基于单片机的粮仓温度监测系统设计(程序代码)(任务书,开题报告,外文翻译,论文13000字,程序代码)

摘要

俗语说:民以食为天。粮食问题在人类生产生活中的位置是显而易见的,粮食问题与人类生产生活有着紧密的联系。而我国作为一个人口大国,如何为全体国民提供充足的粮食供应,提高粮食存贮技术,避免粮食在存贮过程中的霉败变质,是一直以来我们所面对的问题。在这些问题当中,最要解决的就是在粮食存储过程中的粮仓温度监控工程,保证粮仓内温度一直处于适宜粮食存储的温度,从而保证粮食质量不发生改变。在我国,稻米和小麦一直是主要作物。这些粮食在粮仓中长时间堆放,由于种子本身的呼吸作用所释放的热量和水分,在粮仓的密闭条件下不易及时疏放出去,长期积聚,造成粮食内部温度升高,湿度加大,从而引起种子霉变,发芽,导致粮食不能使用而产生浪费。 自古以来,各个朝代都非常重视粮食的存储问题,而我国长期以来缺乏先进的技术支持,导致我国粮食在贮存过程中大量损坏变质。自从建国以来,党和政府高度重视粮食问题,鼓励了一批又一批的科学人才在粮食存贮的问题上取得技术性的突破,为解决我国粮食问题贡献了巨大的力量。

作者主要的研究工作如下:

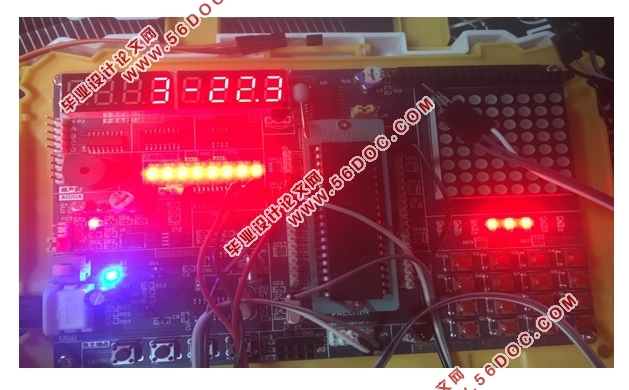

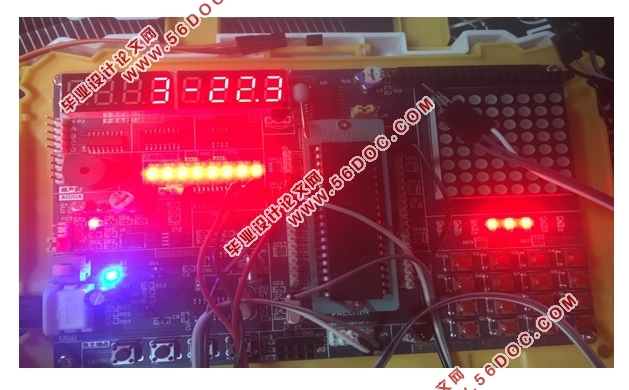

1.构思本次设计的大体思路。本次设计采用的是STC89C52型单片机作为整个系统的控制单元,八位七段数码管构成的显示模块以及蜂鸣器和LED组成的报警模块,通过外扩的四个温度传感器作为温度数据采集模块。通过单片机控制IO口读入温度数据进行数据处理,然后送到显示模块进行显示,并通过判断决定报警模块是否工作。

2.搭建系统仿真电路。在确定好基本方案之后,利用单片机仿真软件proteus进行硬件电路的设计。 利用单片机的P0口作为数据显示端口,P2.3,P2.4,P2.5三个端口配合3-8译码器作为位选端口。同时利用P3.7,P1.4,P1.5,P1.6四个端口连接四个DS18B20传感器,P1.5连接蜂鸣器,P2.0连接LED。

