年产1800吨阿司匹林的车间工艺设计(13000字)

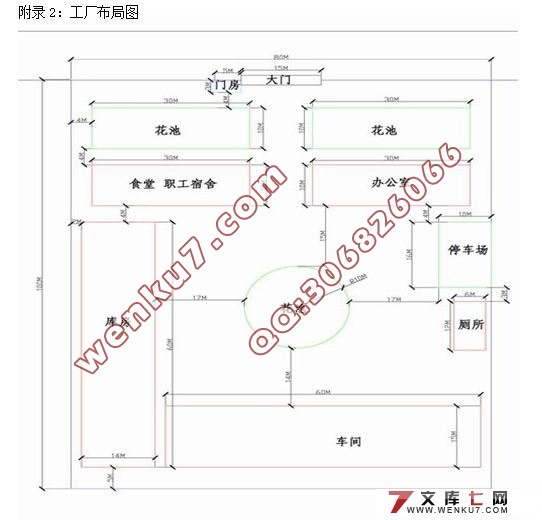

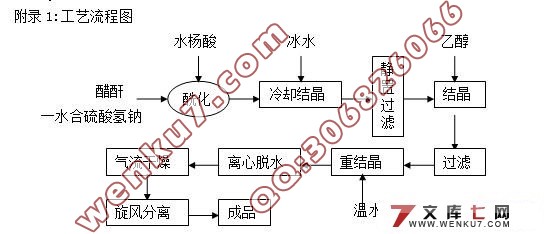

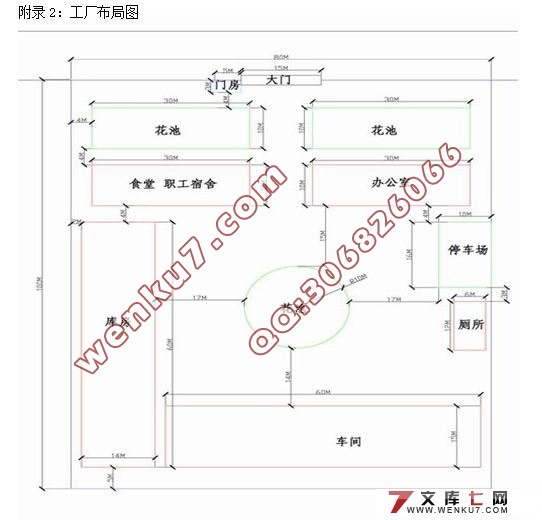

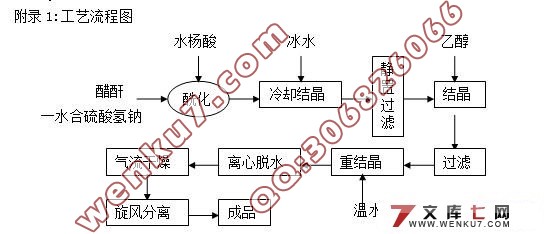

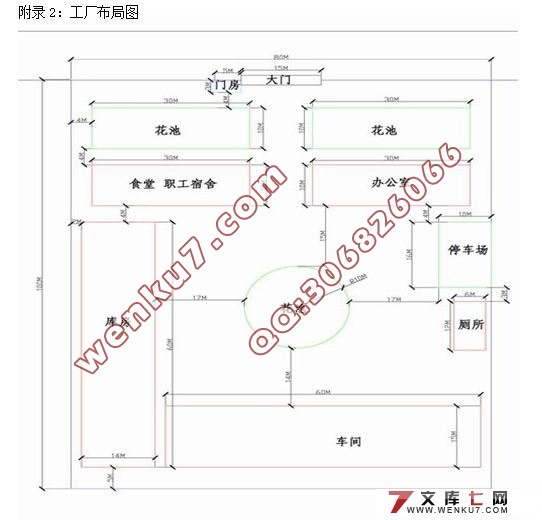

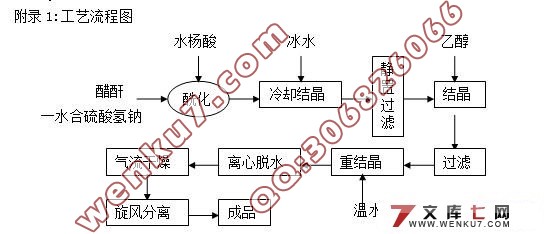

摘 要:本文用醋酐和水杨酸为原料,以一水合硫酸氢钠为催化剂生产阿司匹林,工艺过程简单,产品纯度高,是阿司匹林生产的一条高产、优质、低成本的有效途径。设计一个年产1800吨阿司匹林的生产车间,根据其工艺特点,将生产周期确定为14 h,每天一批,通过物料衡算确定各原料的用量为:水杨酸 5111.01 kg/d;醋酐 7253.29 kg/d;一水合硫酸氢钠 511.01 kg/d;通过热量衡算确定在各阶段加热剂或冷却剂的用量为:酰化反应阶段需水蒸气提供7.44×105 KJ的热量,水蒸气的流量为4.22 m3/h,冰水冷却阶段需10000 kg冰水吸收3.115×106 KJ的热量,乙醇结晶阶段需水蒸气提供3.61×105 KJ的热量,水蒸气的流量为40.18 m3/h,温水结晶阶段需1361.22 kg冷冻盐水吸收2.207×106 KJ的热量。然后根据计算结果进行釜体设计,确定为9 m3的反应釜,15 m3的两个结晶釜和15 m3的精制釜,设计内容包含了釜体各部分尺寸、气流干燥器、旋风分离器及车间布置等方面的设计,最后给出了生产工艺的反应流程简图和车间布置图。

关键词:阿司匹林;物料衡算;热量衡算;生产设计;车间布置

The process design of Aspirin for annual output 1800 tons

Abstract: This article use acetic anhydride and salicylic acid as raw material, choose Sodium bisulfate monohydrate as production catalyst manufacture aspirin, The craft process for Aspirin is a valid path of high produce, superior quality and low cost for the process is simple and product purity is high. Design an aspirin production workshop of annual output of 1800 tons, according to its process characteristics, the production period is determined for every batch 14h, through Mass Balance the quantity of each raw material needed is determined as follows: Salicylic acid 5111.01 kg/d; Acetic anhydride 7253.29 kg/d; Sodium bisulfate monohydrate 511.01 kg/d, through Heat Balance the quantity of heating agent ,coolant dosage needed At various stages is determined as follows: Flow of water vapor for 4.22 m3/h is needed to Provide 7.44×105 KJ heat at Acylation reaction stage, 10000 kg Ice water is needed to absorb 3.115×106 KJ heat at Iced water cooling stage, Flow of water vapor for 40.18 m3/h is needed to Provide 3.61×105 KJ heat at Ethanol crystallization stage, 1361.22 kg Frozen brine is needed to absorb 2.207×106 KJ heat at Warm crystallization stage.According to the results of balance, the kettle is designed as follows: a Reactor of 6 cubic meters, two Crystalline kettle of 15 cubic meters, and a Refining Crystalline kettle of 15 cubic meters, the design also included the body each parts of sizes and air dryer、cyclone and workshop layout, and so on. Finally, a flow chart of the reaction, a workshop layout diagram are given.

Key words: Aspirin; Mass Balance; Heat Balance; Process Design; Workshop Layout

|