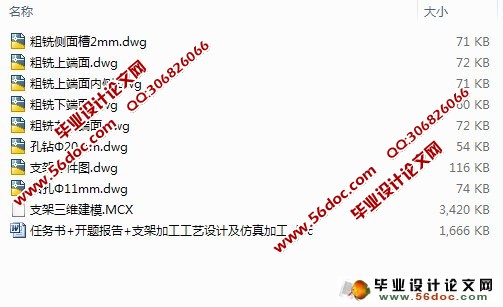

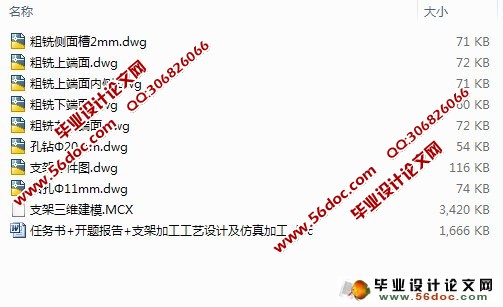

支架加工工艺设计及仿真加工(CAD,Mastercam三维)(任务书,开题报告,毕业论文说明书16700字,CAD图纸8张,Mastercam支架三维建模)

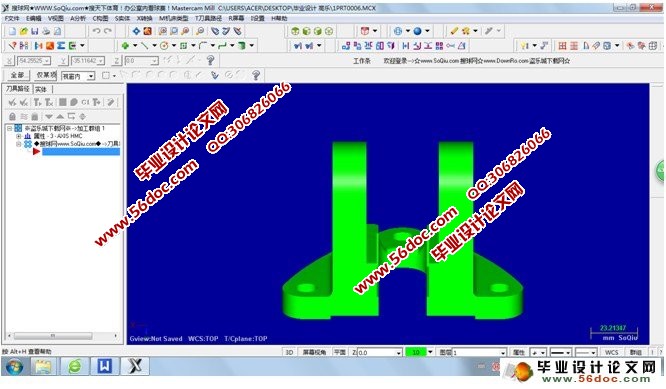

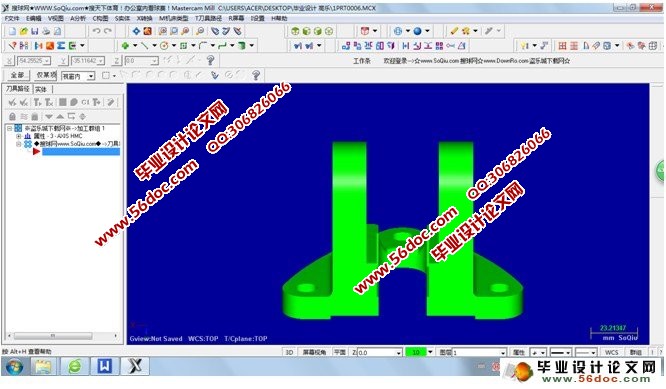

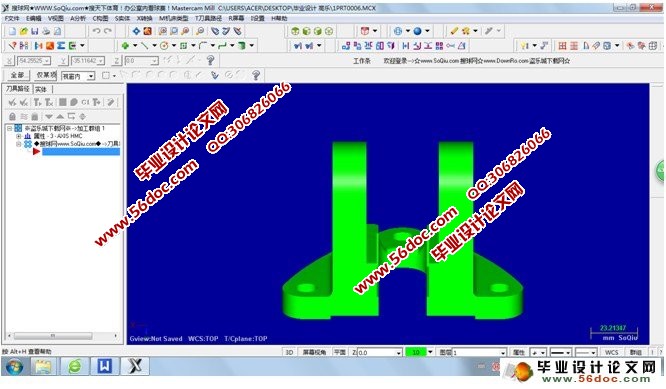

[摘要] Mastercam是用于机械行业中计算机辅助设计及制造(CAD/CAM)的软件系统,它是基于PC机并为机械零件的二维与三维设计提供全方位优良环境,可以实现仿真加工。最重要的特点是它能输出所设计零件的原始数控程序代码(CNC)。本文基于Mastercam软件,首先对支架进行三维造型,然后利用Mastercam对支架仿真加工,主要的研究方向是支架的加工工艺。加工工艺设计好以后,在Masteream平台上生成加工代码。

论文在分析综述了Mastercam性能、特点的基础上,系统的阐述了支架造型方法和步骤,完成支架的造型。在分析了所要仿真加工的支架的形状后,针对不同的加工面相应的加工方法,选择了合理的加工工艺。本文还对不同的加工工艺做了比较,通过比较可以看出,本文中选取的工艺参数和工艺路径是合理的,这对提高加工质量有一定的实际意义。

[关键词] 二维造型;仿真加工;加工工艺

Machining process design and simulation

[Abstract] Mastercam is used in the machinery industry of computer aided design and manufacture (CAD/CAM) software system, which is based on PC and mechanical parts of 2 d and 3 d design provides the omni-directional good environment, can realize the simulation processing. The most important characteristic is that it can output the designed parts of the original numerical control (CNC) program code. Based on Mastercam software, scaffolds for three-dimensional modelling in the first place, then use Mastercam for stent simulation processing, the processing technology of the main research direction is support. After machining process design, generating nc code on Masteream platform.

