CA6140主轴工艺与夹具的设计(选题表,任务书,开题报告,设计说明书23000字,工艺卡,CAD图纸7张)

摘 要

在机械领域中,车床是应用最为广泛、使用最为频繁的一种机床,特别是CA6140车床,它的应用非常的普遍。所以它的加工精度就极其的重要,工件能否达到加工要求就取决于车床本身的精度,而决定CA6140车床加工质量的就是它的主轴。CA6140车床主轴是把旋转运动及扭矩通过主轴端部的夹具传递给工件和刀具,要求有很高的强度及回转精度。

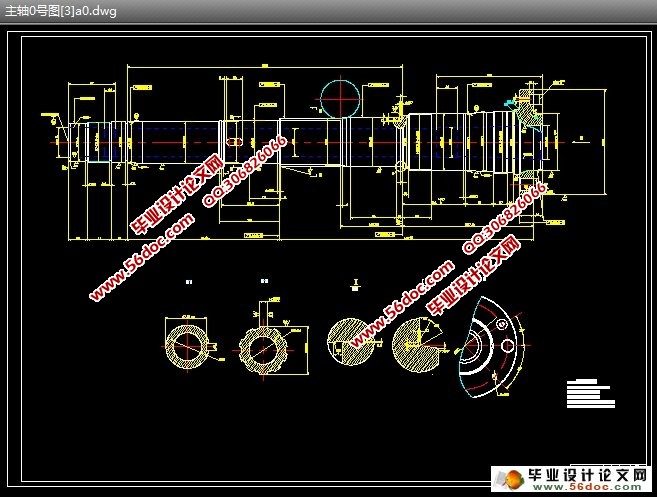

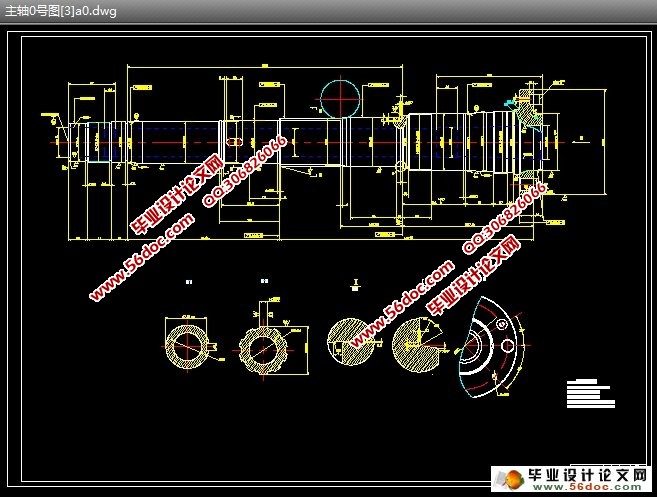

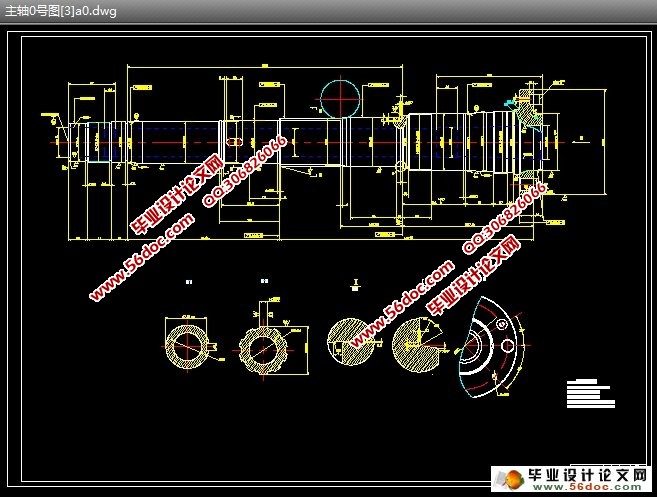

我在本设计中将主轴设计为空心阶梯轴,外圆表面设有花键、垫键等功能槽及螺纹。本文设计详细计算了加工余量、切削用量、尺寸公差并阐述了CA6140主轴的加工工艺过程以及生产中所涉及的重要夹具设计方法。经设计的CA6140主轴较其传统的车床主轴有更高的强度和回转精度。

关键词: 车床;主轴;旋转运动;公差;夹具

ABSTRACT

In machinery field, the lather is the most extensively and frequently used machine. Easpecially the CA6140 lather, its application is very widespread. So its processing accuracy is very important. Whether the work piece can reach the accuracy required is decided by the lather. While, the part deciding the processing quality of CA6140 lather is its mainshaft. The mainshaft of the CA6140 lather is to transmit the rovolve motion and the torque to the workpiece and cutting-tool through the fixture on the end of mainshaft, in which high strengh and rotating accuracy are required .

