前桥装配设备的设计(含CAD零件图装配图,CAXA图)(选题审核表,任务书,开题报告,外文翻译,周记,论文说明书11000字,CAD图9张,CAXA图4张)

摘 要

中国是全球人数人口基数很多的国家,其中流动性也很大得大,同时随着经济的发展和人们生活节奏的加快,为了出行更加便利汽车也成了现代人必不可少得一种快捷得工具。随着汽车行业的发展,汽车也随着时代而普遍出现,无论大型车小型车很多有有。其中的前桥是万分重要不能缺少的一个组成部分,步入二十一世纪以来,世界的汽车的产业发展迅速,百姓对于汽车方面的消费也呈上升趋势,呈现出了十分强劲的势头。与此之同时也促进了非标自动化的加工业的发展。而在多种工业设备过程中,需要很大的工作量,本次设计的项目是前桥装配设备的设计,第一步我们要分析本次设计背景,调查课题就于当前的研究现状的优点与缺陷所在,通过研究分析,能够正确运用机械设计制造系统以及其他所学课程的相关理论制造设计的知识,制定机械设计计划,通过比较分析学习必要的计算方法。掌握并了解设计的基本办法。通过设计,培养可行性强的设计思维、解析、处理问题的能力。确定一种最合理的传动系统方案以实现既定的功能要求。再结合相关理论知识,对自动化的历史、发展应用性方面和本设备综合概括。整个系统机构设计简单,结构精妙,性能稳定,实现多功能。确定研究方向和思路,之后基于工程原理,将对前桥装配设备的设计,采用非标自动化的设计原理,实现方便使用,最后再进行制图与建模:使用AutoCAD,Solidworks、Catia等来进行设计后的制图以及三维建模。

关键词:前桥 ;自动化 ;机械;发展

Abstract

China is a country that with a large population base in the whole world, and its mobility is also very large. At the same time, with the development of the economy and the acceleration of people's living rhythm, in order to travel more and more convenient,at now cars have become an indispensable and fast tool for the modern people. With the development of the automobile industry, the automobile also appears generally with the times, no matter how many large cars and small cars there are. The front axle is an indispensable part. In recent years,after 21th with the rapid development of automobile, we could now the consumption of automobile has increased dramatically, showing a strong momentum. At the same time, it is also promotes the development of non-standard automation processing industry. In the process of a variety of industrial equipment, a lot of work is required. The project of this design is the design of front axle assembly equipment..At the First, analyze the design background, understand the advantages and disadvantages of the current research status. Through research and analysis, correctly use the relevant theoretical knowledge of mechanical design system and other courses, formulate the mechanical design plan, and learn the necessary calculation methods through comparative analysis 。 Master the basic method of design. Through design, cultivate the ability of correct design thinking, analysis and problem solving. Determine the most reasonable transmission system scheme to achieve the established functional requirements. Combined with relevant theoretical knowledge, the history, development and application of automation and the equipment are summarized. The whole system is simple in design, exquisite in structure, stable in performance and multi-function. Determine the research direction and ideas, then based on the engineering principle, the design of the front axle assembly equipment will adopt the design principle of non-standard automation to realize the convenience of use, and finally carry out the drawing and modeling: use AutoCAD, Solidworks, CATIA, etc. to carry out the drawing and 3D modeling after the design

