基于单片机和LabVIEW的四探针法测薄膜电阻设计

来源:wenku7.com 资料编号:WK717169 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK717169

以下是资料介绍,如需要完整的请充值下载。

1.无需注册登录,支付后按照提示操作即可获取该资料.

2.资料以网页介绍的为准,下载后不会有水印.资料仅供学习参考之用. 密 保 惠 帮助

资料介绍

基于单片机和LabVIEW的四探针法测薄膜电阻设计(论文12000字)

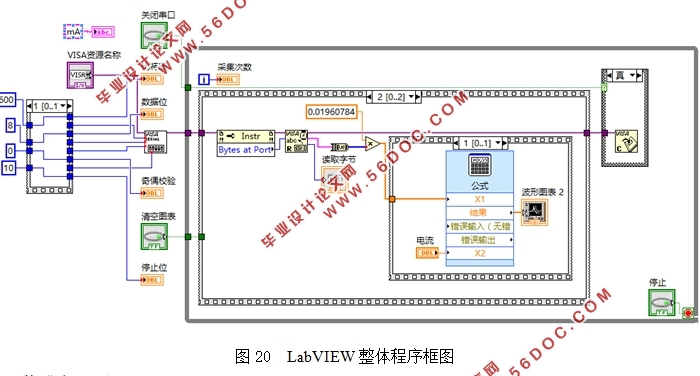

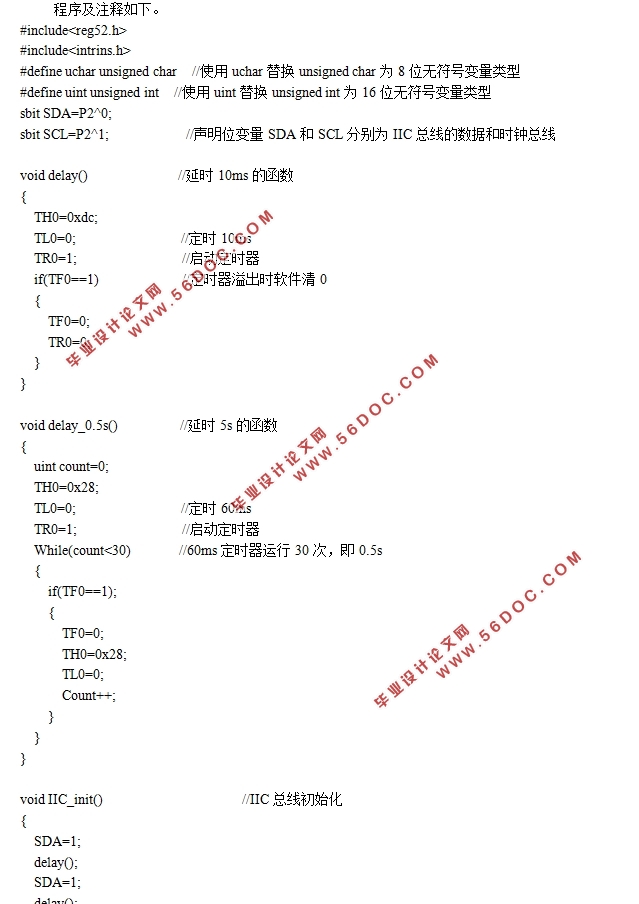

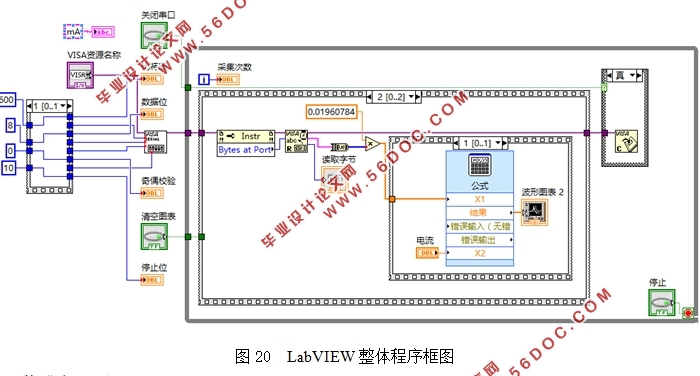

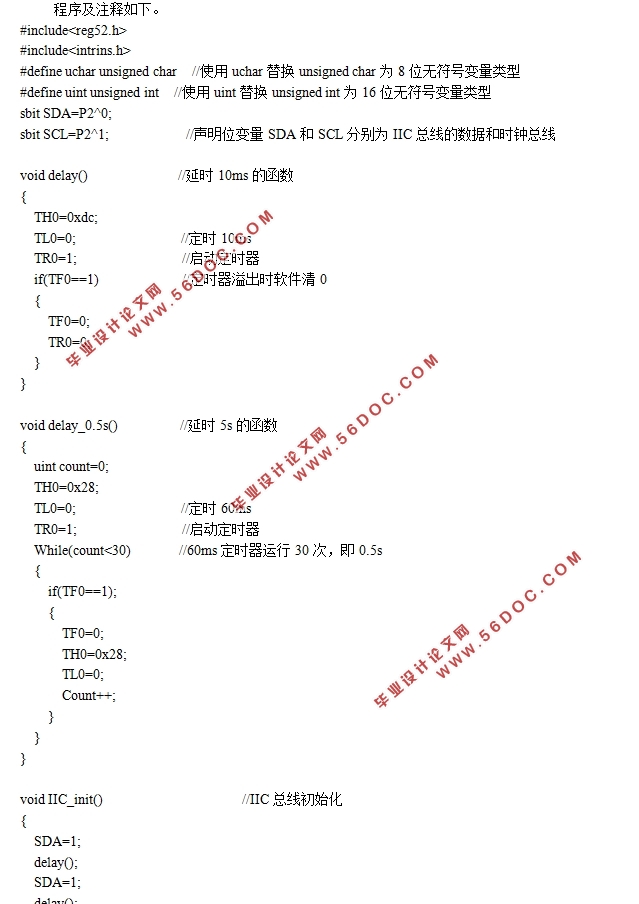

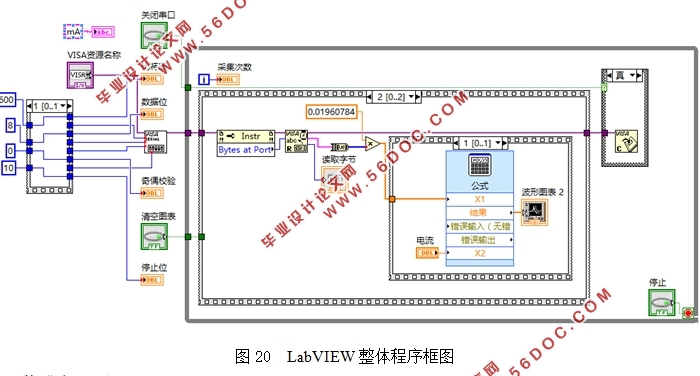

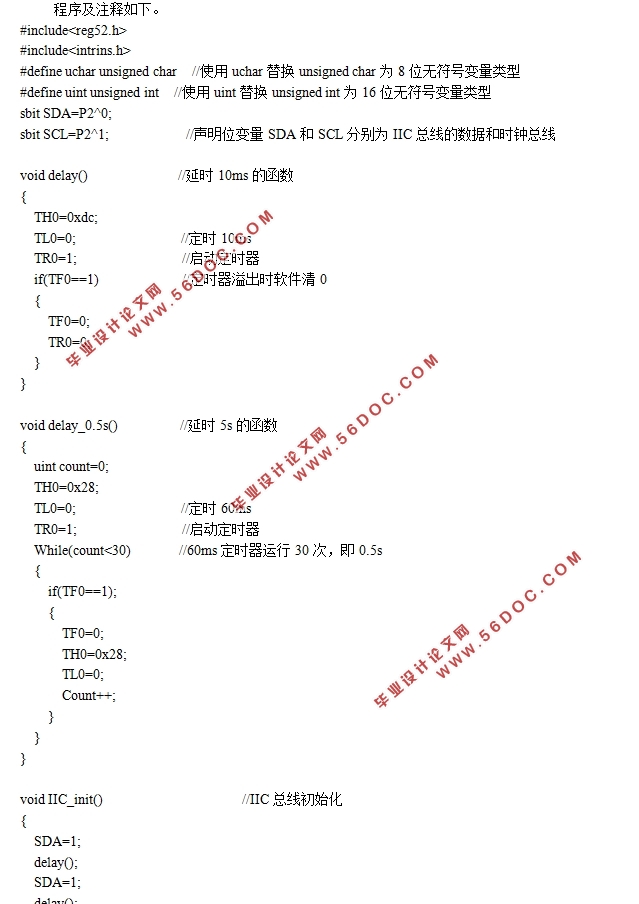

摘要:本文主要讲述利用LabVIEW和单片机组成一个数据采集系统来测量薄膜的电阻的过程。作为薄膜的一个重要的电学性能,薄膜电阻往往通过方块电阻来表征。本次测量方块电阻的方法是四探针法,数据采集端为集成了AT89C52作为主控芯片和PCF8591芯片作为A/D转换器的单片机,上位机部分主要是LabVIEW软件。系统工作时,首先是单片机采集两个探针间的电压量并将其传输到上位机(PC)中,然后通过LabVIEW对数据进行接收和处理后输出到显示终端。

关键词: 单片机;LabVIEW ;薄膜电阻; 四探针法; 数据采集

Measurement of Film Resistance by Four-probe Method Based on Microcontroller and LabVIEW

Abstract: This thesis mainly introduces the progress of building a system based on Microcontroller and LabVIEW to measure the resistance of the film. As one of the important electrical properties of the film, the film resistance is often represented by sheet resistance. We use four-probe method to measure the film sheet resistance in this experiment. In the system, the data-acquisition