B80型熔融造粒机设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书12400字,CAD图10张)

摘 要

诞生于20世纪40年代的粉体技术是一门相当重要的学科。其涉及到地质、石油、化工、医药等多方面。粉体技术在生活中最直接发挥作用的方面是粉体制备技术和设备。粉体的制备方式又有粉碎、化学物理方法、粒化及磨损法制备粉体物料。其中粒化是当下较为热门的一个课题。

粒化,又可称为造粒,作为粉粒体过程处理中的一个重要分支,在化工、医药、国防等方面占有重要地位。由于粉体在加工过程中会产生大量粉尘,造成环境污染,而颗粒化不仅能有效减少污染,还能满足生产工艺需求,提高产品品质,因此粉体粒化成为一个非常重要的环节。随着科学技术的飞速发展,生活水平不断提高,所需要的颗粒越来越小,数量越来越大,造粒技术的地位日益提高的同时,对造粒设备的要求也越来越高。

粉体造粒技术从广义上可分为两大类,一类是成型加工法,另一类是粒径增大法,主要是把细粉末团聚成较粗的颗粒。如今常用的粒径增大造粒技术,根据实现颗粒团聚的基本原理,可以分为以下4种:搅拌法、压力成型法、喷雾和分散弥雾法、热熔融成型法。

4种方法均有典型设备,且广泛应用于各领域生产中。搅拌法设备因结构简单、单机产量大、所形成的颗粒易快速溶解、湿透性强,但颗粒均匀性不好等特点,广泛应用于化肥、食品等行业;压力成型法设备可制造较大的团块,所制成的物料也有相当的机械强度,但适用范围较小,因此应用于建筑和制药等行业。喷雾和分散弥雾法设备的优点在于物料的造粒过程和干燥过程同时进行。此类设备应用范围最为广泛,但是获得的产品强度较低,粒度较小。热熔融成型法设备不仅可以造粒,还能获得条状、片状产品,所以广泛应用于有机化工行业。

酚醛树脂,又称为电木,是一种常见的合成树脂。由于应用在人们生活中,随着经济发展,人口增长,如今对酚醛树脂的需求越来越大。酚醛树脂是典型的非晶体,因此没有固定的熔点,只有软化温度范围。根据查得资料可知,酚醛树脂软化温度在85到105℃之间,密度在1.0到1.7g/cm3之间,且熔融态具有良好的流动性。