Keywords: Nonstandard automation; automation; machinery; development

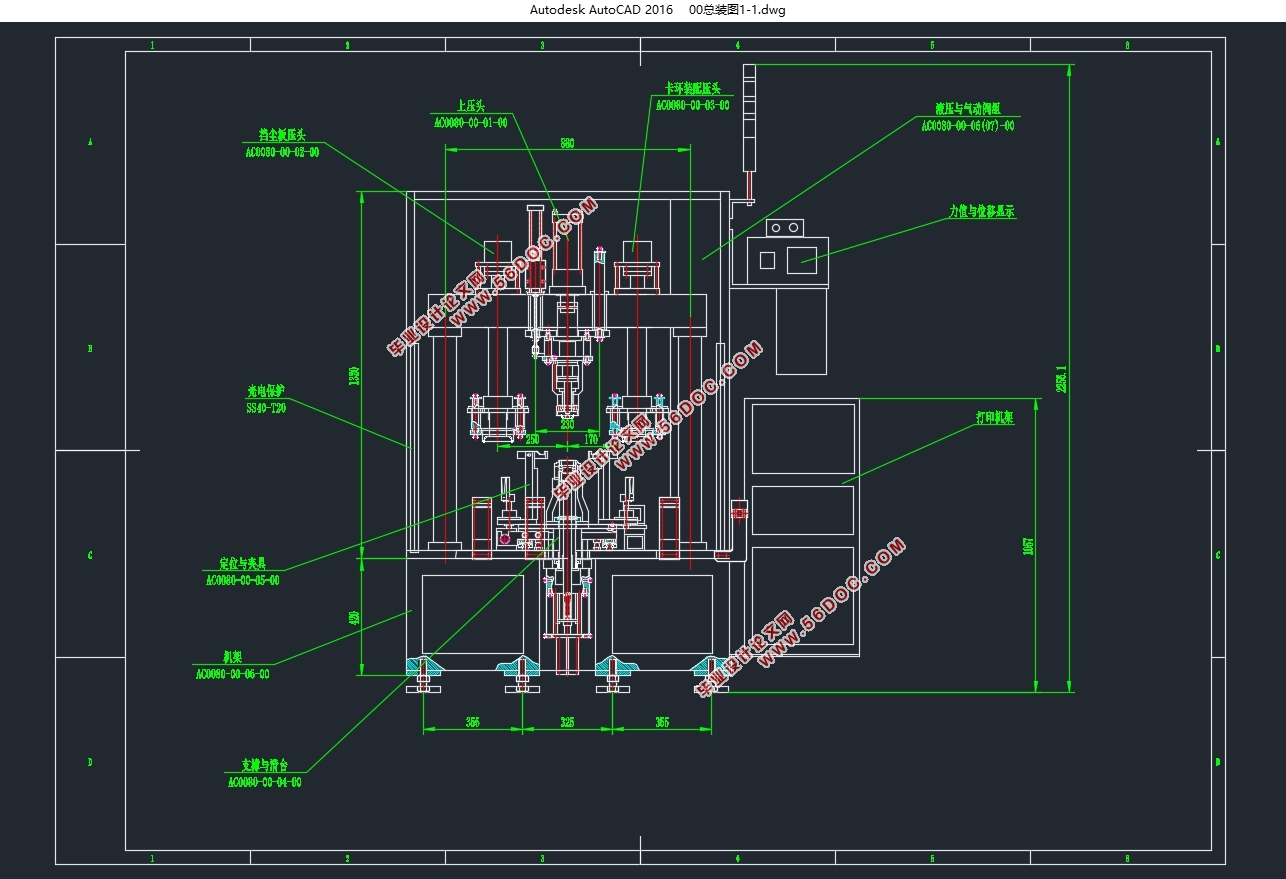

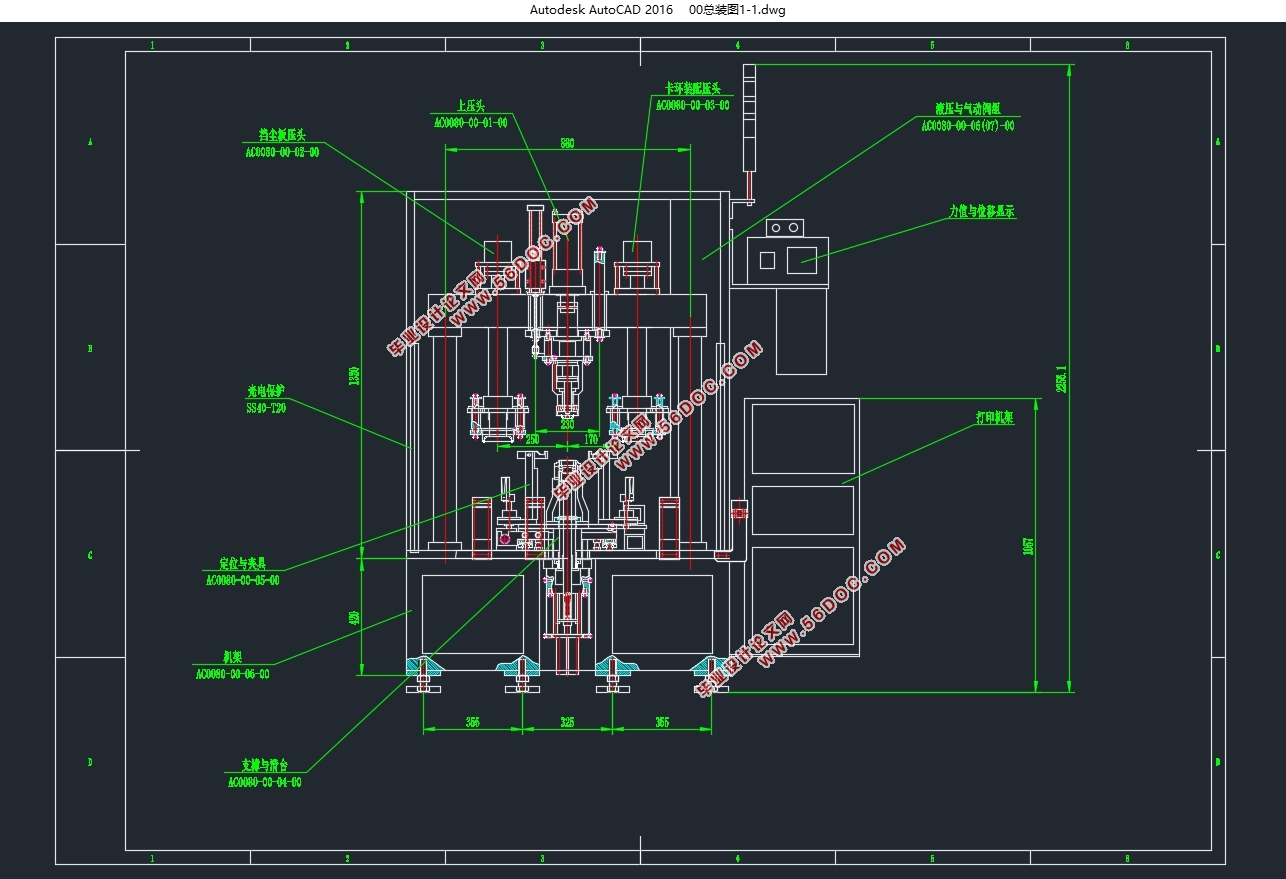

2.2.1前桥装配设备的设计要求

主销后倾角1.5°~3°左右,夹具定位精度≤0.01 mm ,车轮外倾角1°左右,压装机重复压装精度≤0.0lmm,垫片应装在前轴主销承孔上平面上,不要装在下面,保证操作工人的生命安全,主销楔形横销拧紧力矩一般为20N/m~40N/m(8)整个装配过程零件不允许被磁化。

