柱塞泵连杆制造工艺及其工艺装备设计

来源:wenku7.com 资料编号:WK710981 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK710981

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

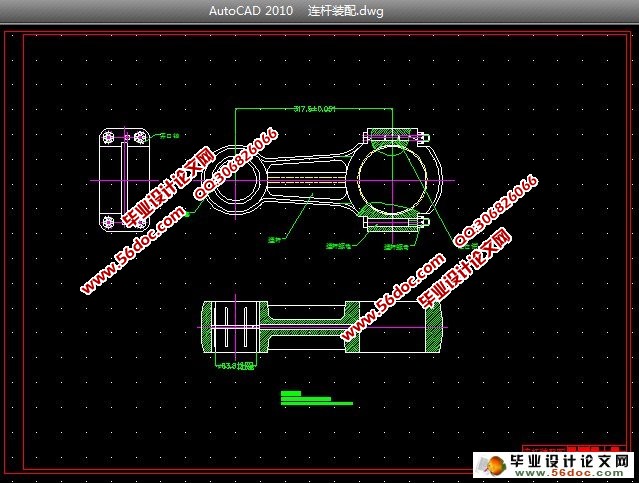

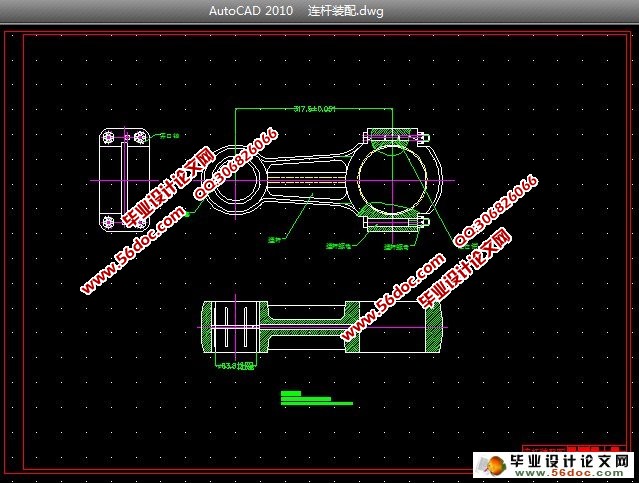

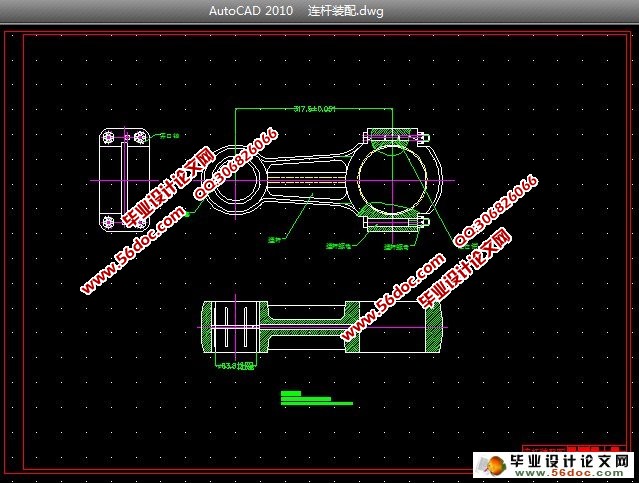

柱塞泵连杆制造工艺及其工艺装备设计(任务书,开题报告,毕业论文说明书16000字,CAD图纸3张)

【摘 要】 连杆零件是柱塞泵的主要传动件之一,本文主要论述了连杆的加工工艺及其夹具设计。连杆的尺寸精度、形状精度以及位置精度的要求都很高,而连杆的刚性比较差,容易产生变形,因此在安排工艺过程时,就需要把各主要表面的粗精加工工序分开。逐步减少加工余量、切削力及内应力的作用,并修正加工后的变形,就能最后达到零件的技术要求。

【关键词】:连杆 加工工艺 夹具设计

Manufacture technology of piston pump connecting rod and design of its process equipment