熔融造粒利用熔融态物料间断滴落在平板上,因表面张力作用,冷却后能得到半球状

颗粒固体的特性实现造粒。根据这一原理,我们选择设计钢带式熔融造粒装置。

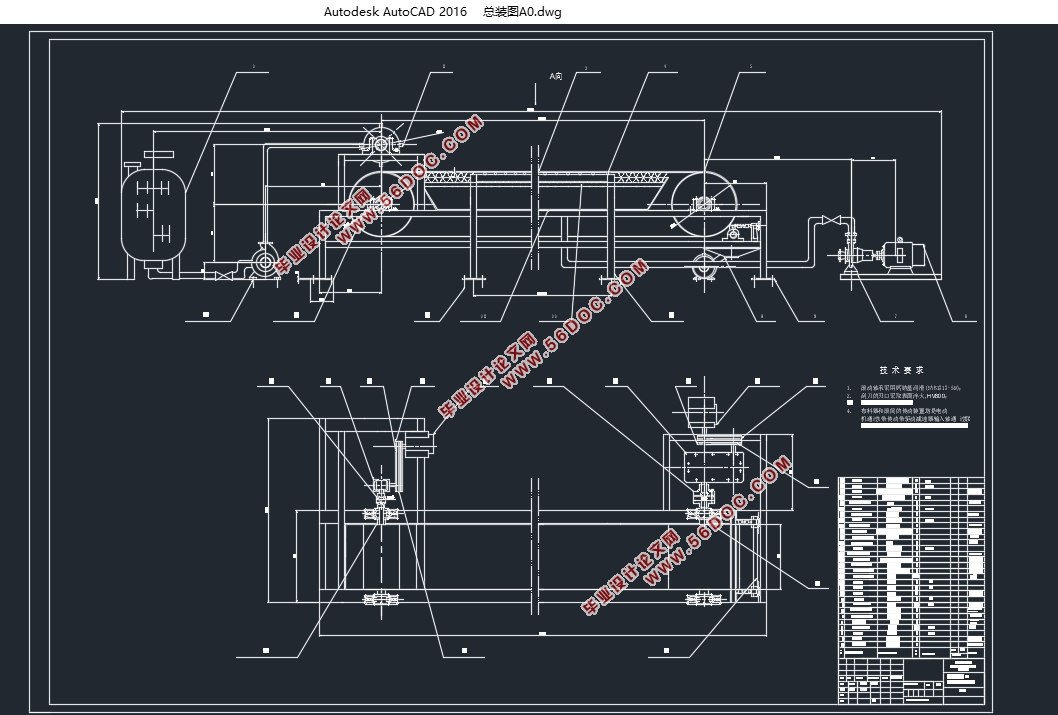

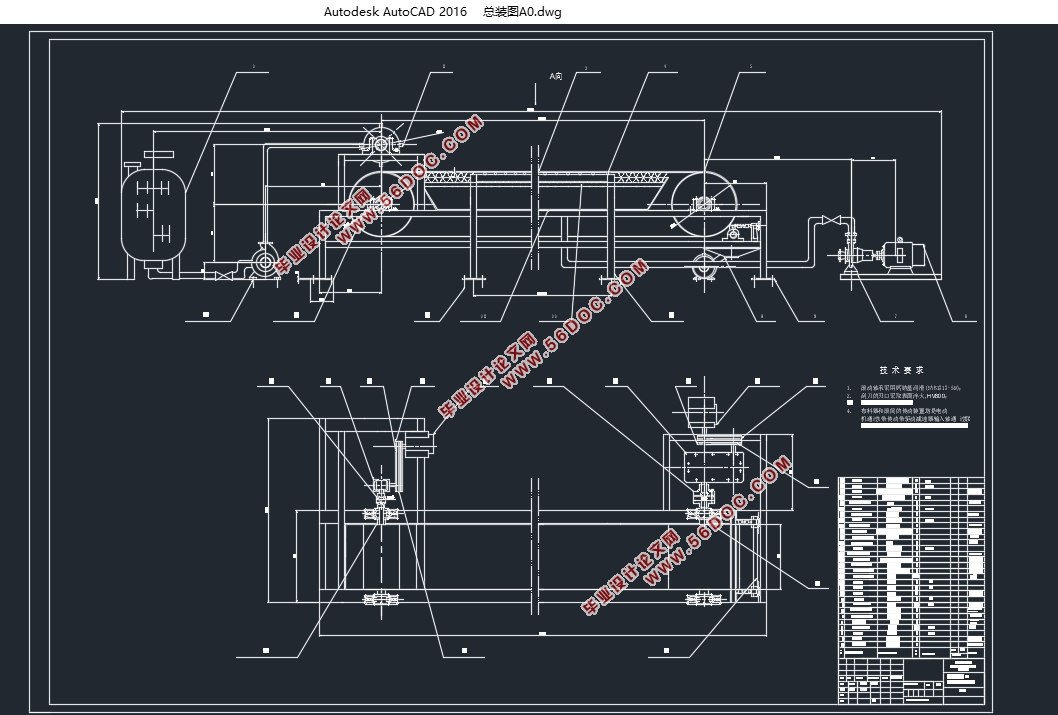

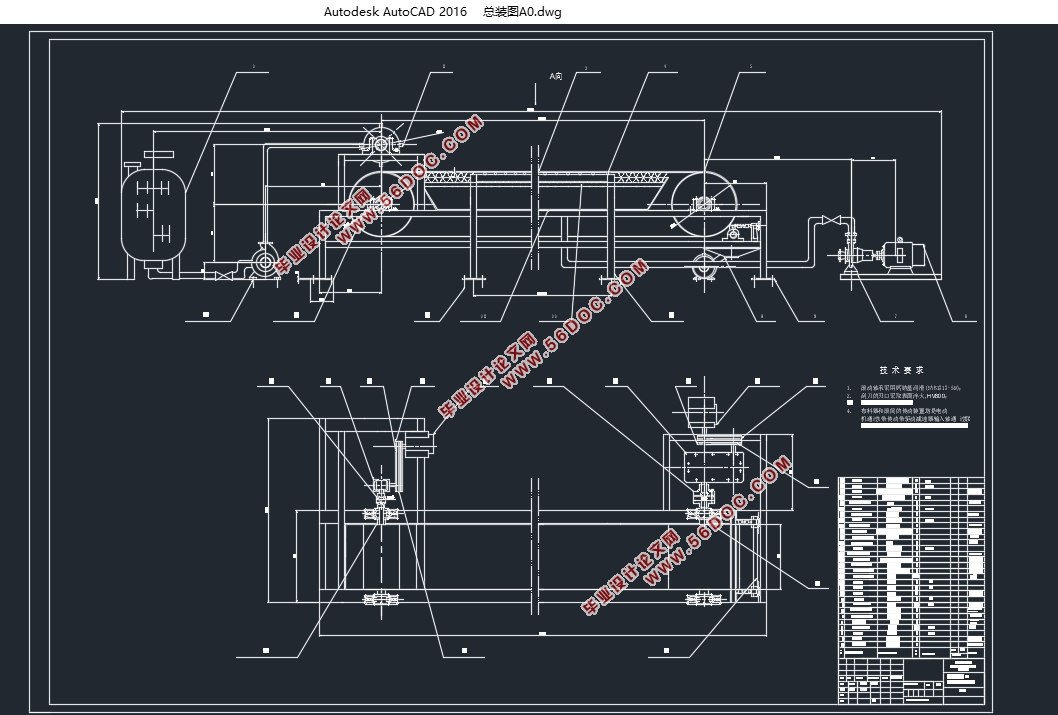

此设备主要部分有:1.布料器;2.钢带输送系统;3.喷淋冷却系统;4温度、速度控制系统。该设备工作方式为:将熔融态物料持续输送进恒温的布料器内,经由布料器滴落

在匀速运动的钢带上。钢带下方设有喷淋冷却装置,使薄钢带上的物料在移动输送过程中冷却固化。最终得到规则的半球状颗粒产品。根据不同的物料和成型方式,可以控制布料器得到条状、半球状和片状产品。

本设计的设备能直接与酚醛树脂生产线连接,实现连续、大产量的生产要求。产出的酚醛树脂颗粒能直接打包,运输。本设计还加入了温度、速度控制系统,实现了造粒过程的自动化,有效降低了成本。

但是此设备也存在一些缺陷,如在长时间生产过程中钢带易出现跑偏现象,需人工调整;获得的产品强度较低,易出现颗粒碎裂等需改进问题。

关键词:造粒机 钢带 熔融造粒 单片机 PLC

Design of B80 Steel-Band type Melting Granulator

Abstract

The powder technology that was born in the 1940s is a very important discipline. It relates to geological, petroleum, chemical, pharmaceutical and other aspects. The most direct role that Powder technology plays in our life is powder preparation technology and equipment. The methods of powder preparation contains crushed, chemical and physical methods, granulation and wear method to prepare powder materials. Granulation is now a more popular topic.

Granulation, also known as granulation, which is an important branch of the powder and granular process, has an important position in the chemical industry, medicine, national defense and other aspects. As the powder in the processing process will produce a lot of dust, causing environmental pollution, and granulation can not only effectively reduce pollution, but also to meet the production process needs, improve product quality, so powder granulation has become a very important part. With the rapid development of science and technology, living standards continue to improve, the need for particles smaller and smaller, the number of growing, increasing the status of granulation technology at the same time, the requirements of granulation equipment is also getting higher and higher.

Powder granulation technology can be broadly divided into two categories, one is the molding process, the other is the particle size increase method, mainly to the fine powder agglomerated into coarse particles. Now China's granulation technology has a considerable level. The size of its equipment has a greater development,too. Now the commonly used particle size increased granulation technology, according to the basic principles of particle agglomeration, can be divided into the following four: mixing method, pressure forming method, spray and dispersion mist method, hot melt molding method.