目 录

1 绪论 1

1.1 国内外发展现状 1

1.1.1国外自动化的发展现状 1

1.1.2国内自动化的发展现状 1

1.2发展趋势和现实意义 1

1.3前桥装配自动化优点 2

1.4研究内容 3

2 前桥装配设备总体设计 5

2.1前桥装配设备内容 5

2.2前桥装配设备的设计 5

2.2.1前桥装配设备的设计要求 6

2.2.2前桥装配设备的设计路线 6

2.3综合设备零件设计原则 7

3 主要零部件的设计 8

3.1电机的选型 8

3.2轴的选择 9

3.3计算轴的最小直径 9

3.4轴的结构尺寸确定 10

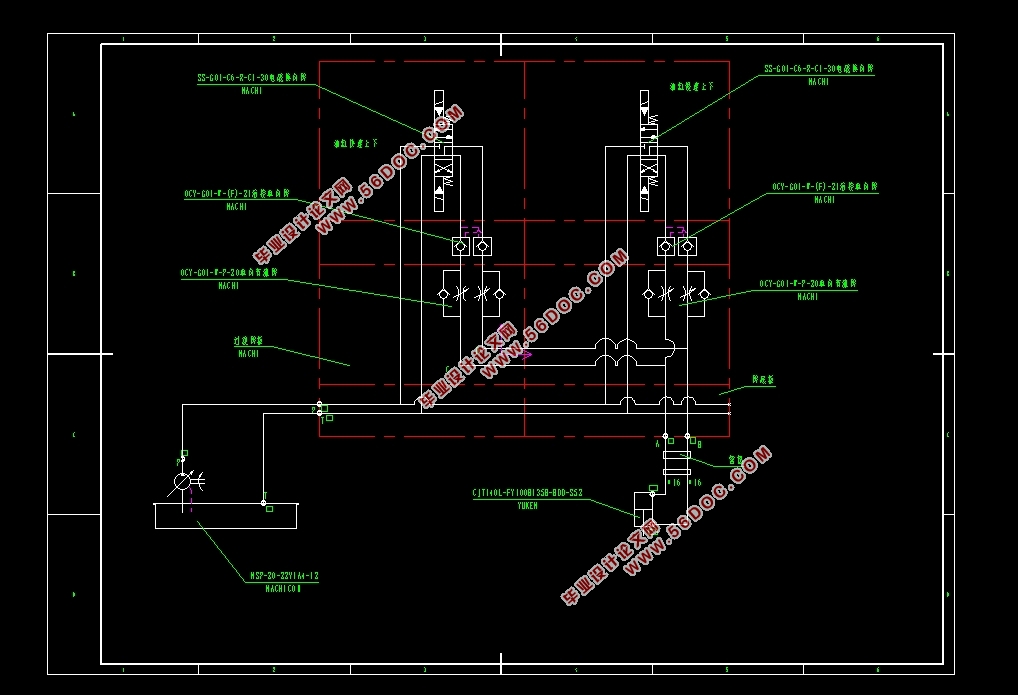

