压力测试治具的设计(附PCL程序)

来源:wenku7.com 资料编号:WK711038 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK711038

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

压力测试治具的设计(附PCL程序)(毕业论文11400字,PLC程序,CAD原理图)

摘 要

治具的作用是使得工作变得更加的变量治具的受用原因是有许多治具之所以产生是因为商业的需要,因为有许多类型的治具是客制化的,某些是为了提高生产力、重复特定动作、或使工作更加精确。因为治具的设计基本上是建立于逻辑,类似的治具可能会因为使用于不同的时间和地点而分别产生。治具在工业时代前就已被广泛使用,包括机械治具、木工治具、焊接治具、珠宝治具、以及其他领域。某些类型的治具也称为“模具”或“辅具”,其主要目的是为重复性和准确的重复某部分的重制。一个明显的例子是当复制钥匙时,原始的钥匙通常被固定于治具上,如此机器就能借由原始钥匙外观的导引复制出新的钥匙。本毕业设计就是设计一款压力测试治具

关键词:PLC 传感器 AD转换

Abstract

The role of governance is to make work more variables fixture good enough because there are many fixture arises because of the need of business, because there are many types of fixture is customized, some of which are to increase productivity repeat a specific action, or make it more precise. Because the rule of the design is basically built on logic, a similar fixture may be due to the use of different time and place and are generated. Fixture had been widely used in the pre-industrial era, including mechanical fixtures, carpentry fixtures, welding fixtures, jewelry fixtures, as well as other areas. Some types of fixtures also known as "mold" or "aids", whose main purpose is to repeat repeatability and accurate remake of a section. An obvious example is when a duplicate key, the original key is usually fixed to the fixture on, so the machine will be able to replicate the new key by key appearance by the original guide. The graduation project is to design a pressure test fixture