【ABSTRACT】 The connecting rod is one of the main driving medium of diesel engine, this text expounds mainly the machining technology and the design of clamping device of the connecting rod. The precision of size, the precision of profile and the precision of position , of the connecting rod is demanded highly , and the rigidity of the connecting rod is not enough,easy to deform, so arranging the craft course, need to separate the each main and superficial thick finish machining process. Reduce the function of processing the surplus , cutting force and internal stress progressively , revise the deformation after processing, can reach the specification requirement for the part finally

【Keyword】: Connecting rod clamping device

目录

毕业设计任务书.............................................................I

开题报告..................................................................II

指导老师审查意见..........................................................III

评阅老师评语..............................................................IV

答辩会议记录..............................................................V

中文摘要..................................................................VI

外文摘要.................................................................VII

1 绪论.....................................................................1

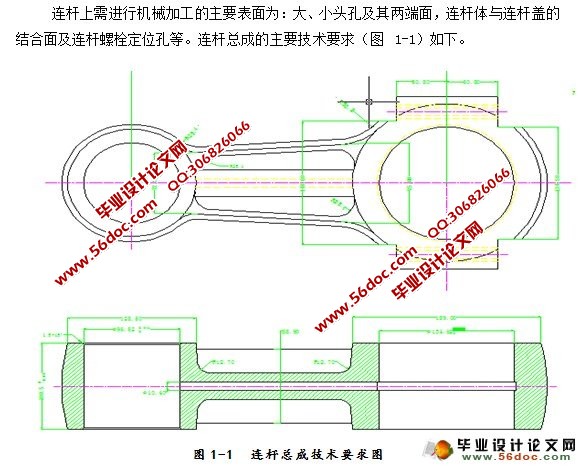

2 零件分析.................................................................1

2.1连杆的结构特点.......................................................1

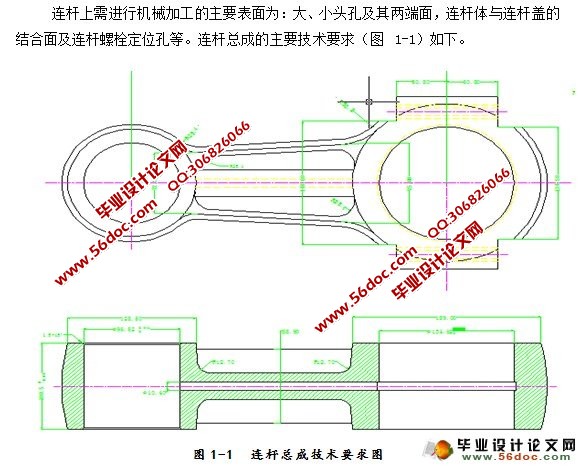

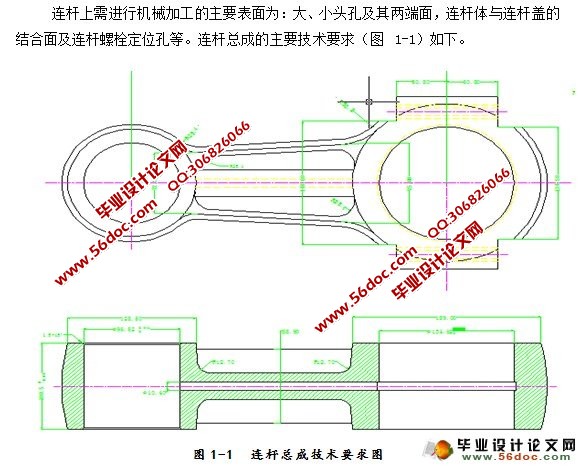

2.2连杆主要的技术要求...................................................2

2.2.1 大小头孔尺寸精度.形状精度........................................3

2.2.2 大,小头孔轴心线在两个互相垂直方向的平行度.......................3

2.2.3.大、小头孔两端面的技术要求.......................................3

