切刀下置式莲子剥壳机-剥壳及分离装置设计(CAD,CAXA,零件装配图)(任务书,开题报告,毕业设计周记,论文说明书8600字,CAD图2张,CAXA图8张,零件图,装配图)

摘 要

随着中国经济迅猛发展,莲子低下的生产力远远不能满足市场的需求,莲子进入市场需要经过剥壳、去衣、去芯和干燥等一系列加工过程,其中莲子的剥壳是加工难度和强度最大的一道工序,目前人们采用最多的是手工剥壳,手工剥壳是用弧形刀片先对莲壳割一圈,然后用手将割后的莲子壳仁分离,手工去壳不但容易割伤手,而且还不卫生、容易损伤莲仁、效率低,严重制约了莲子的广泛种植。该设计通过创新设计在剥壳工艺上解决剥壳率低、破碎率高,在设备性能上解决可靠性低、工作稳定性差等问题,形成成熟定型的剥壳机产品,以满足莲子剥壳的实用性要求。莲子剥壳机的问世,是莲子生产加工领域的一项重要发明。它是莲子的产量大大增加,并且很大程度上降低了农民的劳动强度,还可以将拨好的莲子加工成各种莲子产品,同时莲子壳也可以加工饲料等用处。

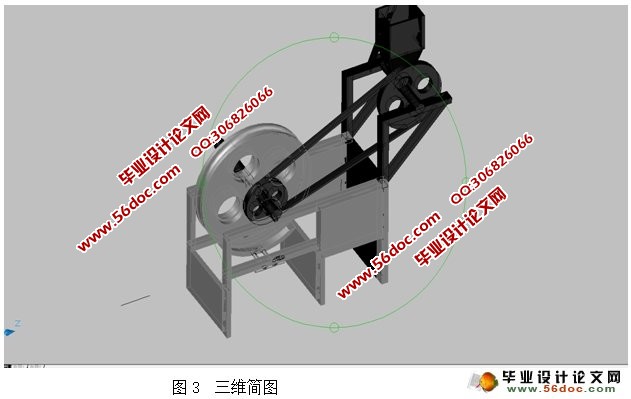

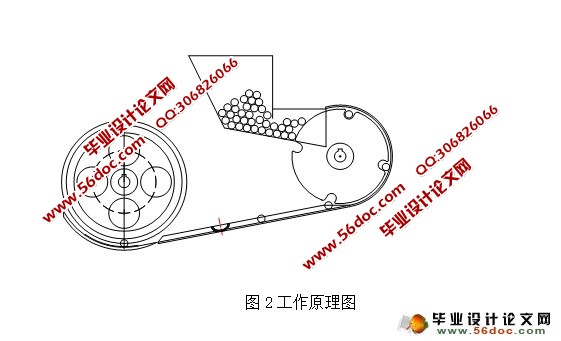

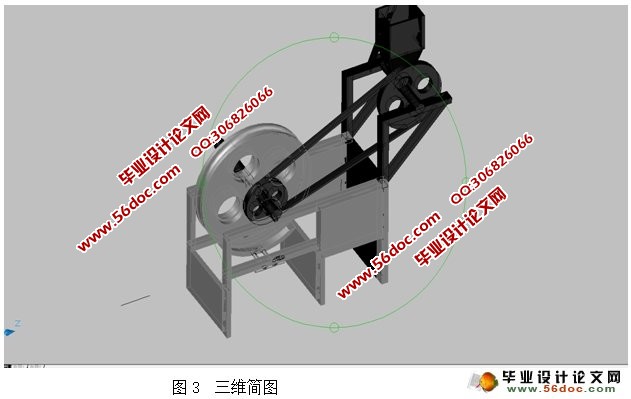

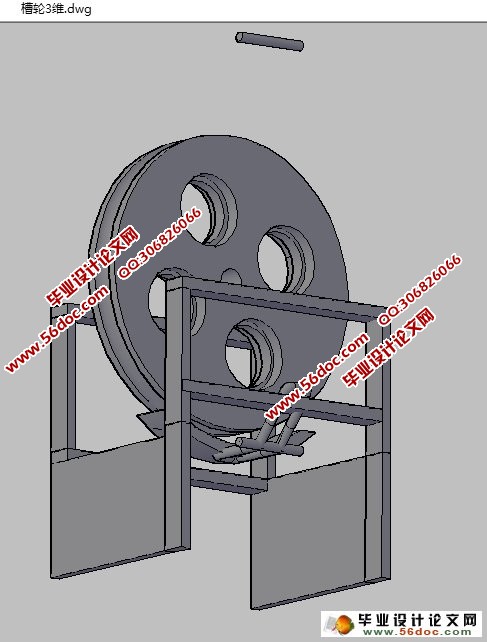

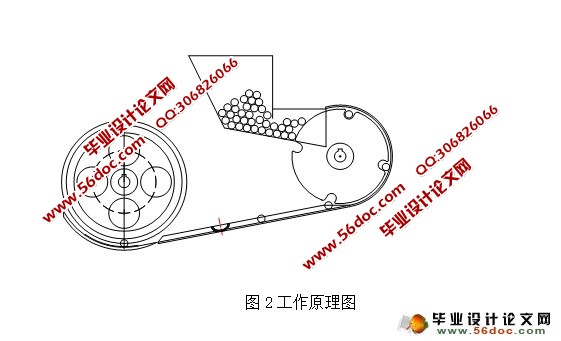

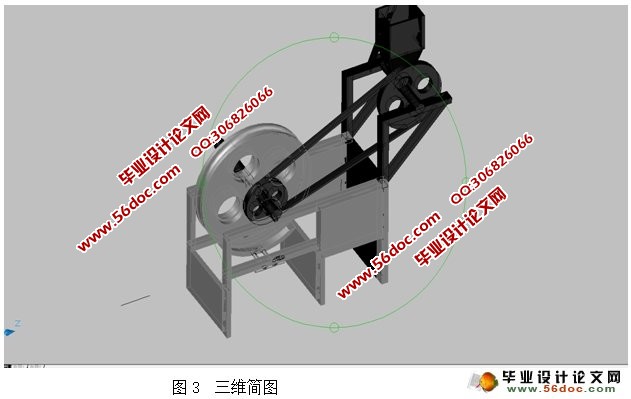

本设计采用刀具切割来到壳仁分离的目的,剥壳方式为滚动切割式莲子剥壳机,莲子沿导料槽进入切割装置,槽轮带动莲子沿莲子赤道逆时针转动切割,刀具在莲子赤道上切出一条闭合的轨迹,从而达到壳仁分离效果,性能相对稳定,切割顺畅,较少出现堵塞现象,剥壳率较高,损坏率低,在设计上有所创新。

关键词:莲子;剥壳机;设计

Abstract

With China's rapid economic development, low productivity lotus seeds can not meet the market demand, lotus seeds enter the market to go through sheller, to clothing, to a series of core and drying processes, including lotus seed sheller is processing difficulty and intensity the largest one process, now people use most is hand-peeled, hand peeled with curved blade to cut a circle of lotus shell, then hand cut lotus seeds shell kernels after separation, hand peeled not only easy to cut hand, and does not care, easy to damage the lotus kernels, inefficient, severely restricted the widespread planting lotus. The design on the rind through innovative design process solutions shelling low broken rate on equipment performance to solve the low reliability, poor job stability, the formation of mature stereotypes Sheller products to meet the lotus seed sheller utility requirement. The advent of lotus seed sheller is an important invention lotus seeds production and processing sector. It is the lotus seed production has increased significantly, and greatly reduces the labor intensity of farmers, can also be processed into a variety of dial good lotus seeds lotus seed products, while lotus seed shell can also be processed feed and other uses.

The design uses a cutting tool purpose shell Jen came separation, peel way scroll Cutting lotus seed sheller, lotus seeds into the cutting device along the guide trough, groove wheel drive lotus seeds counterclockwise rotation of the cutter along the equator lotus seeds, lotus seeds and tools in the equatorial cut out on a closed track, so as to achieve shell kernel separation, performance is relatively stable, smooth cut, less clogging phenomenon, a high peel rate, damage rate, to be innovative in design.