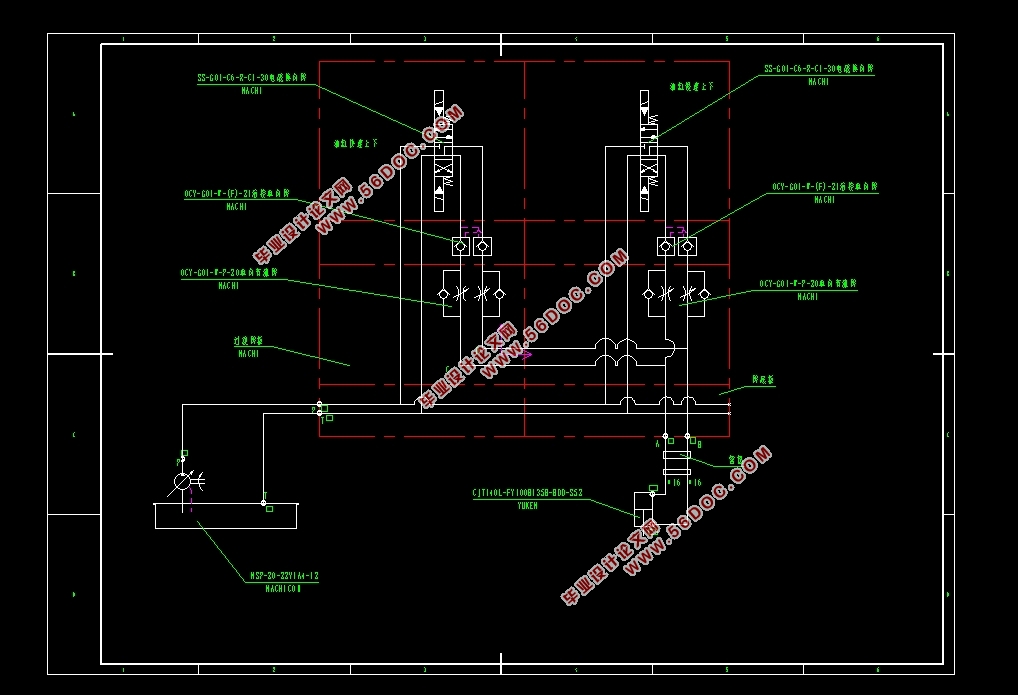

3.5气动系统部分 12

3.6气缸选型 13

3.6.1气缸的理论输出力 13

3.6.2气缸的负载率 15

3.7导轨部分 16

3.8压装力及其性能 17

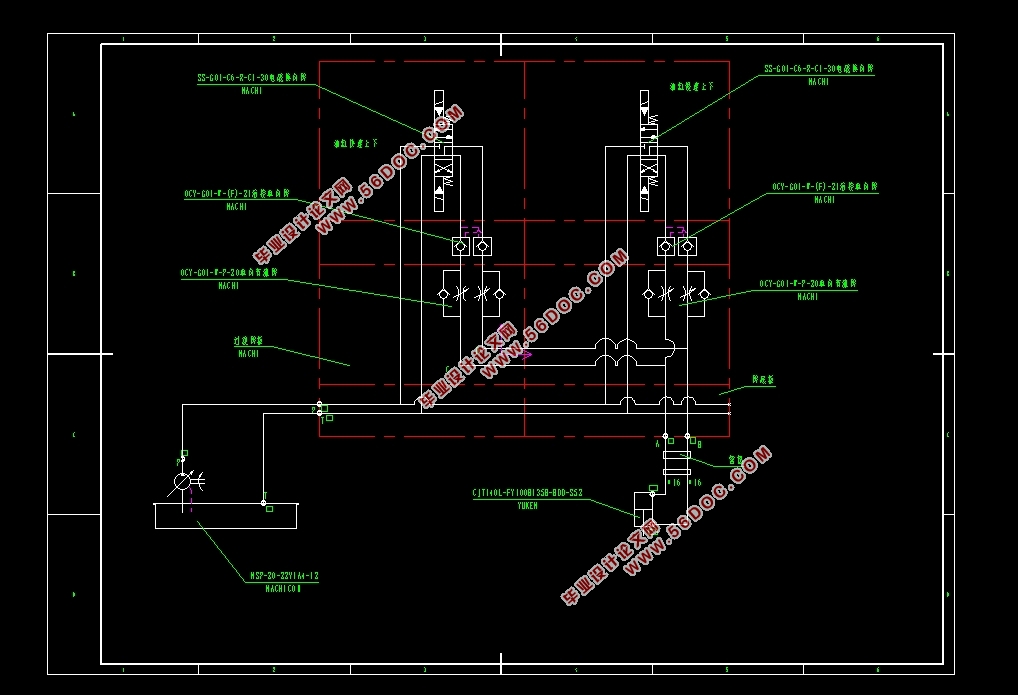