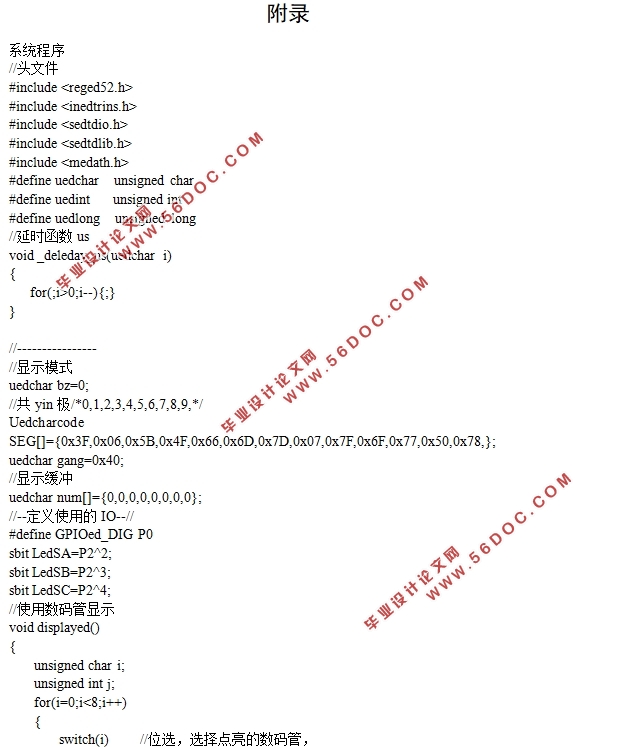

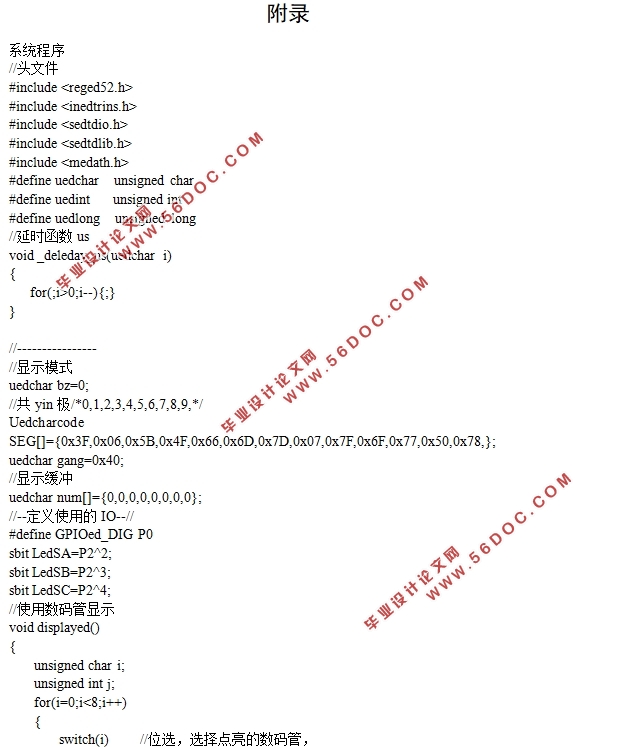

3.设计系统软件。根据芯片技术手册查阅关于DS18B20的相关工作时序,通过读写操作相应的进行拉低或者拉高电平,并及时检测总线上的电平对其进行初始化。通过定义变量将读到的温度数据赋值给P0,定义三个变量分别对应P2.3,P2.4,P2.5作为位选端口,P1.4,P1.5,P1.6,P3.7四个端口作为温度传感器的连接端口,根据参考相关程序,完成软件编写。

关键词:STC89C52 ;DS18B20;温度监测;循环显示 ;报警

Abstract

As the saying goes: Hunger breeds discontentment. The food problem occupies an irreplaceable position in human life, andthe food problem is closely related to human life. How can China provide a sufficient food supply for all citizens, improve food storage technology, and avoid the deterioration of food in the storage process, which is the problem we have always faced. Among these problems, the most important solution is in the grain storage process of the granary temperature monitoring project to ensure that the temperature inside the granary has been in the appropriate food storage temperature, so as to ensure that food quality does not change. In China, rice and wheat have been the main crop. These grains in the granary for a long time piling up, due to the respiration of the seeds of the release of heat and moisture, in the barn under the confined conditions are not easy to drain out, long-term accumulation, resulting in increased internal temperature of the grain, humidity increased, causing Seed moldy, germination, leading to food can not be used and waste. Since ancient times, the dynasties have attached great importance to the storage of grain, and China's long-standing lack of advanced technical support, leading to China's food in the storage process a lot of damage to deterioration. Since the founding of the People's Republic of China, the party and the government have attached great importance to the food problem and encouraged a batch of scientific talents to make technical breakthroughs in the food storage, and have made great contributions to solving the food problem in China.

The main research work of the author is as follows:

1. The general idea of this design. This design uses the STC89C52 single-chip as a control unit, eight seven-segment digital control module consisting of a display module and a buzzer and LED alarm module, through the expansion of four temperature sensors for temperature data acquisition. Through the microcontroller to control the IO port to read the temperature data for data processing, and then sent to the display module for display, and through the decision to determine whether the alarm module is working.