Keywords: lotus; Sheller; design

剥壳机的基本结构设计

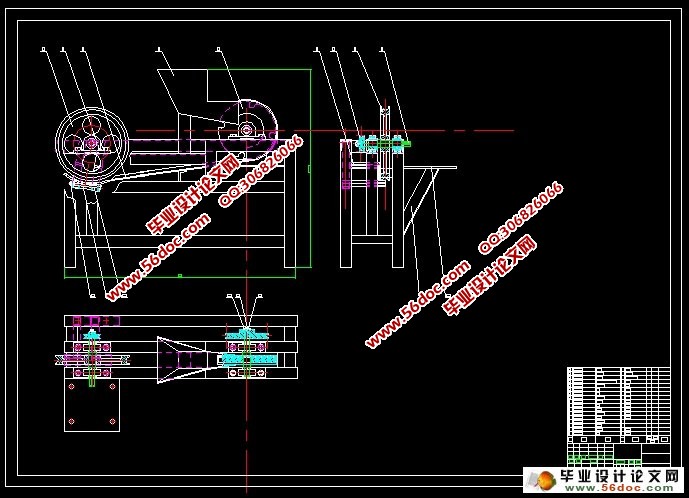

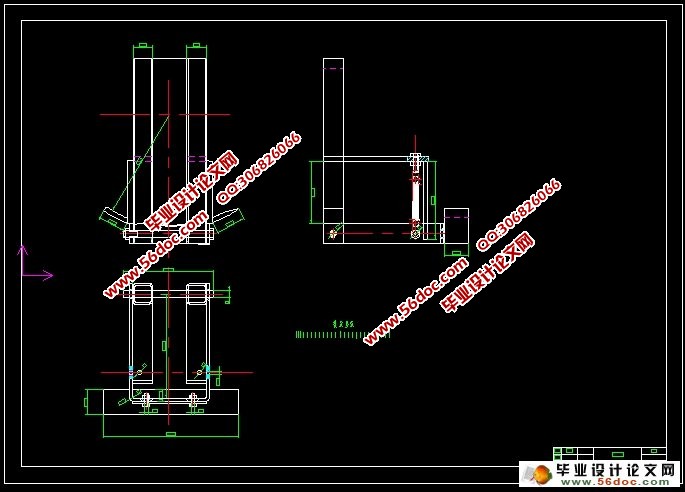

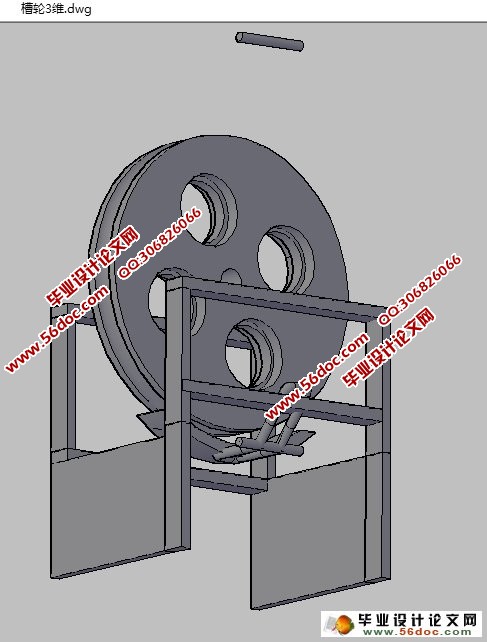

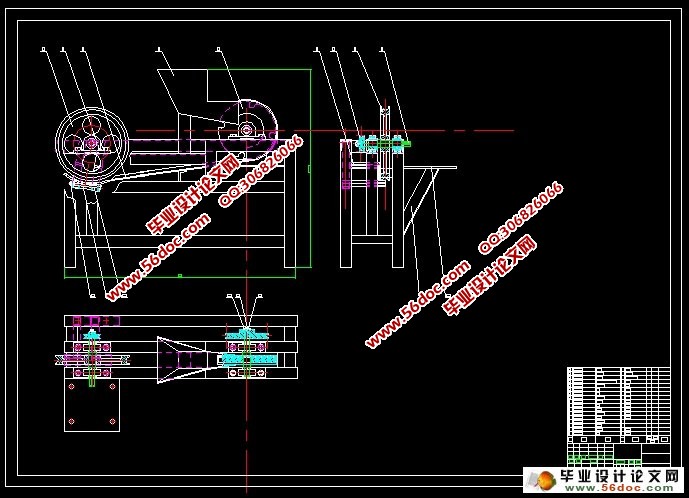

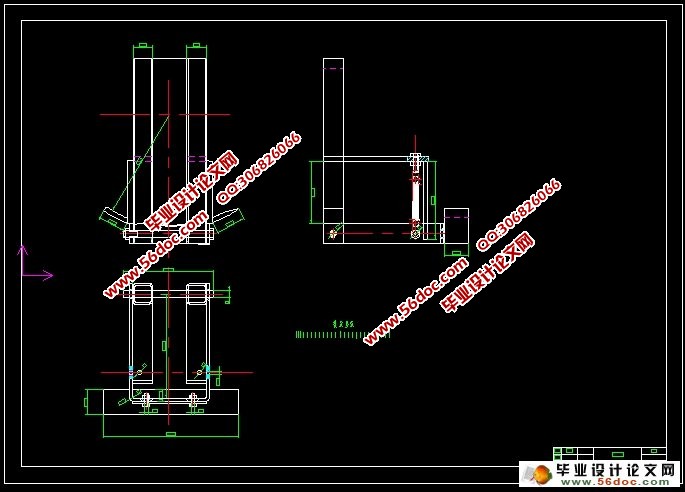

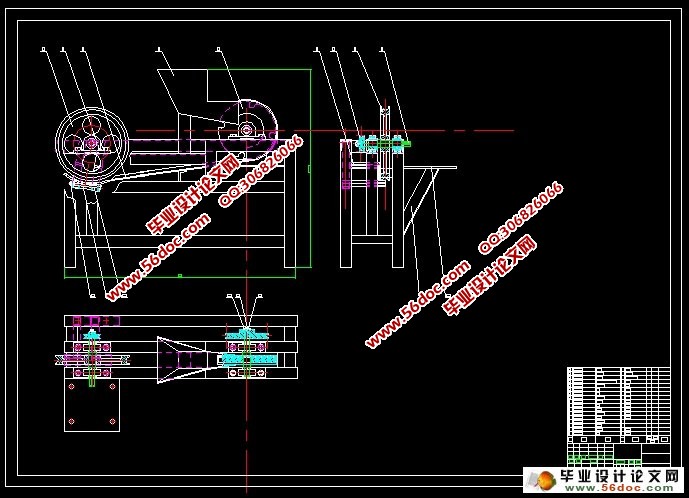