3.8.1液压缸的结构 18

3.8.2带动工作台的液压缸的计算 18

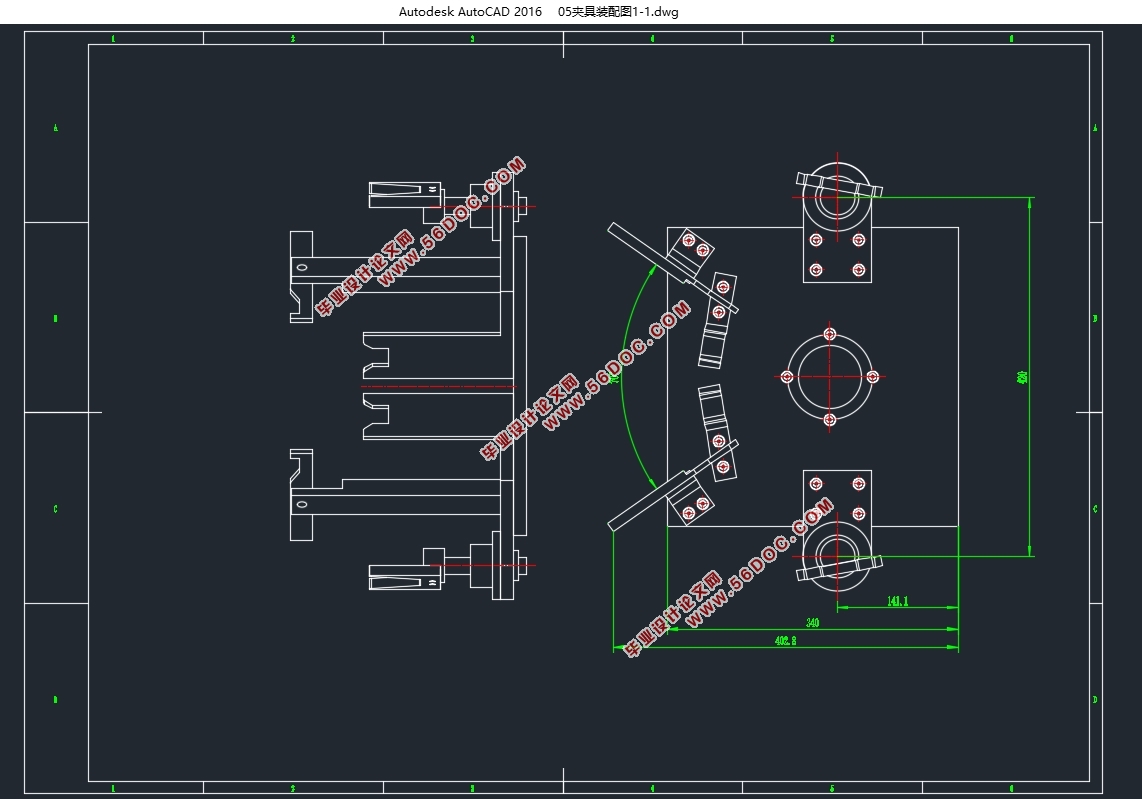

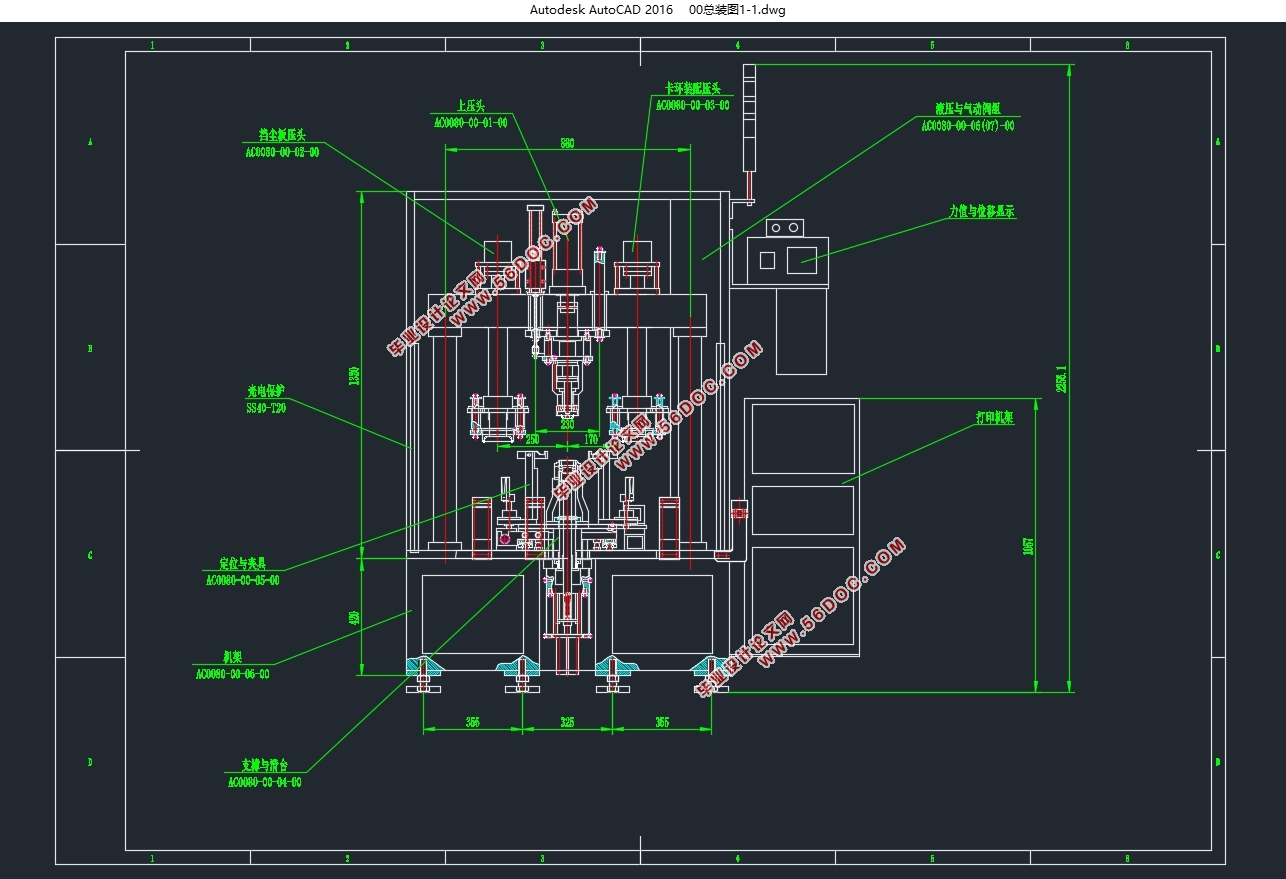