2.2.4.螺栓孔的技术要求.................................................3

2.2.5.有关结合面的技术要求.............................................3

2.5.6 连杆螺栓孔的加工.................................................3

2.5.7 连杆体与连杆盖的铣开工序.........................................4

3 工艺规程设计.............................................................4

3.1 确定毛坯制造形式.....................................................4

3.2 热处理工艺及其目的...................................................6

3.3 连杆的机械加工工艺过程分析...........................................7

3.3.1 工艺过程的安排...................................................7

3.3.2 定位基准的选择...................................................7

3.3.3 确定合适的夹紧方法...............................................9

3.3.4 连杆两端面的加工.................................................9

3.3.5 连杆大小头孔加工................................................10

3.3.6 连杆螺栓孔加工..................................................10

3.4 连杆加工工艺设计应考虑的问题........................................10

3.5 切削用量的选择原则..................................................11

3.5.1切削用量的选择..................................................11

3.5.2切削用量的选择原则..............................................12

3.5.3确定加工余量....................................................13

3.6 连杆的机械加工工艺卡片..............................................14

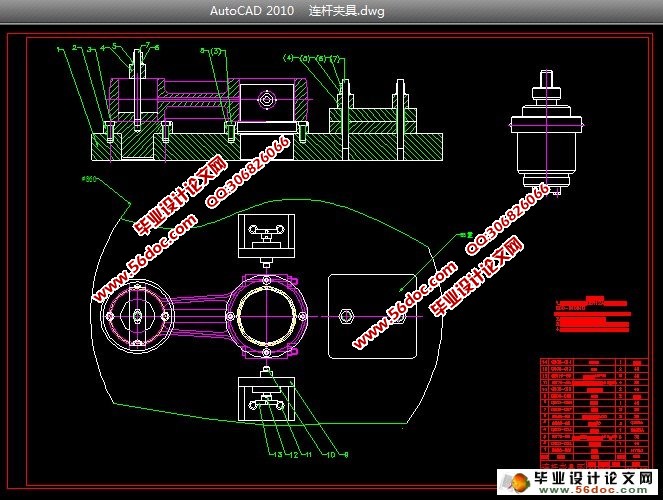

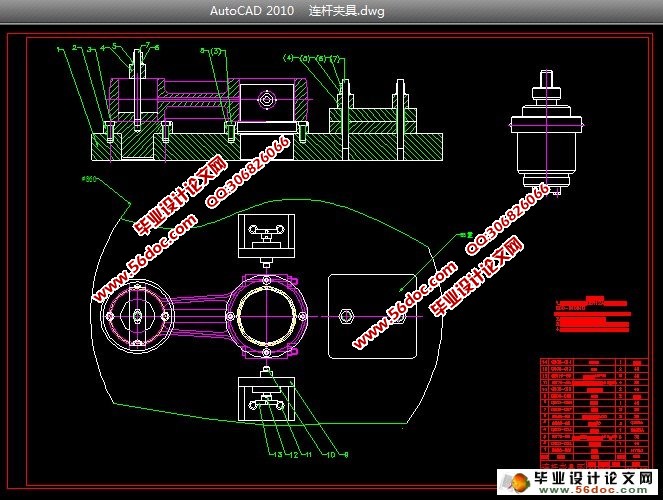

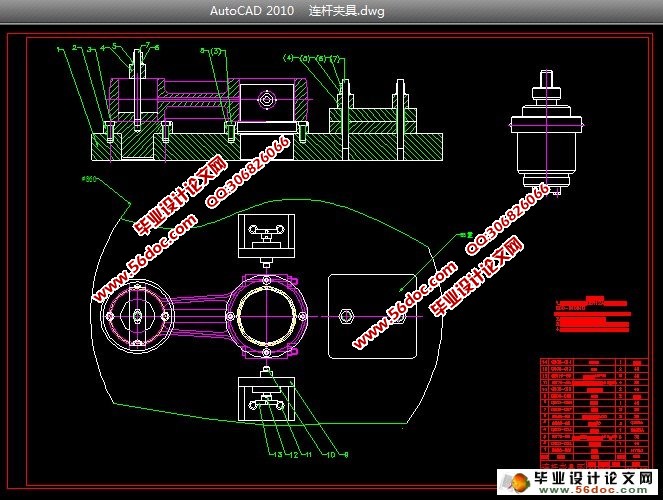

四.工装设计...............................................................19

4.1夹具的注意问题.......................................................19

4.2大头孔精车工装.......................................................19

五.总结...................................................................23

参考文献..................................................................24

致谢......................................................................25

|