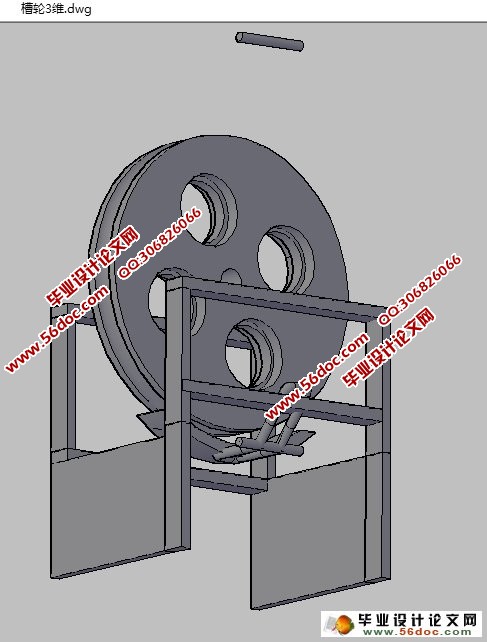

根据莲子的结构特性以及力学性能,本次设计的剥壳机大体思路是由料斗(1),槽轮(2),导料槽(3),刀架(4),出料口(5),机架(6)等所组成。其特征是:在槽轮的轮柱面上开有椭圆弧凹槽与导料槽相对应,导料槽为椭圆弧弹性凹槽,在导料槽的出口处设置一个刀架和槽轮的凹槽相对应,导料槽的凹槽面为弹性橡胶,刀架通过定位栓在定位孔中连接切割刀片,刀架由选好的弹簧连接在机架上,切割刀片的刀刃部分相对槽轮的圆心形成一段圆渐开线连接一段圆弧。