Keywords: PLC sensor AD converter

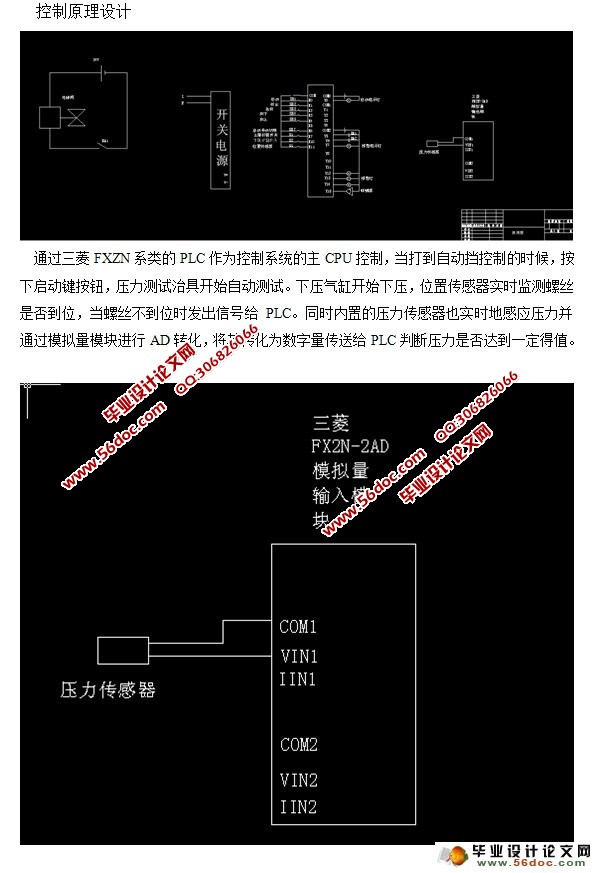

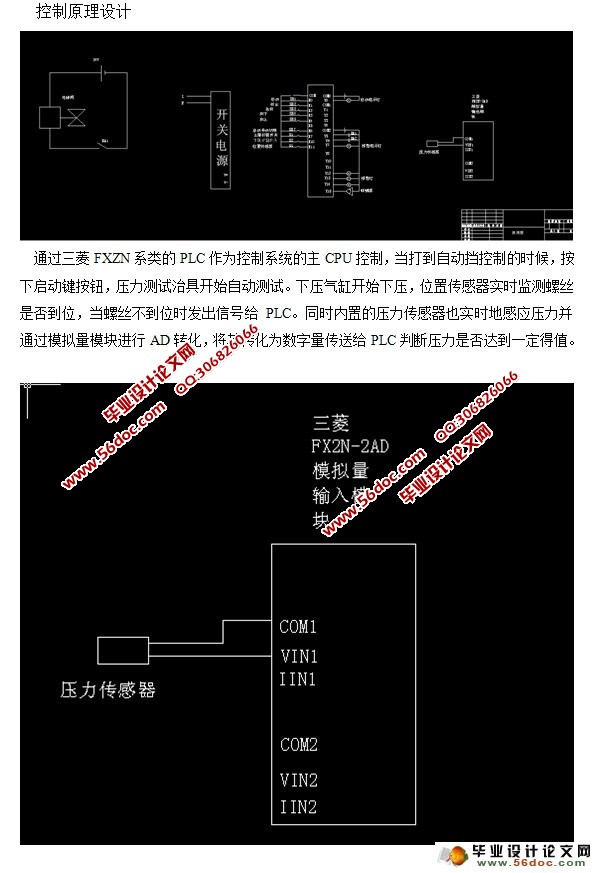

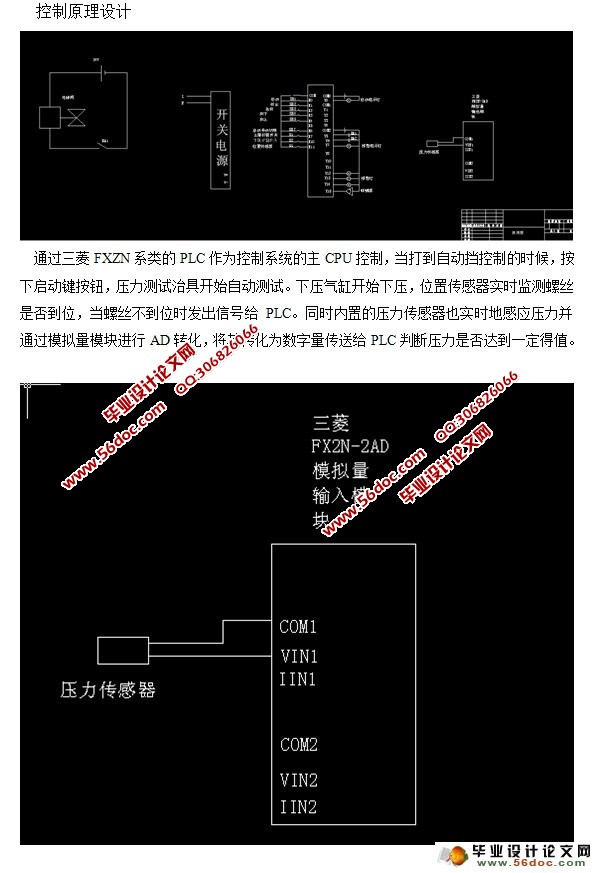

通过三菱FXZN系类的PLC作为控制系统的主CPU控制,当打到自动挡控制的时候,按下启动键按钮,压力测试治具开始自动测试。下压气缸开始下压,位置传感器实时监测螺丝是否到位,当螺丝不到位时发出信号给PLC。同时内置的压力传感器也实时地感应压力并通过模拟量模块进行AD转化,将其转化为数字量传送给PLC判断压力是否达到一定得值。

