller, and sent packing material guide roller, forming device; material supply system, including the hopper, measuring device, guide groove; and the metering transmission system. This design uses a drum type metering device for trunk shaper and it improved better than any other types which exist in this society.

This design can improve the packaging performance, such as simple structure, light weight, small size, low cost of equipment, operation safety, convenient operation, and easy to repair and management for users.

Key Words: granule packing machine; shaper; meter

目 录

摘要 I

Abstract II

1 绪论 1

1.1题目背景和意义 1

1.2国内外发展现状 1

1.2.1国外发展现状 2

1.2.2国内发展现状 3

2 包装机概述 6

2.1产品包装概述 6

2.2包装机的分类 7

2.3包装机的组成 8

2.4颗粒包装机的工作原理 9

3 方案设计及选择 10

3.1物料供送系统结构方案 10

3.2包装材料供送机构方案 12

4 机械部分设计 15

4.1计量装置设计计算 15

4.2生产能力计算 16

4.3制袋成型器的选择和设计计算 17

4.3.1常用成型器 17

4.3.2成形器的结构尺寸计算 20

4.4引导装置 24

4.5轴的设计 24

4.5.轴的结构设计 24

4.5.2轴的强度校核 26

4.6电机的选择 27

4.7其他零件的设计 28

5 总结 29

参考文献 30

致谢 31

|