These four methods has typical equipments, and they are widely used in various areas of production. Stirring equipments due to simple structure, stand-alone production, the formation of particles easy to quickly dissolve, wet permeability, but the particles not uniform and etc, are widely used in the fertilizer, food and other industries. The pressure forming method can produce larger clumps, and the materials produced have considerable mechanical strength, but the scope of application is small, so it is used in construction and pharmaceutical industries. The advantages of the spray and dispersion equipments are that the granulation process of the material and the drying process are carried out simultaneously. The range of applications is the most widely available, but the resulting product is low in strength and smaller in size. Hot melt molding equipments can not only granulation, but also get strip, sheet products, it is widely used

in organic chemical industry.

Phenolic resin, also known as bakelite, is a common synthetic resin. As the application in people's lives, with the economic development, population growth, and now the demand for phenolic resin is growing. Phenolic resin is a typical amorphous, so there is no fixed melting point, only softening temperature range. According to the survey data, the phenolic resin softening temperature between 85 to 105 ℃, the density between 1.0 to 1.7g/cm3, and the molten state has good mobility. Melt granulation using molten material intermittently dripping on the plate, due to surface tension, after cooling can be hemispherical solid particles to achieve the characteristics of granulation. According to this principle, we chose to design steel strip melting granulation device.

The main parts of this equipment are: 1. distributor; 2. steel conveyor system; 3. spray cooling system; 4 temperature, speed control system. The device works as follows: The molten material is continuously conveyed into a constant temperature dispenser and drips through a cloth feeder on a uniformly moving strip. The lower part of the strip is equipped with a spray cooling device to cool and solidify the material on the steel strip during the moving conveyance process. And finally we get the regular hemispherical grain products. According to the different materials and molding methods, we can control the feeder to get strip, hemispherical and flake products. The equipment of this design can be directly connected with the phenolic resin production line to achieve continuous, large production requirements. The phenolic resin particles which is output can be directly packaged and transported. The temperature, speed control system is also joined in the design, to achieve the granulation process automation, effectively reducing the cost.

But this device also has some shortcomings, such as in the long process of production of steel strip prone to deviation phenomenon, to be manually adjusted; access to the product strength is low, prone to grain fragmentation and other issues to be improved.

Key Words: granulator; steel-band; melt granulation; singlechip; PLC

目 录

摘 要 I

ABSTRACT III

第一章 概 述 - 1 -

1.1 粉体技术 - 1 -

1.2 粉体设备 - 1 -

1.3 酚醛树脂介绍 - 2 -

1.4 B80型熔融造粒机介绍 - 4 -

1.5 B80型熔融造粒机经济评价 - 5 -

第二章 钢带式熔融造粒机的计算 - 7 -

2.1 物料泵的选取 - 7 -

2.2 物料罐尺寸选取 - 7 -

2.3 保温材料的选择 - 7 -

2.4 单位颗粒产品质量M - 7 -

2.5 颗粒冷却固化时间 - 8 -

2.5.1 预冷时间 : - 8 -

2.5.2 凝固时间 : - 8 -

2.5.3冷却时间 : - 8 -

2.6 钢带设计 - 8 -

2.6.1冷却钢带的有效宽度: - 9 -

2.6.2颗粒冷却固化时间t: - 9 -

2.6.3钢带冷却区长度L(m): - 9 -

2.7 滚筒轴的设计 - 10 -

2.7.1.主动滚筒轴的设计 - 10 -

2.7.2.从动滚筒轴的设计 - 13 -

2.8 滚筒的传动装置 - 13 -

2.8.1 电动机的选取 - 13 -

2.8.2 减速器的选取 - 13 -

2.8.3 带轮的选取 - 14 -

2.9 冷却水量 - 16 -

2.10 水泵的选取 - 17 -

2.11 布料器计算 - 18 -

2.11.1 转鼓的横截面积计算 - 18 -

2.11.2 布料器转速计算 - 18 -

2.11.3 布料器宽度计算 - 18 -

2.11.4 布料器内的物料重量 - 18 -

2.11.5布料器内传动装置 - 19 -

2.12 刮料装置 - 21 -

2.12.1受力分析: - 21 -

2.12.2刮刀设计 - 21 -

2.12.3刮刀架、支撑轴和压力调节器的设计 - 22 -

2.13 下料口的设计 - 23 -

2.14 控制系统的设计 - 23 -

2.14.1 温度控制系统的设计 - 23 -

2.14.2电机控制保护系统 - 26 -

结 束 语 - 30 -

参考文献 31

致 谢 33

|