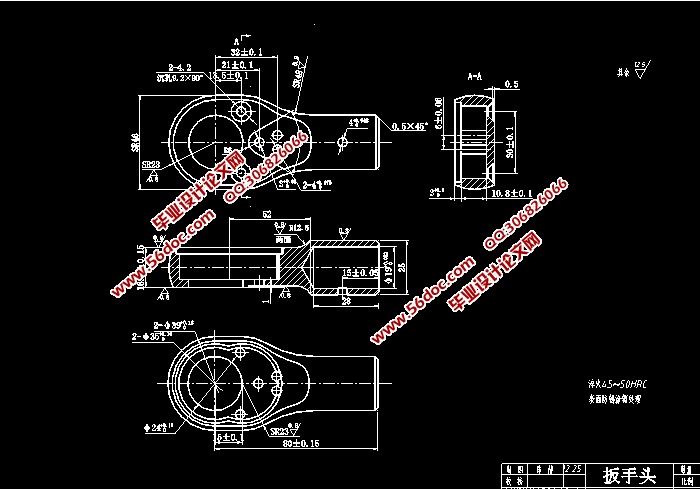

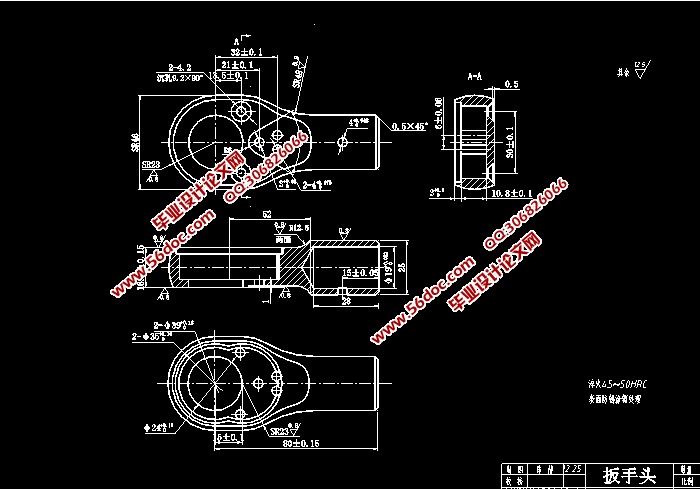

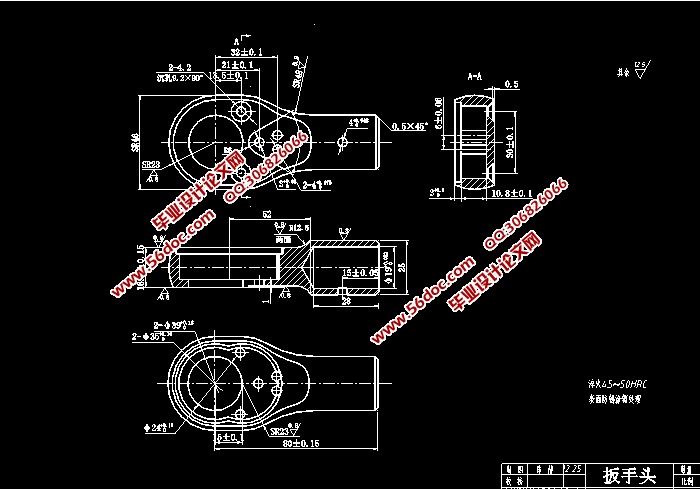

扳手头工艺规程设计及加工实现(含CAD零件图)(外文翻译,论文说明书12000字,CAD图1张)

摘要:扳手头是一种广泛使用的工具零部件,结构虽然简单,但在人们日常生活中有着十分重要的作用。伴随中华人民共和国制造业的飞速成长,机械制造加工行业必然和国际一流水平接轨,目前中国的机械制造水平已经接近日本、美国等发达国家水平。这就对对于扳手头的质量、可靠性等提出了更高的要求。且数控制造作为机床加工企业之中最为关键的的一部分,也必会迈进一个新的纪元。

