水酶法提取山桐子油工艺研究

来源:wenku7.com 资料编号:WK76352 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK76352

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

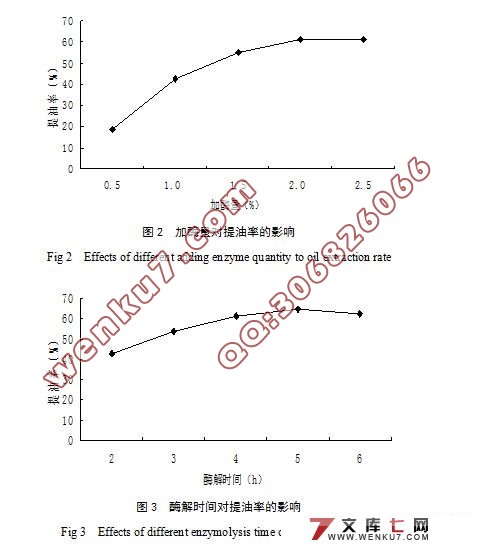

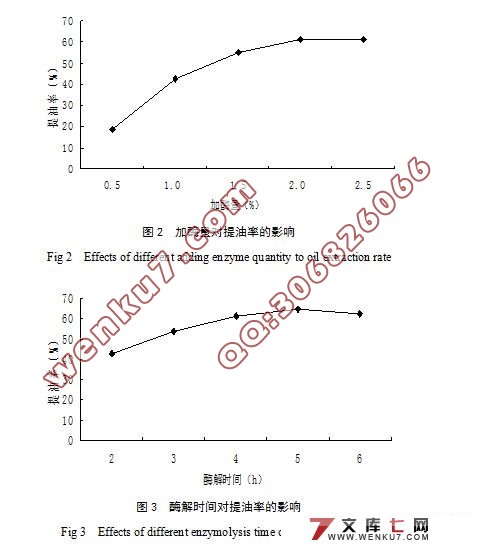

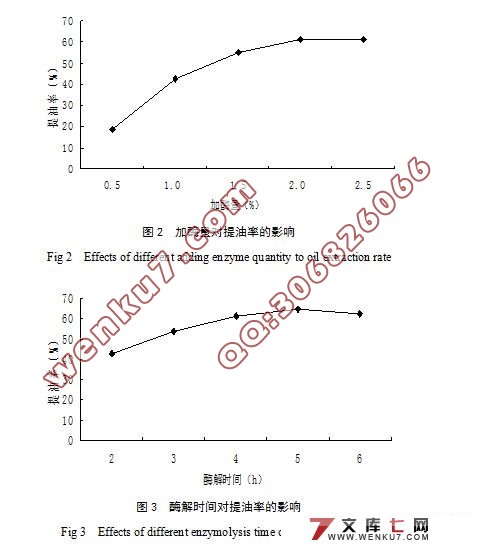

摘 要:以山桐子为原料,利用水酶法提取山桐子油。首先从纤维素酶、碱性蛋白酶、淀粉酶、复合酶中选取提取山桐子油的最佳用酶。试验结果表明纤维素酶对提取山桐子油的作用最佳,其提油率达到61.28%。再通过单因素和正交试验,分别研究了料液比、加酶量、酶解时间、酶解温度对提油率的影响。获得的最佳工艺条件为料液比1﹕4,加酶量2.5%,酶解时间5h,酶解温度50℃,此时的提油率达到68.96%。

关键词: 山桐子;水酶法;纤维素酶;提油率

Aqueous Enzymatic Extraction Oil Of Idesia Polycarpa Maxim

Abstract: This paper reported the study that used Idesia polycarpa Maxim seeds as raw materials to extract the seed oil by aqueous enzymatic method. First, to select the optimum enzyme of extracting Idesia polycarpa Maxim oil by screening cellulose, alkaline protease, amylase and complex enzyme (cellulose : alkaline protease : amylase = 1:1:1) , The result showed that the cellulase is the best one among the four kinds of enzyme, the oil extraction rate reached to 61.28%. Through single factors and orthogonal experiments, the effects of the ratio of solid to liquid, enzymes addition, enzymolysis time and enzymolysis temperature to oil extraction rate were studied. The optimum condition was obtained as follows: the ratio of solid to liquid is 1︰4 , enzyme addition is 2.5%, enzymolysis time is 5h and enzymolysis temperature is 50℃, under this condition the oil extraction rate reached to 68.96%.

Key words: Idesia polycarpa Maxim; Aqueous enzymatic method; Cellulose; Oil extraction rate

目 录 9800字

摘 要 1

关键词 1

1 前言 2

2 材料与方法 4

2.1 材料、仪器设备与试剂 4

2.1.1 试验材料 4

2.1.2 主要仪器设备 4

2.1.3 试剂 4

2.2 试验方法 4

2.2.1 工艺流程和操作要点 4

2.2.2 检测指标与方法 5

2.2.3 单因素试验 5

2.2.4 正交试验及验证试验 6

3 结果与分析 7

3.1 山桐子中粗脂肪含量的测定 7

3.2 酶制剂的筛选 7

3.3 料液比对提油率的影响 8

3.4 加酶量对提油率的影响 8

3.5 酶解时间对提油率的影响 9

3.6 酶解温度对提油率的影响 10

3.7 正交试验结果分析 11

3.8 验证试验结果 12

4 小结与讨论 12

参考文献 12

致 谢 13

|