内齿块式径向调绳离合器装置设计(含CAXA零件图装配图)(开题报告,中期检查表,外文翻译,论文说明书19000字,CAXA图6张)

摘 要

提升机是矿山大型固定设备之一,是联系井下与地面的主要运输工具,在矿山生产建设中起着重要的作用。矿井提升机主要用于煤矿、金属矿和非金属矿中提升煤炭、矿石和矸石、升降人员、下放材料、工具和设备。

矿井提升机与压气、通风和排水设备组成矿井四大固定设备,是一套复杂的机械——电气排组。所以合理的选用矿井提升机具有很大的意义。

矿井提升机的工作特点是在一定的距离内,以较高的速度往复运行。为保证提升工作高效率和安全可靠,矿井提升机应具有良好的控制设备和完善的保护装置。矿井提升机在工作中一旦发生机械和电器故障,就会严重地影响到矿井的生产,甚至造成人身伤亡。

熟悉矿井提升机的性能、结构和动作原理,提高安装质量,合理使用设备,加强设备维护,对于确保提升工作高效率和安全可靠,防止和杜绝故障及事故的发生,具有重大意义。

双滚筒在大型煤矿上广泛应用,提升人员和物料的效率非常高。绳索在两个滚筒上的缠绕方向相反,所以两个载重室的运动方向相反。但是,随着长时间的运转,绳索受到力的作用而产生拉长变形。因此,导致载重室不能准确的回的初始位置。所以,调绳离合器的作用就凸显起来。

