基于单片机的汽车数字油量表设计(附程序代码)(论文10000字,程序代码)

摘要:本文章介绍了一种以MSP430单片机为核心的汽车数字油量表的设计。汽车邮箱中油量液位信息由液压传感器(投入式液位变送器)采集并转成电信号,经由信号处理电路处理滤波,排除干扰。然后通过MSP430芯片内部集成的ADC将模拟量转换为数字量。接着单片机根据存储器中的校准数据,计算出测得的液体深度,进一步可获取油箱内剩余油量的信息并由LCD1602液晶显示屏实时显示剩余油量值。相较于传统的指针式汽车油量表精度低,显示不直观,外观单调等缺点,本设计以MSP430单片机为核心,液压传感器采集数据,LCD1602显示数据,具有高精度,显示直观,模块简单易于外观封装美化,性能稳定可靠等特点,迎合现代市场需求,具有良好的市场前景。

关键词:数字油量表 液压传感器 MSP430 LCD1602液晶显示

Design of automobile digital oil meter based on single chip microcomputer

Abstract: In this paper, an automobile digital oil meter based on MSP430 MCU is designed.The information of the oil level in the autommobile mailbox is acquired by the hydraulic sensor (liquid level transmitter of input type ) and turned into electrical signals, Signal processing and removing interference by signal processing circuit.And then through the MSP430 MCU internal integrated A/D converter to convert analog signal to digital quantity.Then the MCU calculates the depth of the oil according to the data stored in external memory calibration, further obtains the information of tank residual oil amount and LCD1602 will display real-timely the value of remaining oil.The traditional pointer type vehicle oil scale has much shortcomings like the precision is low, the display is not intuitive, the appearance is monotonous and so on,compared with it,the design based on MSP430 MCU as the core, the hydraulic sensor collects data, LCD1602 displays data small size,with high precision, intuitive display, module is simple so that easy to encapsulate and beauty appearance, performance is stable and reliable, catering to the needs of the modern market, having a good market prospects.