In this design, my job contains the things as below. Mainshaft is a hollow stepped shaft. There are functional slots and thread, such as spline, pad key and so on. In the paper, allowance, cutting consumption and tolerance are calculated. Also elaborates the craft processes of the mainshaft of CA6140 lather, and the design of important fixture. After being designed, compared with traditional lather, the strength and rotating accuracy are enhanced.

Key words: Lather; Mainshaft; Rotating Movement; Tolerance; Fixture

目 录

摘要 I

Abstract II

第 1 章 绪论 1

1.1 概述 1

1.2车床的发展史 1

1.3本课题研究的内容和设计思想 1

第 2章 零件的分析 4

2.1零件的作用 4

2.1.1支承轴颈 4

2.1.2头部锥孔 4

2.1.3头部短锥 4

2.1.4装配轴颈 4

2.1.5轴向锁紧 5

2.2零件的工艺分析 5

2.2.1加工阶段的划分 5

2.1.3工序顺序安排 5

2.1.4主轴锥孔的磨削 6

2.3 本章小结 5

第 3 章 工艺规程的设计 7

3.1主轴的材料、毛坯与热处理 7

3.1.1主轴的毛坯 7

3.1.2主轴的材料和热处理 7

3.2主轴加工工艺过程 8

3.2.1主轴加工的主要问题和工艺过程设计所应采取的相应措施 8

3.2.2主轴加工定位基准的选择 9

3.2.3主轴主要加工表面加工工序的安排 9

3.2.4各工序工步的排序 11

3.3 本章小结 11

第 4 章 机械加工余量、工序尺寸及毛坯尺寸的确定 12

4.1各工序工步的加工余量的计算 12

4.2各工序工步的切削用量的计算 19

4.3本章小结 49

第 5 章 专用夹具的设计 50

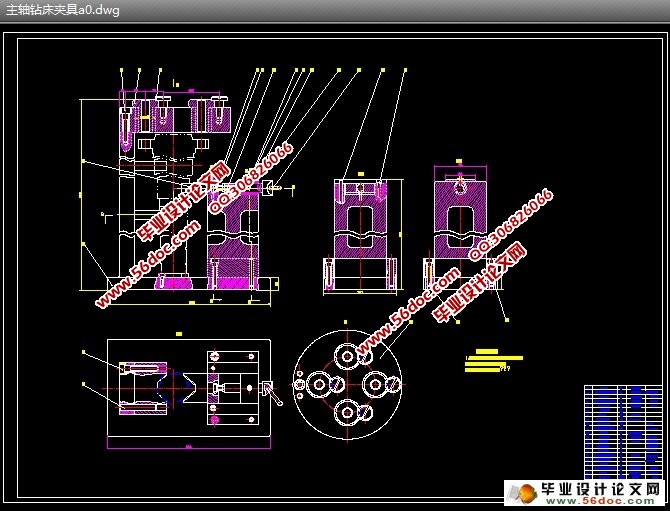

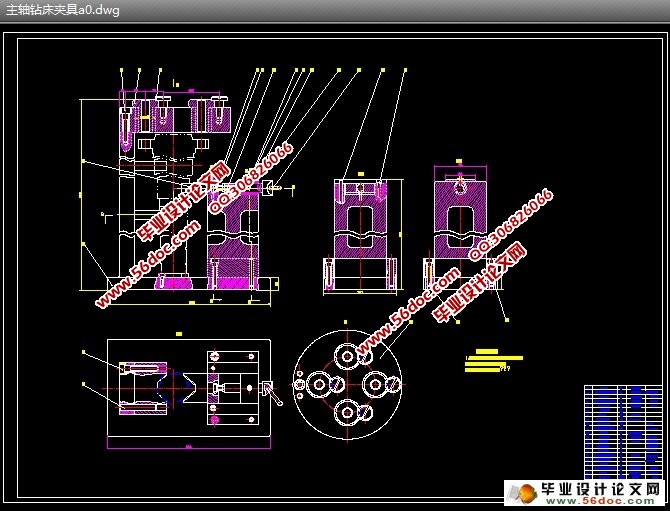

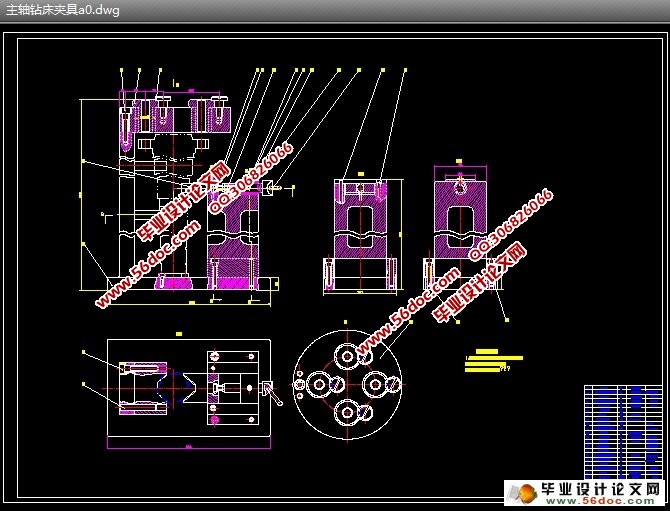

5.1 钻床夹具的设计 50

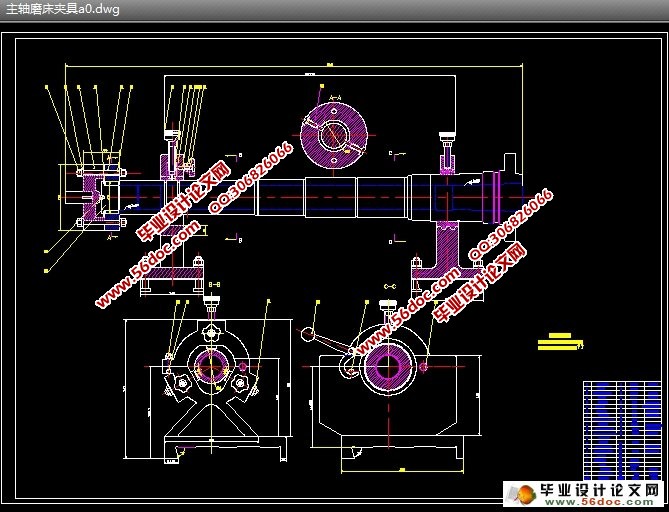

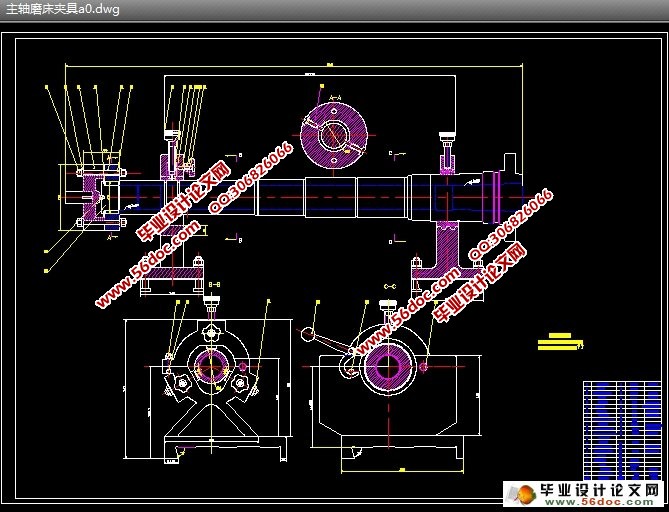

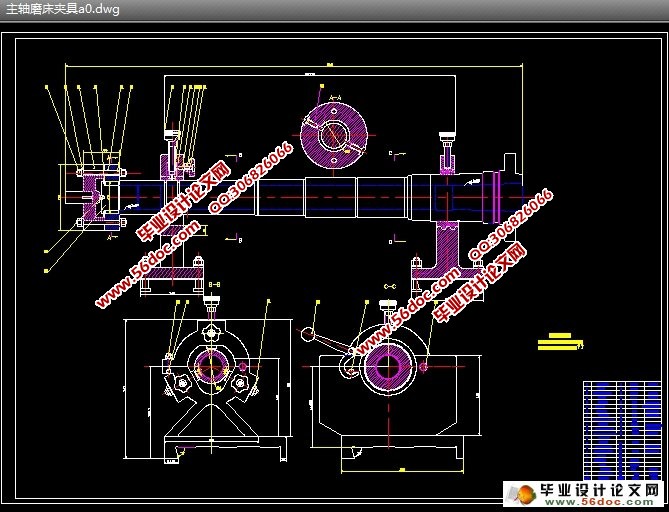

5.2 磨床夹具的设计 50

5.3 本章小结 51

结论 52

参考文献 53

致谢 54 |