Paper on the basis of analyzing the Mastercam properties were reviewed, the characteristics, the system elaborated the stents modelling methods and steps, to complete the modelling of stents. Based on the analysis of the simulation processing by the shape of the scaffold, according to different processing and surface processing methods, choose the reasonable processing technology. This article also made a comparison of different processing technology, through the comparison, you can see that in this article, the selection of process parameters and process route is reasonable, it has certain practical significance to improve the processing quality.

[Key words] two-dimensional modelling; The simulation processing; The processing technology

1 零件分析

1.1 对零件进行功用分析

1.2 零件的工艺分析

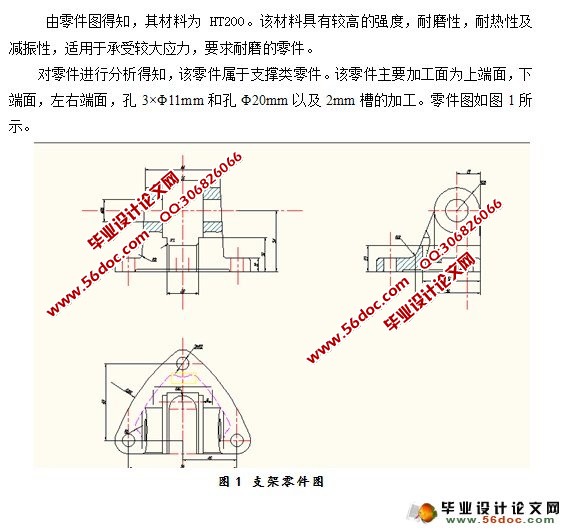

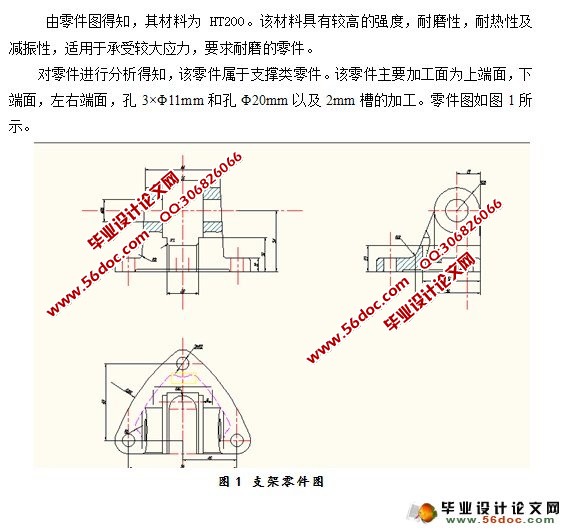

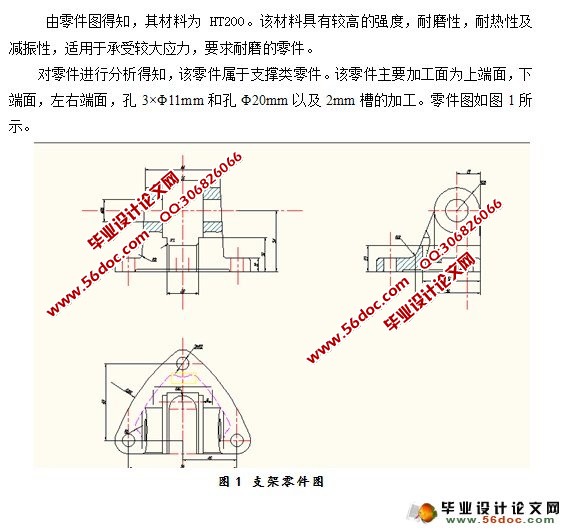

由零件图得知,其材料为HT200。该材料具有较高的强度,耐磨性,耐热性及减振性,适用于承受较大应力,要求耐磨的零件。零件分析

对零件进行分析得知,该零件属于支撑类零件。该零件主要加工面为上端面,下端面,左右端面,孔3×Φ11mm和孔Φ20mm以及2mm槽的加工。

目 录

任务书……………………………………………………………………………………Ⅰ

开题报告…………………………………………………………………………………Ⅱ

指导教师审查意见………………………………………………………………………Ⅲ

评阅教师评语……………………………………………………………………………Ⅳ

答辩会议记录……………………………………………………………………………Ⅴ

中文摘要…………………………………………………………………………………Ⅵ

外文摘要…………………………………………………………………………………Ⅶ

1 零件分析 1

1.1 对零件进行功用分析 1

1.2 零件的工艺分析 1

2 选择毛坯尺寸,设计毛坯图 2

2.1 选择毛坯 2

2.2 确定机械加工余量、毛坯尺寸和公差 3

3 选择加工方法,制定工艺路线 6

3.1 定位基准的选择 6

3.2 表面加工方法的确定 6

3.3 制定工艺路线 8

4 机械加工工序设计 10

4.1 确定加工余量及工序尺寸 10

4.2 选择加工设备及刀具、量具、夹具 11

4.3 确定切削用量及基本工时 12

5 支架仿真加工 28

5.1 钻Φ20mm孔 29

5.2 铣削加工下端面 31

5.3 铣削加工上端面、左右两端面、钻3×Φ11mm孔及铣2mm槽 33

6 结 论 39

参考文献 39

致 谢 40

|