2. Build the system simulation circuit. After determining the basic program, the use of single-chip simulation software proteus hardware circuit design. Use the microcontroller 0 port as the data display port, P2.3, P2.4, P2.5 three ports with 3-8 decoder as a bit selected port. At the same time using P3.7, P1.4, P1.5, P1.6 four ports to connect four DS18B20 sensor, P1.5 connected buzzer, P2.0 connected LED.

3. Design the system software. According to the chip technical manual access to the relevant work on the DS18B20 timing, by reading and writing operations corresponding to pull down or pull high, and timely detection of the level of the bus to initialize it. Assign the temperature data to P0 by defining the variable, define three variables corresponding to P2.3, P2.4, P2.5 as the bit select port, P1.4, P1.5, P1.6, P3.7 A port as a temperature sensor connection port, according to the relevant procedures to complete the preparation of the software.

Key words: STC89C52 ;DS18B20;temperature monitoring;cycle display;alarm

目录

第1章 绪论 1

1.1研究背景,目的及意义 1

1.2国内外研究现状 1

1.3主要研究内容及组织结构 2

第2章 粮仓温度监测系统的相关技术和需求分析 4

2.1单线总线技术 4

2.2需求分析 4

第3章 粮仓温度监测系统的总体方案设计 6

3.1 三种设计方案 6

3.2设计方案的比较与选择 7

第4章 粮仓温度监测系统的软,硬件方案设计 8

4.1硬件方案设计 8

4.1.1温度采集模块 8

4.1.2显示模块 12

4.1.3报警模块 15

4.1.4数据处理模块 16

4.2软件方案设计 19

4.2.1软件开发工具的选择 19

4.2.2模块软件设计 20

第5章 粮仓温度监测系统的调试与仿真 28

5.1仿真电路及分析 28

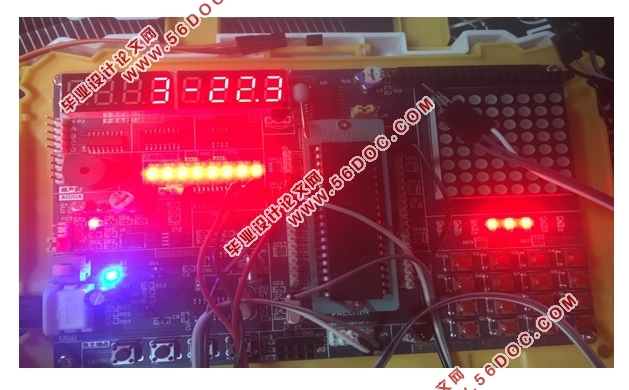

5.2实物及分析 29

第6章 总结与展望 30

6.1总结 30

6.2展望 30

参考文献 31

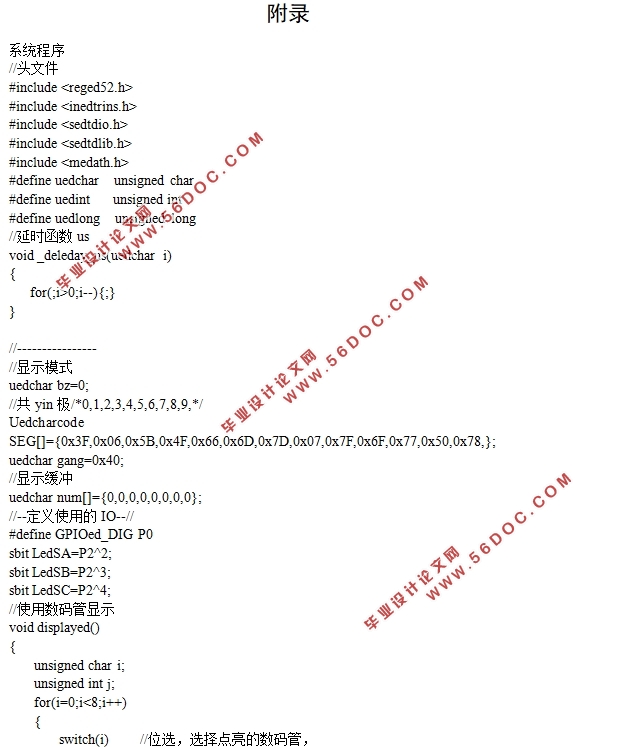

附录 32

致谢 45

|