论文采用对已获取的资料和信息进行分析研究的方法,通过阅读相关文献和书籍,了解相关问题的理论基础的手段,得出了本次的毕业设计的结果。首先需要对扳手头进行分析,以及切削用量的选择,工件的定位装夹,加工顺序,结合数控加工的特点,分别进行工艺方案分析,机床的选择,刀具加工路线的确定,数控程序的编制,最终形成可加工流程。此设计说阐述了机械加工工艺设计步骤以及的CNC编程的过程,分析了非自动编程的方法。在这种情况下,通过对零件进行的工艺设计流程和数控加工编程进行了综合探讨,最后的结果通过仿真验证,建立了零件的数控加工代码,得出了本零件最终效果。按照毕业设计的相关要求,完成了本次毕业设计,掌握了零件设计的工艺规程及数控编程技术基本知识。

关键词:扳手头;工艺规程设计;机床加工;数控技术

Design of wrench head machining process planning and realization

Abstract: The wrench head is a widely used tool component. Although the structure is simple, it has a very important role in people's daily life. With the rapid growth of the manufacturing industry in the People's Republic of China, the machinery manufacturing and processing industry must be in line with the world-class level. At present, China's machinery manufacturing level is close to the level of developed countries such as Japan and the United States. This imposes higher requirements on the quality and reliability of the wrench head. CNC manufacturing, as the most crucial part of the machine tool processing industry, will also enter a new era.

The paper adopts the method of analyzing and researching the acquired data and information, and obtains this graduation design by reading relevant documents and books and understanding the theoretical basis of related issues. Firstly, the head of the wrench needs to be analyzed, the choice of cutting amount, the positioning and clamping of the workpiece, the processing sequence, and the characteristics of the numerical control processing are used to analyze the process plan, the selection of the machine tool, the determination of the tool processing route, and the programming of the NC program. The final process can be formed. This design statement elaborated the machining process design steps and the CNC programming process, and analyzed the non-automatic programming methods. In this case, the process design process of the part and the numerical control machining programming were comprehensively discussed. The final result was verified by simulation, and the numerical control machining code of the part was established, and the final effect of the part was obtained. In accordance with the relevant requirements of the graduation project, completed this graduation project, mastered the process specification part design and NC programming basics.

Keywords: wrench head; process design; machining; numerical control

扳手头零件图工艺分析

扳手头零件的结构外形表面粗糙度度要求是Ra1.6,因而本部分应分粗精加工二个期间,以确保其尺寸准确性和表面粗糙度要求。由于制件平面尺寸均有公差精度要求,故而制造时划分粗、精加工二个期间进行,以确保其尺寸准确性和表面粗糙度。

因此,本部分主要应分为粗加工两个阶段,两个阶段是不同的阶段,是相当独立的,互不影响,以确保其尺寸精度和表面光洁度的要求。由于工件平面尺寸的公差要求都要求都非常高,一次性加工是无法满足要求的,所以制造部门要进行粗加工,精加工两个,以保证其尺寸精度和表面光洁度。

1)工艺内容:这制件大体是圆柱面、组合孔系,毛坯部件是采用钢锭。

2)工艺的要求;这制件的正面大体是平面,柱形凸体,普通孔构成,该制件的反面无工艺的要求。其零件工程图图形标注完整、正确、满足数控工艺的要求,制造地方十分清楚。分析图纸,可以知条形表面轮廓长和宽皆无公差精度要求,故而制造制件的六个端面时只需适当进行粗加工。

目 录

摘要 I

ABSTRACT II

1 绪论 1

1.1 设计概要 1

1.2 设计背景及发展方向 1

2 数控制造工艺流程 2

3扳手头零件零件设计与分析 5

3.1 扳手头零件图工艺分析 5

3.2 扳手头零件的造型设计 6

4 工艺设计 8

4.1 毛坯部件选择 8

4.2 定位特征的正确选择 9

4.2.1 粗基准的正确选择 9

4.2.2 精基准选用的准则 9

4.3 加工工具的正确选择 9

4.4 工装选择 10

4.5 切削机床的采用 10

4.6 工艺路线的制定 11

4.7 工艺流程图绘制 11

4.8 机加参数与时间的求算 12

5 扳手头零件数控编程设计 18

5.1 NC编程简介及扳手头零件编码方式选择 18

5.2 基于SIEMENS UG的NC编程 18

5.2.1粗铣扳手头轮廓面及上下端面 19

5.2.2精铣扳手头轮廓面及上下端面 21

5.2.3清角铣扳手头轮廓面及上下端面 23

5.3 后处理程序 24

结论 25

参考文献 26

致谢 27

附录A 工艺卡片 28

附录B 英文文献 29

附录C 中文翻译 34

|