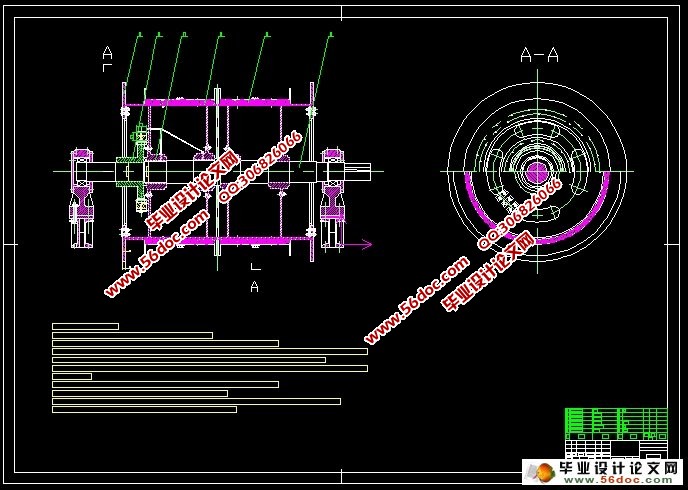

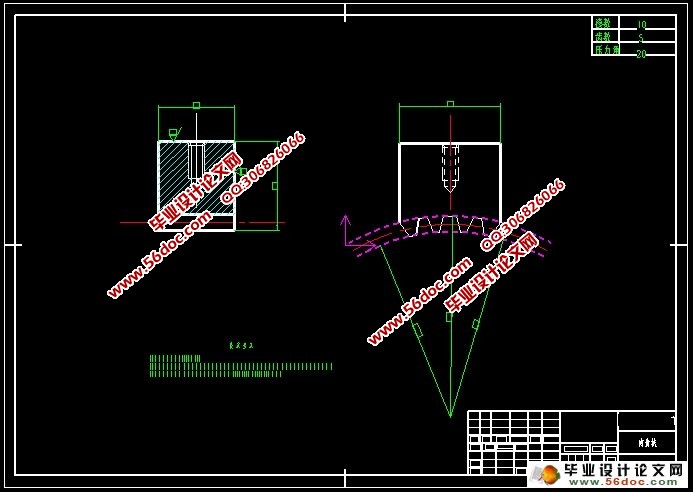

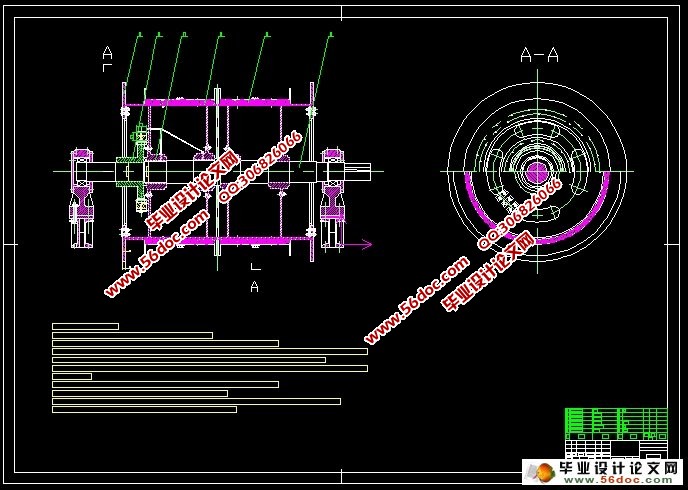

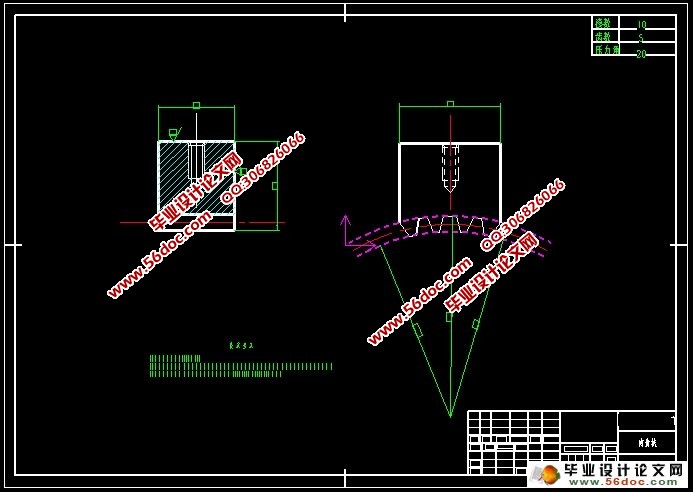

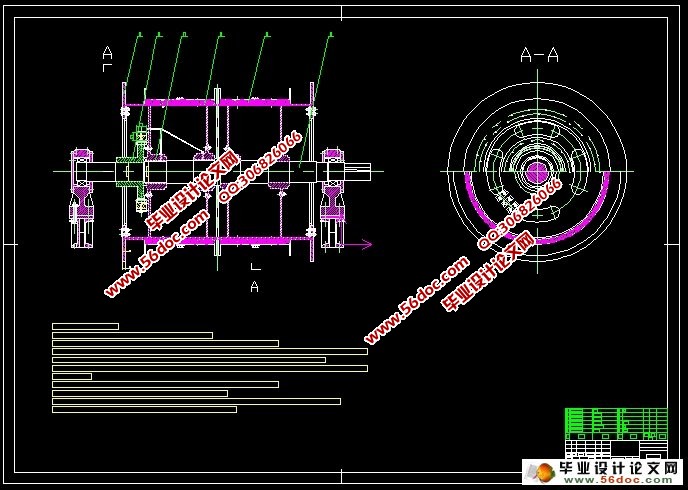

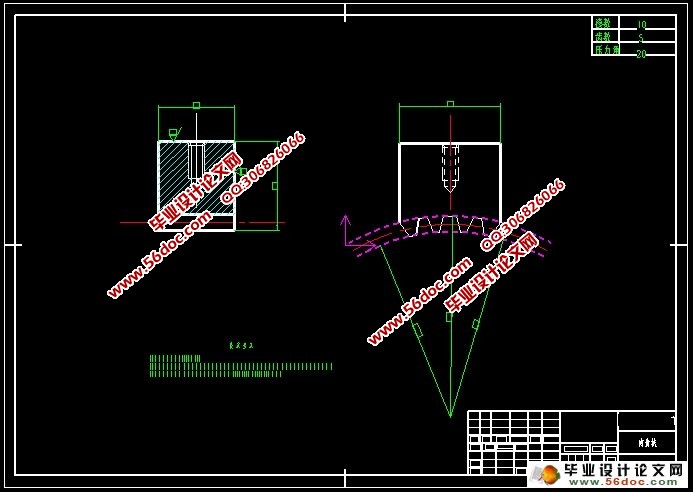

径向齿轮离合器目前广泛使用,但由于结构复杂,加大了轴向长度,增加了设备的重量,设备本身的成本较高。结合径向齿轮离合器的特点,我们设计了一种把原内齿圈做成内齿块,原齿块和固定毂合为一个外齿轮毂,为主要结构的新型多齿块径向手动离合器。 两个滚筒一个是活动的,一个是固定的。在活动滚筒的所在轴上安装离合器。该离合器主要由:外齿轮毂、内齿块、拉杆机构等组成。内齿块两端的滑槽与活动滚筒的腹板连成一体。正常提升时,内齿块与外齿轮毂啮合。。动力从主轴传递到外齿轮毂,再到内齿块上,通过两侧滑槽传递到活动滚筒上。主轴带动滚筒一起转动,完成提升或下放任务。调节绳长时,固定活动滚筒后,转动内齿块上方的螺杆,拉动内齿块沿滑槽移动,与外齿轮毂脱开。依次把几个内齿块都脱离外齿轮毂后,主轴就与活动滚筒脱离开来,即可进行调绳操作。