2.3剥壳机的工作原理

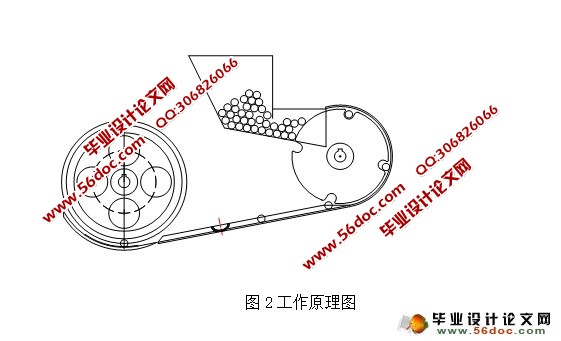

剥壳机的主要结构如图2所示,其主要工作原理为:将需剥壳的鲜莲子均匀放入料斗,莲子通过料斗进入倒料轮,在倒料轮带动下依次顺序进入导料槽,顺着导料槽进入槽轮,莲子在重力作用下处于滚动状态,在滚动过程中,莲子逐步调整滚动姿势至达到理想的切割姿势,随后进入由刀架与槽轮构成的切割通道,莲子在此通道内继续受到刀架板与槽轮的压力以及槽轮的切向摩擦力而处于理想的纯滚动状态,刀架板的中间镶有切割刀片,当莲子滚过切割通道时被切割刀片连续环切从而完成割壳。

目 录

摘 要 I

Abstract II

第一章 绪论 - 1 -

1.1莲子剥壳传统工艺方法 - 2 -

1.2莲子剥壳机械加工方法及现状 - 2 -

1.2.4冲击式莲子剥壳机 - 3 -

1.2.5切割式莲子剥壳机 - 3 -

1.3设计任务及要求 - 4 -

第二章莲子剥壳机总体设计 - 5 -

2.1莲子几何特征及其力学特性 - 5 -

2.2 剥壳机的基本结构设计 - 5 -

2.3剥壳机的工作原理 - 6 -

第三章 莲子剥壳机切割部分工件设计 - 7 -

3.1槽轮的结构设计 - 7 -

3.2传动轴的设计 - 8 -

3.3轴承选取 - 9 -

3.4切割组件的结构设计 - 10 -

3.5切割刀片的选取设计 - 10 -

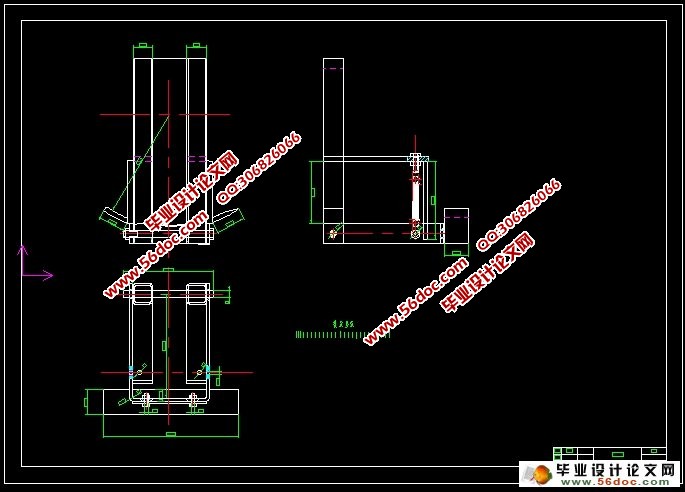

3.6刀架设计 - 11 -

3.6.1支撑臂 - 11 -

3.6.2 U型臂 - 12 -

3.7皮带轮的选择 - 13 -

第四章设计总结 - 14 -

4.1结论综述 - 14 -

4.2存在的不足 - 14 -

4.3莲子剥壳机的技术发展趋势 - 15 -

参考文献 - 16 -

致谢 - 17 -

|