目 录

1. 引言…………………………………………………………………………1

1.1背景介绍……………………………………………2

1.2产品介绍……………………………………………2

1.3治具设计流程以及所需要的知识……………………………………………2

2. 系统方案设计……………………………………………………………9

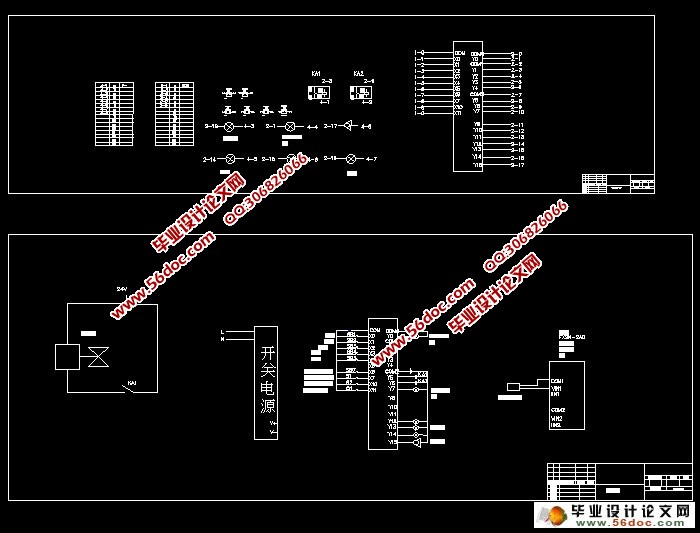

2.1控制原理设计…………………………………………………………9

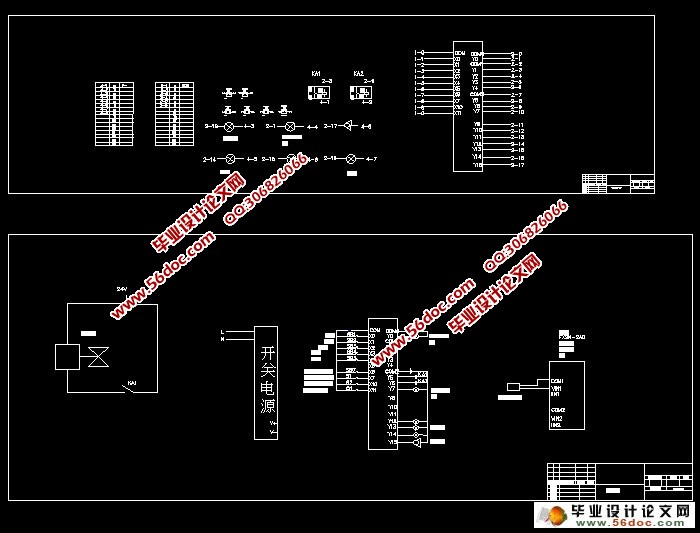

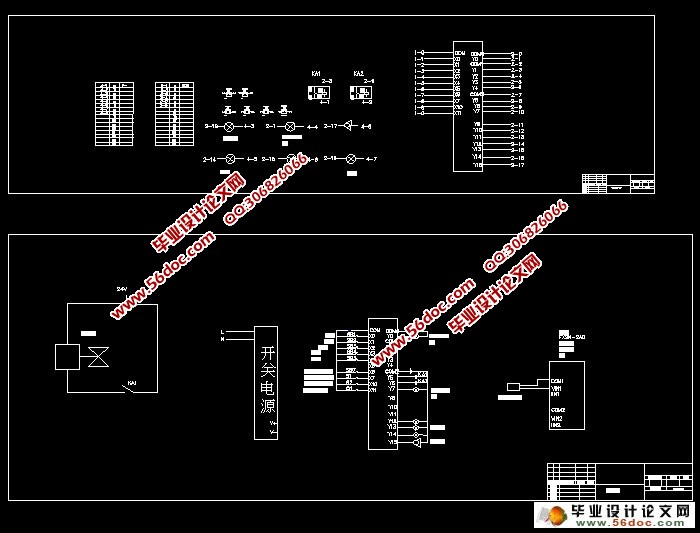

2.2 电路图原理设计…………………………………………………9

2.2.1 PLC cpu部分设计……………………………………………………10

2.2.2 PLC模拟量模块设计…………………………………………………12

3. 系统元件的选型……………………………………………………………9

2.1PLC cpu模块的选型…………………………………………………………9

2.2 模拟量模块的选型…………………………………………………9

4. 软件流程设计……………………………………………………………9

2.1程序流程设计…………………………………………………………9

2.2 主程序设计…………………………………………………9

参考文献

|