调绳离合器在双滚筒矿用提升机上有巨大的作用,具有一定的现实意义。

关键词:矿用提升机 调绳离合器 内齿块 外齿轮毂 滑槽

Abstract

Hoist is large and fixed equipment of underground and ground, is the main means of transport, in mine production and construction plays an important role in. Mine lifting machine is mainly used for coal, metal and non-metallic minerals in coal, ore and gangue lifting, lifting personnel, lower material, tools and equipment.

Mine hoist with compressed air, ventilation and water drainage device consisting of four mine fixed equipment, is a set of complex machinery -- Electrical group. Therefore the reasonable selection of mine hoisting machine has great significance.

The characteristics of mine hoist is within a certain distance, in high speed reciprocating operation. In order to ensure the promotion work efficiency and safety, mine hoist should have good control equipment and perfect protection device. Mine hoist in the work upon the occurrence of mechanical and electrical failures, it will seriously affect the mine production, and even cause casualties.

Familiar with mine hoist performance, structure and principles of action, improve installation quality, rational use of equipment, strengthen equipment maintenance, to ensure that enhance the work efficiency and safety, prevent and eliminate the faults and accidents, is of great significance.

Double cylinder in large coal mine on the widely used, promote personnel and material efficiency is very high. The rope in the two rollers on the wound in the opposite directions, so the two load compartment of the motion in the opposite direction. However, with the long time running, the rope by the force resulting from the action of stretching deformation. Therefore, led to the load chamber can not accurately back to the initial position. Therefore, adjusting rope role highlighted up.

Radial gear clutch is widely used at present, but because of the complex structure, increased axial length, increased the weight of the equipment, the equipment itself high cost. Combined radial gear clutch features, we design a kind of the inner gear ring made in the tooth block, the original tooth block and the fixed hub to an outer gear hub, as the main structure of a new type of multi tooth blocks radial manual clutch. The two roller is a activity, one is fixed. In the movable roller is mounted on the shaft clutch. The clutch consists of : the outer gear hub, tooth block, a draw rod mechanism. Internal tooth blocks at both ends of the sliding groove and the movable drum webs integrally. During normal hoisting, inner gear block and the outer bevel gear meshing.. The power from the main shaft to pass to the outer gear hub, and then to the internal tooth block, through both sides passed to the activities of the roller. The main shaft drives the roller to rotate together, raising or lowering the task completed. Adjusting rope length, fixed activity after the drum, rotating the inner tooth blocks at the top of the screw, pull move inside the gear block move along the slide groove, and the outer gear hub off. In turn several internal tooth block disengages from the outer gear hub, main shaft and movable roller can be separated from, adjusting rope operation.

Adjusting rope in double drum mine hoist has a huge role, has the certain practical significance.

Key words: mine hoist rope adjusting clutch inner tooth block outer gear hub

目录

前言 1

第一章 绪论 3

1.1 国内外提升机研究状况 3

1.2提升机的用途 7

1.3提升机的分类和结构 8

1.4 矿井提升机操作、维护与检修 11

1.4.1 操作规程 11

1.4.2 设备运转过程中的检查及维护内容 12

1.4.3 提升机运行规定 15

1.4.4定期维护、润滑 18

1.4.5 检修规程 19

1.5课题研究的目的和意义 21

1.6小结 22

第二章 矿井提升机的组成及分类 23

2.1 科技名词定义 23

2.2 矿井提升机的组成 23

2.3 矿井提升机的分类 24

2.4小结 29

第三章:调绳离合器的类别与分析 30

3.1支轮连接式调绳离合器 30

3.2蜗轮蜗杆式 31

3.3轴向齿轮式 33

3.4 径向齿轮式 34

第四章:多齿块径向手动离合器的设计 36

4.1结构组成 37

4.2主要参数的计算 39

4.2.1 外齿轮毂的齿数及调绳精度 39

4.2.2 齿块的数量以及齿块齿数 40

4.2.3 齿轮的模数 40

4.3材料选用 41

4.4 应用效果 42

致 谢 44

参考文献 45

|