terminal is integrated with an AT89C52 as the main control chip and a PCF8951 as the A/D converter. LabVIEW is the main part of the host computer. When the system works, the voltage between the two probes is collected and transmitted to the host computer (PC), and then the data are received and processed by the LabVIEW and displayed to the screen.

Key words: Microcontroller; LabVIEW; film resistance; four-probe method; data acquisition

目 录

1. 前言…………………………………………………………………………………………1

1.1 虚拟仪器………………………………………………………………………………1

1.2 单片机…………………………………………………………………………………1

1.3系统硬件及工作流程……………………………………………………………………1

1.4 LabVIEW和串口通信……………………………………………………………………7

1.5 四探针法和薄膜电阻……………………………………………………………………8

2. 实验部分…………………………………………………………………………………10

2.1 编写程序………………………………………………………………………………10

2.2 烧录程序………………………………………………………………………………10

2.3 LabVIEW编程…………………………………………………………………………11

2.4 薄膜电阻测量…………………………………………………………………………15

3. 结果与讨论……………………………………………………………………………15

3.1 程序及串口调试………………………………………………………………………15

3.2 实验测量结果…………………………………………………………………………15

3.3 结果处理及分析………………………………………………………………………18

4、总结与展望………………………………………………………………………………18

附录……………………………………………………………………………………………19

参考文献………………………………………………………………………………………23

致谢……………………………………………………………………………………………25

|