Keywords: Digital oil meter Hydraulic sensor MSP430 MCU LCD1602

目 录

1.引言 1

1.1汽车油量表的概况及发展趋势 1

1.1.1 发展背景 1

1.1.2 发展历程 1

1.1.3 发展趋势 2

1.2本课题的研究意义 2

1.3对本课题的要求 3

2.方案论证及设计 3

2.1整体模块设计 3

2.2压力传感器的选择与论证 3

2.3系统主控芯片的选择与论证 4

2.4显示模块的选择与论证 5

3.系统的硬件电路设计与原理 5

3.1系统整体结构设计 5

3.2液压传感器模块 6

3.2.1产品概述 6

3.2.2主要工作参数 6

3.2.3供电电路及电路连接 7

3.3 信号处理电路模块 7

3.4 主控芯片MSP430模块 8

3.4.1 MSP430特性简介 8

3.4.2 MSP430的部分引脚简介 8

3.4.3供电电路 9

3.4.4 A/D转换器 10

3.5 显示模块 10

3.5.1 LCD1602主要技术参数 10

3.5.2 LCD1602连接 10

3.5.3 LCD1602工作原理 11

4.系统的软件设计 12

4.1 软件系统流程 12

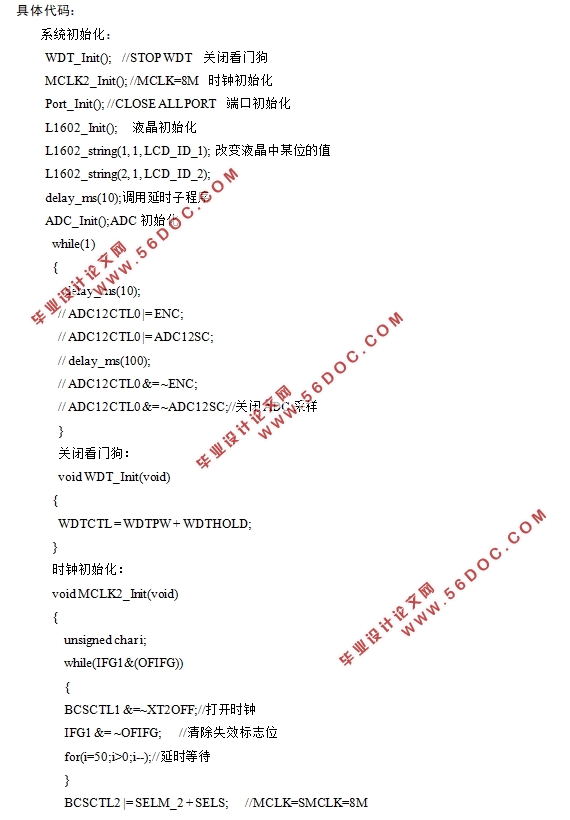

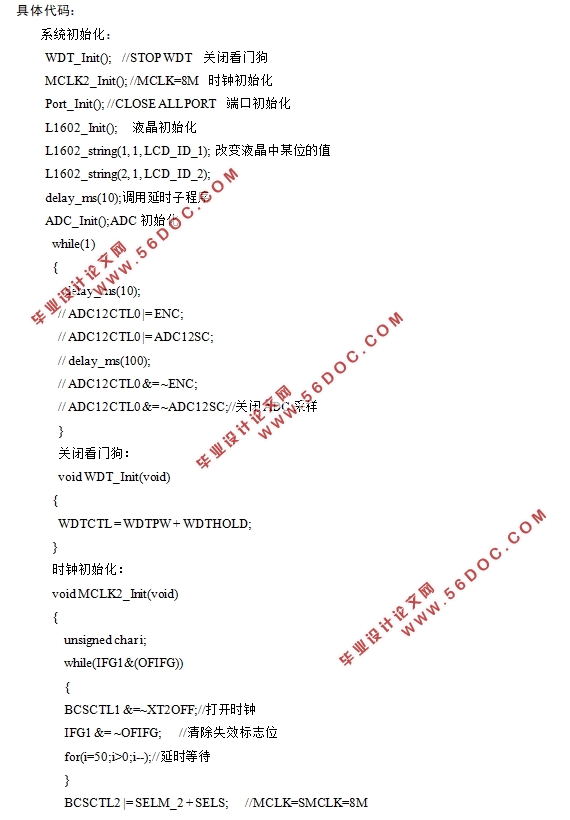

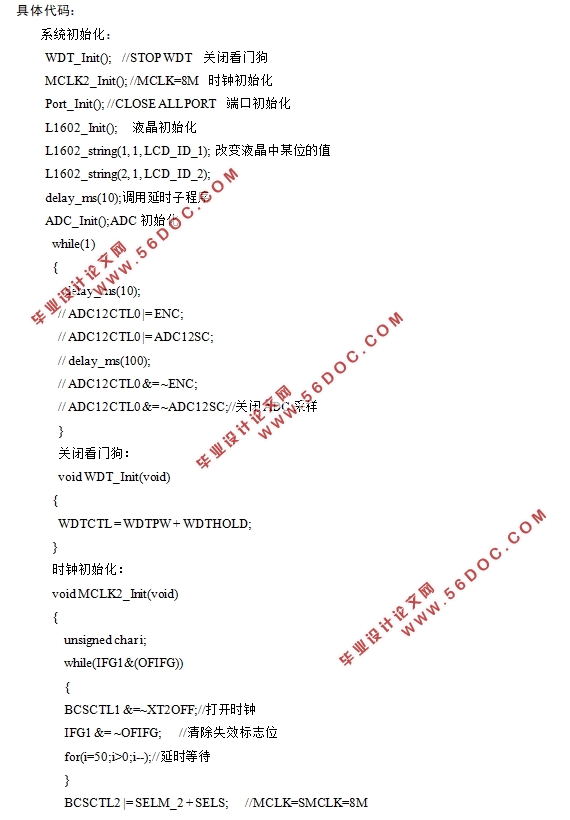

4.2 软件系统代码设计 13

4.2.1 ADC的初始化 13

4.2.2软件滤波 13

5.系统测试 14

6.结论 15

参考文献 15

致谢 17

附录 18

|