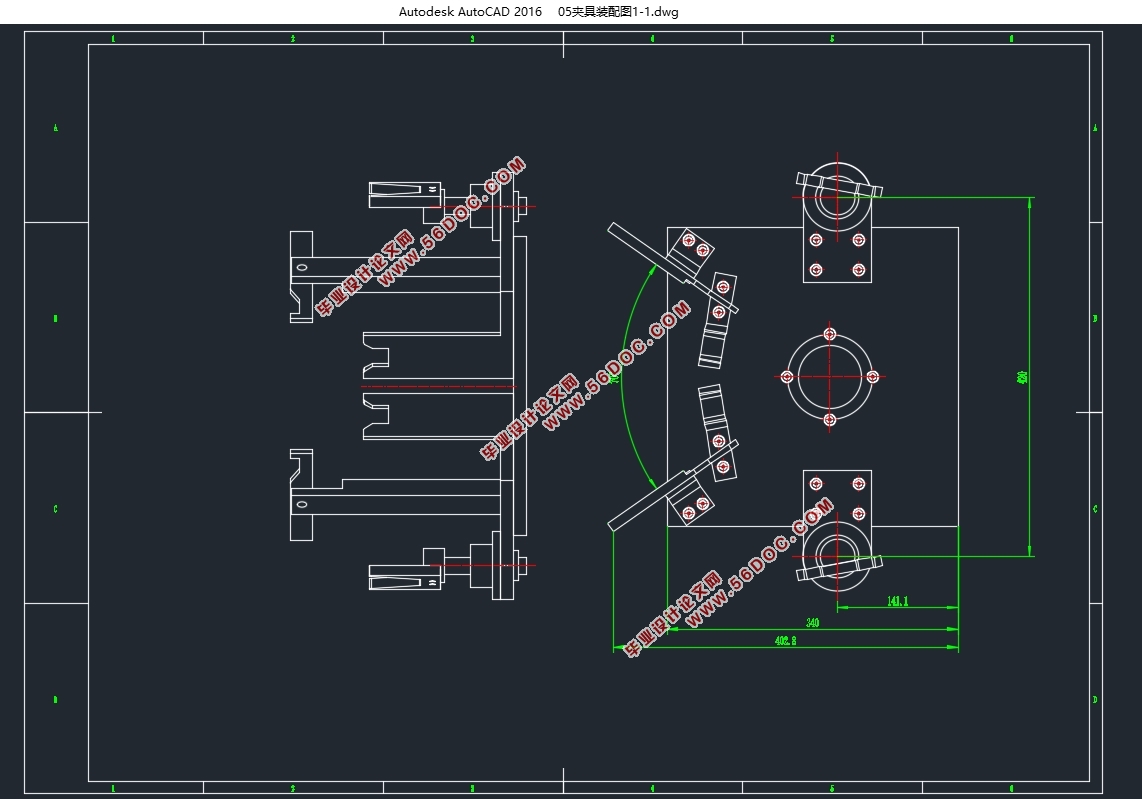

4前桥装配设备部件的示意图 21

4.1前桥装配设计整体视图 21

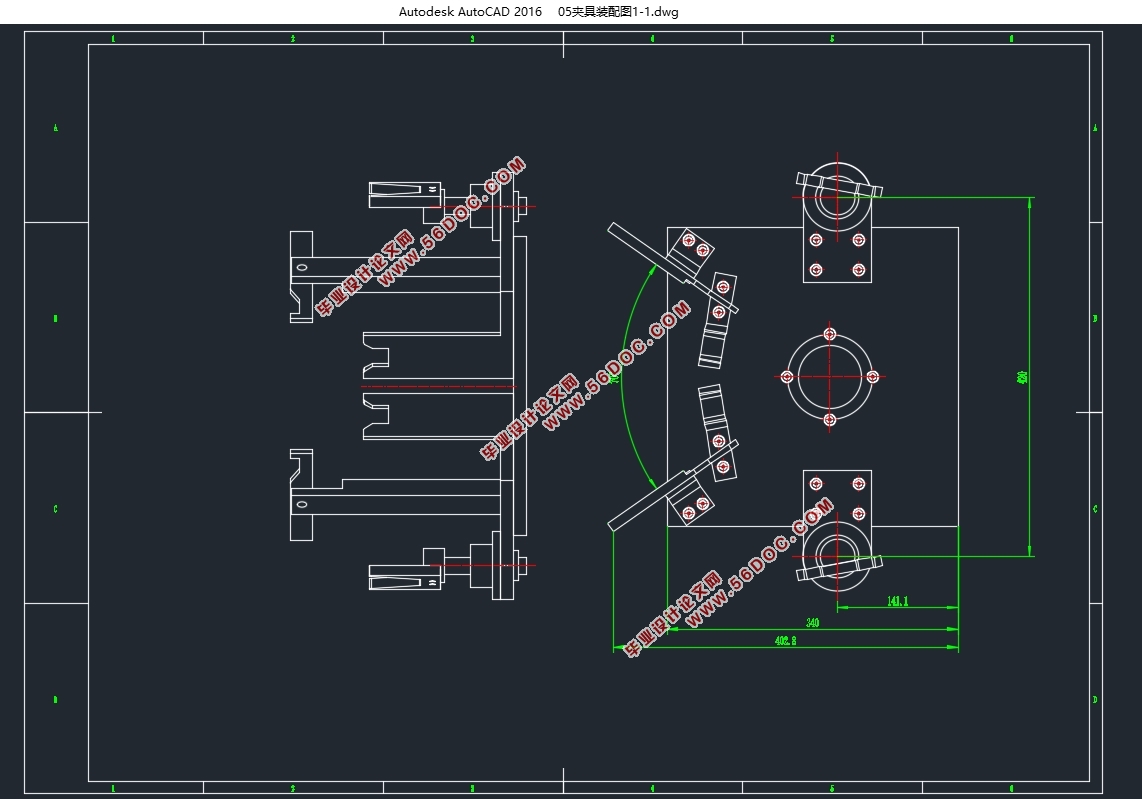

4.2压装组件 22

4.3设备压装过程 24

5 结论 28

参考文献 30

致 谢 31

|